Process and device for welding and cutting flammable-explosive medium pipeline in on-line mode

A flammable, explosive, cutting and welding technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as economic losses and achieve the effect of avoiding production stoppages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

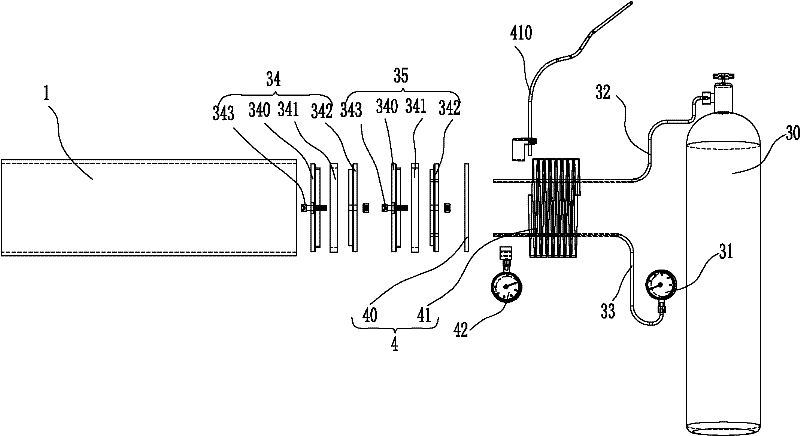

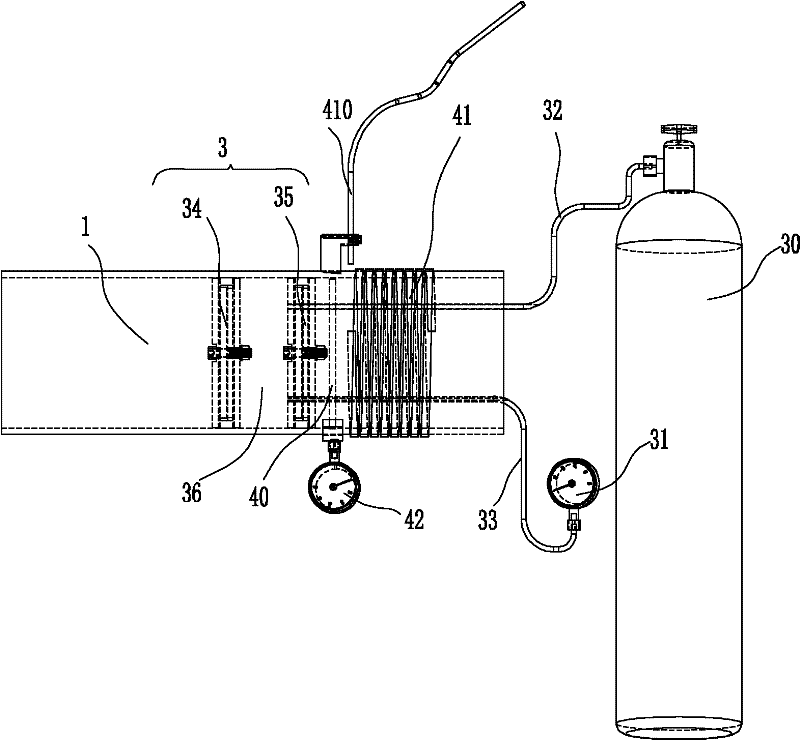

[0034] The inflammable and explosive medium pipeline online cutting and welding process of the present invention includes the following process steps:

[0035] 1), first, intercept the steel pipe 1 that needs to be operated and empty the material, so that the pipeline that needs to be processed is in an empty state;

[0036] 2), for the steel pipe 1 that needs to be cut and processed, inject inert gas (nitrogen) from the emptying point (not shown in the figure) of the steel pipe 1, so that the oxygen content in the steel pipe 1 is below 0.1%;

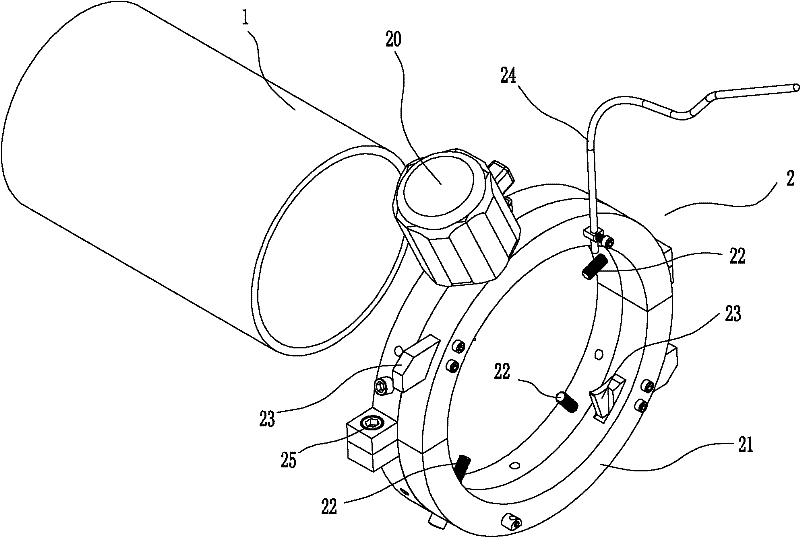

[0037] 3) if image 3 As shown, the annular rotary cutting device 2 is installed at the steel pipe 1 that needs to be cut and processed. When performing the annular cutting of the first cutting opening, firstly, the annular knife rest 21 is clamped on the steel pipe 1, locked by the bolt 25, and passed Adjust the positioning bolt 22 to make the ring knife holder 21 tightly hug the steel pipe 1 and be perpendicular to the steel pipe 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com