Lithium ion battery membrane with heat resistance and high mechanical strength and preparation method thereof

A lithium-ion battery, mechanical strength technology, applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve the problems of sharp drop in strength, large thermal shrinkage, fire or explosion, etc., to solve the problem of large thermal shrinkage, Improves heat resistance and prevents fire and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

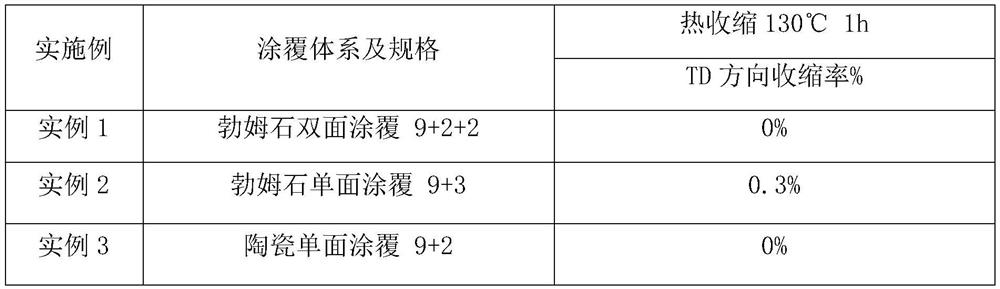

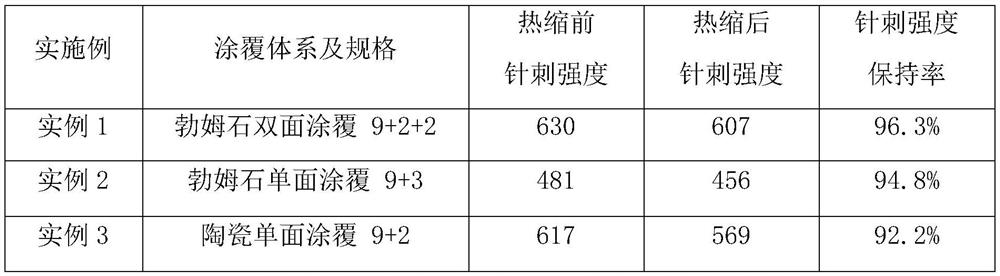

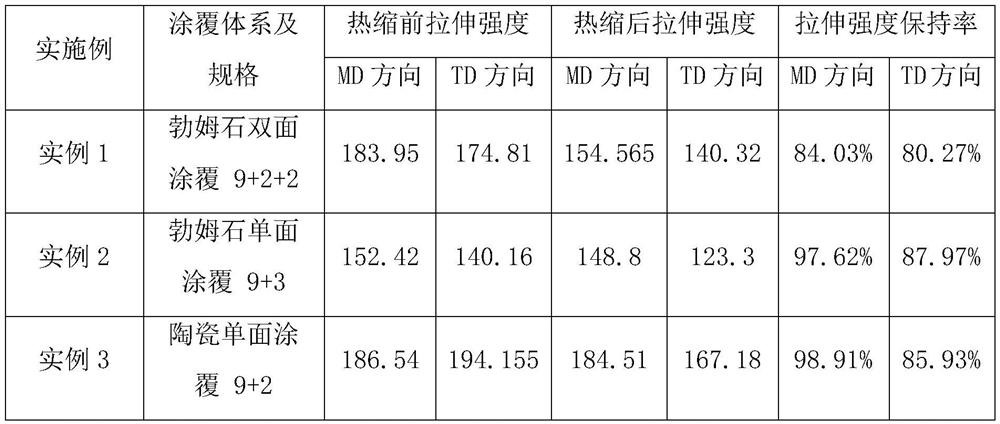

Embodiment 1

[0039] Add 0.26kg of sodium carboxymethyl cellulose to 7.5kg of deionized water, mix and stir evenly to obtain slurry A; add 20kg of boehmite with a D50 of 0.5μm and 0.1kg of dispersant to 32kg of water, mix and stir evenly to obtain slurry B; A After the two kinds of slurries, B and B are mixed, the slurry C is prepared by high-speed dispersion or ball milling; 3kg of binder and 0.04kg of wetting agent are added to the slurry C to prepare a coating slurry; the above-mentioned The slurry is coated on both sides of the 9 μm base film, and after drying, a power lithium-ion battery separator is obtained. The thickness of the single-layer coating is 2 μm, accounting for 30.77% of the thickness of the separator; the inorganic filler boehmite in the coating accounts for 92.19%, and the binder polyacrylic resin accounts for 6.22%.

Embodiment 2

[0041]Add 0.16kg of sodium carboxymethyl cellulose to 4.6kg of deionized water, mix and stir evenly to obtain slurry A; add 20kg of boehmite with D50 of 0.8μm and 0.08kg of dispersant to 35kg of water, mix and stir evenly to obtain slurry B; A After the two kinds of slurries of B and B are mixed, slurry C is prepared by high-speed dispersion or ball milling; 3kg of binder and 0.04kg of wetting agent are added in slurry C to prepare coating slurry; the above-mentioned slurry is coated on The surface of one side of the 9μm base film is dried to obtain a power lithium-ion battery separator. The thickness of the coating is 3 μm, accounting for 25% of the thickness of the diaphragm; the inorganic filler boehmite in the coating accounts for 92.65%, and the binder polyacrylic resin accounts for 6.25%.

Embodiment 3

[0043] Add 0.26kg sodium carboxymethyl cellulose to 7.5kg deionized water, mix and stir evenly to obtain slurry A; add 20kg of alumina with a D50 of 0.8μm to 32kg water, mix and stir evenly to obtain slurry B; two kinds of slurry A and B After the materials are mixed, the slurry C is prepared by high-speed dispersion or ball milling; 2.5kg of binder and 0.03kg of wetting agent are added to the slurry C to prepare a coating slurry; the above slurry is coated by micro-gravure coating On the surface of one side of the 9μm base film, after drying, a power lithium-ion battery separator is obtained. The thickness of the single-layer coating is 2 μm, accounting for 18% of the thickness of the diaphragm; the inorganic filler alumina in the coating accounts for 93.39%, and the binder polyacrylic resin accounts for 5.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Puncture strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com