Patents

Literature

75results about How to "Avoid Collision Deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of aluminum oxide microbeads

ActiveCN104150882ALower firing temperatureAvoid stickingOther chemical processesPhase conversionBall mill

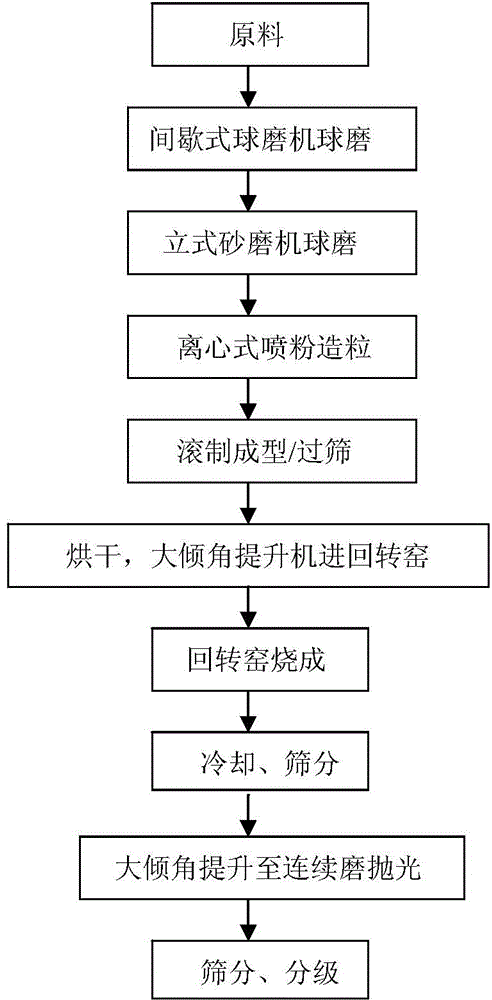

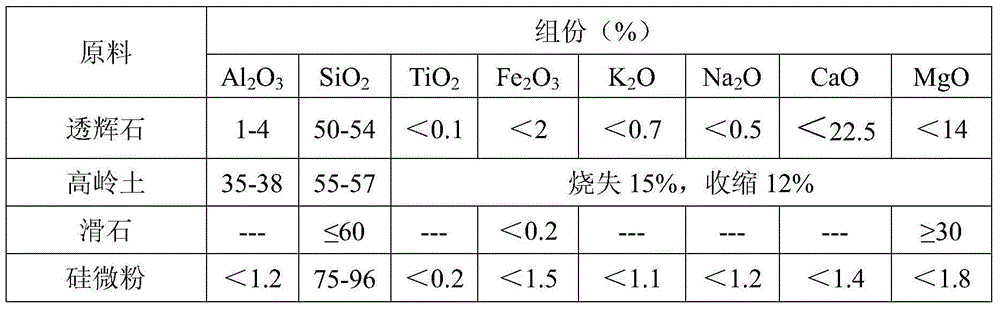

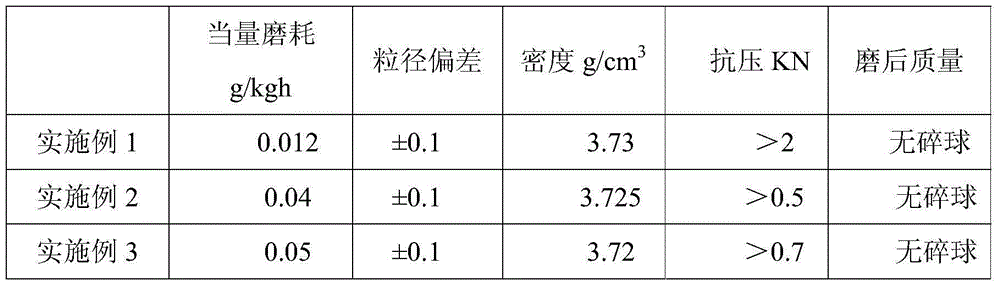

The invention discloses a preparation method of aluminum oxide microbeads. The preparation method comprises the following steps: by adopting aluminum oxide powder with lower alpha phase conversion rate (80-90%) as a main raw material, adding a composite sintering additive, ball-milling through an intermittent ball mill and a vertical sand mill, and then performing centrifugal type spray pelletization, rolling to forming, drying, sintering in a rotary kiln, and continuous grinding and polishing, to obtain the aluminum oxide microbeads. According to the preparation method, the aluminum oxide powder with relatively low alpha phase conversion rate is adopted, activity of the remaining gamma-aluminum oxide phase in the aluminum oxide powder promotes the sintering of the aluminum oxide, the addition amount of the sintering additive is decreased, and meanwhile the problem that the aluminum oxide microbeads during the sintering of the rotary kiln are caked and collided to be deformed due to excessive glass phase can be solved. Rotary kiln sintering equipment is introduced, the microbeads are under a moving status during the sintering of the rotary kiln, and are evenly heated during sintering, thus being uniform in the structure and performances. The prepared aluminum oxide microbeads have the characteristics of being low in abrasion, high in strength and density, uniform in particle size, free from breakage of beads, and the like.

Owner:JINGANG NEW MATERIALS

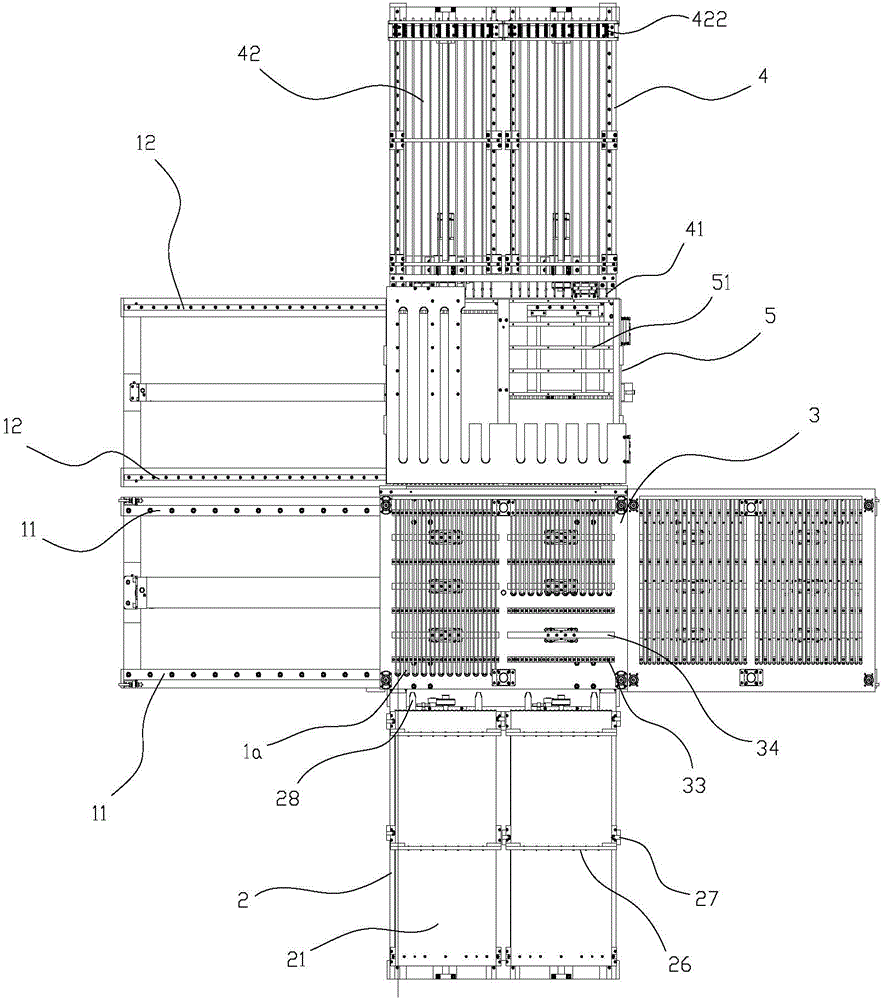

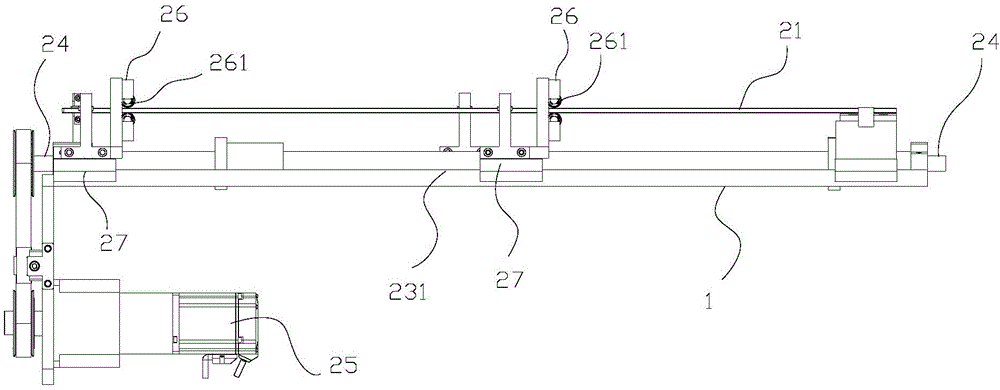

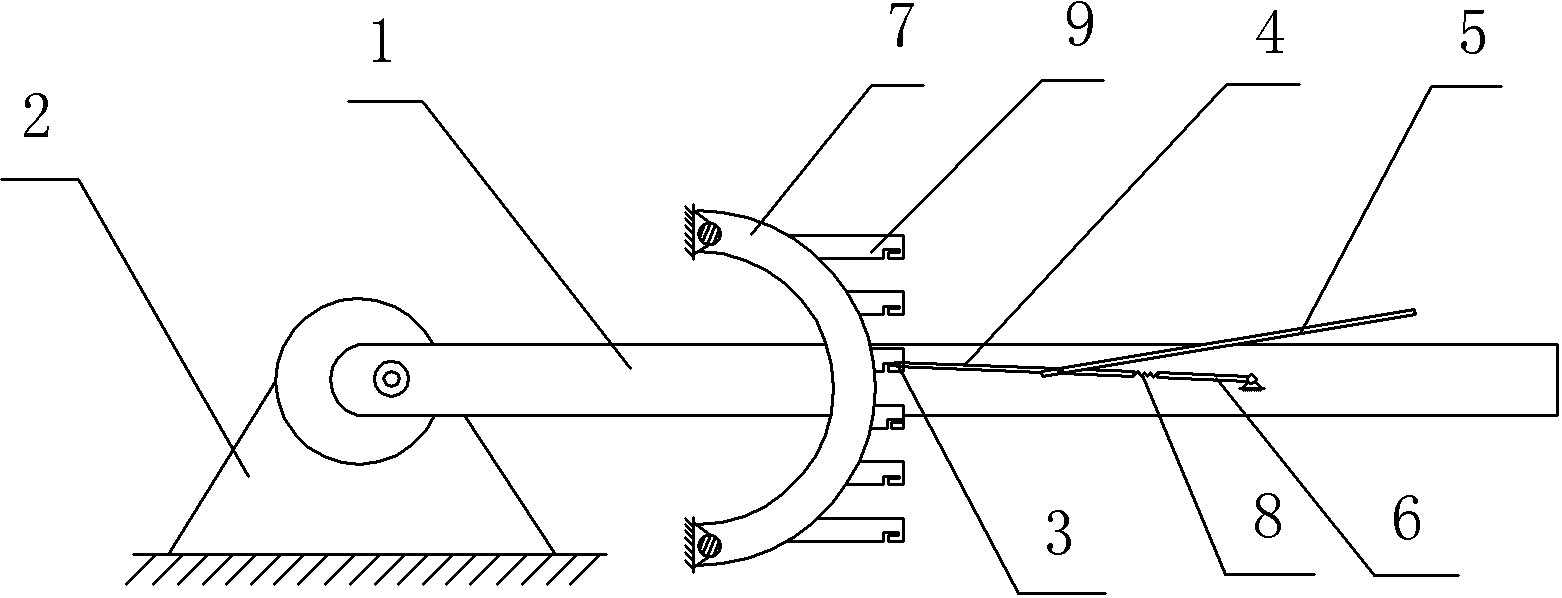

Equipment for enabling copper pipe to pass through fin of condenser

ActiveCN104308490AHigh degree of automationStable designHeat exchange apparatusMetal working apparatusEngineeringCopper tubing

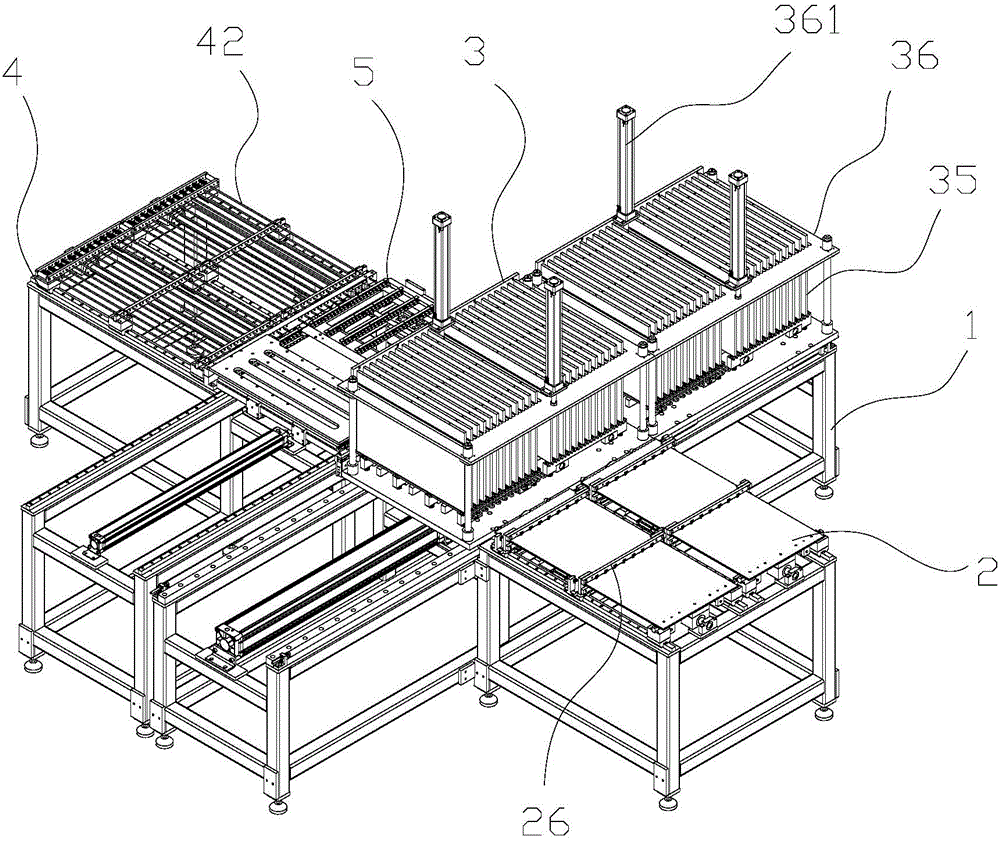

The invention discloses equipment for enabling a copper pipe to pass through a fin of a condenser. The equipment comprises a support, as well as a push plate driving system, a copper pipe collector, a fin collecting disc and a traction device which are sequentially positioned on the support, wherein the copper pipe is placed on a supporting base of the copper pipe collector, and clearance layers formed between clapboards or partition posts are stacked; a push plate passes through the upper part of the supporting base which can reciprocate up and down so as to push the copper pipe into the fin hole of the fin collecting disc; meanwhile a draw rod enters into the fin hole from the other side of the fin collecting disc under the effect of a guide mechanism, so as to draw the copper pipe, and a drawing head is inserted into the opening end of the copper pipe; when the draw rod is retreated from the fin hole, the copper pipe is synchronously guided into the fin hole, after that, the push plate and the draw rod are reset, the upper-layer copper pipe orderly falls to the supporting base so as to be subjected to the next round of pipe passing. The equipment is simple in operation and high in stability and safety, and can be used for improving the pipe passing efficiency and the alignment accuracy, reducing the equipment stagnation period in a pipe passing process and reducing the human cost and the equipment loss.

Owner:广州绅特模具制造有限公司

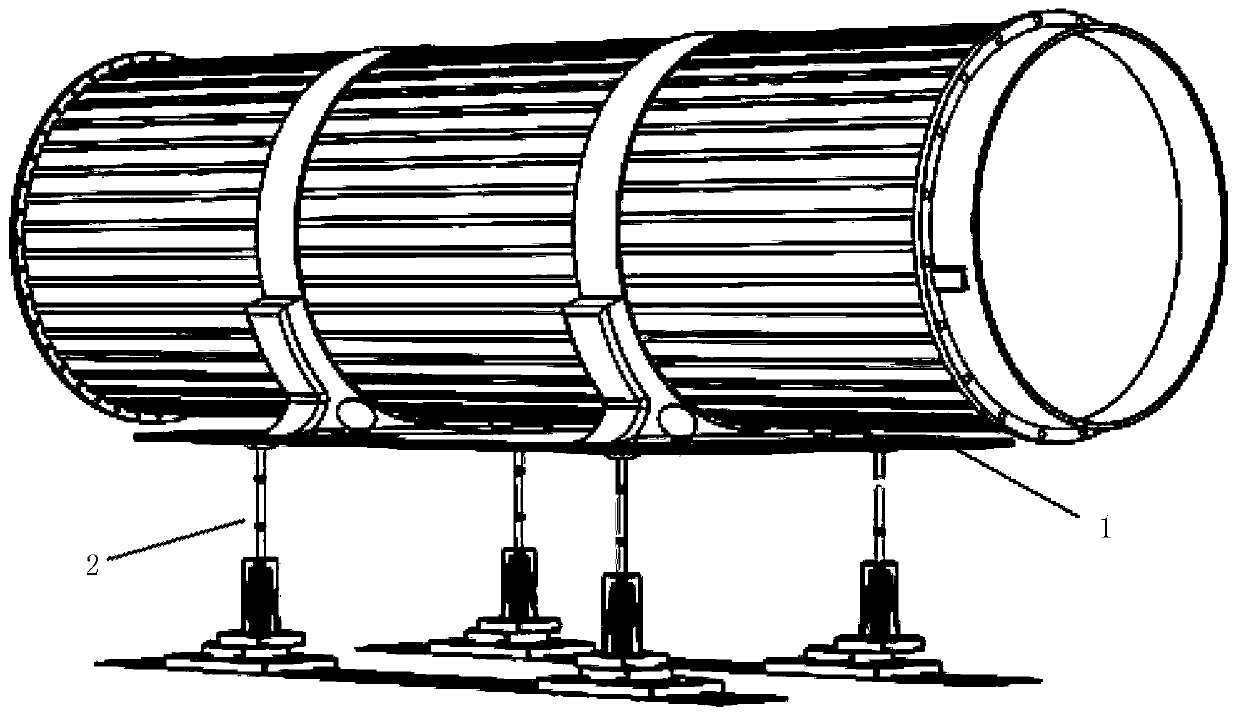

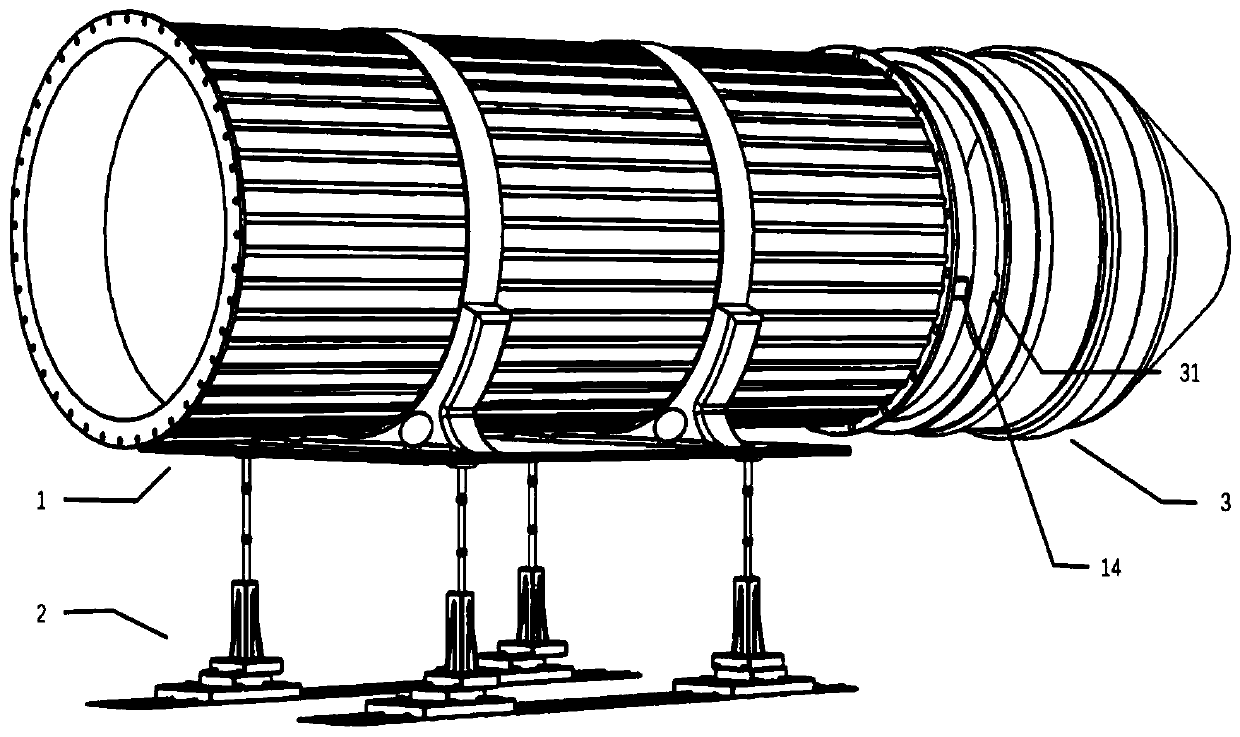

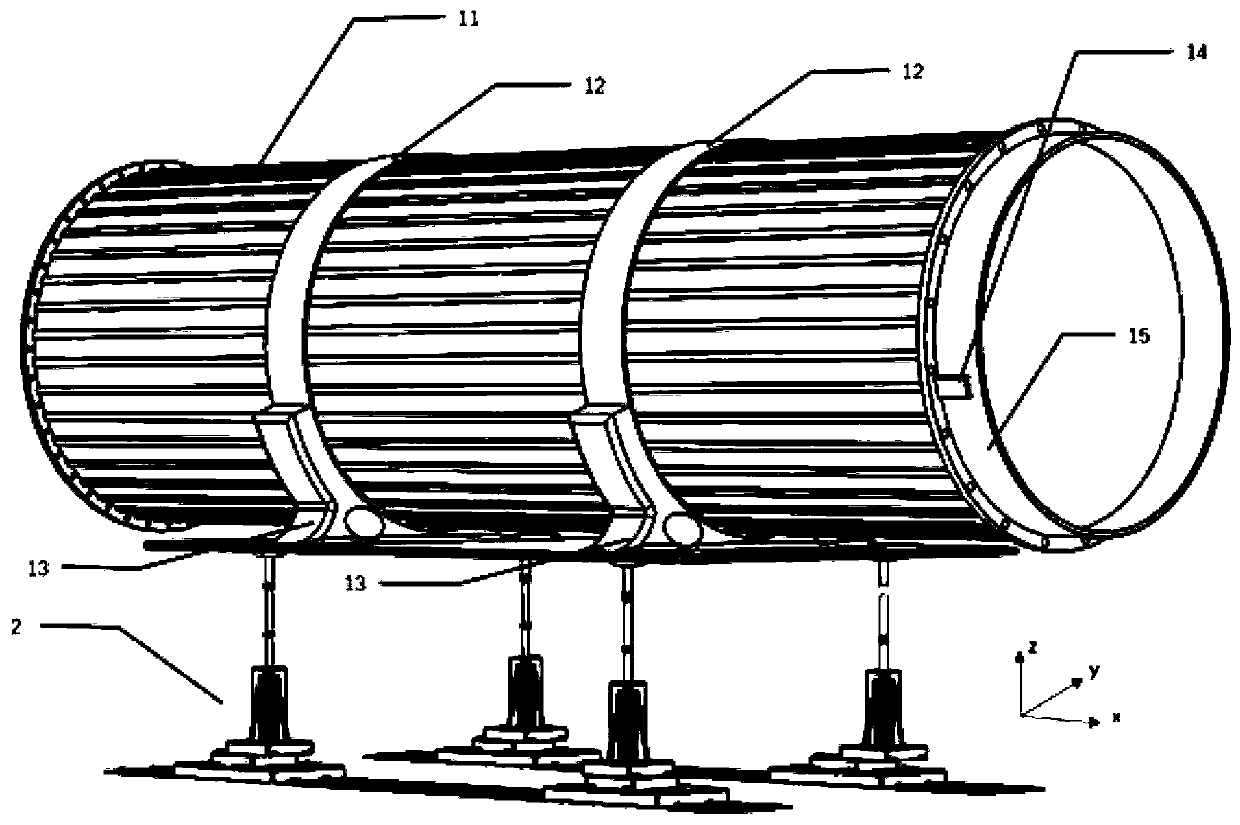

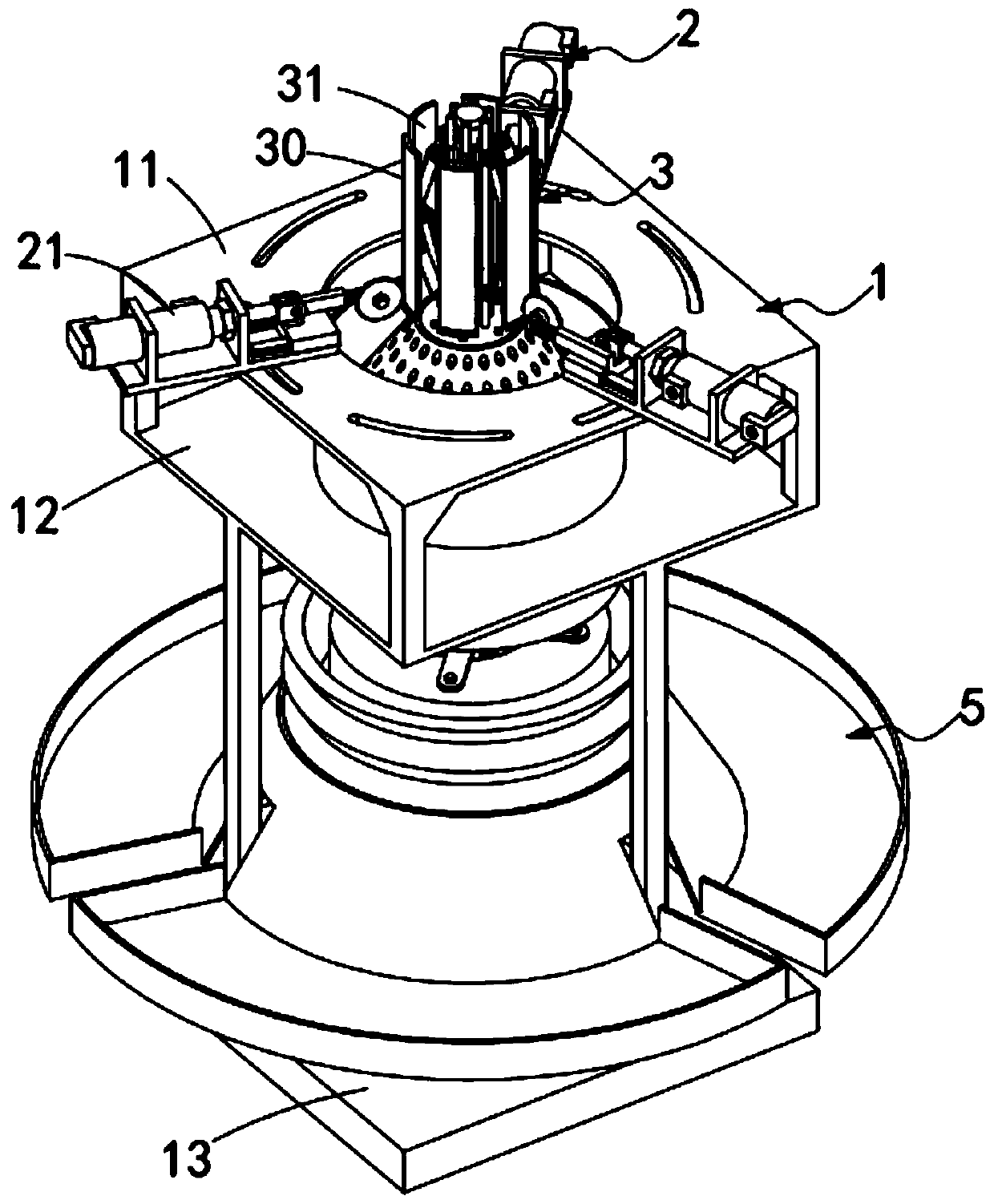

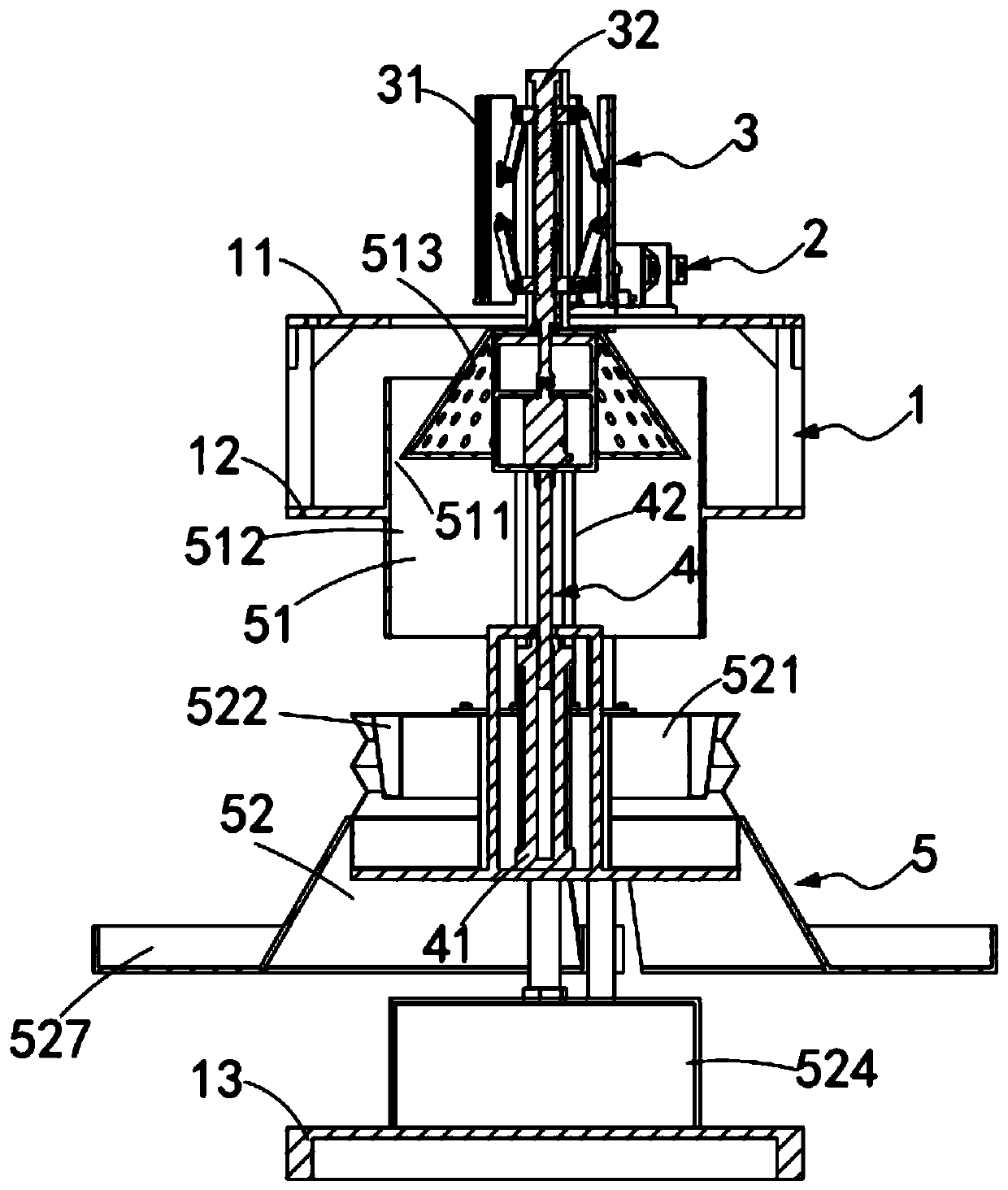

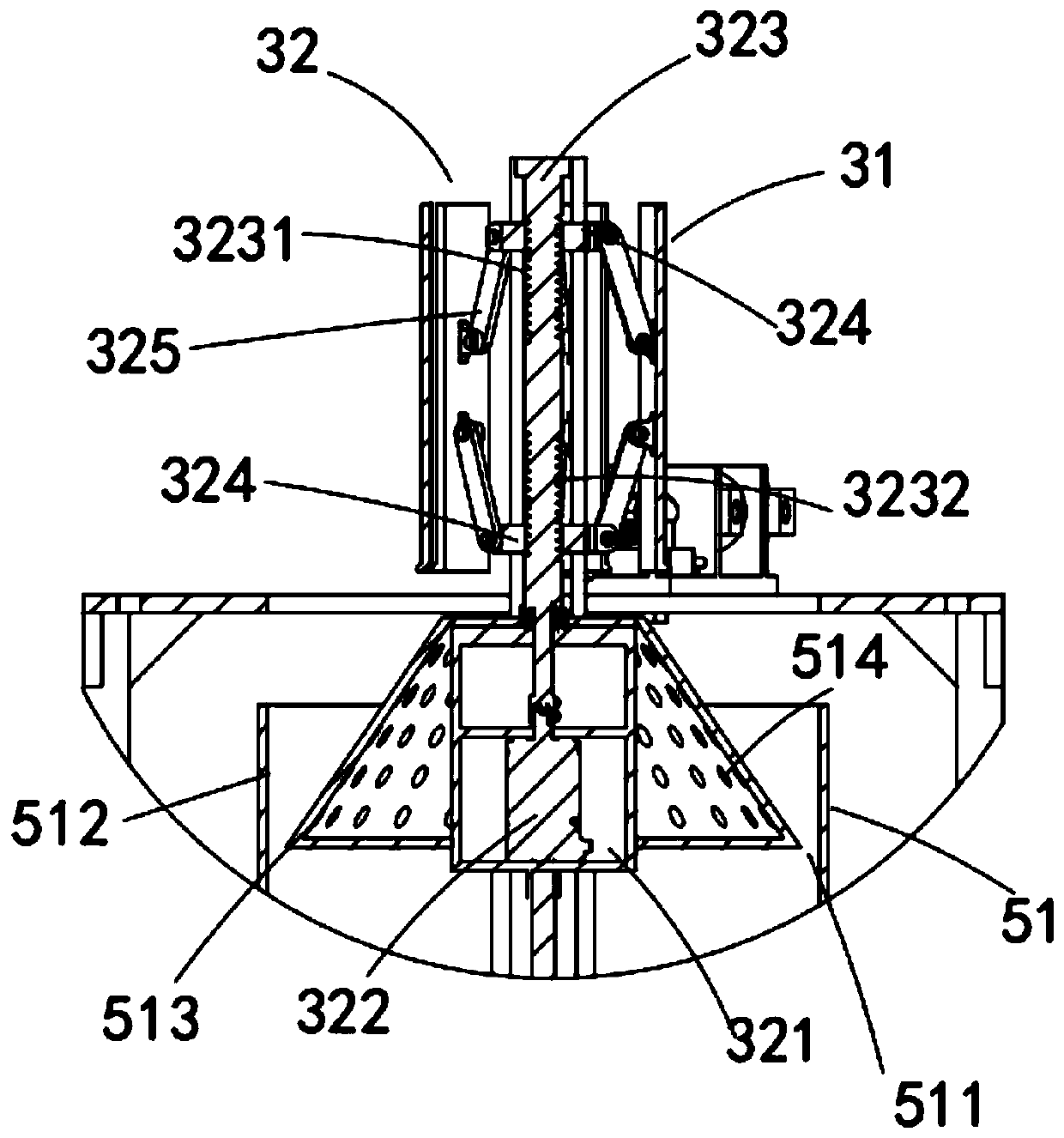

Cabin section assembling platform and cabin section assembling method

ActiveCN110733617AAccurate force informationAvoid Collision DeformationWaterborne vesselsAmmunitionStructural engineeringMechanical engineering

The invention belongs to the field of robot assembling and particularly relates to a cabin section assembling platform. The invention aims to solve the problems in the prior art that a cabin section assembling platform is low in precision, complicated in design, insufficient in reliability, slow in response and difficult to coordinate. The cabin section assembling platform provided by the invention comprises a bearing module, a posture adjusting module, a detection module and a base; the posture adjusting module supports the bearing module to bearing a cabin section; the posture adjusting module comprises a plurality of mechanical arms, a spherical hinge and a controller; the mechanical arms are arranged on the plane of the base in a sliding way; and the controller drives the mechanical arms and the spherical hinge based on the detection module to realize spatial six-degree-of-freedom motion of the bearing module and the cabin section. The cabin section assembling platform has redundancy based on mutual cooperation of a plurality of mechanical arms and can continuously work under the condition of local failure; and the cabin section assembling platform has high bearing capacity, detects internal stress and cabin section stress through distributed force sensing and can complete high-precision and high-efficiency cabin section flexible assembling.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

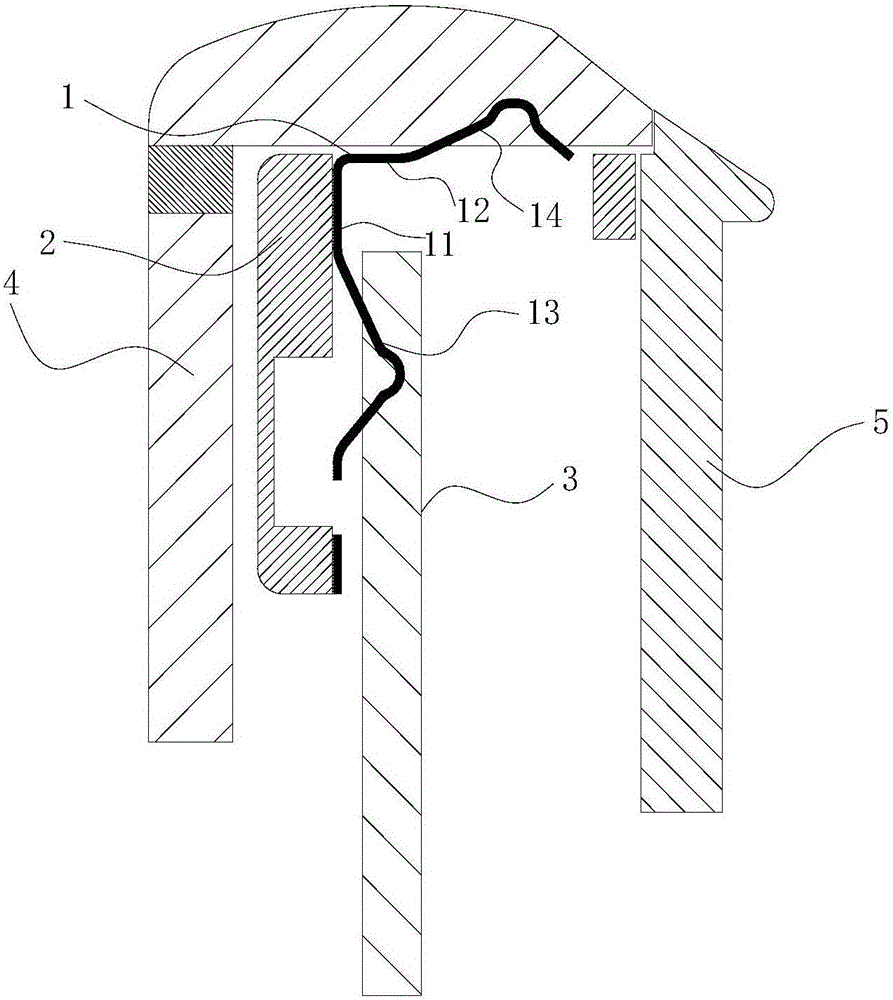

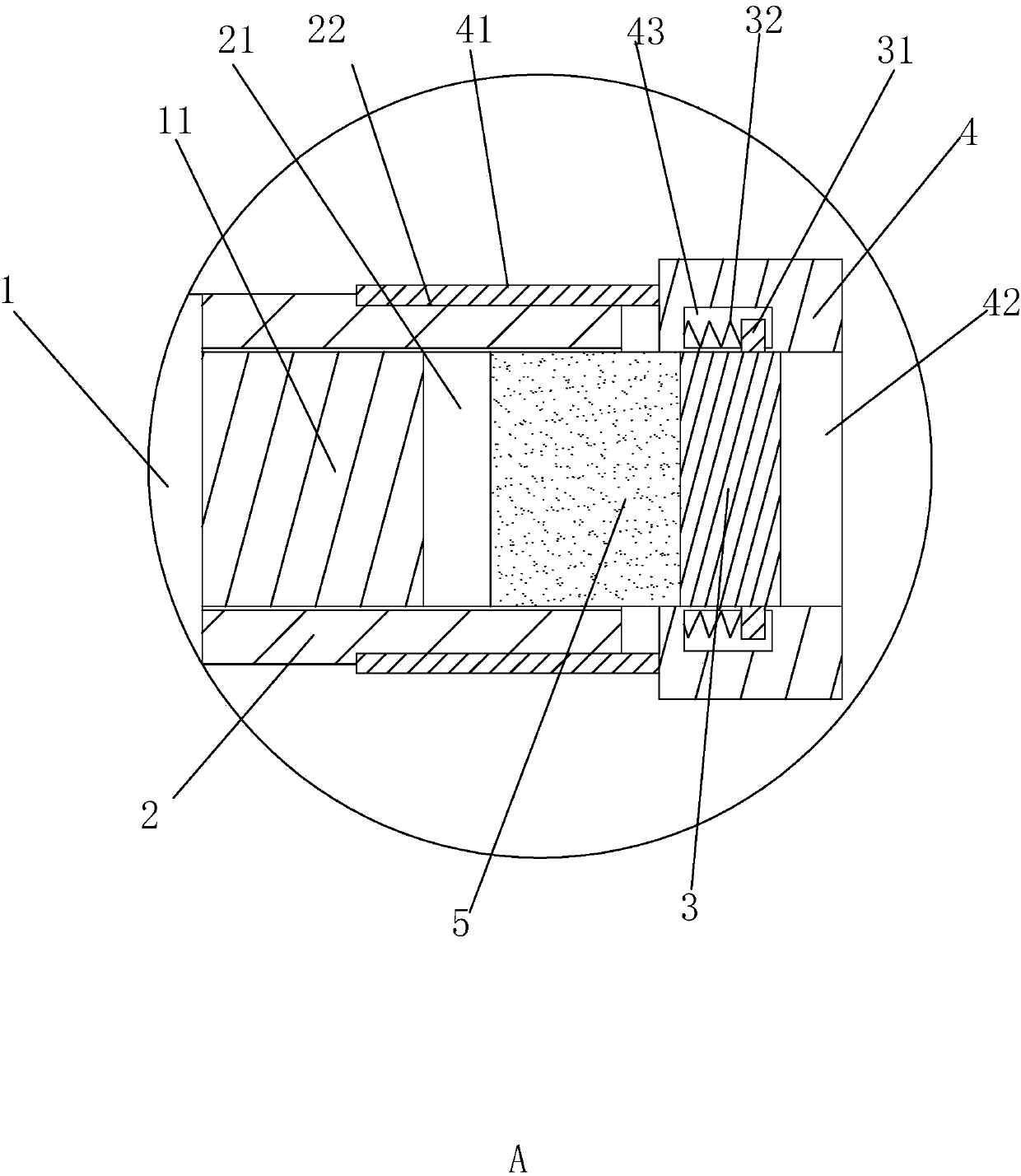

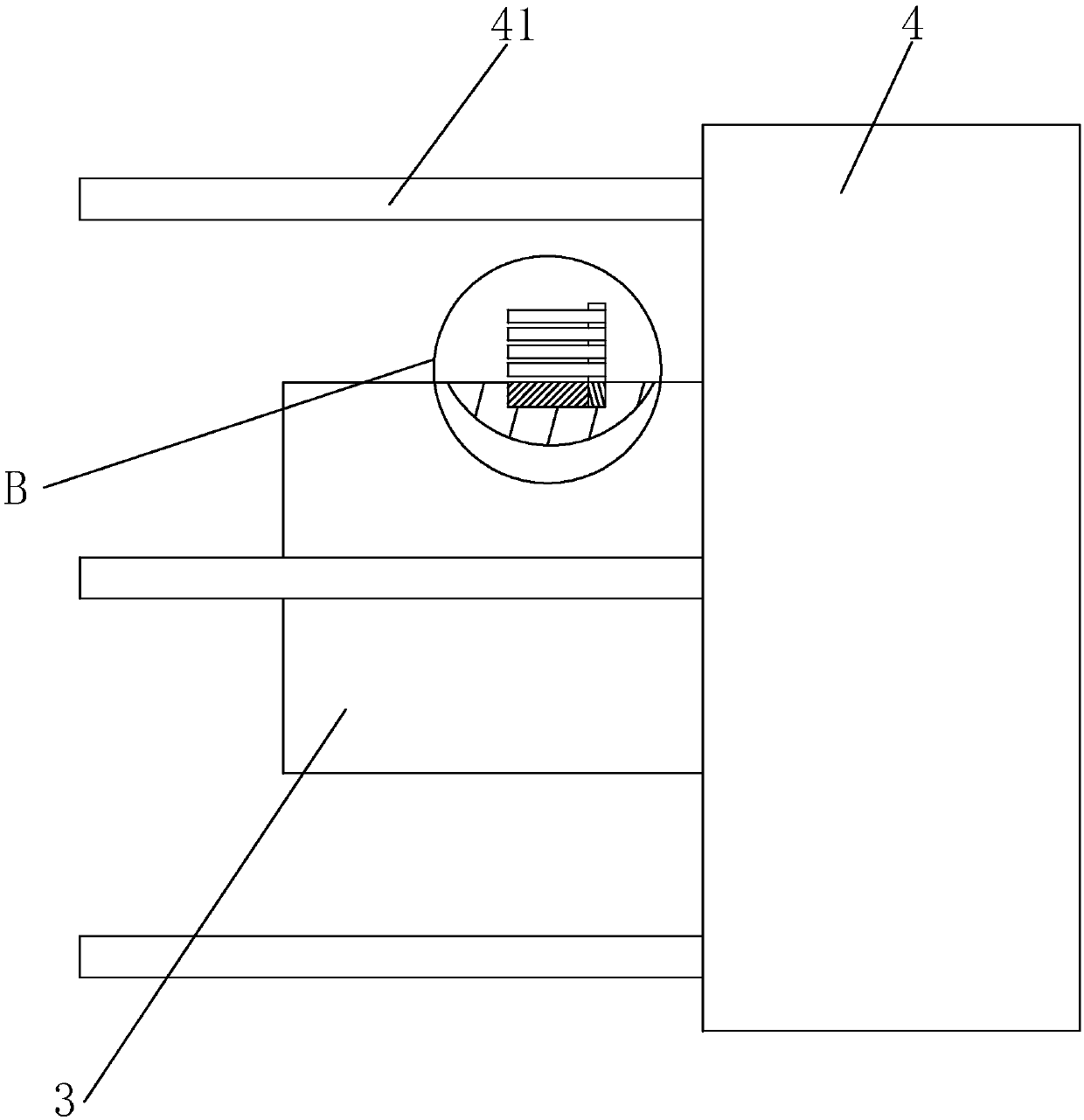

Elastic sheet assembly and electronic equipment

ActiveCN105896126ASimple structureEasy to assemble and disassembleCoupling contact membersFixed connectionsEngineeringElectronic equipment

The invention discloses an elastic sheet assembly, and relates to the technical field of electronic equipment. The elastic sheet assembly comprises an elastic sheet, wherein the elastic sheet is electrically connected with a circuit board and an abutting piece, the elastic sheet assembly also comprises an elastic sheet support, the elastic sheet is fixedly mounted on the elastic sheet support, and the elastic sheet support is detachably connected with the circuit board. Meanwhile, the invention also discloses electronic equipment comprising the abovementioned elastic sheet assembly. The elastic sheet assembly is simple in structure and is convenient to assemble and disassemble, the stable reliability of the connection between the abutting piece and the circuit board is improved, the elastic sheet is effectively prevented from collision and deformation during the assembly and disassembly process of the electronic equipment, and the service lifetime of the elastic sheet is prolonged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Simple clamp for industrial machinery

ActiveCN107486801ARealize clamping warning functionPrevent deformationWork holdersBiochemical engineeringLoudspeaker

The invention provides a simple clamp for industrial machinery. The simple clamp comprises a movable arc clamping plate, an electric telescopic rod, a travel switch, a loudspeaker, a rubber ejector rod, a guide block, a placement groove and an elastic cushion, wherein the movable arc clamping plate is fixedly arranged on the left end face of the electric telescopic rod; the electric telescopic rod is arranged in the middle of the left end face of a vertical plate; the travel switch is arranged on the right end face inside the movable arc clamping plate; the loudspeaker is arranged on the right end face of the movable arc clamping plate; and the rubber ejector rod is assembled in a guide hole and connected with the guide hole through a spring. According to the design, the pipeline clamping warning function is realized, the guide block is arranged on the left end face of the supporting plate, the placement groove is formed in the middle of the upper end face of the supporting plate, the elastic cushion is arranged in the placement groove, and the stable unloading function is achieved through the design. The simple clamp disclosed by the invention is reasonable in structure, high in practicality and high in stability and has full functions.

Owner:浙江黄岩永久工艺厂

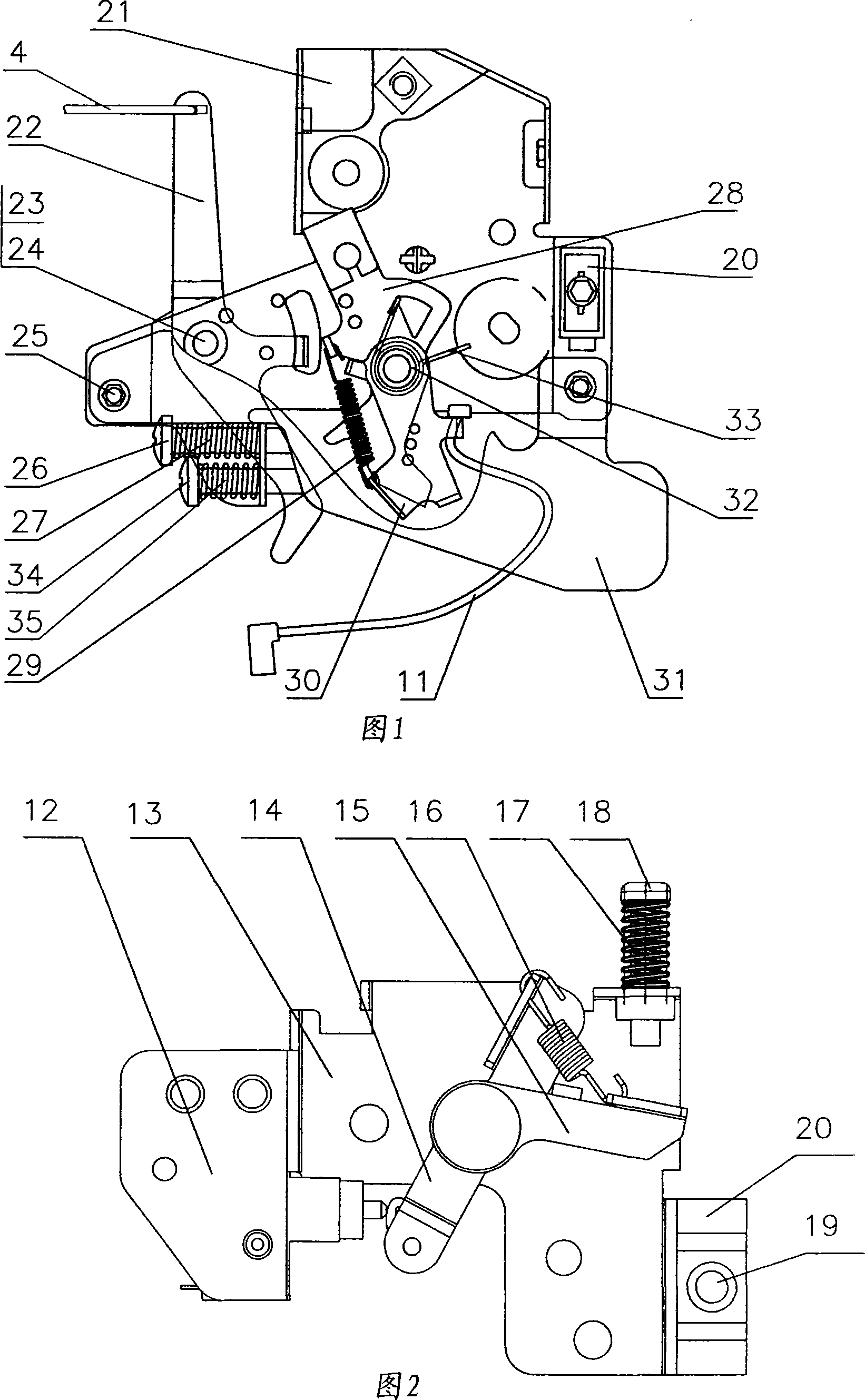

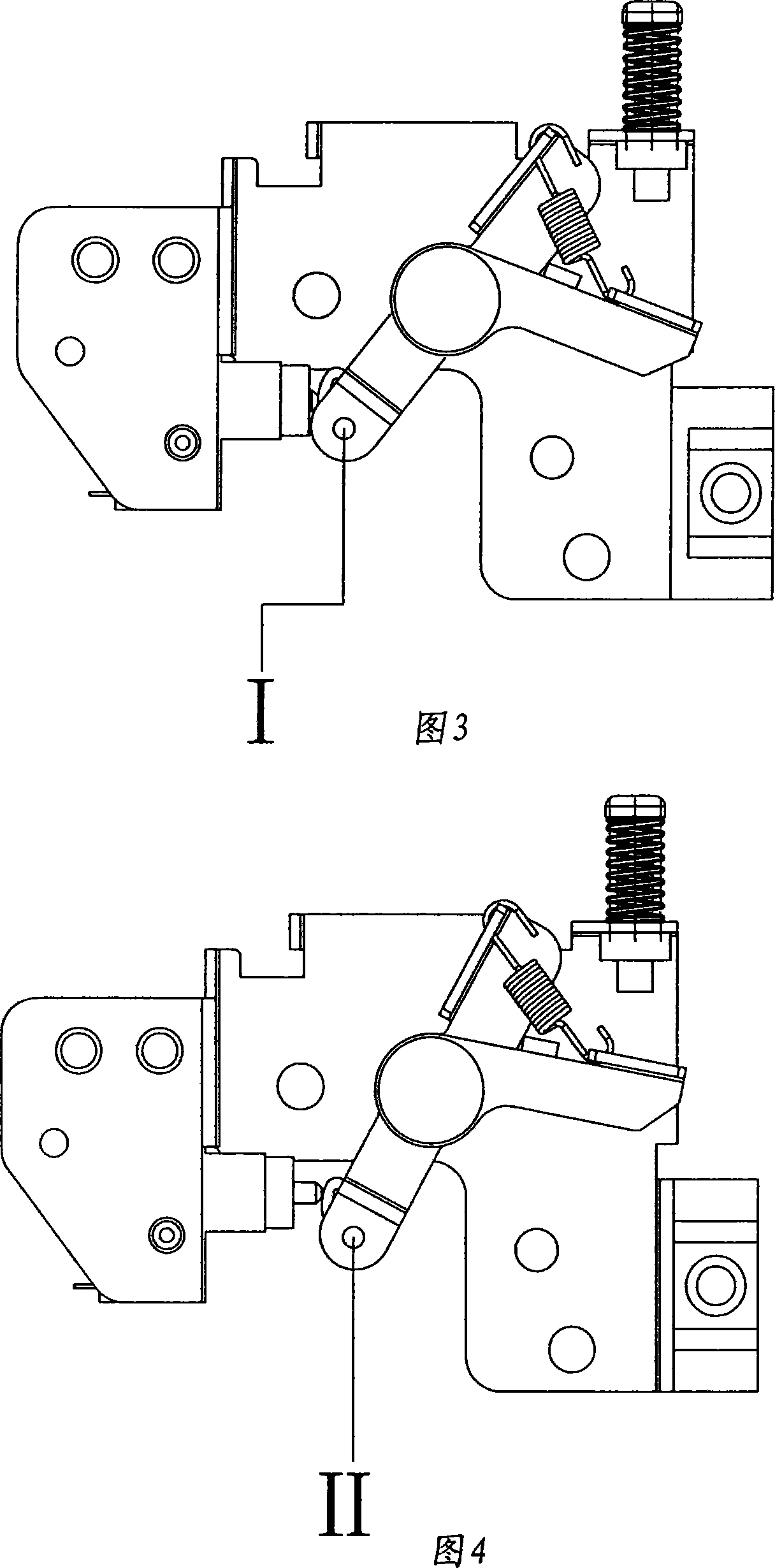

Engine oil-valve operation combination

InactiveCN101070785AReduce in quantityReduce the number of resellsEngine controllersMachines/enginesThrottle controlInsertion stent

This invention discloses a combination of engine throttle control. Off switch, manipulating handle, speed control handle and spring adjustment screws are installed in the throttle control stent portfolio. The speed control handle and manipulate Spring handle share a pin installed in combination throttle manipulation stent, one end of manipulating handle connecting with the throttle cable end control flameout at the same time the on-off switches, between the other end of the manipulation handle and the spring control handle has a manipulated handle back in spring. Speed control handle connects with the Spring Speed connection through the stent. This invention functions in the preservation of the premise greatly simplified the structure, which is conducive to reducing costs, ease of assembly. Meanwhile, the governor will not be prominent in the main stent, thus avoiding the transport process may exist in the collision deformation, is more conducive to transportation.

Owner:LONCIN MOTOR

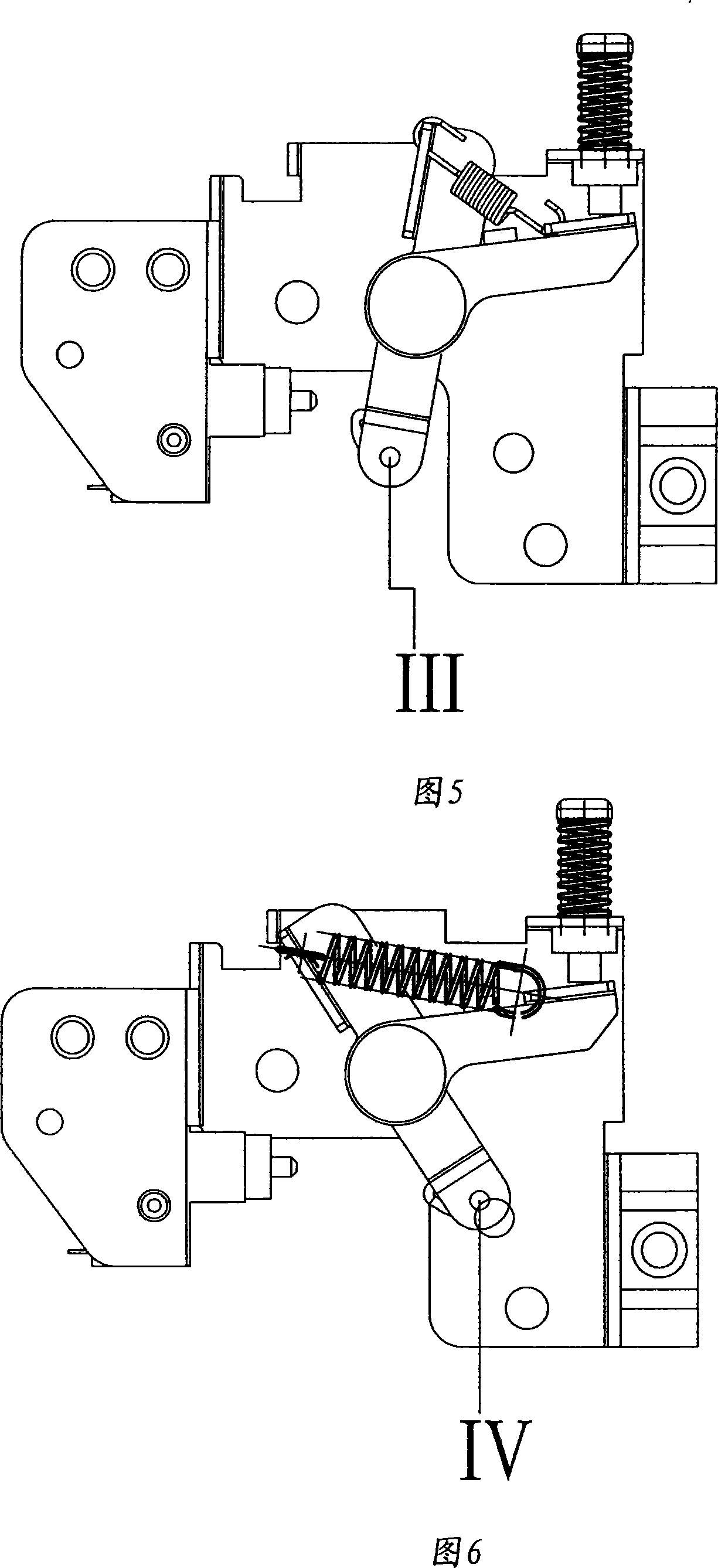

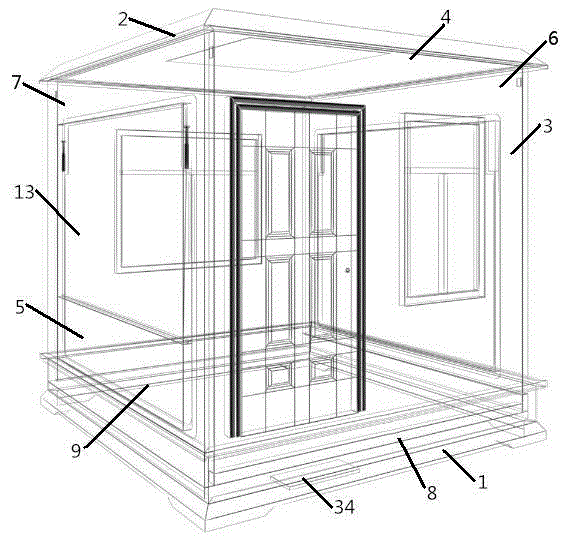

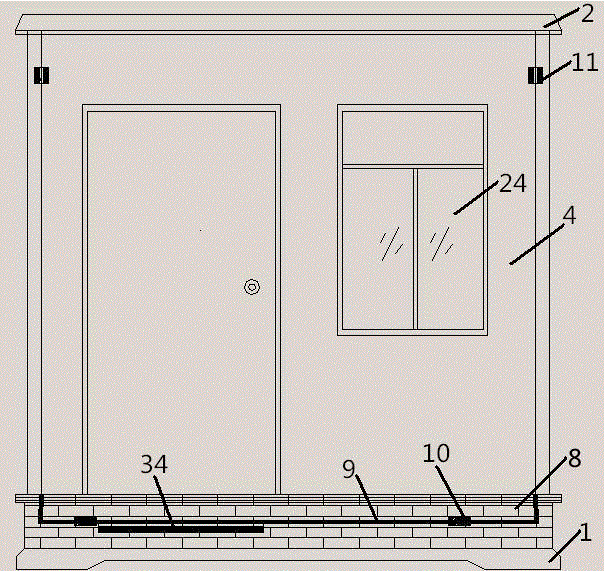

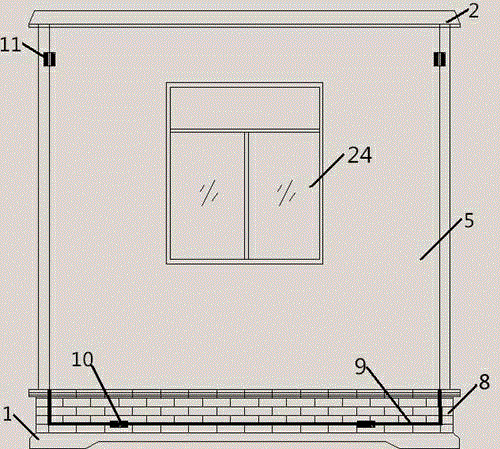

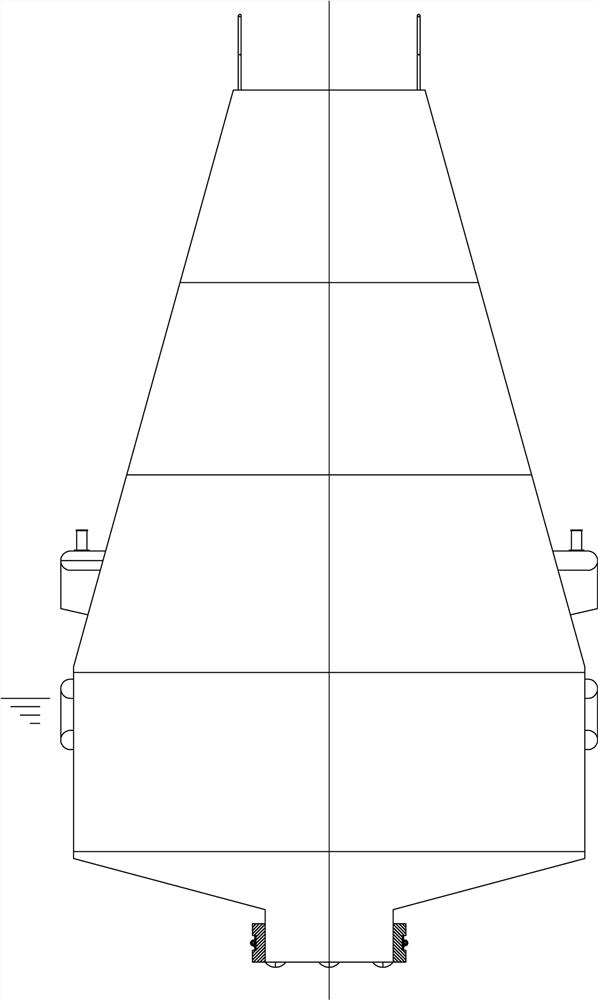

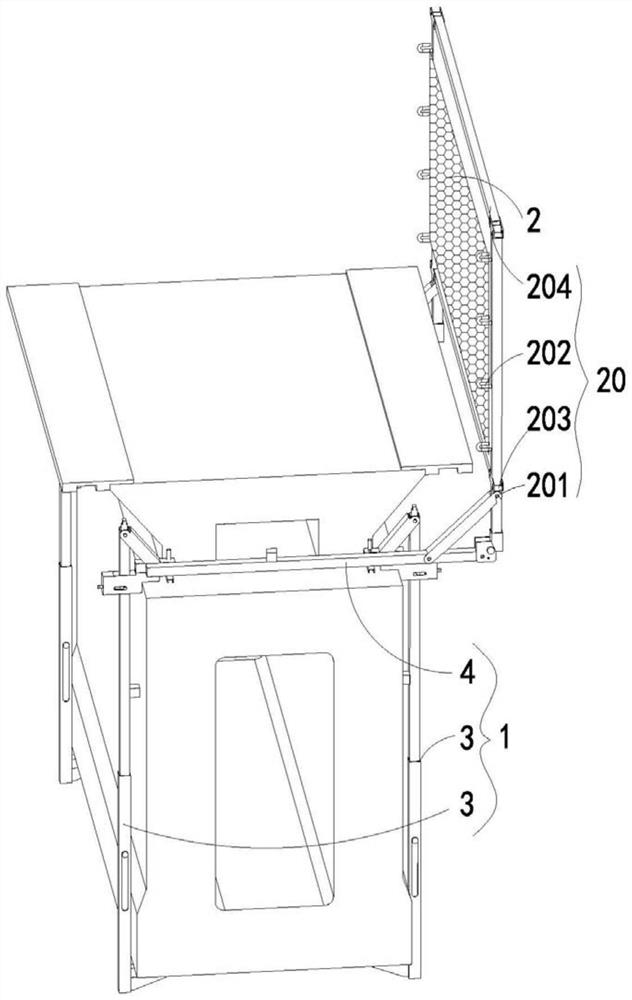

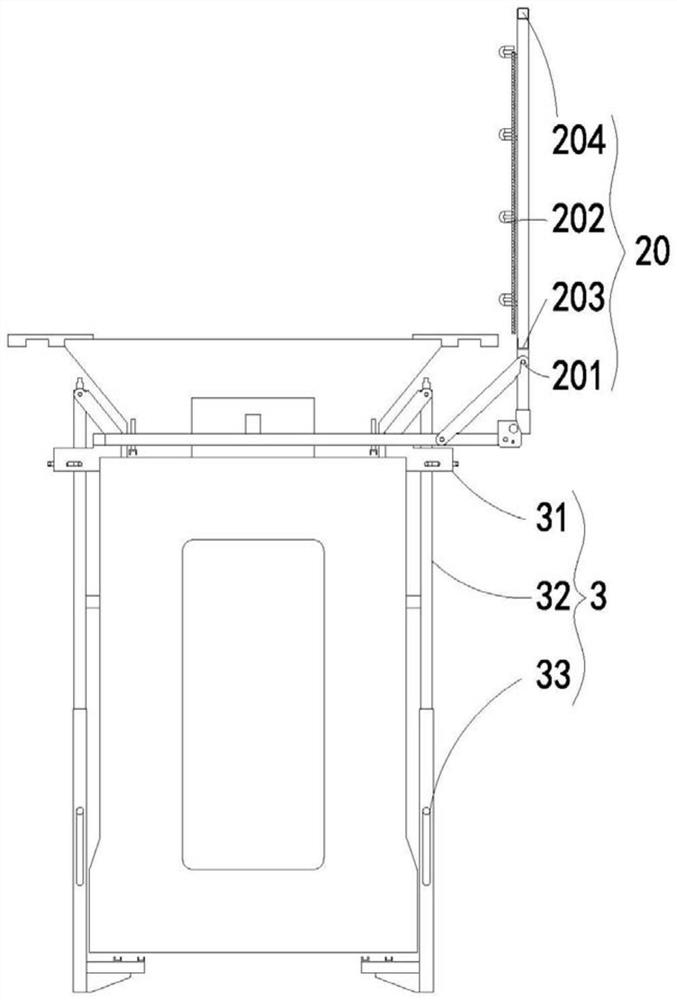

Worm-type portable folding house

ActiveCN104863264AAvoid Collision DeformationReduce frictionCurtain accessoriesBuilding constructionsBiochemical engineeringHinge angle

The invention discloses a worm-type portable folding house. The worm-type portable folding house comprises a base, a roof plate and a house body, wherein the house body is composed of a front wallboard, a rear wallboard, a left wallboard and a right wallboard; the worm-type portable folding house is characterized in that the base is provided with a tank body, the house body is fixed on the tank body, the height value of the front wallboard is less than the length value of the tank body, and the height value of the left wallboard is less than the width value of the tank body; the front wallboard, the rear wallboard, the left wallboard and the right wallboard are all provided with a folding line, the wallboards at the two ends of the folding line are hinged together by a hinge, and the sum of the thickness values of the front wallboard, the rear wallboard, and the left wallboard and the right wallboard is not greater than the depth value of the tank body. According to the worm-type portable folding house provided by the invention, the water resistance can be prevented, the deformation friction and damage of the wallboards caused by collision can be prevented in the process of transporting, air and water cannot enter the wallboards even if the wallboards are piled for a long time in the open air, and the damage caused by moths and mice can be prevented; furthermore, the worm-type portable folding house is low in storage cost; in addition, the wallboards can be piled for 15 layers in a warehouse, therefore the logistics cost can be greatly reduced.

Owner:随州市珠峰科技工程有限公司

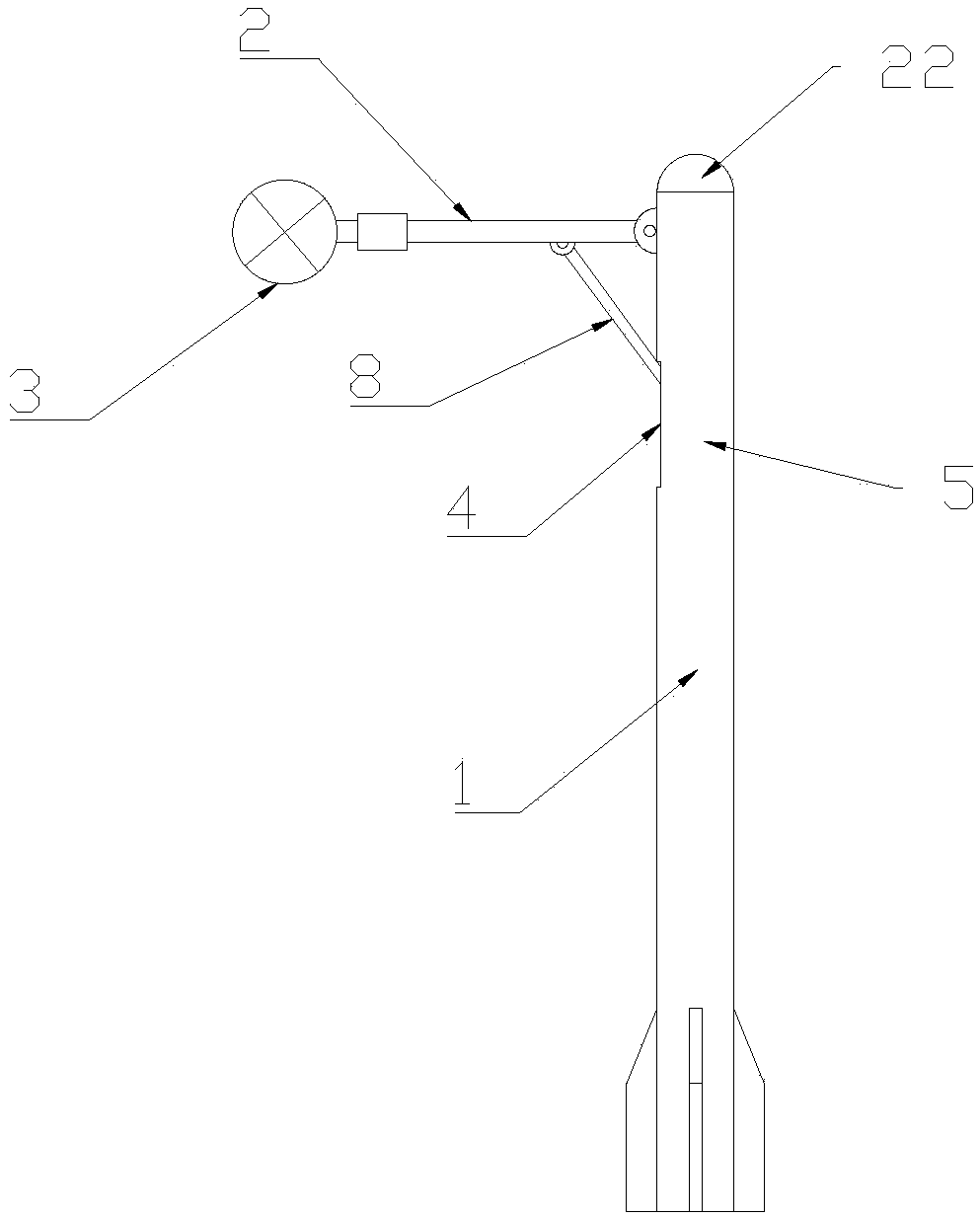

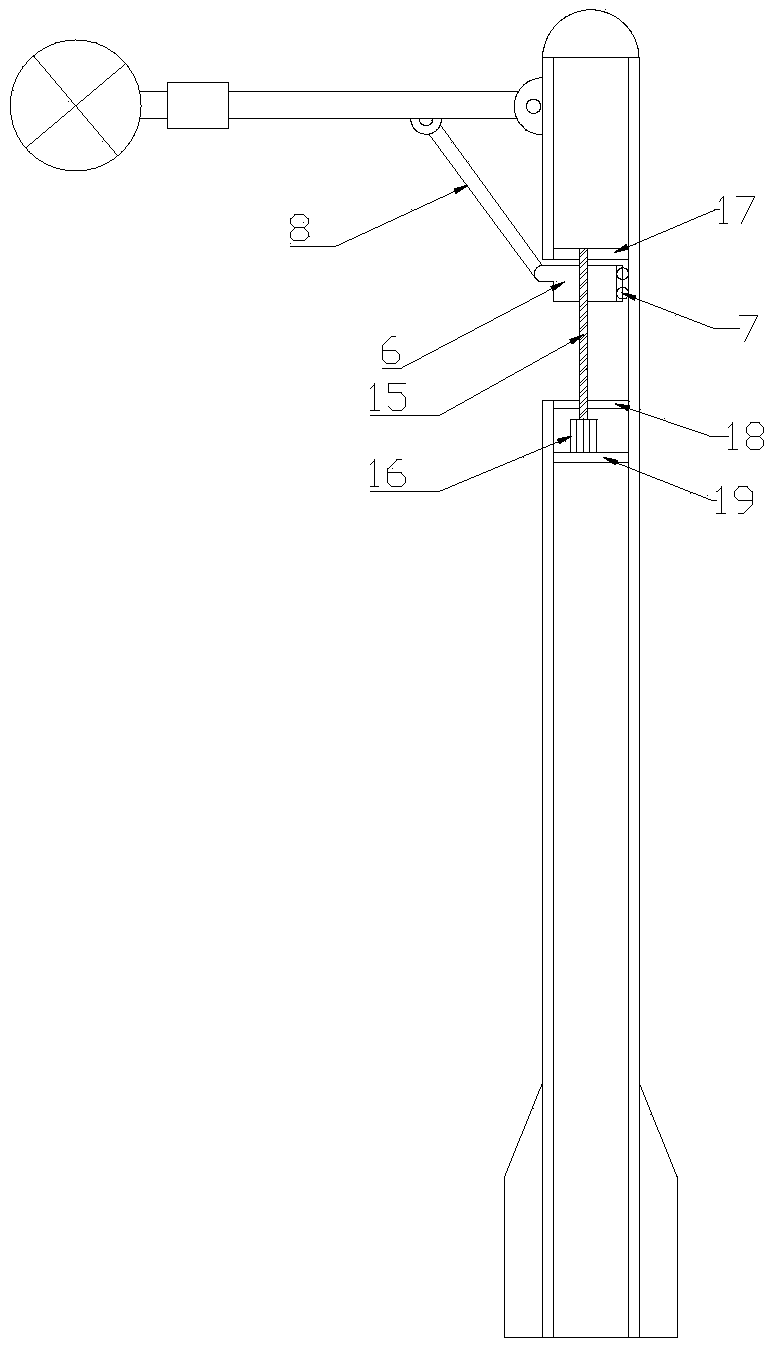

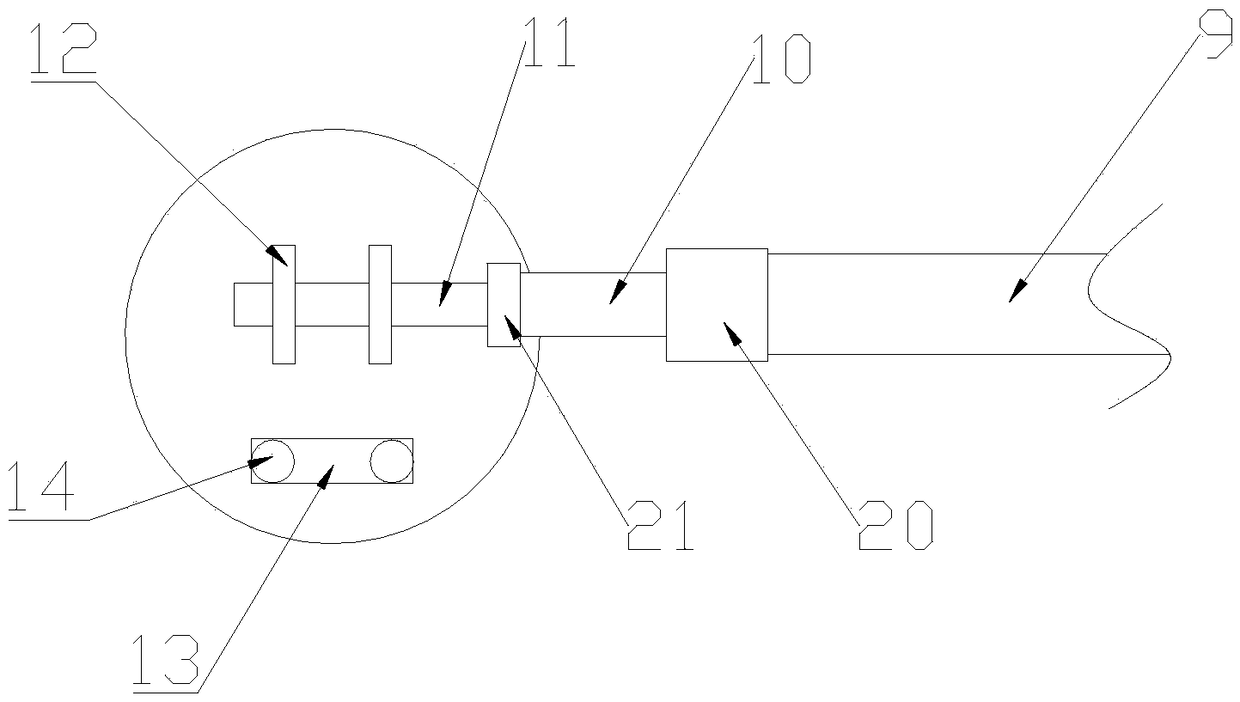

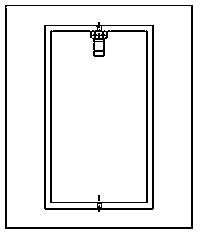

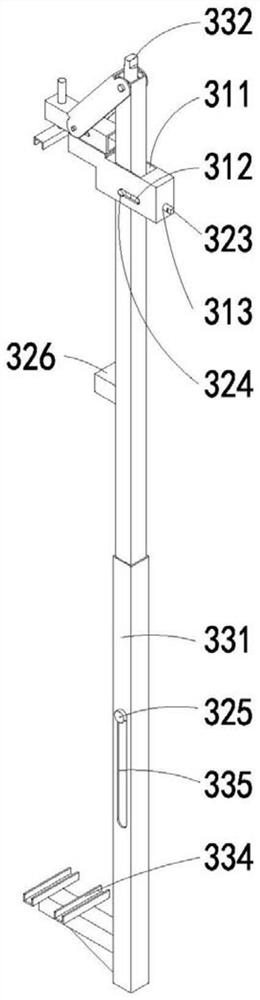

Traffic sign rod

ActiveCN108643076AAvoid Collision DeformationGuarantee the safety of lifeTraffic signalsRoad signsRight-to-leftTraffic sign

The invention discloses a traffic sign rod. The traffic sign rod comprises a stand column, a cross beam and signboards. A sliding groove is formed in the side of the stand column, and a lead screw transmission mechanism is installed in the sliding groove. An inclined support is hinged to the output end of the lead screw transmission mechanism. The top end of the inclined support is hinged to the bottom of the middle section of the cross beam. A main beam, a telescopic beam and a rotating beam are arranged on the cross beam from right to left. The telescopic beam is connected to the left side of the main beam in a sleeving mode. The rotating beam is connected to the telescopic beam in a sleeving mode. An I-shaped connecting piece is fixed to the outer side of the left end of the rotating beam, the signboards are fixed to the front and back of the I-shaped connecting piece separately, a rubber block is arranged under the I-shaped connecting piece, springs are arranged on both sides of the front side of the rubber block, and the outer sides of the springs are fixedly connected with the inner sides of the signboards. According to the traffic sign rod, the cross beam is three-section design, and the telescopic beam can realize automatic extending and contraction and adjust the extension length according to the actual demand to ensure that a driver can see clearly; the signboards matched with the rotating beam can prevent the signboards from being collided and deformed to a certain extent; the main beam can be lowered or raised under the action of the lead screw transmission mechanism, and the safety of maintenance personnel is ensured.

Owner:江苏方大光电科技有限公司

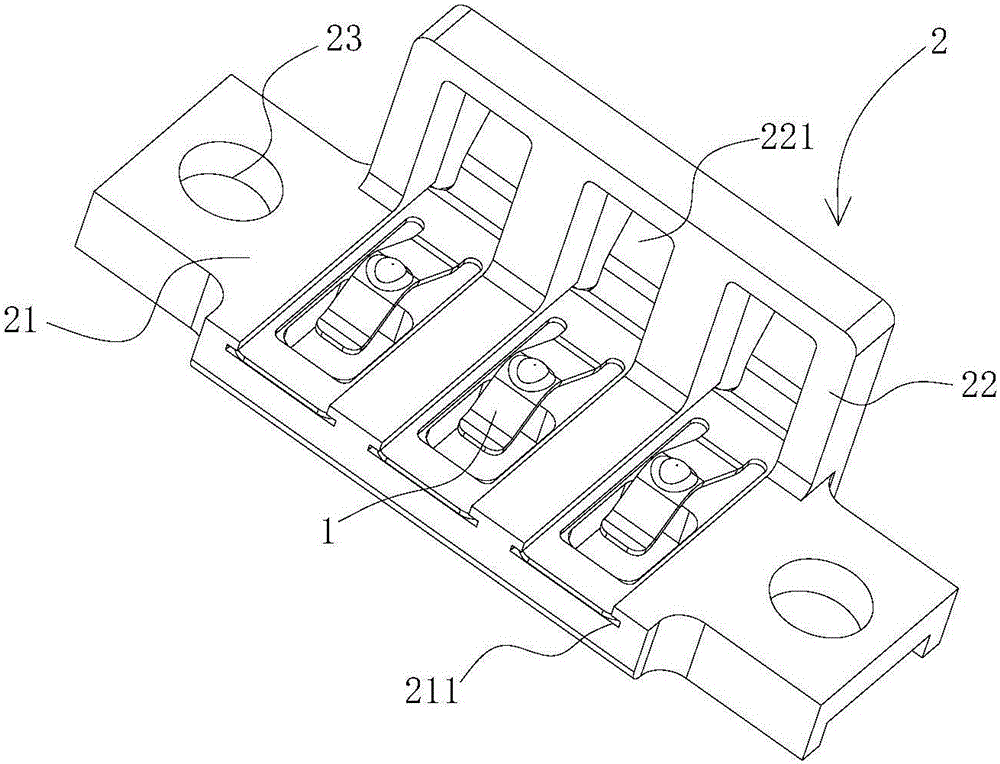

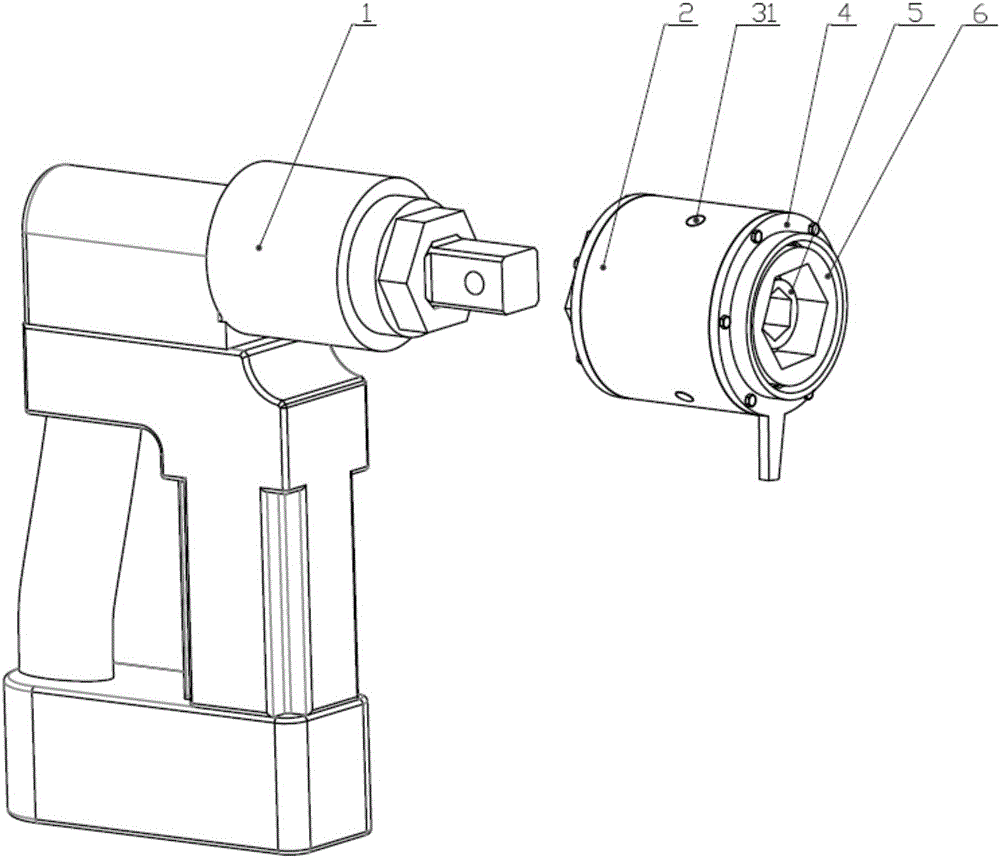

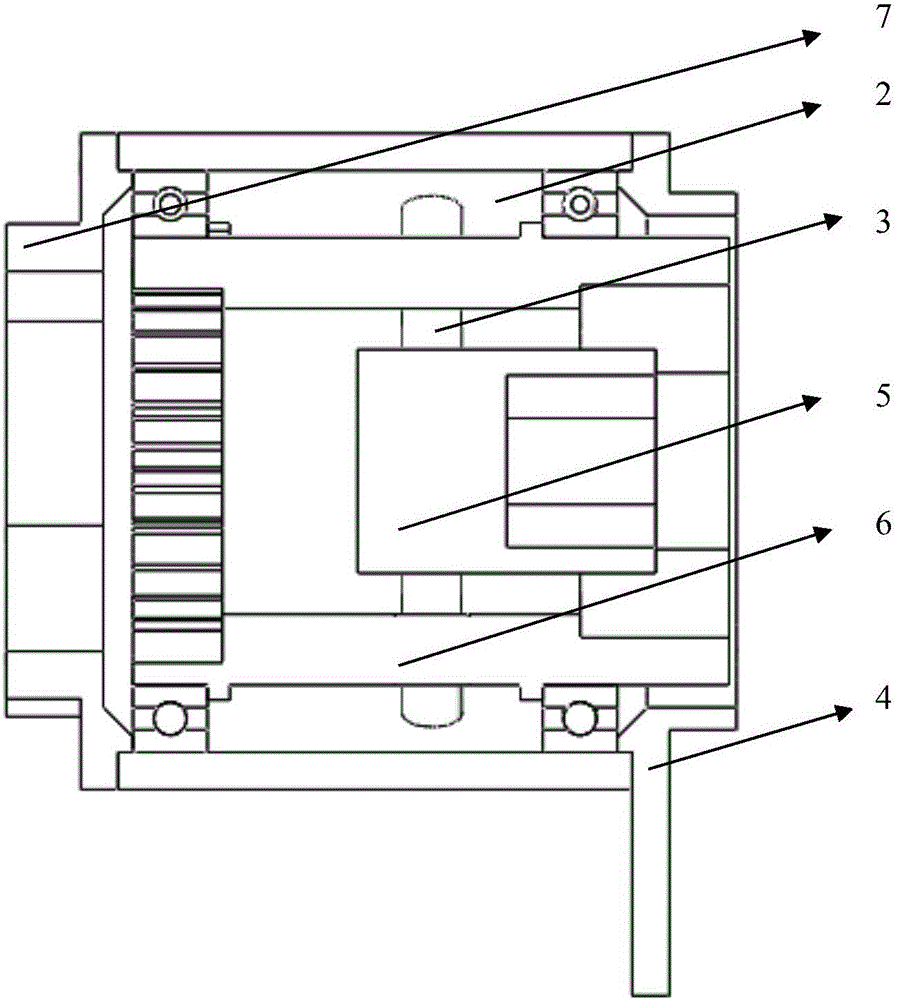

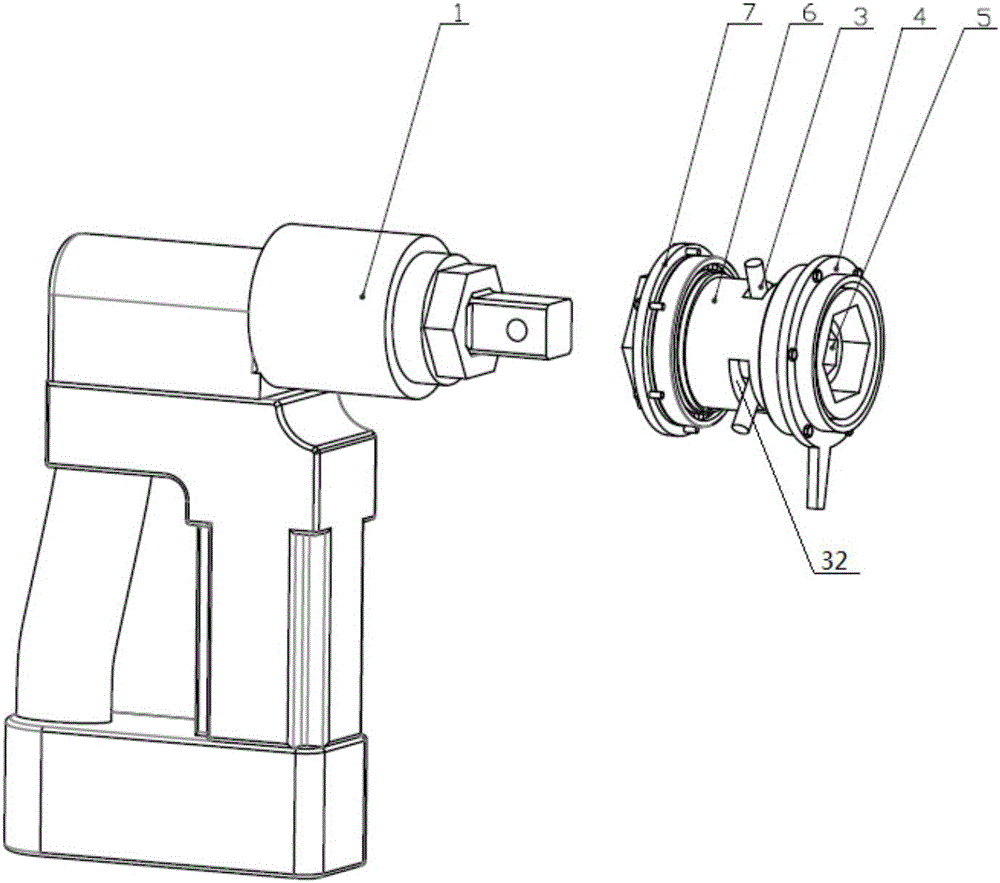

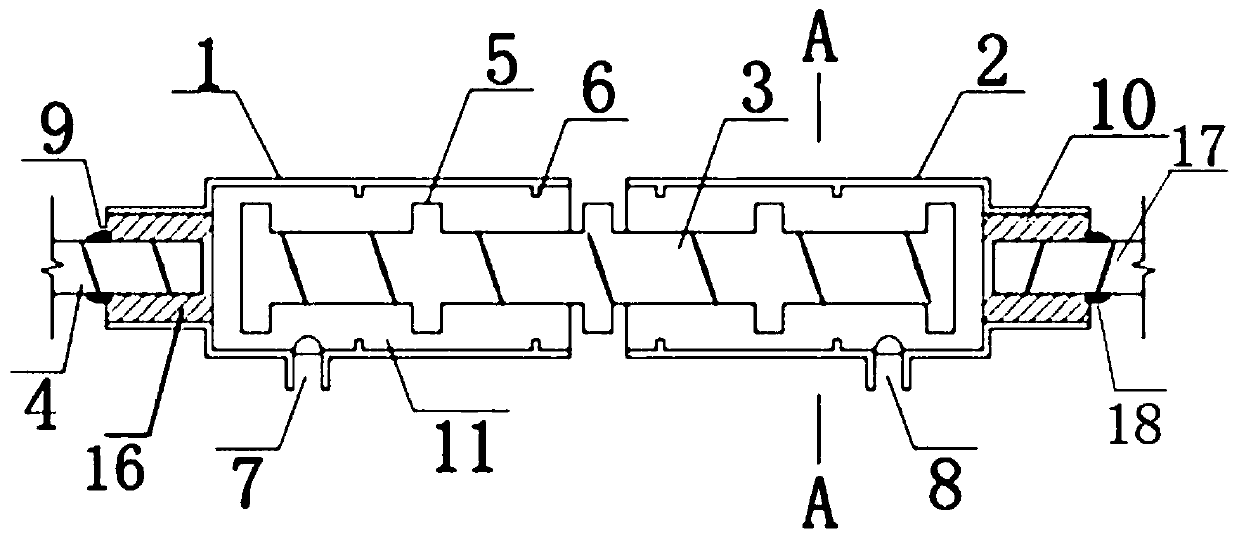

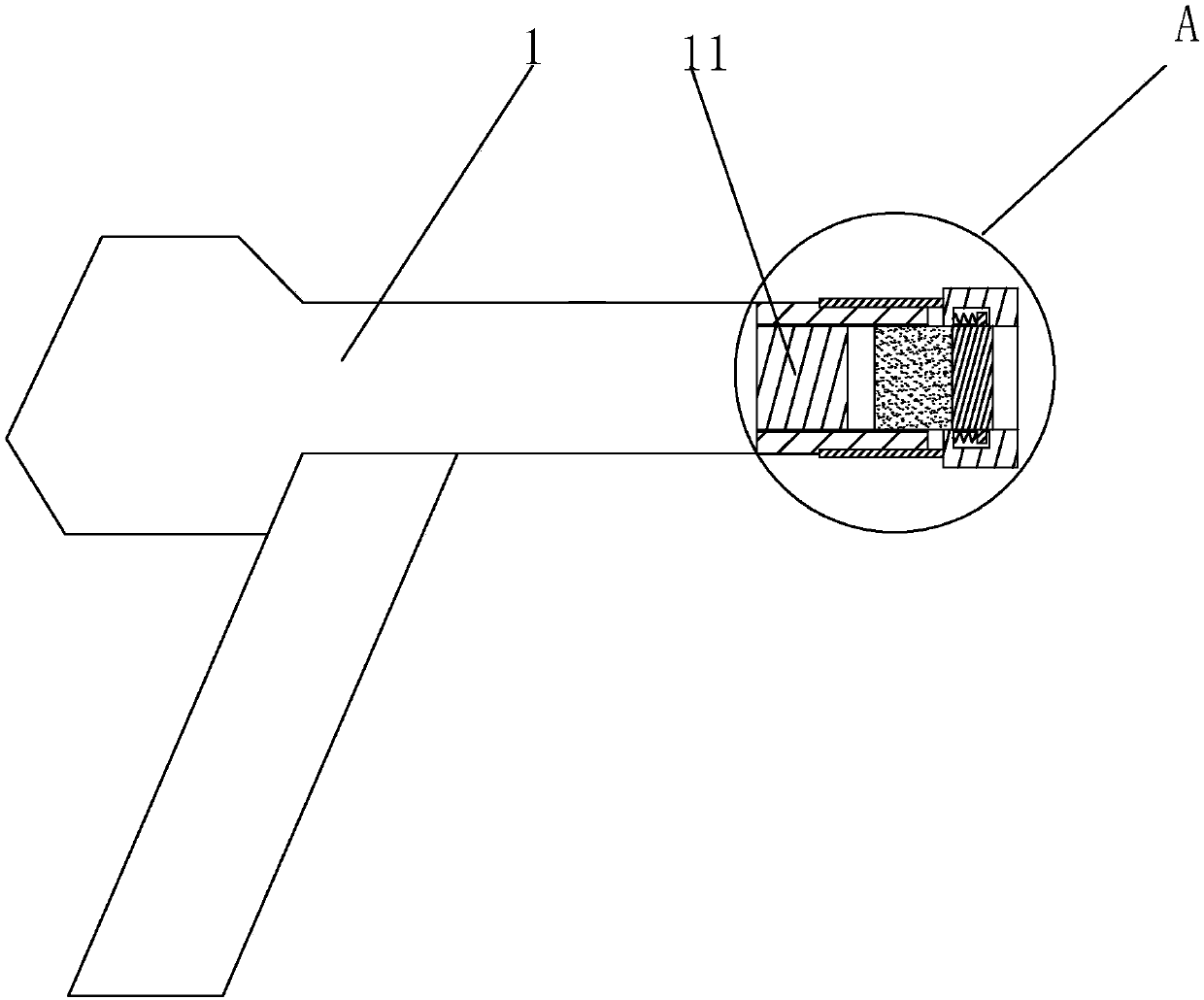

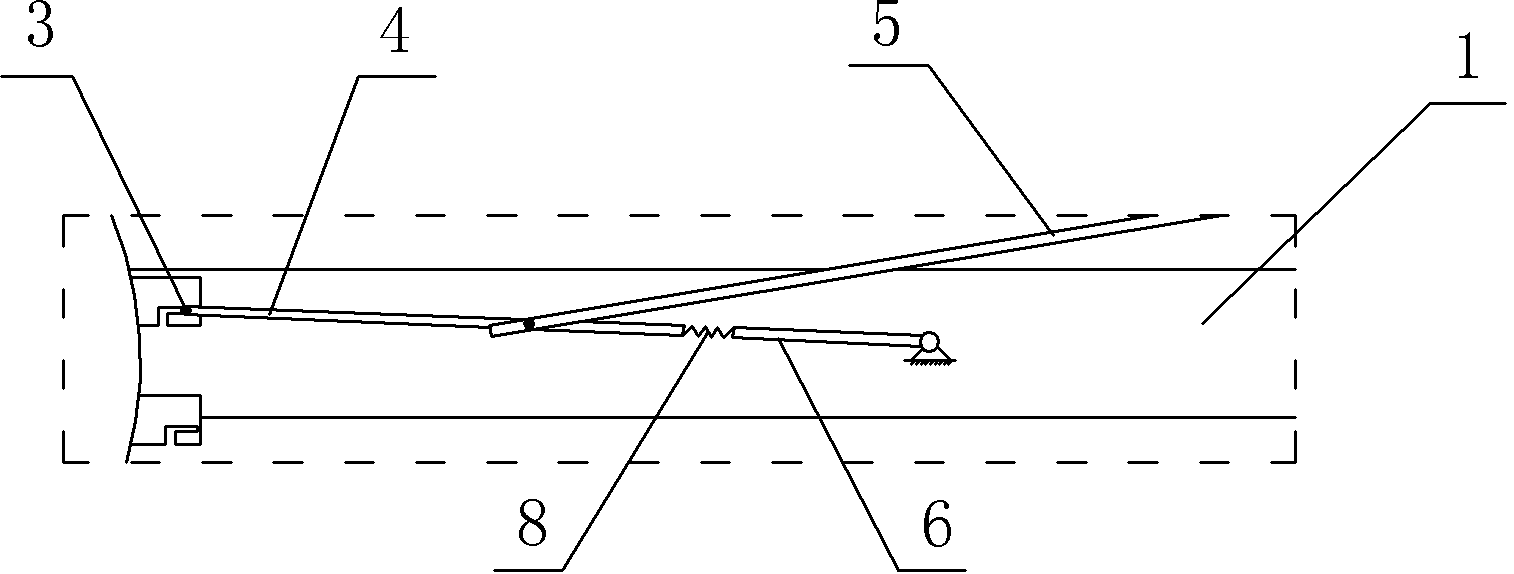

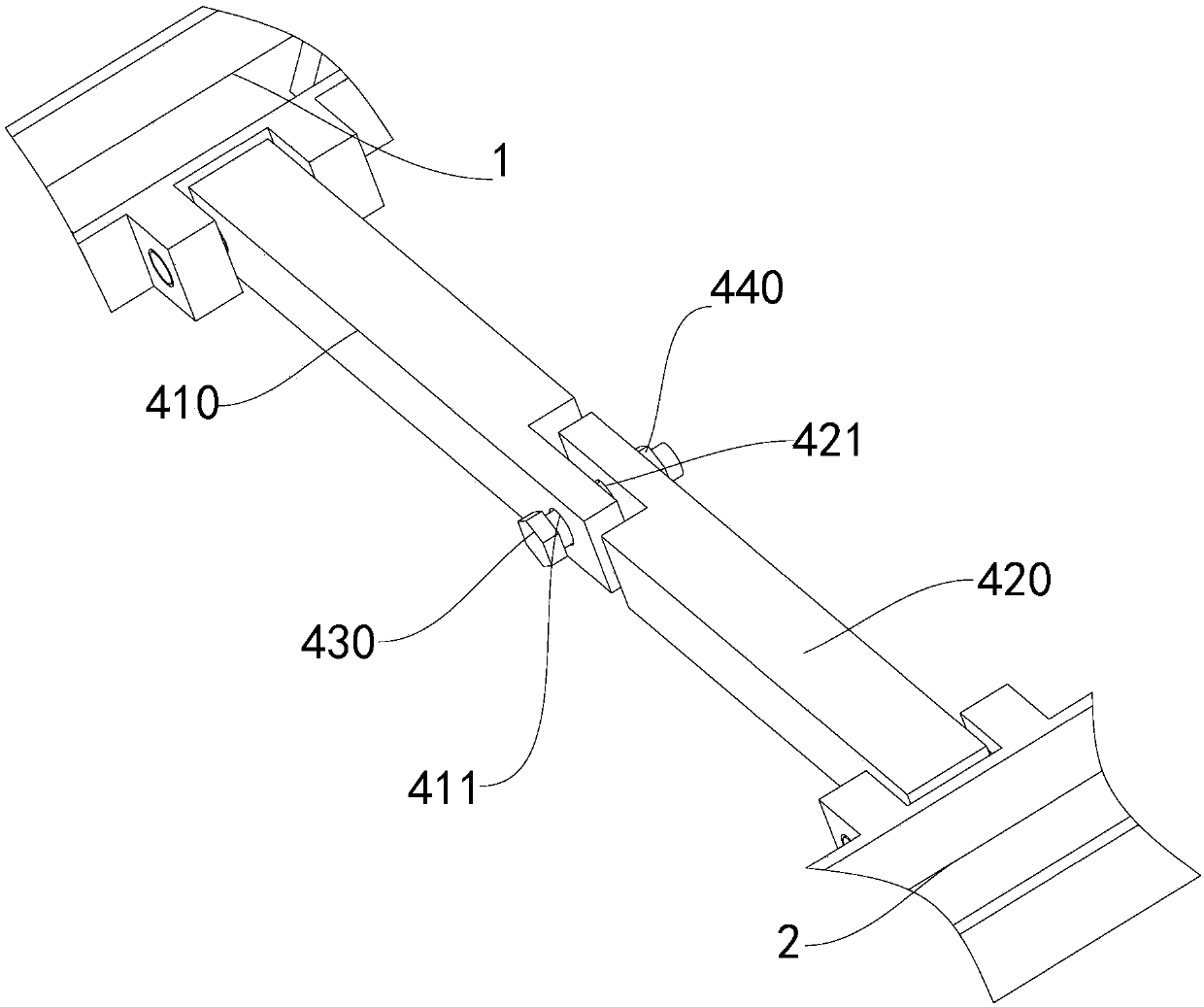

Mounting adapter for split nested unilateral bolt fastener

InactiveCN105952742ARealize one-sided installationAvoid unbalanced forceRod connectionsEngineeringFastener

The invention relates to a mounting adapter for a split nested unilateral bolt fastener. The mounting adapter comprises a main body, an inner sleeve (5) fixed on the main body and an outer sleeve (6) arranged outside the inner sleeve (5) in a sleeving manner, wherein the inner sleeve (5) is used for accommodating and fixing a bolt (9); the outer sleeve (6) is connected with a rotation output shaft of a driving mechanism and used for accommodating and driving a nut (11) to rotate; an inner gear is arranged on the inner wall of the outer sleeve (6) and used for being meshed with an outer gear (8) on the rotation output shaft of the driving mechanism; the main body comprises a cylindrical housing (2) arranged outside the outer sleeve (6) in a sleeving manner; hinge pin holes (31) are formed in the cylinder body of the housing (2); circular-arc-shaped holes (32) are formed in the cylinder body of the outer sleeve (6); and hinge pins (3) are fixedly mounted on the outer wall of the inner sleeve (5) and penetrate the corresponding circular-arc-shaped holes (32) and hinge pin holes (31). Compared with the prior art, the mounting adapter has the advantages of small space occupation and high reliability.

Owner:TONGJI UNIV

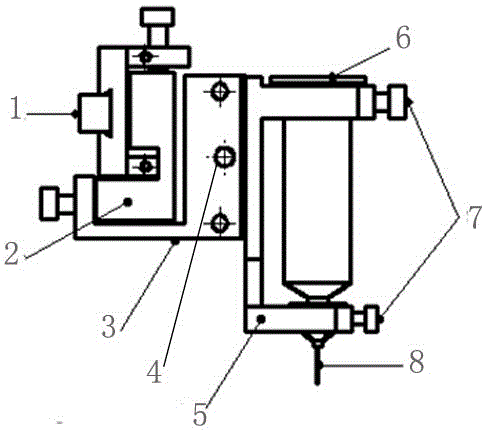

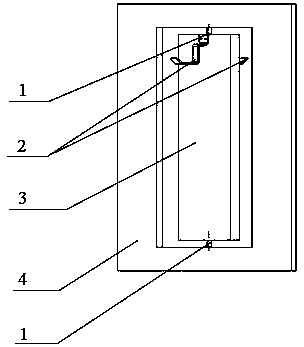

Glue injection equipment

InactiveCN105964494AQuick alignmentPrevent bump deformation or bendingLiquid surface applicatorsCoatingsInjection equipmentSmall deviations

The invention discloses glue injection equipment. The glue injection equipment comprises an equipment fixed frame, front-and-back adjusting frames, up-and-down adjusting frames, left-and-right adjusting frames, needle cylinder fixing frames and needle cylinders; the up-and-down adjusting frames are installed on the equipment fixed frame, each front-and-back adjusting frame is installed on the corresponding up-and-down adjusting frame, each left-and-right adjusting frame is installed on the front-and-back adjusting frame, each needle cylinder fixing frame is installed on the corresponding left-and-right adjusting frame, each needle cylinder is provided with a needle and installed on the corresponding needle cylinder fixing frame, and each needle cylinder fixing frame is installed on a guide rail on the side portion of the corresponding left-and-right adjusting frame in an up-and-down sliding mode through a sliding block on the side portion. According to the glue injection equipment, the needles can be rapidly aligned to products to be subjected to glue injection, and a lot of time consumed due to a small deviation for adjustment is not needed; the needles can make contact with an upper deviation and keep still in the glue injection process, by means of the sliding blocks and the guide rails, the needle cylinder fixing frames can move upwards along the guide rails automatically, collision deformation or bending of the needles is prevented, and therefore protection on the needles is achieved, and new needles do not need to be replaced frequently.

Owner:FINETOP SCI &TECH

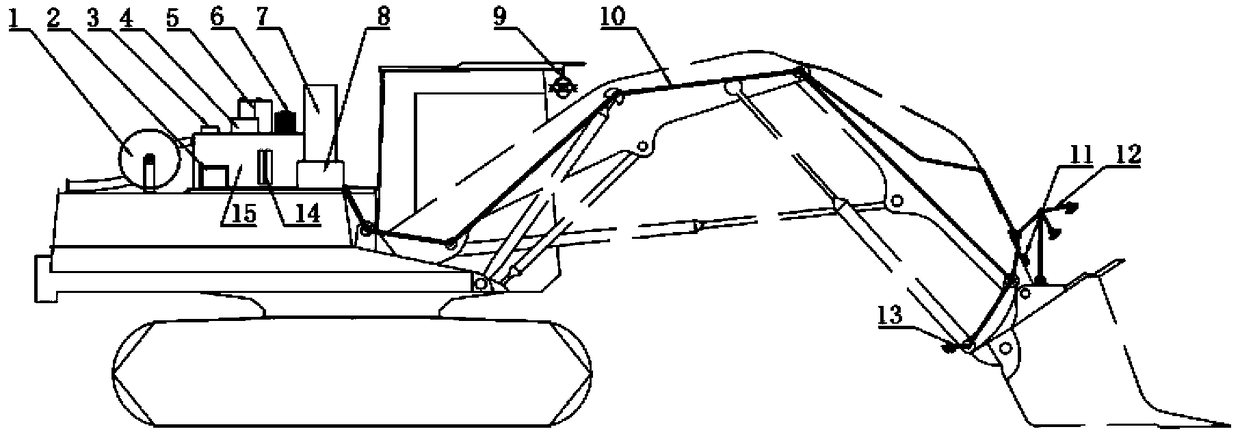

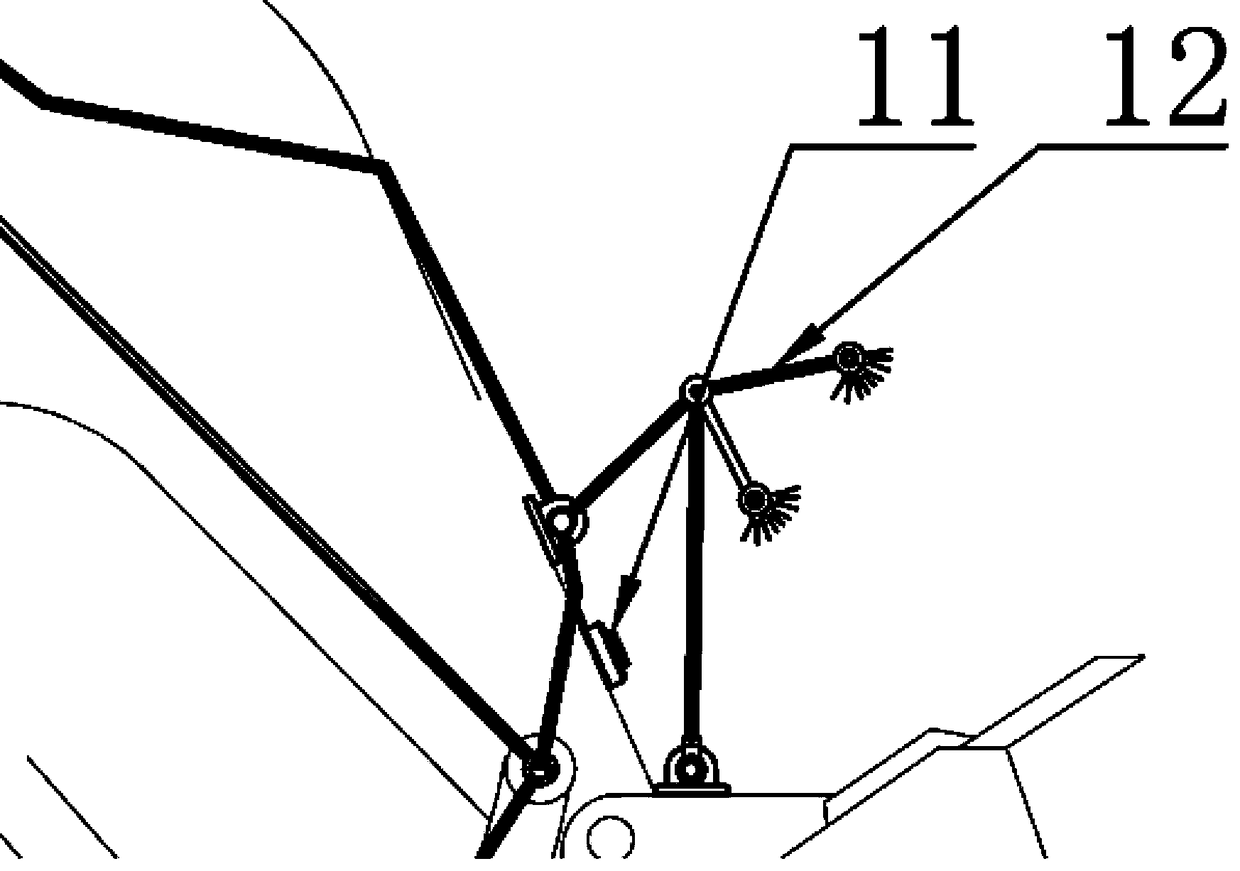

Smoke suppression and dust falling system and method facing centralized slag loading area

PendingCN108787211AImprove economyImprove efficiencyUsing liquid separation agentSeparation devicesAutomatic controlSlag

The invention discloses a smoke suppression and dust falling system and method facing a centralized slag loading area. The system comprises a walking type engineering machine used for dross clearing in the slag loading area, the walking type engineering machine carries a smoke detection device of the smoke amount of the environment where the device is located, the smoke detection device is connected with a spraying control system used for spraying and dust falling through a master controller, the spraying control system is connected with a drug configuration device used for providing drug spraying through a drug conveying device, and the walking type engineering machine is provided with a cab control device used for controlling the spraying control system, the drug conveying device and thedrug configuration device. The novel dust suppression scheme is creatively adopted to be combined with an automatic control system, the system is directly arranged on a construction machine, on the appropriate time, centralized operation is achieved, and the effects of rapidly suppressing dust, removing smoke and purifying air are achieved.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD

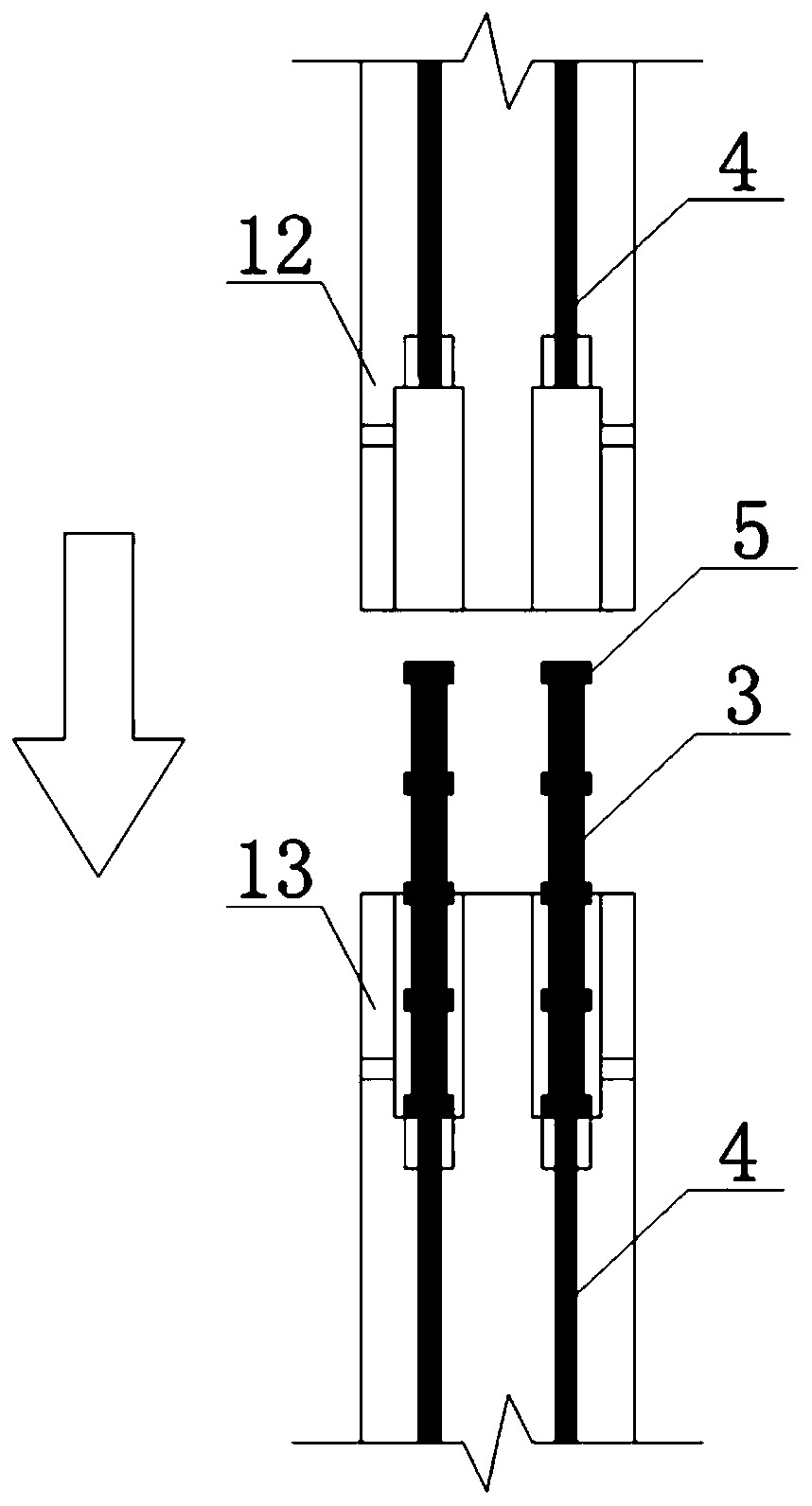

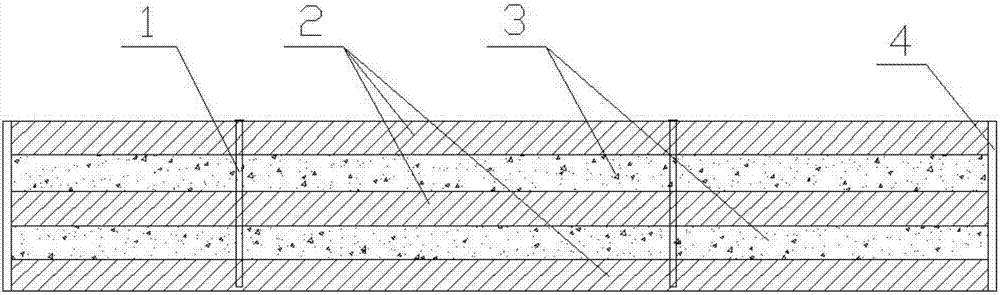

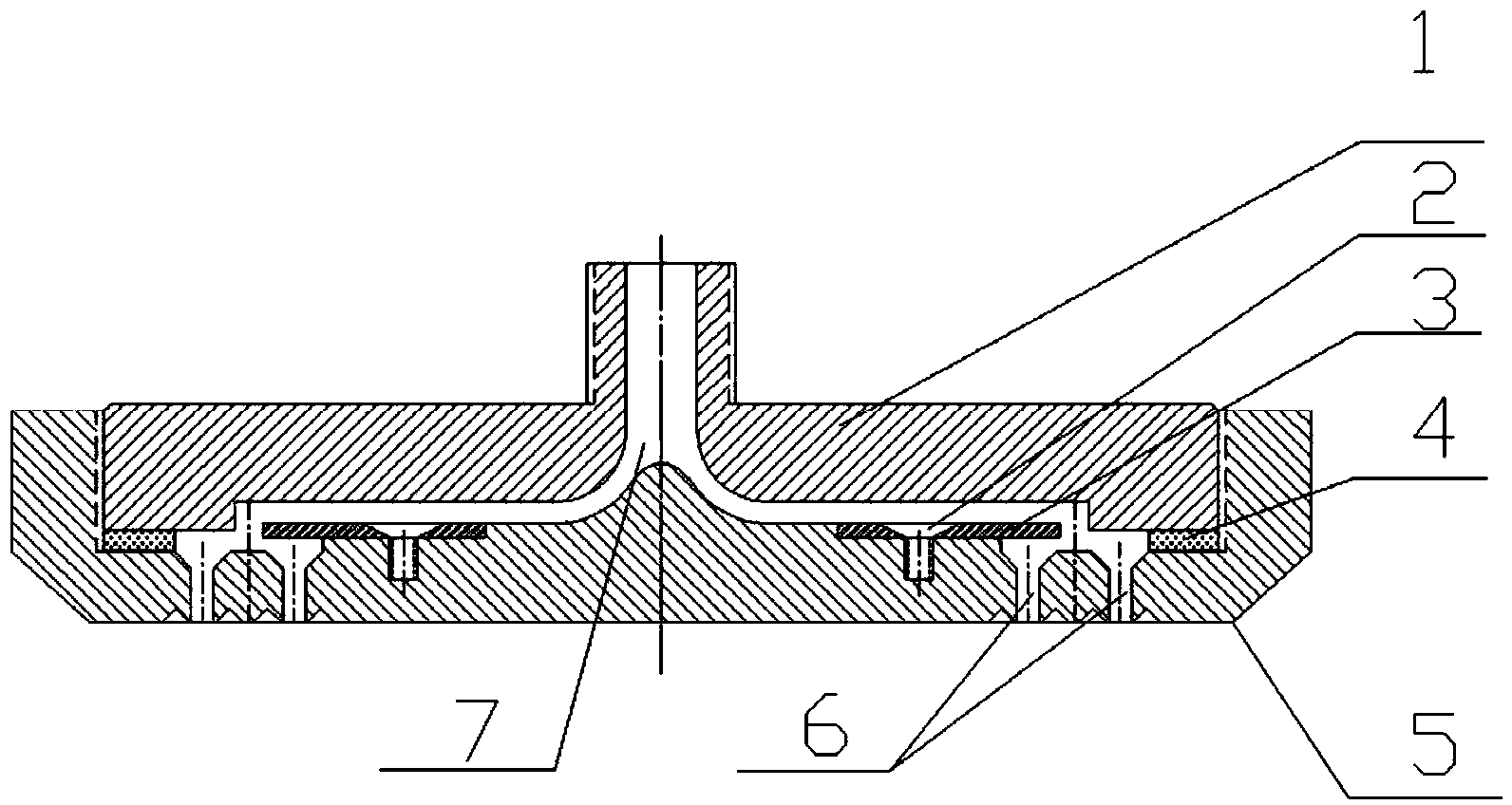

Spliced grouting sleeve and building prefabricated part

ActiveCN109989529AImprove stabilityAvoid Collision DeformationBuilding reinforcementsArchitectural engineeringSlurry

The invention discloses a spliced grouting sleeve which comprises a first sleeve, a second sleeve and a connecting steel bar, the first sleeve and the second sleeve can be spliced into a complete grouting sleeve, the connecting steel bar is used for connecting the first sleeve and the second sleeve, and a sleeve cavity of the first sleeve and a sleeve cavity of the second sleeve are filled with grouting materials; one end, far away from the second sleeve, of the first sleeve is provided with a first connecting end, and the first connecting end is detachably connected with an embedded steel barof a first prefabricated part; a second connecting end is arranged at the end, away from the first sleeve, of the second sleeve, and the second connecting end is detachably connected with an embeddedsteel bar of a second prefabricated part; and the first sleeve is provided with a grouting opening, and the second sleeve is provided with a slurry discharging opening. The grouting sleeve can effectively avoid the problems that in an assembly type building, due to the fact that steel bars are exposed, prefabricated parts are deformed and damaged and the steel bars are rusted and bent, and therefore transportation and storage are convenient.

Owner:SHANGHAI INST OF TECH

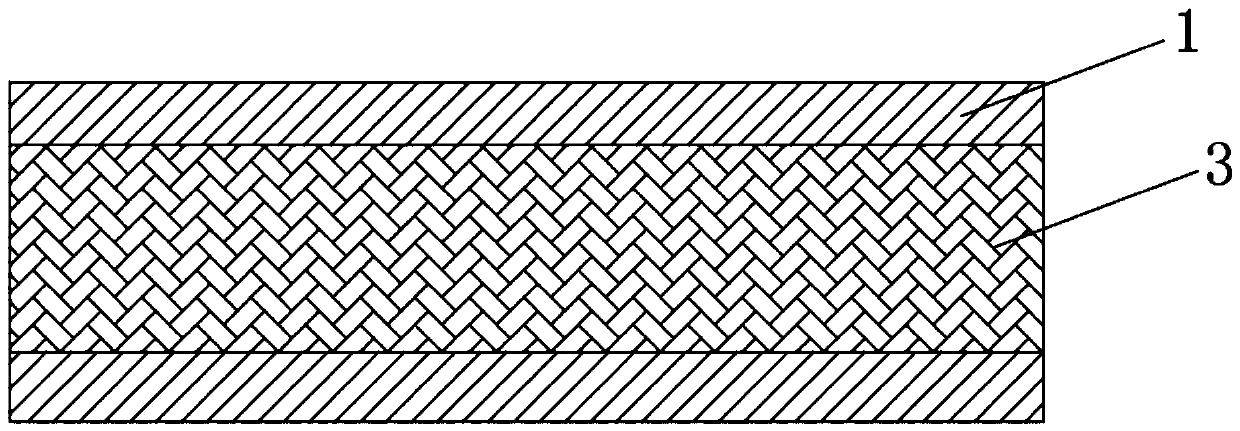

Lightweight electric automobile floor

ActiveCN107263953AAvoid Collision DeformationProtection securityMetal layered productsEnergy absorptionMetal sheet

The invention discloses a lightweight electric automobile floor. The floor is of a five-layer composite structure, the five layers are fixed together by rivets and are a high-strength sheet metal, a foamed aluminum board, a high-strength sheet metal, a foamed aluminum board and a high-strength sheet metal from bottom to top in sequence, and the periphery of the floor is reinforced by adopting a vertical metallic framework in an encircled manner, so that the floor is integrated, the strength is not reduced, and the body weight is greatly reduced. The structural design is simple, a composite vehicle floor technology for alternatively superposing multiple foamed aluminum layers and multiple high-strength sheet metal layers is adopted, collision deformation of the platform floor is avoided, the passenger safety is protected, fire and explosion caused by collided deformation of a battery pack can be avoided, and energy generated by collision can be effectively absorbed. Meanwhile, the traditional foamed aluminum formula is changed, so that the lightweight electric automobile floor has an excellent energy absorption effect, and the application range of the floor is widened.

Owner:界首市中源汽车修造有限公司

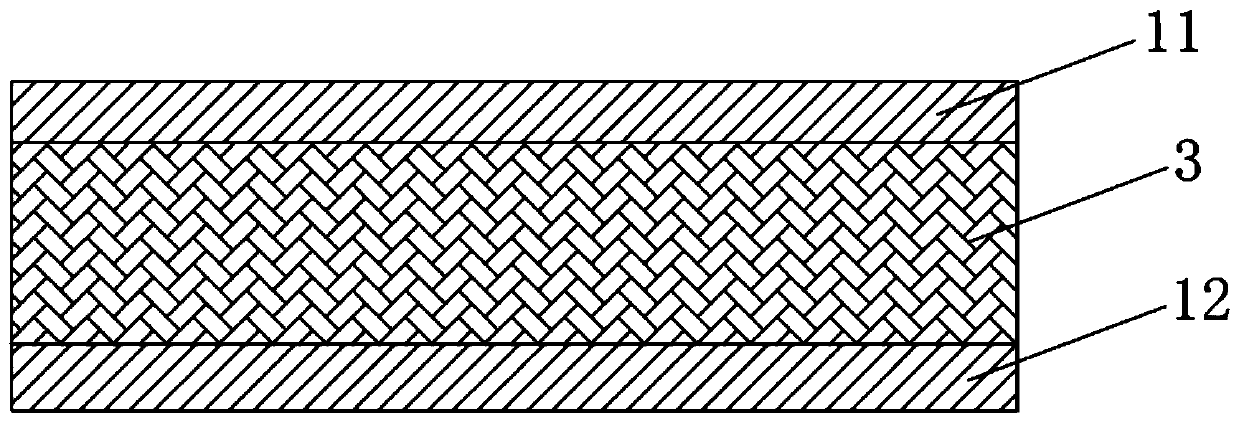

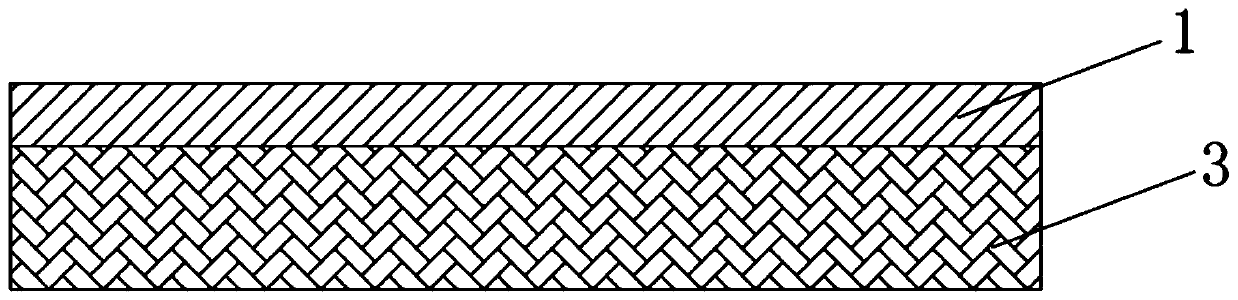

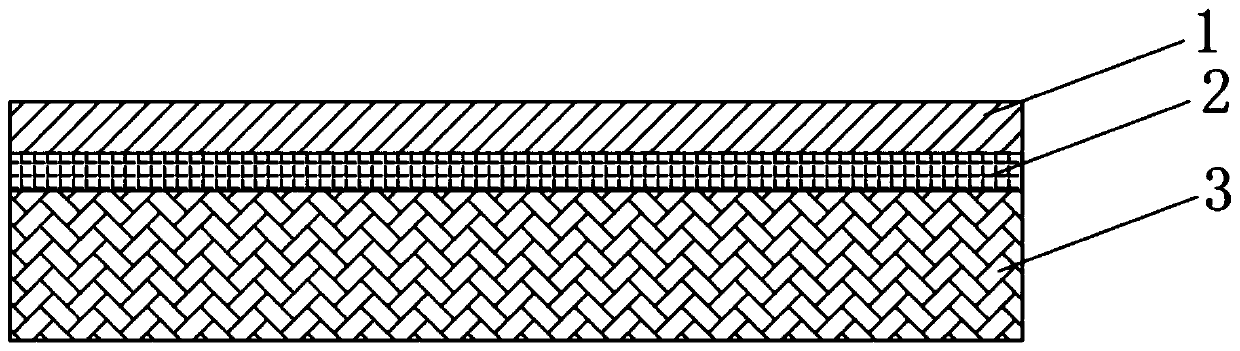

Composite double-sided metal sheet

PendingCN109774272AAvoid Collision DeformationPrevent the spread of fireSynthetic resin layered productsGlass/slag layered productsPhenolsHot-melt adhesive

The invention provides a composite double-sided metal sheet. The composite double-sided metal sheet comprises two metal layers and a wood layer in the middle, wherein the two metal layers comprise theupper metal layer and the lower metal layer, the upper metal layer and the wood layer are connected into one body by coating an hot melt adhesive or phenol glue, and the lower metal layer and the wood layer are connected into one body by coating an hot melt adhesive or phenol glue. Due to the arrangement of the metal layers which are prepared from metal sheets with the thickness of 0.1-2 mm, themetal layers can achieve a protection effect on the whole composite sheet, collision deformation is avoided, a fire insulation effect can be achieved, and fire behavior expansion is prevented. The functions of the product are increased, through the combination of metal and wood, the advantages of the metal and the wood can be given play to respectively, and the problem that a single material cannot meet performance requirements is solved.

Owner:陈彦

Method for replacing water seal of floating access door

ActiveCN112921941AAvoid deformationAvoid tilting forceBarrages/weirsDry-docksStructural engineeringUltimate tensile strength

The invention discloses a method for replacing a water seal of a floating access door. The method comprises the following steps that horizontal leaning wood is disassembled by using a disassembling tool consisting of a jack, a screw and a steel plate; the positions of fastening bolts in a bearing groove are sequentially placed to the surface of new leaning wood through a sample placing plate, the fastening bolts of the original leaning wood are reserved, and bolt cutting and rewelding do not need to be conducted; the horizontal leaning wood is mounted through a trolley and wooden wedges, and the leaning wood is accurately aligned in a narrow space; and a theodolite and an angle square are used to measure the flatness of the surface of the leaning wood. Compared with an existing replacement method, the method provided by the invention has the advantages that the construction steps can be simplified, and the construction amount is reduced; and through reasonable use of various tools, the construction intensity is reduced, and the access door water seal quality is improved.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

Protection cover device for liquid static spraying gun

ActiveCN107899820AAvoid wear and tearAvoid Collision DeformationSpraying apparatusCotton clothEngineering

The invention discloses a protection cover device for a liquid static spraying gun. The liquid static spraying gun comprises a gun body and a nozzle, and the nozzle is in threaded connection with an anti-collision sleeve. A threaded hole allowing the nozzle to be inserted in is formed in the anti-collision sleeve, and a plug for sealing the anti-collision sleeve is arranged at one end of the anti-collision sleeve. A connecting block is arranged at one end of the plug, and a plurality of connecting clamping strips are arranged on the connecting block in a circumferential array manner. A plurality of limiting sliding channel grooves allowing the connecting clamping strips to be embedded in a sliding manner are formed in the surface of the outer circumference of the anti-collision sleeve, anda through hole allowing the plug to penetrate is formed in the connecting block. A pair of sliding grooves is formed in the inner circumferential wall of the through hole in a mirroring manner, and apair of limiting blocks embedded into the sliding grooves in a sliding manner is arranged on the surface of the outer circumference of the plug in a mirroring manner. The limiting blocks are fixedlyconnected in the sliding grooves through connecting springs, and the position, away from the limiting blocks, of the surface of the outer circumference of the plug is wrapped by a water absorption cotton cloth layer. After the plug is mounted on the anti-collision sleeve, part of the water absorption cotton cloth layer is in contact with the outside. The protection cover device can achieve an anti-collision protection function on the nozzle, and meanwhile the blocking phenomenon of dust is avoided.

Owner:TIANCHANG JINLING ELECTRONICS

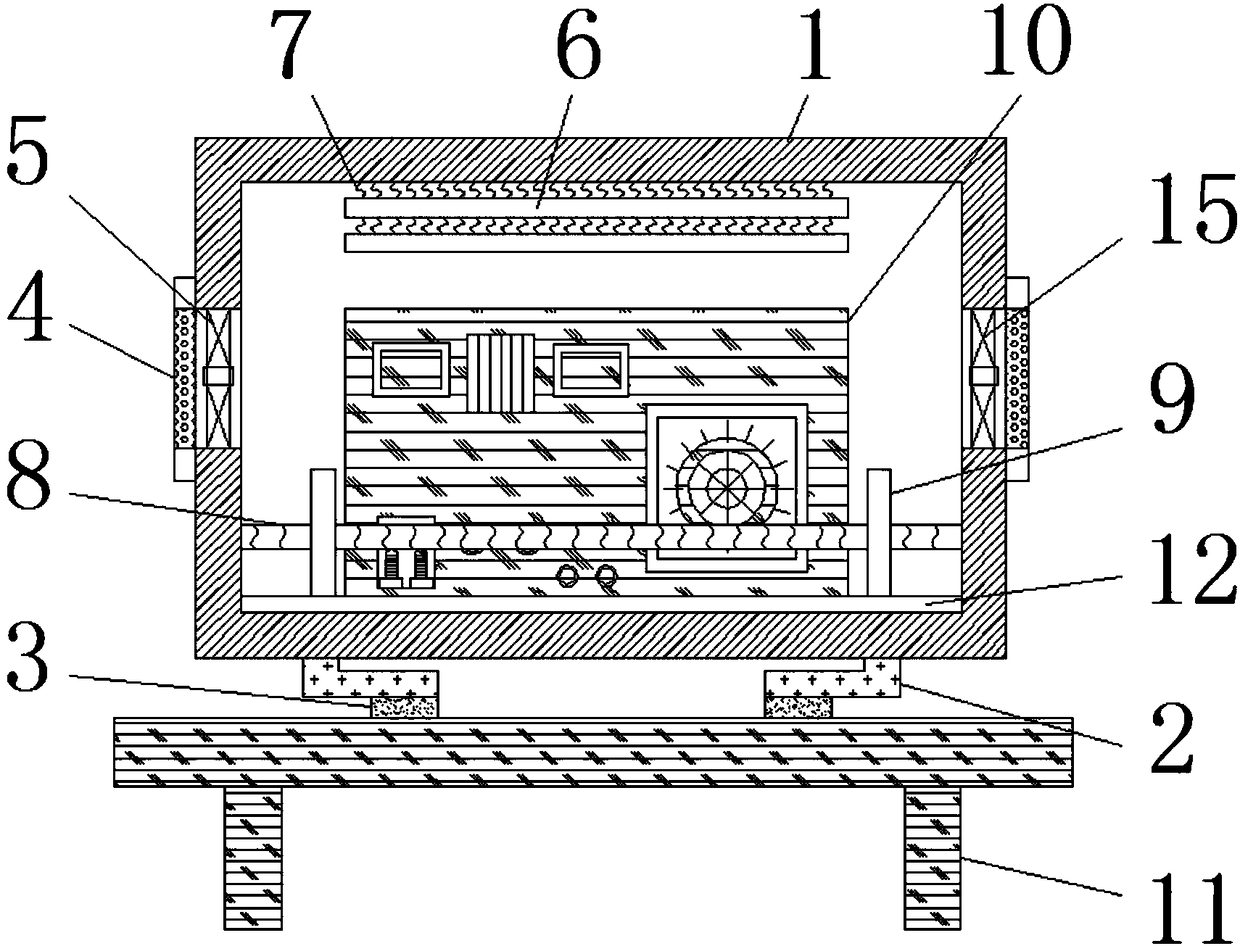

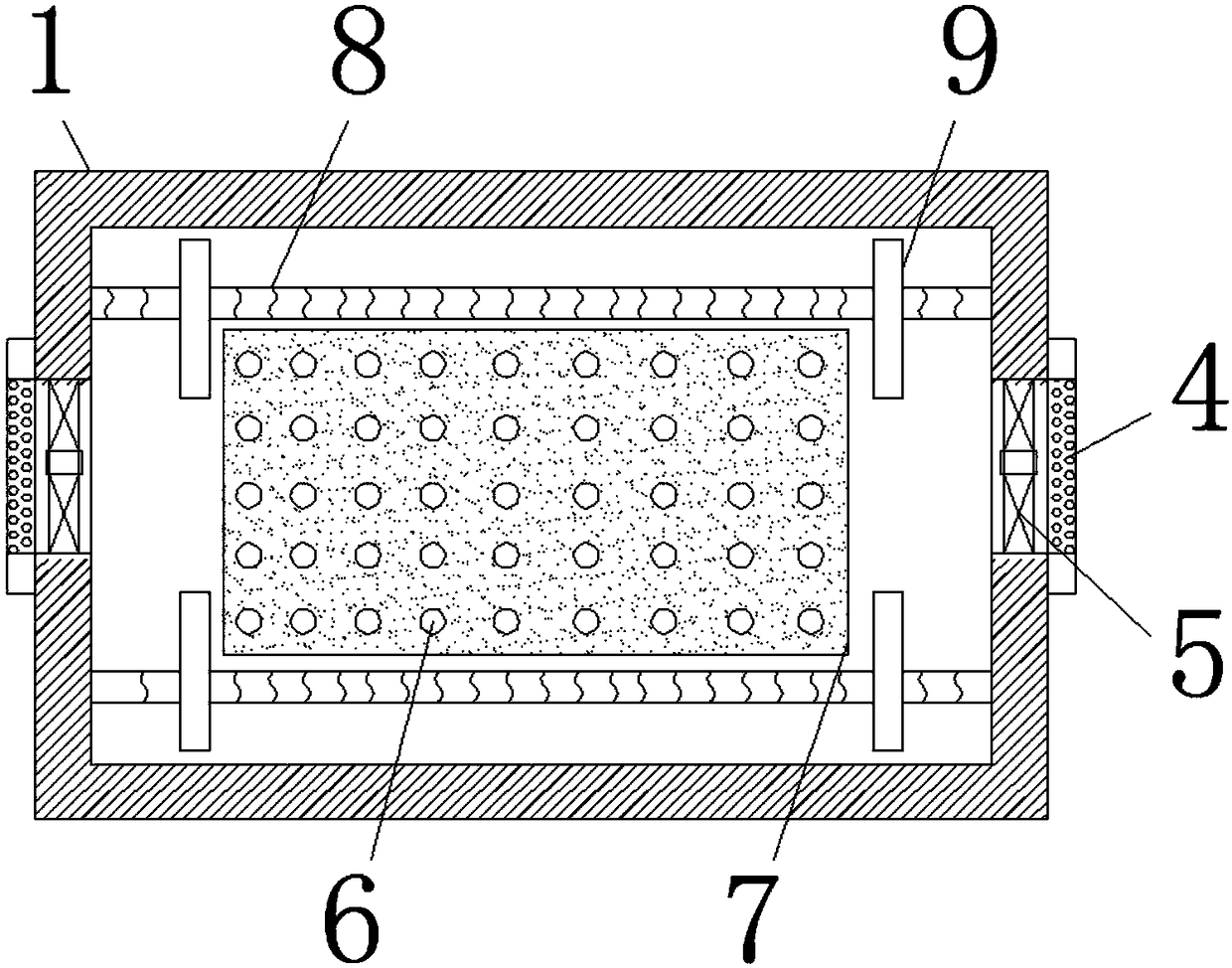

BDV capacitor tester having shockproof heat dissipation effect

PendingCN108508299AWith shockproof cooling effectGood for taking awayElectrical testingEngineeringCapacitor

The invention discloses a BDV capacitor tester having a shockproof heat dissipation effect. The BDV capacitor tester comprises a box body, a fixed rod and a suction fan, wherein the suction fan is mounted inside the left side of the box body, a dust screen is arranged on the outer side of the suction fan, a rotating hook is arranged on the outer side of the dust screen and provided with a fixed hook, the suction fan is mounted inside the right side of the box body, a horizontal plate is arranged on the upper surface of the inside of the box body, the lower end of the horizontal plate is provided with a spring, a tester is disposed below the spring, the fixed rod is fixed on the outer side of the tester and provided with a fixed block, the lower surface of the box body is provided with a connecting rod, and a bearing is mounted at the lower end of the connecting rod. The BDV capacitor tester having the shockproof heat dissipation effect not only enables a device to dissipate heat, but also can fix devices of different sizes, and the dust collection of the devices and precautions against earthquakes can also be implemented.

Owner:NISTRONICS JIANGXI

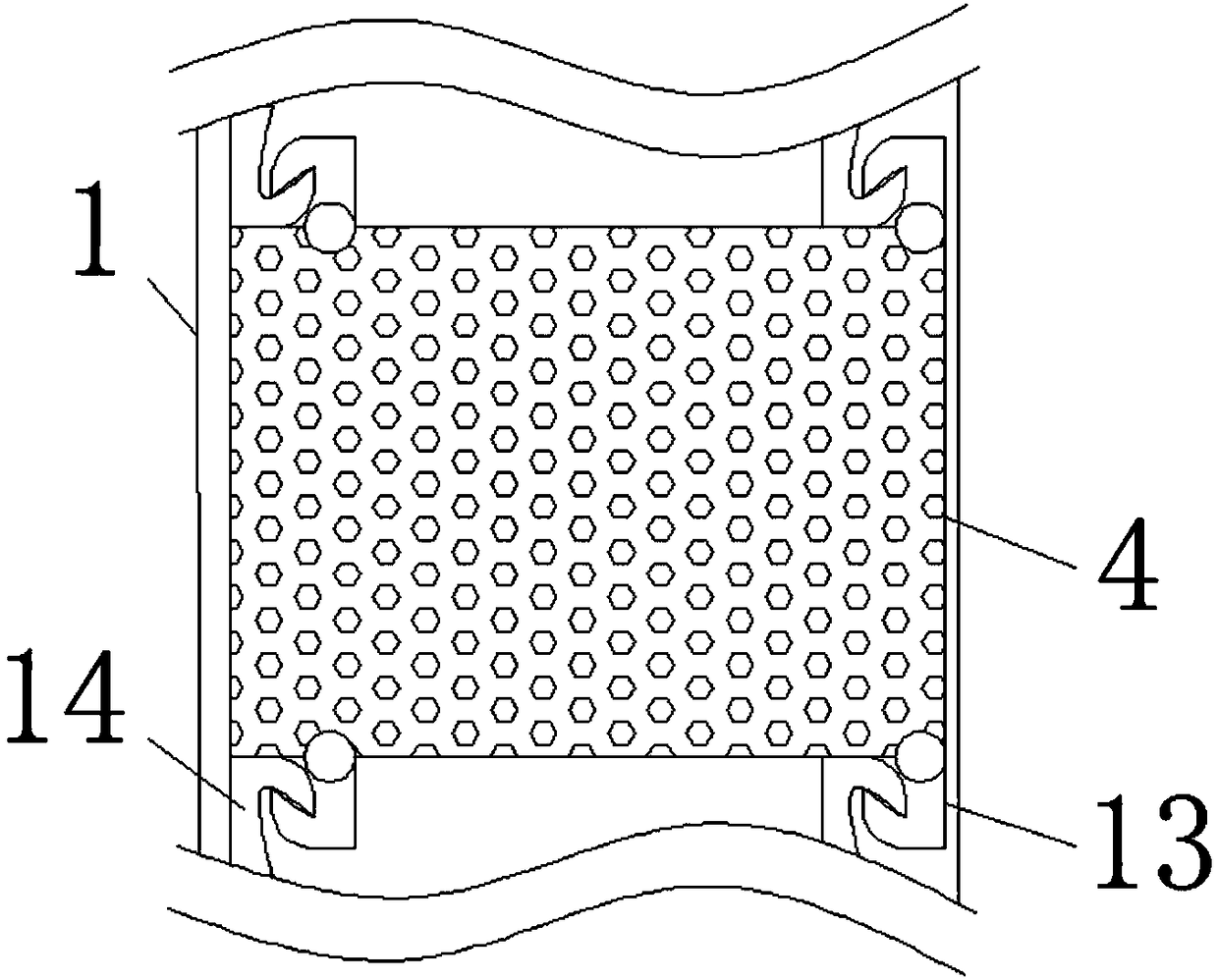

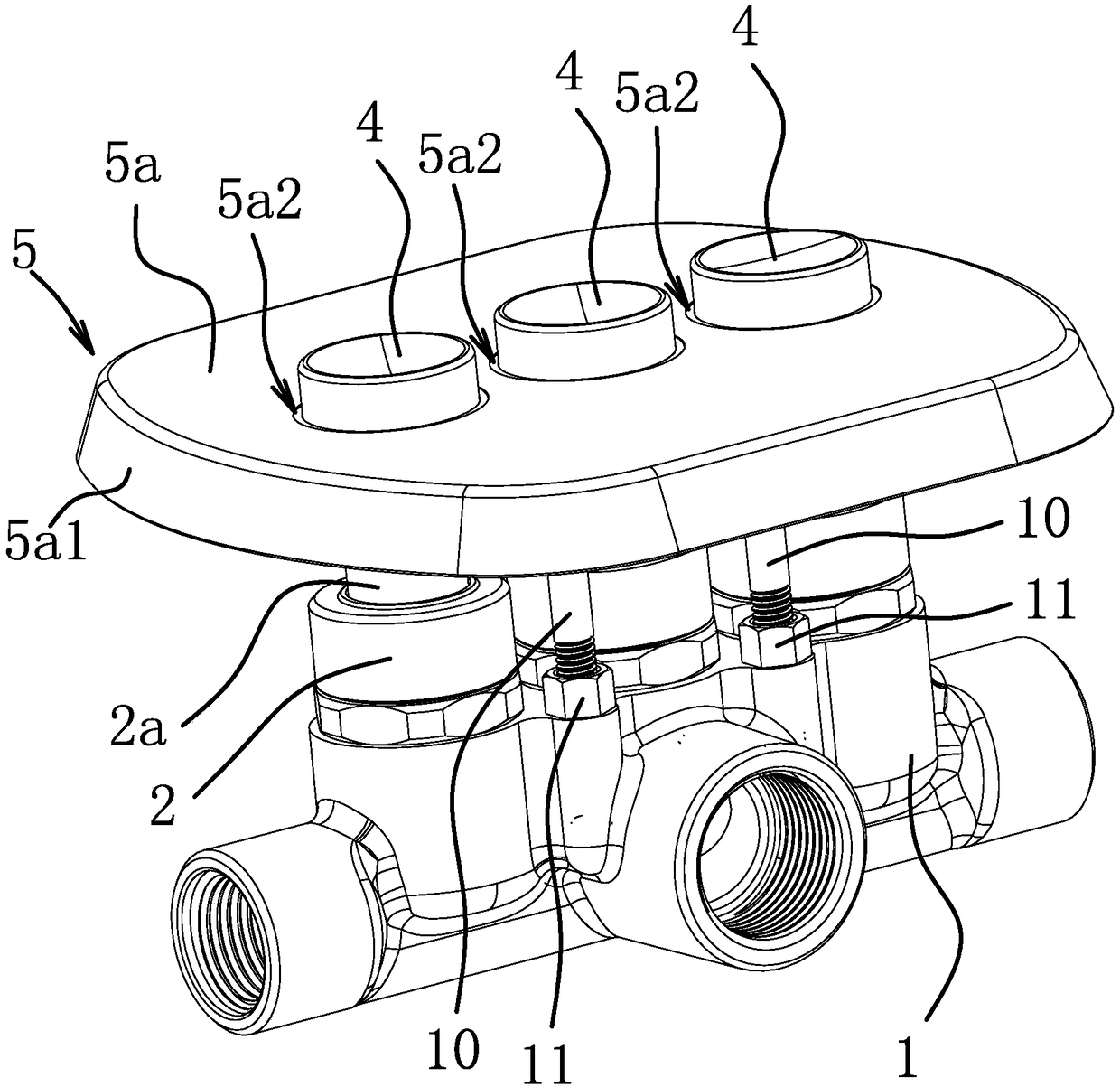

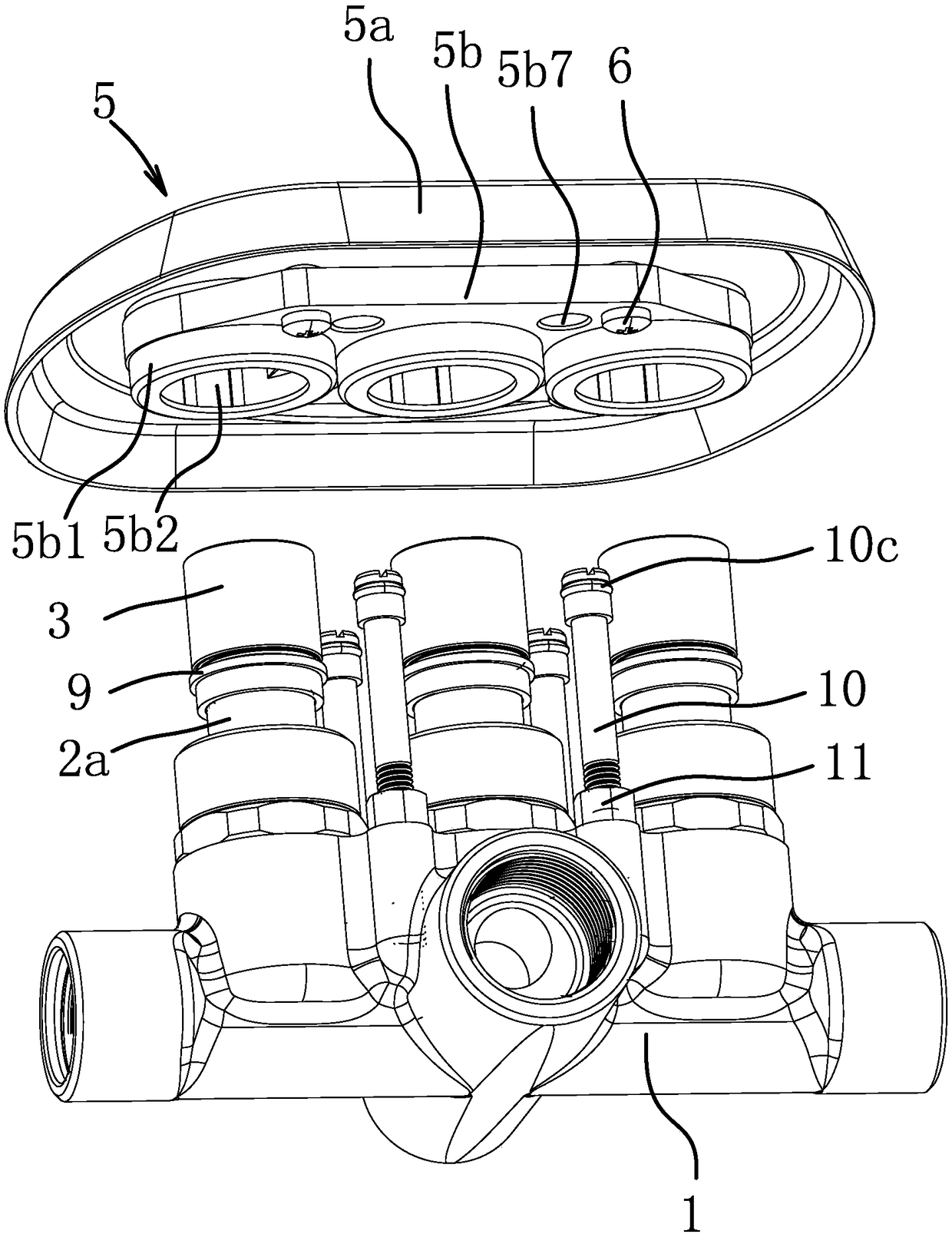

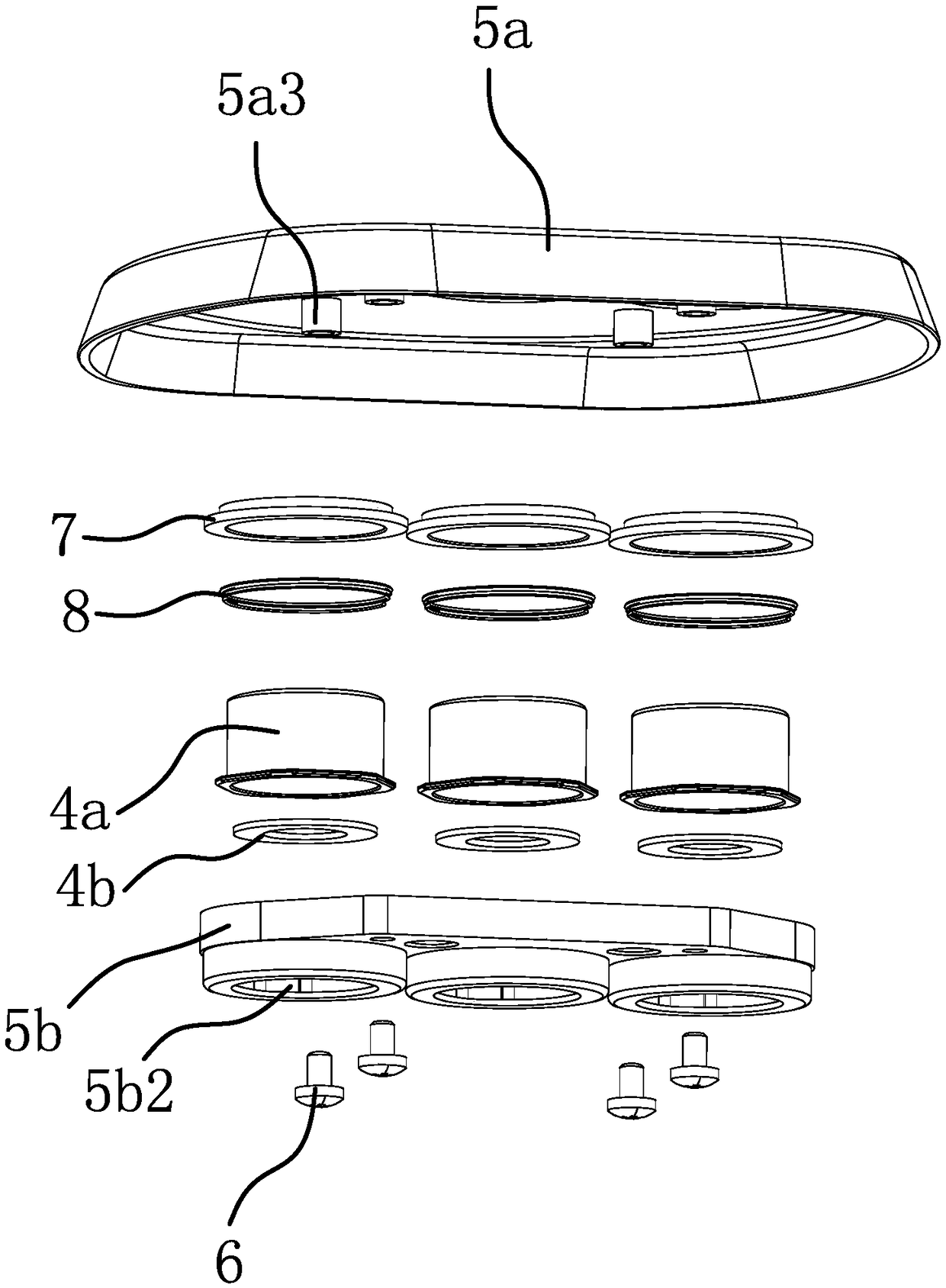

Button panel

PendingCN108825864AReduce noiseEven by forceOperating means/releasing devices for valvesEngineeringControl valves

The invention provides a button panel and belongs to the technical field of kitchen and bath supplies. Through the button panel, the problem that noise is generated easily in the using process of button parts of an existing button panel is solved. The button panel is mounted on a control valve. The control valve comprises button valve elements. The button panel comprises a panel part. The panel part is provided with button holes. The button parts are slidably mounted in the button holes. The button panel furnace comprises springs. The two ends of each spring act on the panel part and the corresponding button part. Each button part is buckled to the corresponding button valve element. Through the button panel, the noise generated by the button parts in the using process can be reduced. Moreover, the button panel is convenient to install.

Owner:TAIZHOU FENGHWA COPPER IND

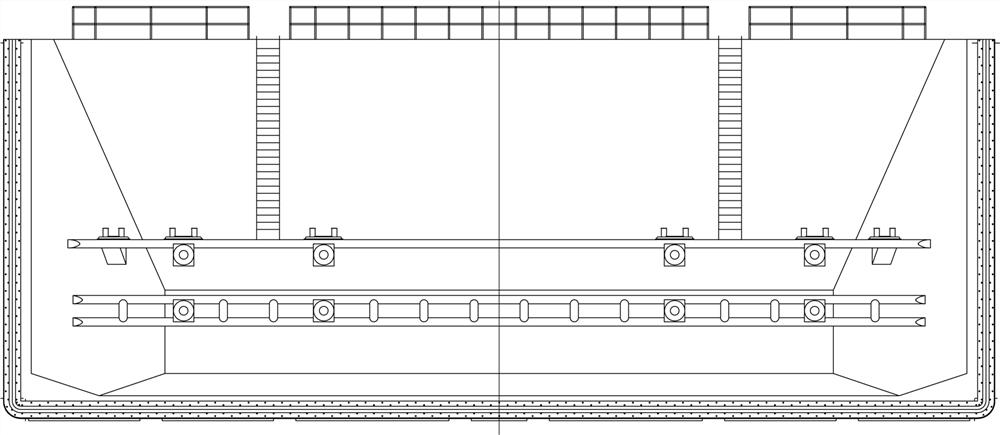

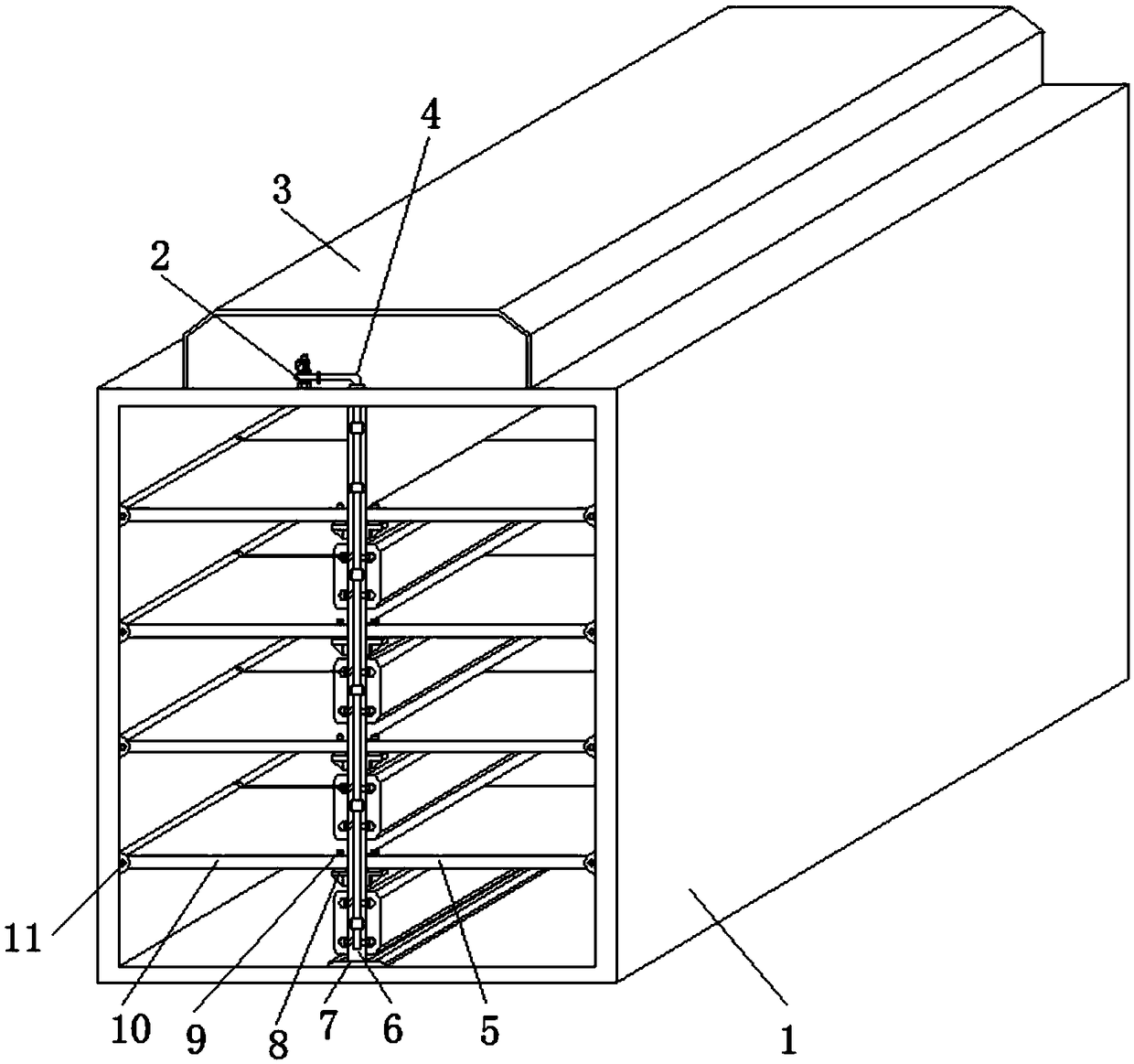

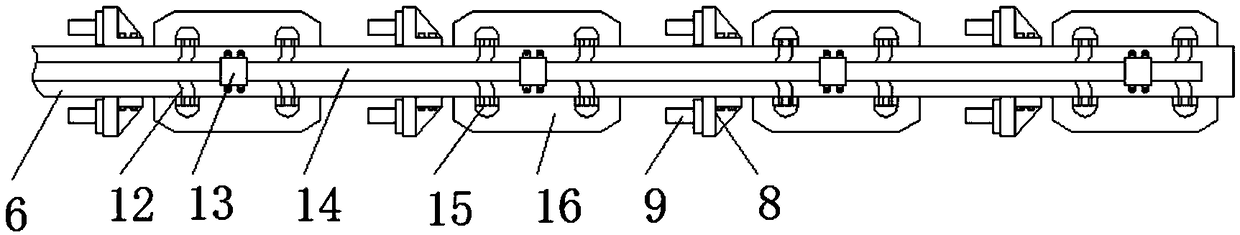

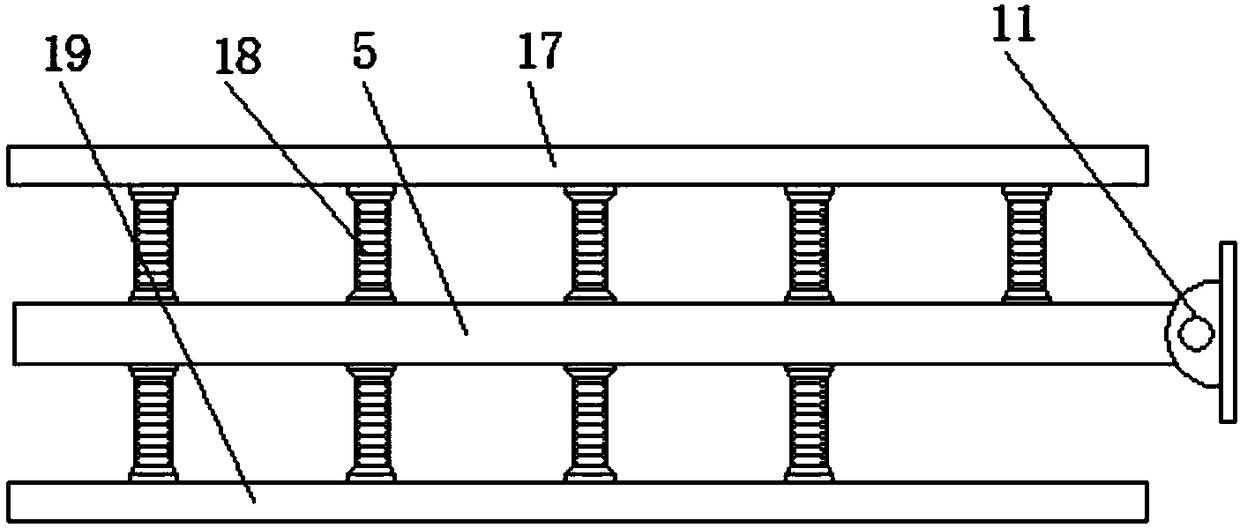

Logistics transportation cargo tank with fire-fighting measure

InactiveCN109018617APrevent cargo accumulation and deformationAvoid Collision DeformationContainers to prevent mechanical damageInternal fittingsWater tanksTransport engineering

The invention discloses a logistics transportation cargo tank with a fire-fighting measure. The logistics transportation cargo tank comprises a logistics cargo tank body. A water tank is spirally fixed to the center line position of the top of the logistics cargo tank body, and the interior of the water tank communicates with a connecting pipe through a water pump. A middle partition frame is spirally fixed to the vertical center line in the logistics cargo tank body through a fixing base. Multiple first cargo storage partitions and second cargo storage partitions are rotationally connected totwo side arms of the logistics cargo tank body through rotating connecting frames at equal intervals. According to the logistics transportation cargo tank, the first cargo storage partitions and thesecond cargo storage partitions are fixedly arranged on the middle partition frame at equal intervals, cargos can be placed in a layered manner through the first cargo storage partitions and the second cargo storage partitions, cargo stacking deformation is prevented, and in addition, damping top plates and damping bottom plates on the first cargo storage partitions and the second cargo storage partitions can be used for conducting damping supporting protection on cargos.

Owner:马勇

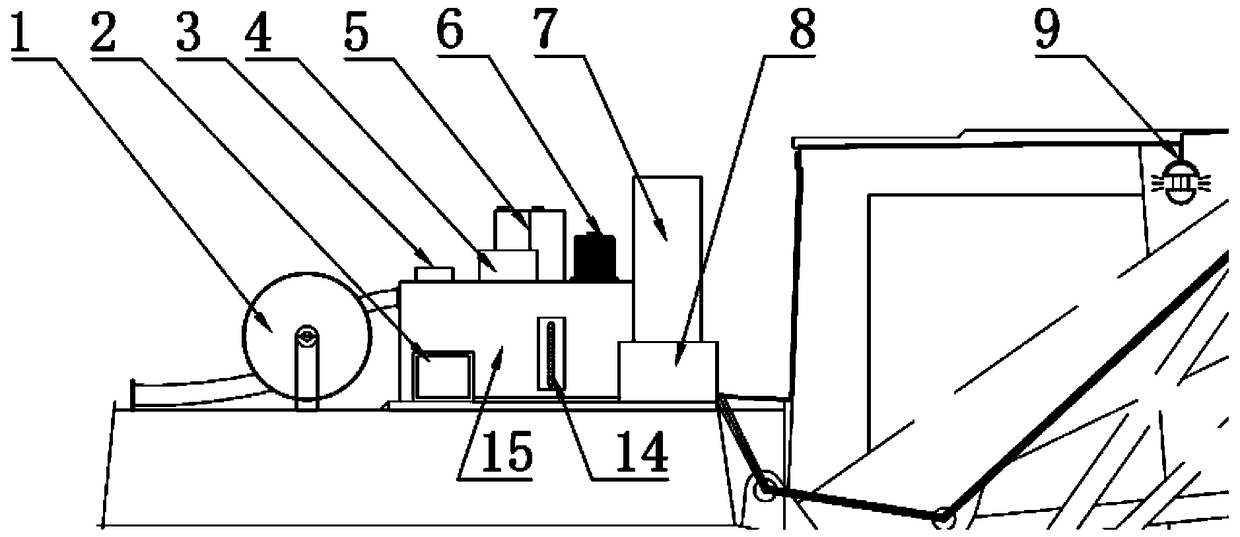

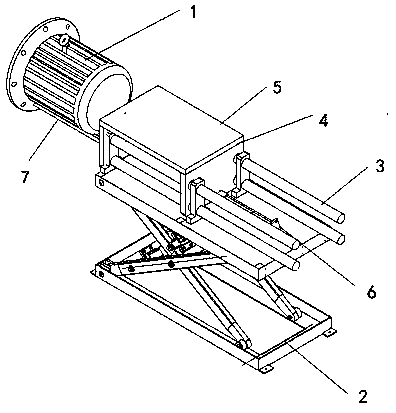

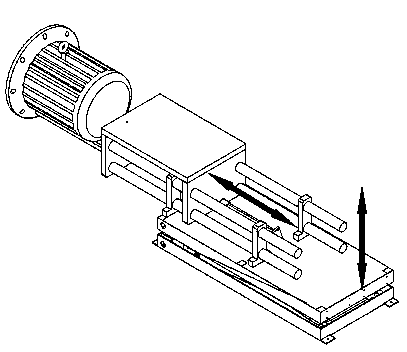

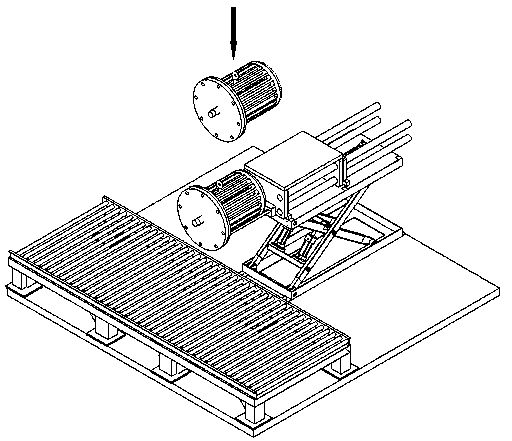

Large-scale motor assembling and carrying device and assembling and carrying method

PendingCN110316677AFirmly assembledAvoid Collision DeformationLifting framesMechanical conveyorsMechanical equipmentSurface flatness

The invention discloses a large-scale motor assembling and carrying device and assembling and carrying method. The large-scale motor assembling and carrying device is arranged on one side of a conveying material belt; the device comprises a lifting component and a translation component, wherein the lifting component is used for completing overall installation of the device and realizing movement in the vertical direction of the device, and the translation component is arranged above the lifting component and enables the device to move in the horizontal direction; the movement direction of thetranslation component is perpendicular to the running direction of the conveying material belt; and a motor supporting component used for supporting a motor is fixedly arranged at the end part of theside, close to the conveying material belt, of the translation component. According to the assembling and carrying device and method, by means of modes such as lifting and displacement of the mechanical equipment, smooth assembling of the motor in the assembling process of a large-scale fan is realized, the problems of collision deformation of a machine shell, damage to the quality of a galvanizedlayer on the surface of the machine shell and the like are solved, and the quality and the surface flatness of a finally-processed finished product are ensured.

Owner:江苏中联风能机械股份有限公司

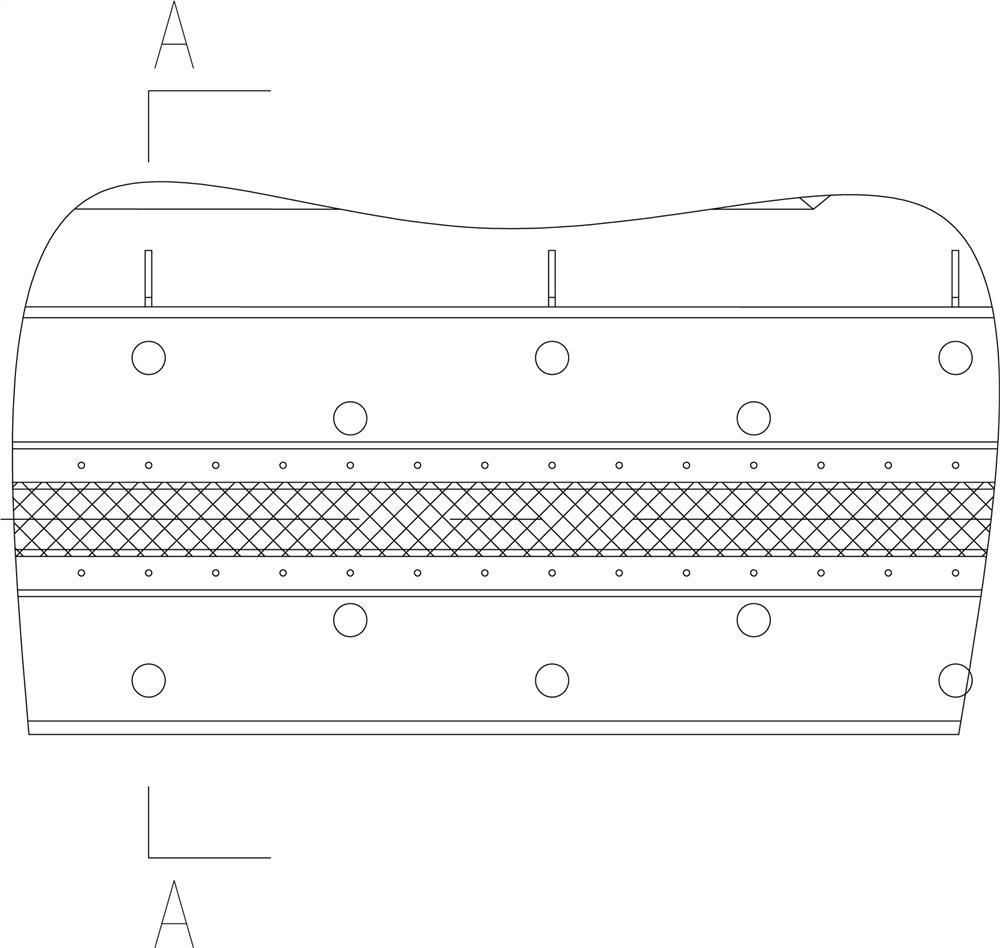

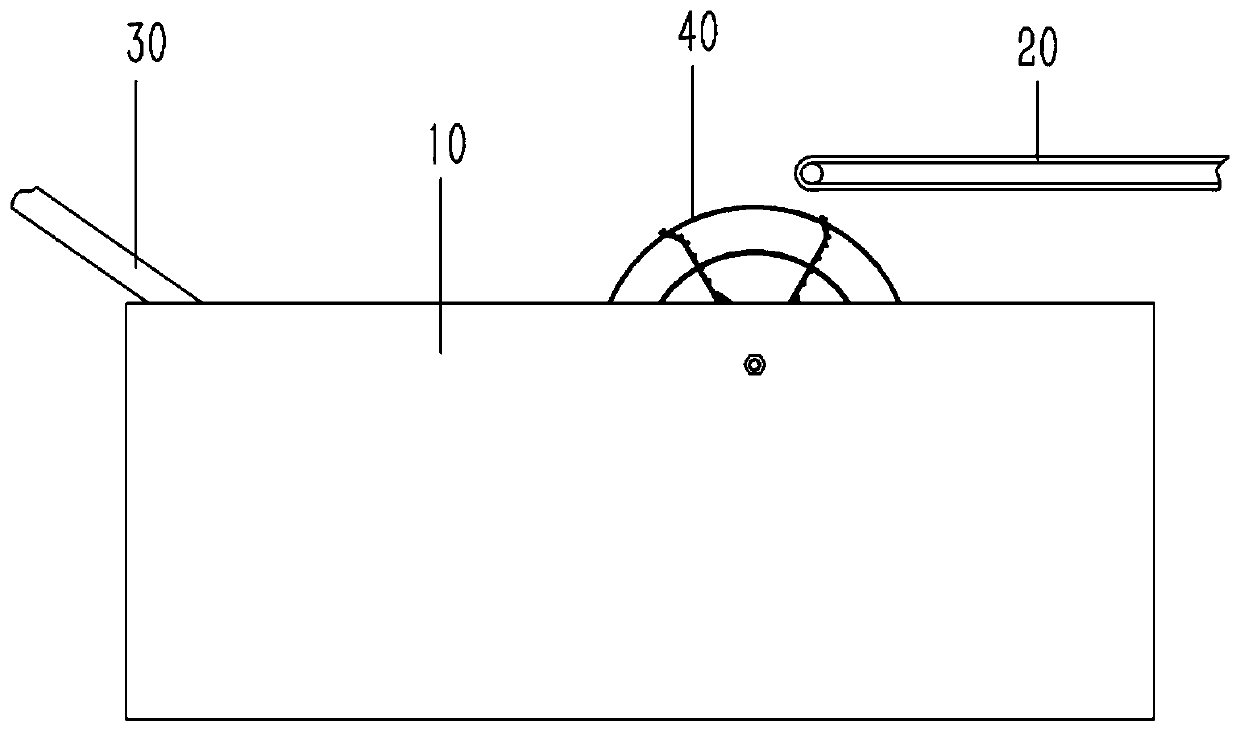

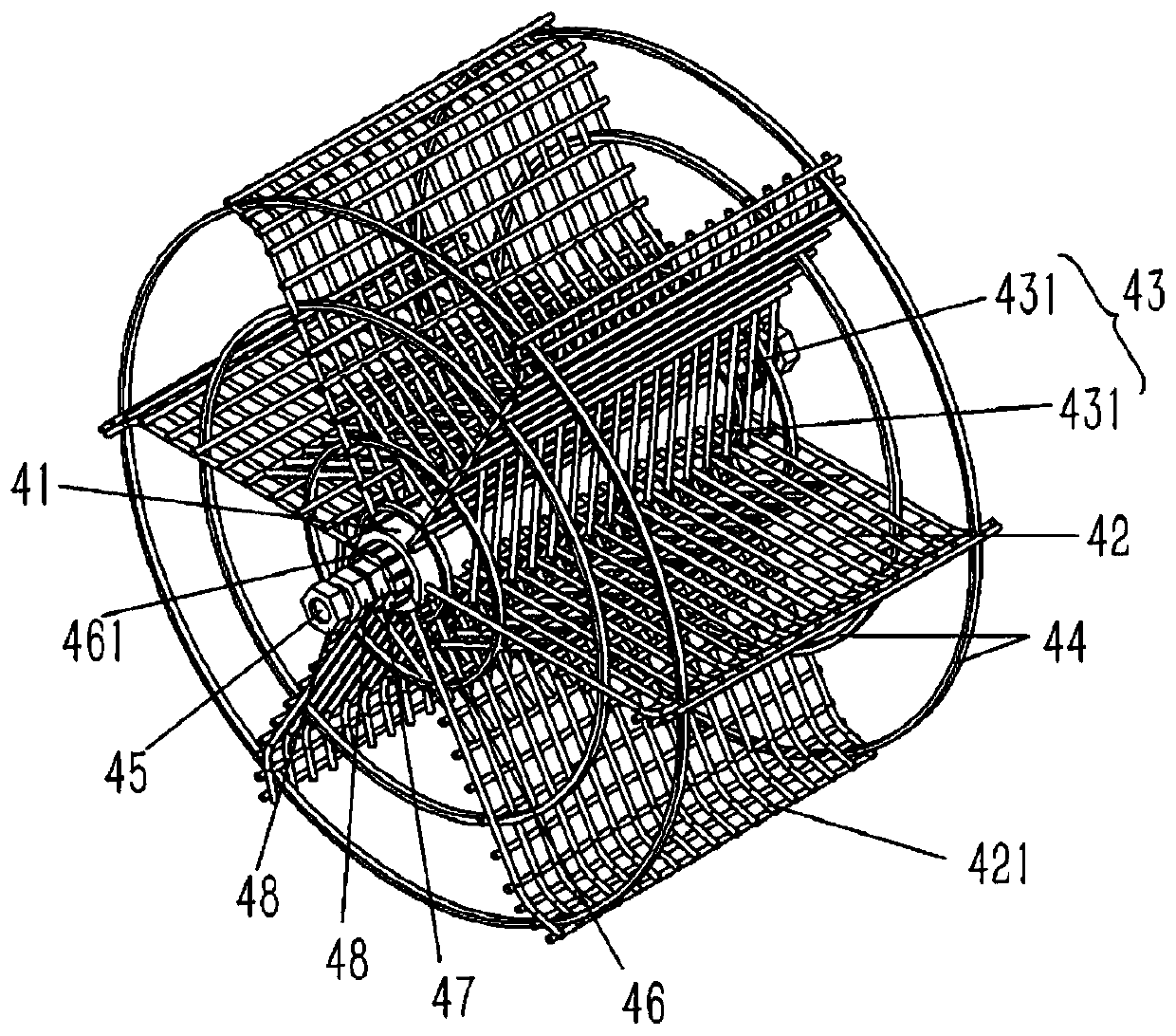

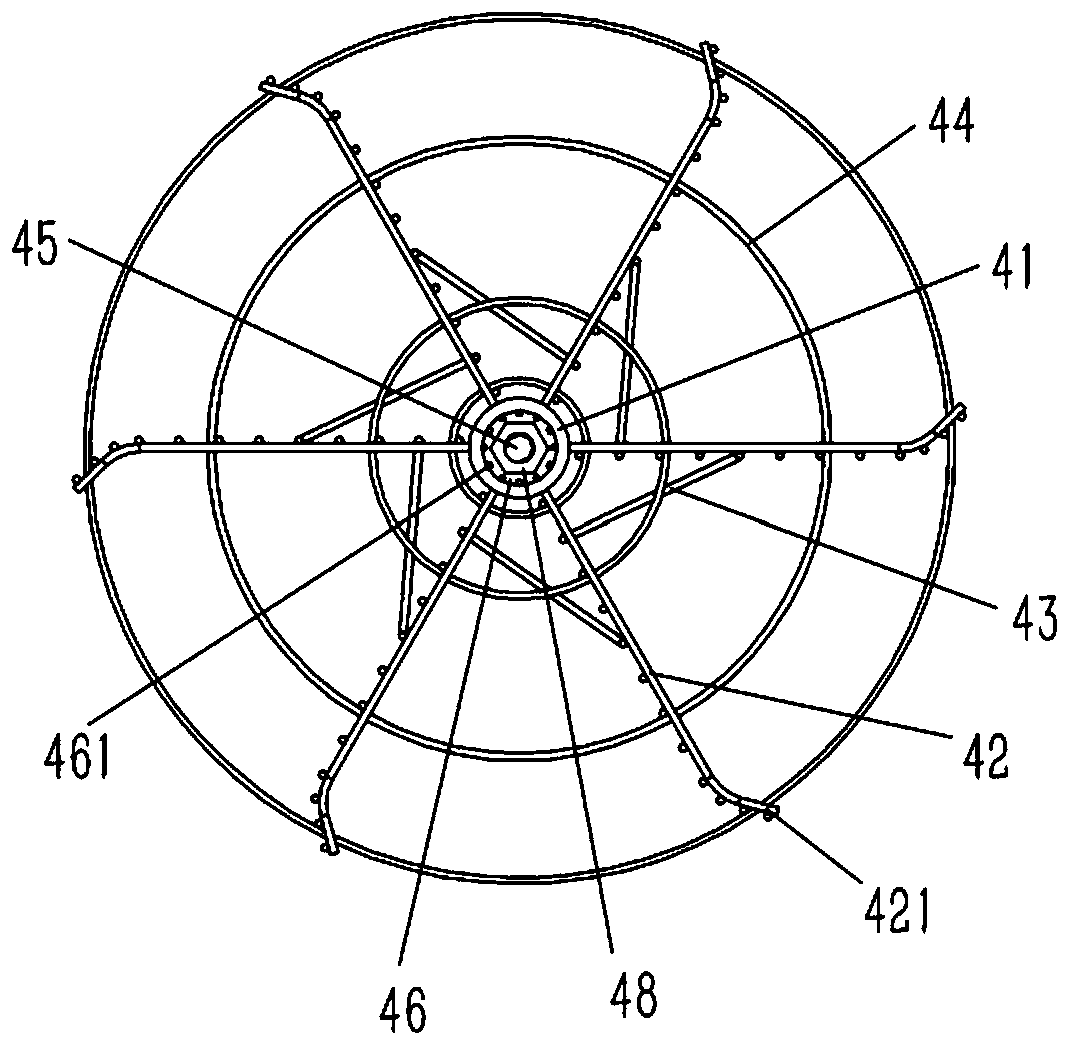

Bearing quenching device with rotating wheel type buffering structure

ActiveCN111500836AReduce impactAvoid Collision DeformationFurnace typesHeat treatment furnacesImpellerWire gauze

The invention discloses a bearing quenching device with a rotating wheel type buffering structure, and the device comprises a quenching oil groove, a horizontal input chain belt is arranged above oneend of the quenching oil groove, an output chain belt is inserted and arranged aslant at the other end of the quenching oil groove, a buffering vane wheel is inserted in the quenching oil groove directly below an output end of the input chain belt, the buffering vane wheel comprises a shaft sleeve, a rotating shaft is inserted and connected in the shaft sleeve, and two ends of the rotating shaft are inserted and connected fixedly on a side wall of the quenching oil groove; an external wall of the shaft sleeve is fixedly provided with several buffering vanes in the shape of a steel wire gauze,external side edges of the buffering vanes are bended to form guide plates leaning upwards, and several reinforcing rings are fixed at two side edges of the buffering vanes; a rib plate is arranged aslant between neighboring buffering vanes, and the rib plate is composed of several parallel ribs.

Owner:江苏立一新材料科技有限公司

Mechanism for transferring welding stations of frame parts of motorcycle

InactiveCN102267028BFast transferEasy transferWelding/cutting auxillary devicesAuxillary welding devicesProduction lineVehicle frame

The invention discloses a mechanism for transferring welding stations of frame parts of a motorcycle. The mechanism is characterized in that: a partition wall is arranged between two adjacent welding stations; the partition wall is provided with a door frame; a rotating plate is arranged in the door frame in a matching mode; rotary shafts which are vertically arranged in the middle parts of the upper and lower ends of the rotating plate are arranged on the door frame in a rotatable mode; and a hanging hook which is used for hanging the frame parts of the motorcycle is arranged on at least one side of the rotating plate. Compared with the conventional logistics transferring device of frame welding production line parts of the motorcycle, the mechanism for transferring the welding stations of the frame parts of the motorcycle has the advantages that: the lean manufacturing of transferring of a welding process flow can be realized to quickly and conveniently transfer the parts; an arc light can be blocked, and the physical and psychological health of a welder can be protected; the parts can be effectively prevented from being collided and deformed; product quality is ensured; production efficiency is greatly improved; and the mechanism is simple in principle, stable and reliable in structure and low in cost.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

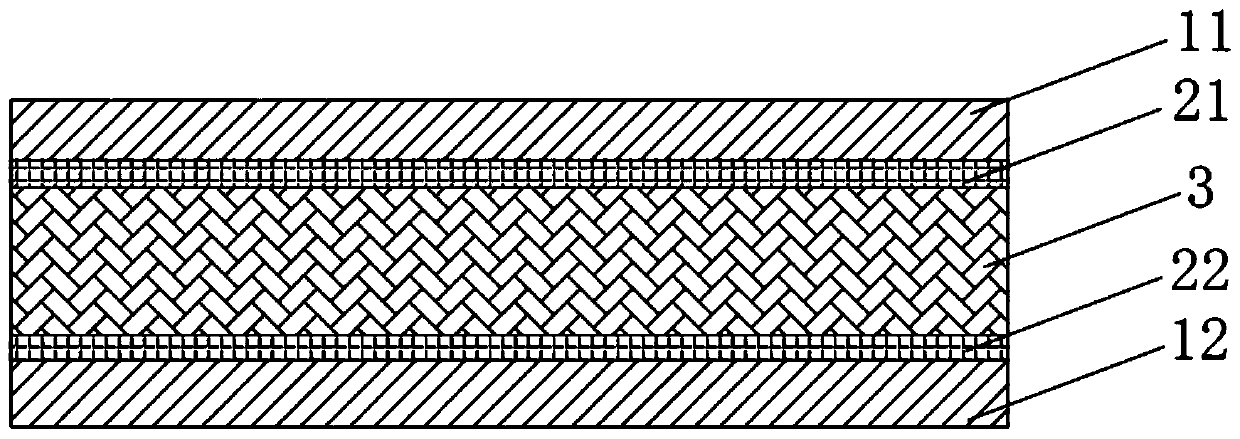

Composite single-surface metal board

PendingCN109774273APlay a protective effectAvoid magnificationSynthetic resin layered productsGlass/slag layered productsHot meltComposite plate

The invention provides a composite single-surface metal board. The board comprises a wooden layer, and a metal layer is arranged on the surface of the wooden layer; the metal layer and the wooden layer are connected integrally by adopting hot melt glue or phenol glue for gluing. According to arrangement of the metal layer, the metal layer adopts a metal board with the thickness of 0.1 mm-2 mm, andcan protect the whole composite board to avoid deformation caused by collision, achieve the fire insulation effect, and prevent fire spreading. The effects and functions of the composite board are added, and through the combination of metal and wood combination, the board can exert the respective advantages of the raw materials and meet the performance requirements which a single material cannotmeet.

Owner:陈彦

Rail transit beam high-place operation safety protection device

PendingCN111809525AAchieve fixationReliable securityBridge erection/assemblyBuilding material handlingSafety netStructural engineering

The invention provides a rail transit beam high-place operation safety protection device which comprises a rail beam erected on a pier, a plurality of protection units and a protection net, wherein the protection units are arranged on the rail beam at intervals, and the protection net is arranged in the area between the adjacent protection units on the side face of the rail beam. The protection unit comprises two locking mechanisms and a safety net fixing mechanism; the two locking mechanisms are oppositely arranged on the two sides of the horizontal extending direction of the rail beam in a spaced mode, abut against the outer surface of the rail beam and are detachably connected with the rail beam. The safety net fixing mechanisms are fixedly connected with the two locking mechanisms respectively, the parts, exceeding the width of the rail beam, of the safety net fixing mechanisms extend upwards in the direction away from the upper surface of the rail beam to form hanging parts of theprotection net, and the two horizontally-extending ends of the protection net are hung on the hanging parts of the safety net fixing mechanisms of the adjacent protection units respectively.

Owner:武汉兴汉宇应用科技有限公司

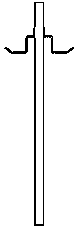

Locating rod with teeth

InactiveCN104318961APrevent slidingPrecise positioningInstrumental componentsEngineeringMechanical engineering

Owner:重庆市南川区泰城钢化玻璃制品有限责任公司

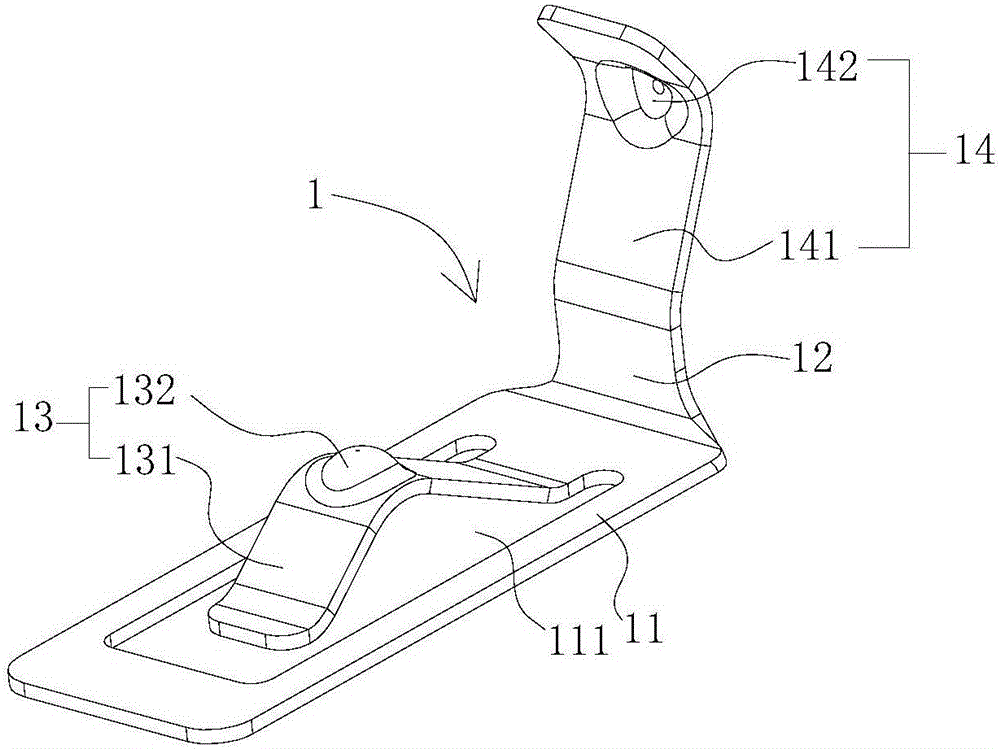

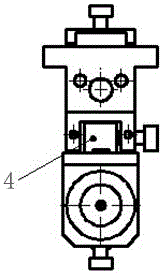

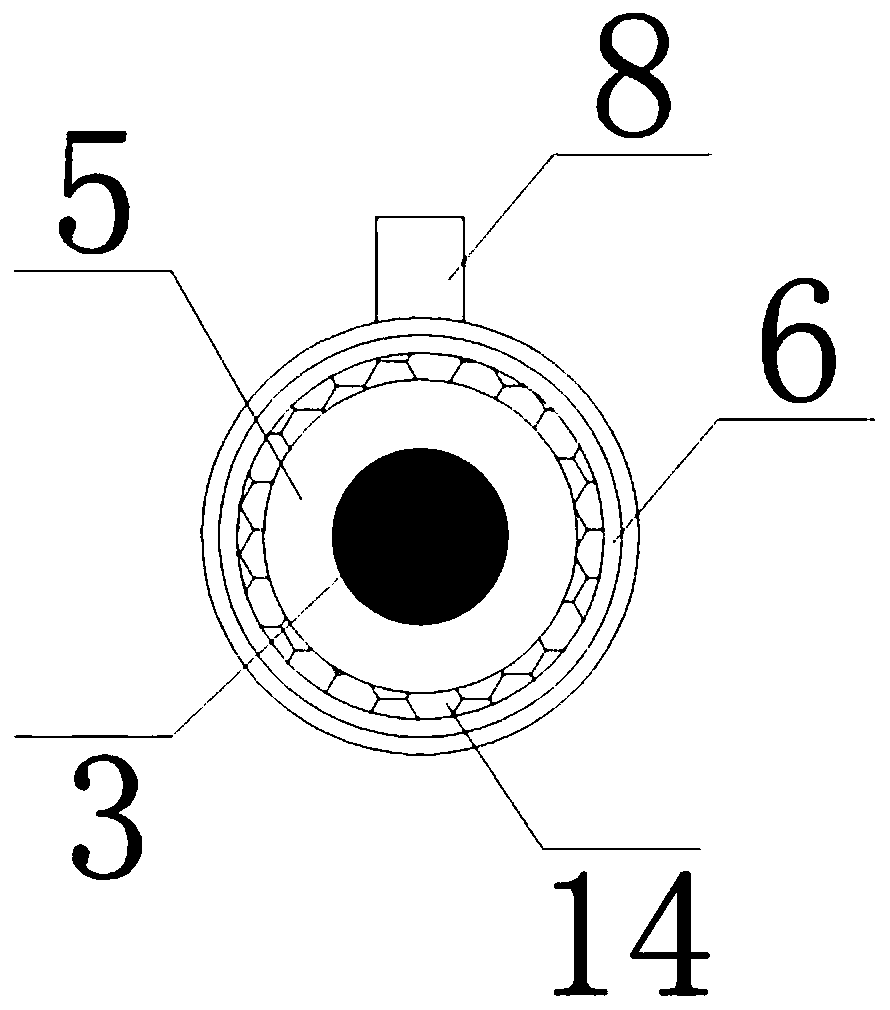

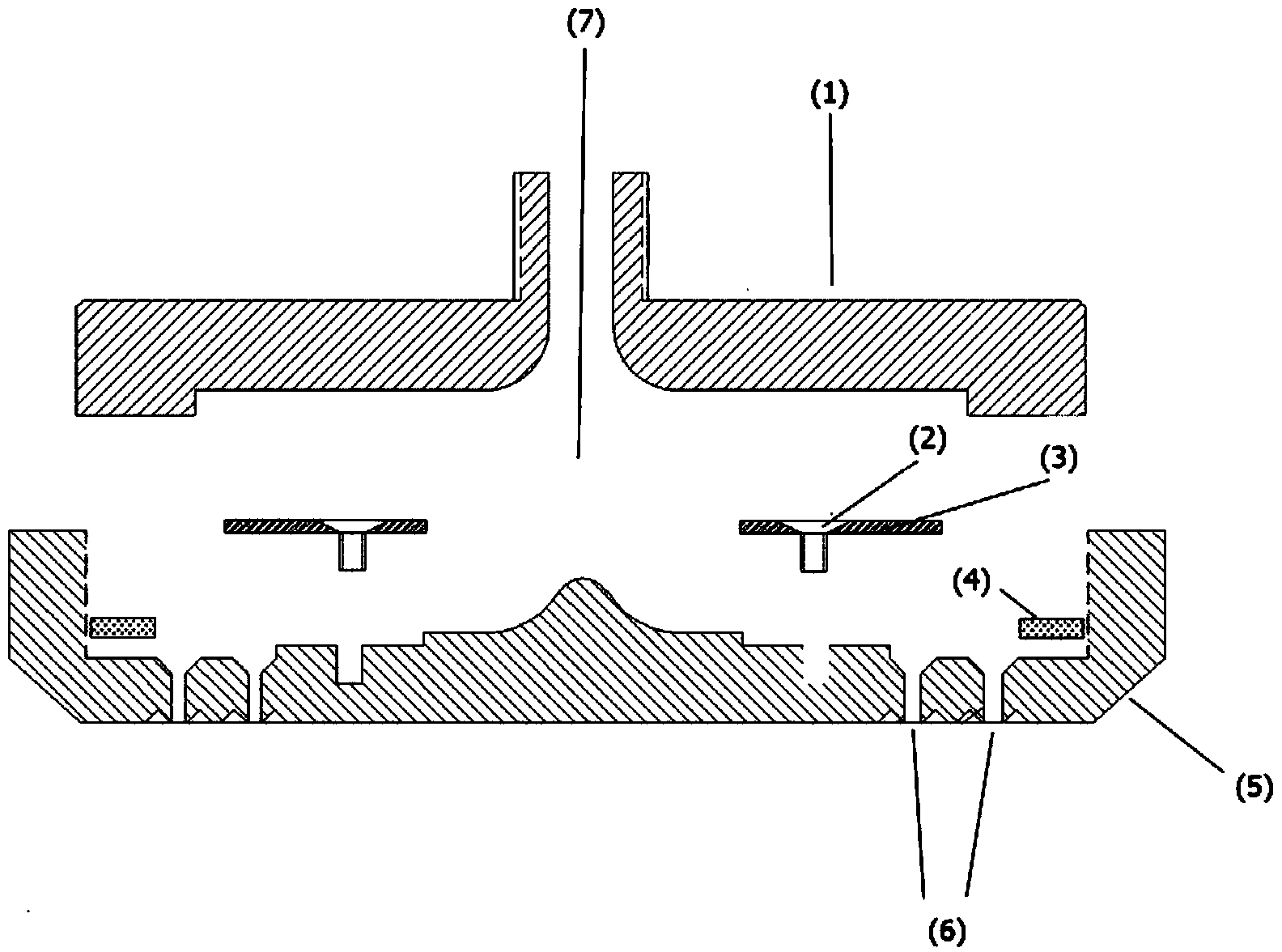

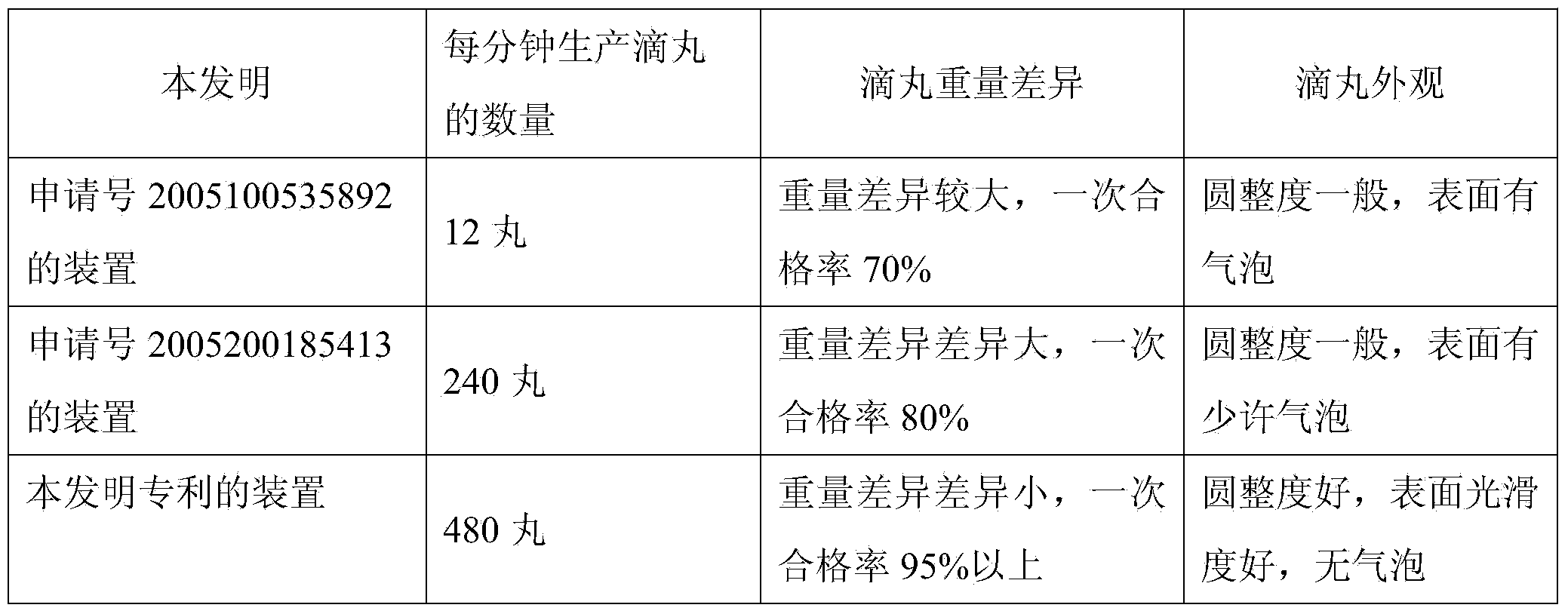

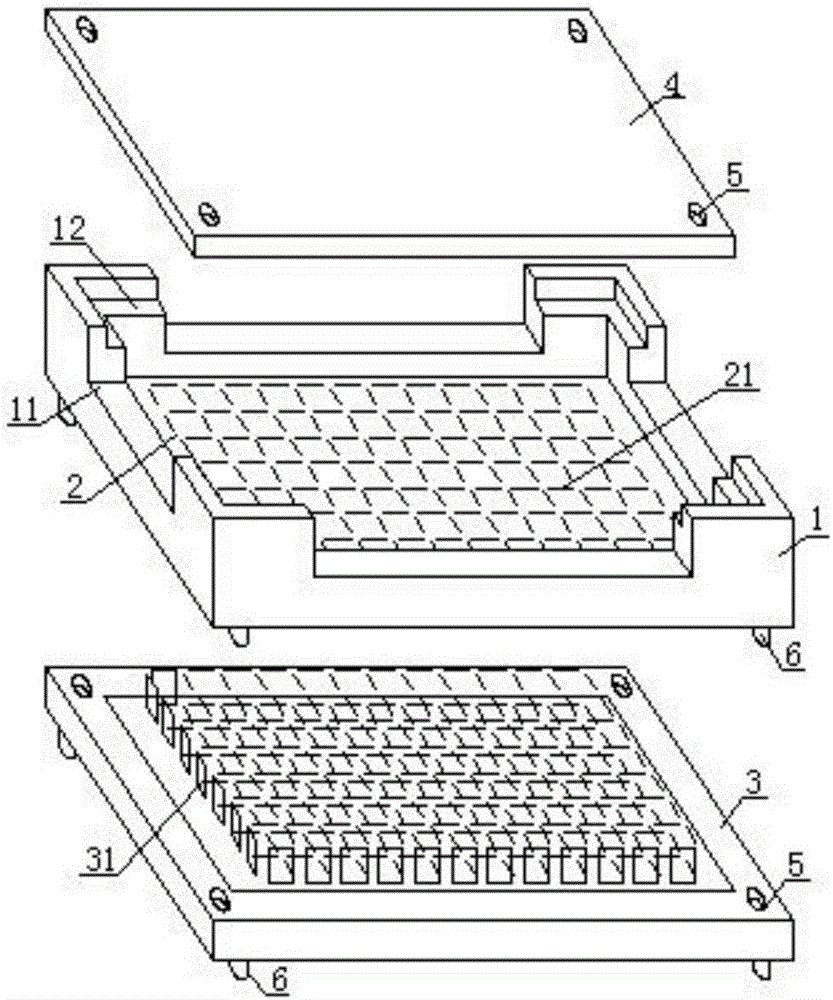

Multi-row dropping head device with pressure-dividing disc special for preparing big dropping pill of over 100mg

ActiveCN104042445AAvoid Collision DeformationReduce resistancePharmaceutical product form changeBiomedical engineeringDropped head

The invention belongs to the field of medicine manufacturing machine equipment and particularly relates to a multi-row dropping head device with a pressure-dividing disc special for preparing a big dropping pill of over 100mg. The dropping head device comprises the following parts: a dropping head device upper cover (1), a fixing bolt (2), a liquid medicine pressure-dividing disc (3), a rubber cushion (4), a dropping head device lower cover (5), an inner circle of dropping nozzle, an outer circle of dropping nozzle (6) and a liquid medicine flowing area (7).

Owner:JIANGXI JIMINKEXIN PHARMA

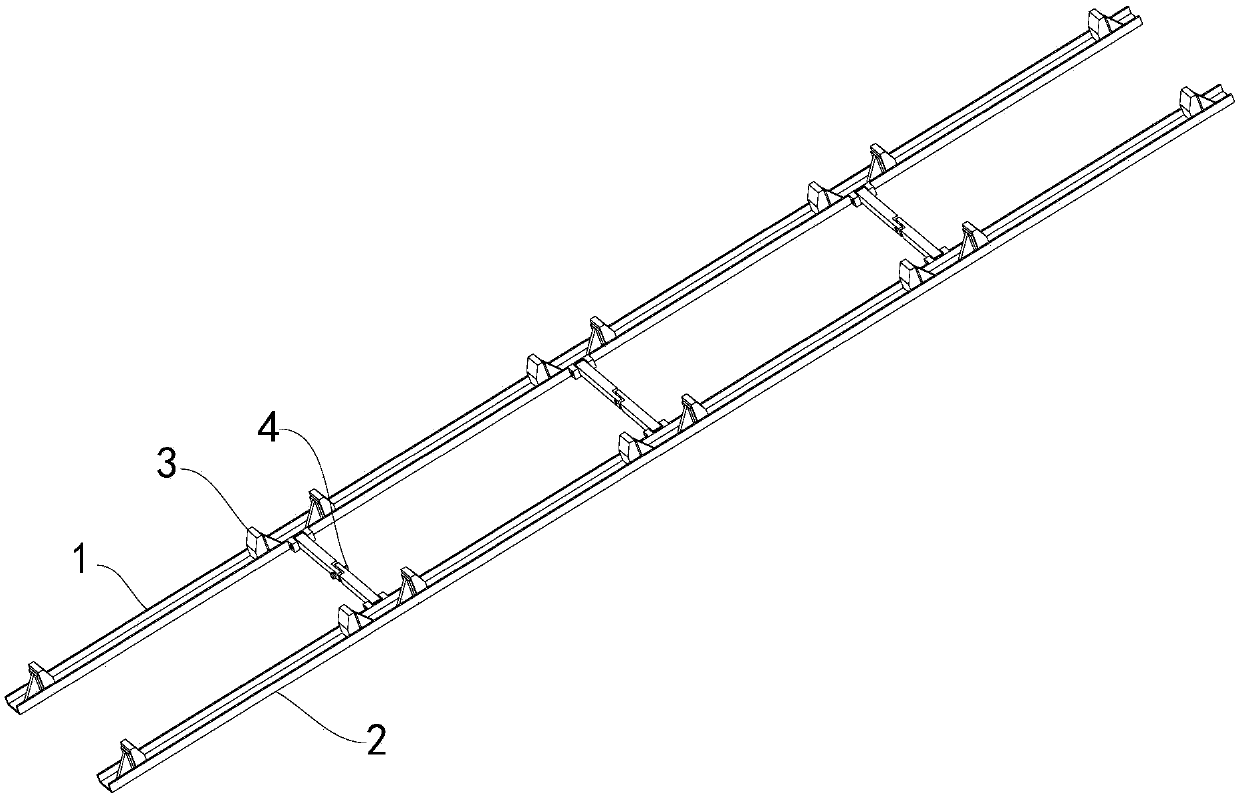

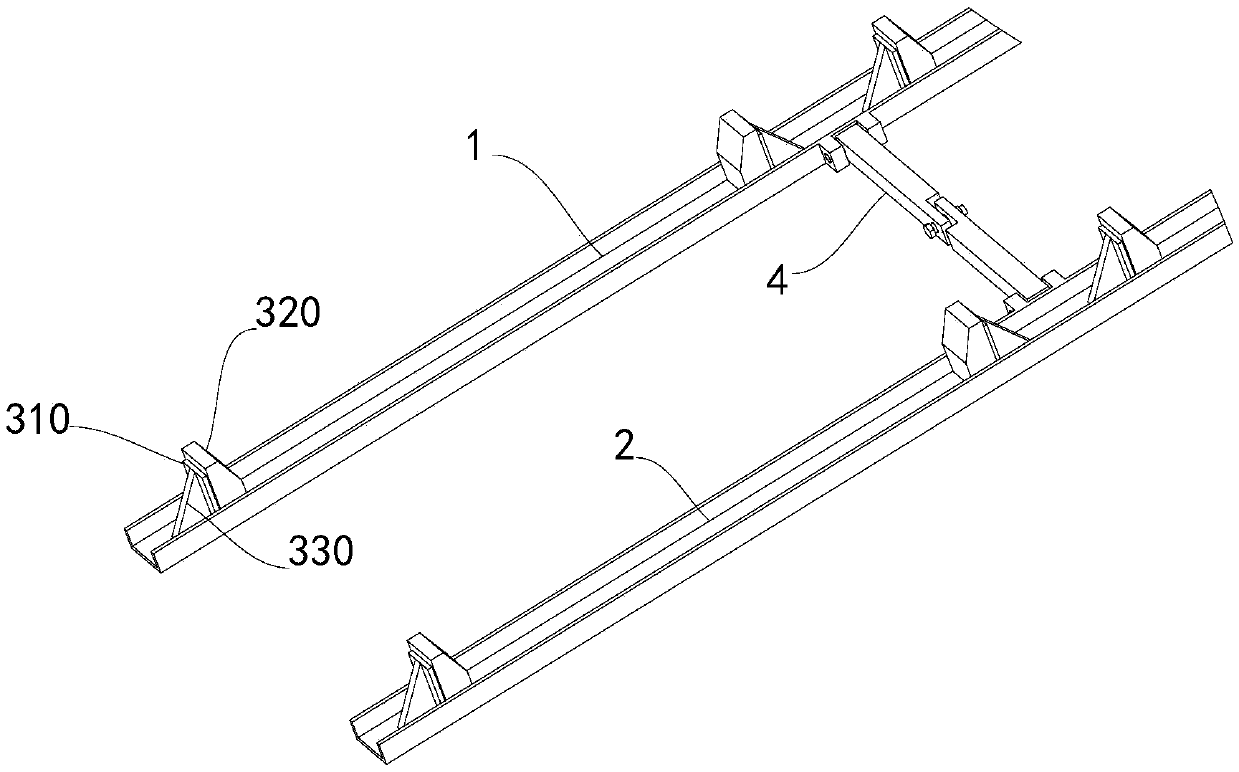

Steel coil storage frame

PendingCN109533643APrevent crashSimple structureExternal framesArchitectural engineeringRaw material

The invention relates to a steel coil storage frame comprising first channel steel, second channel steel, a limiting mechanism and a connection assembly. The first channel steel and the second channelsteel are arranged side by side. A groove in the first channel steel and a groove in the second channel steel are both upward. The first channel steel and the second channel steel are connected through a connecting assembly and are provided with limiting mechanisms oppositely. The limiting mechanisms comprise two baffles and two wedge blocks. The two baffles are arranged in the groove of the first channel steel or in the groove of the second channel steel oppositely fixedly at a preset distance, and the opposite sides of the two baffles are each movably provided with one wedge block. The steel coil storage frame has the beneficial effects that steel coils from steelworks to a warehouse are stored on a special storage frame and do not make contact with the ground directly, meanwhile the wedge blocks are attached for supporting, the steel coils are prevented from rolling and cracking up surrounding facilities, the problem of rusting caused by raw material storage exceeding the time limit is prevented effectively, and the storage frame is simple in structure, low in manufacture cost and good in protection effect.

Owner:湖北大帆金属制品有限公司

Automatic slitting machine for arc-shaped paperboard

ActiveCN110497456AAvoid Collision DeformationAvoid pollutionMetal working apparatusCardboardPulp and paper industry

The invention provides an automatic slitting machine for an arc-shaped paperboard. The automatic slitting machine comprises a slitting mechanism, a material bearing mechanism sleeved with a paper tube, a lifting mechanism for lifting the paper tube, and a buffering and dust collecting mechanism for performing dust collection treatment on paper scraps generated in the paper tube cutting process andbuffering the arc-shaped paperboard obtained after cutting. The slitting mechanism is used for slitting the paper tube, the arc-shaped paperboard formed after slitting is inserted into a circular buffer groove formed through expansion of a vacuum bag along a guide channel. The arc-shaped paperboard is protected through buffering formed by the expansion of the vacuum bag. In the vacuum bag contraction process, the arc-shaped paperboard is slowly turned over to a receiving plate for placement, and the technical problem of collision deformation of the arc-shaped paperboard after cutting is solved.

Owner:阜阳市鑫格特机电设备有限公司

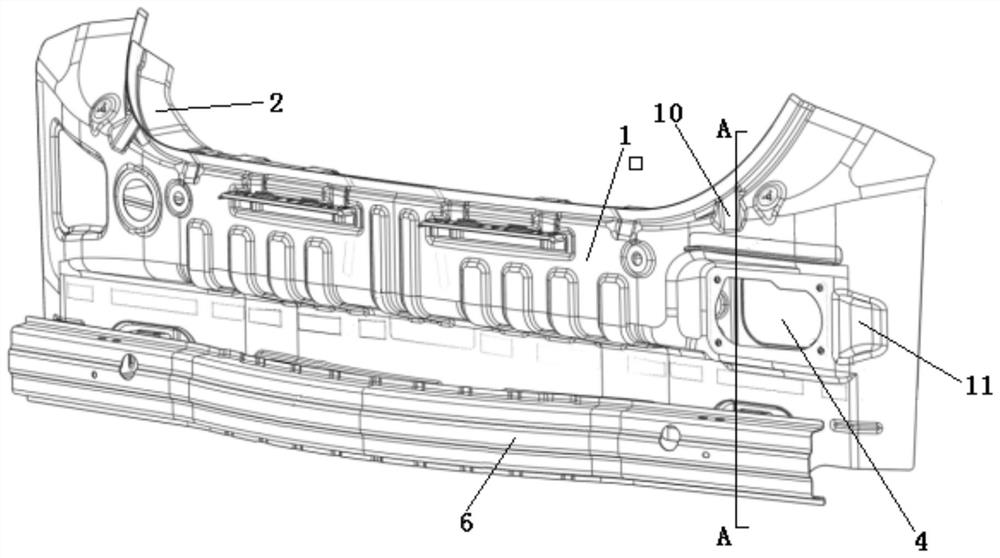

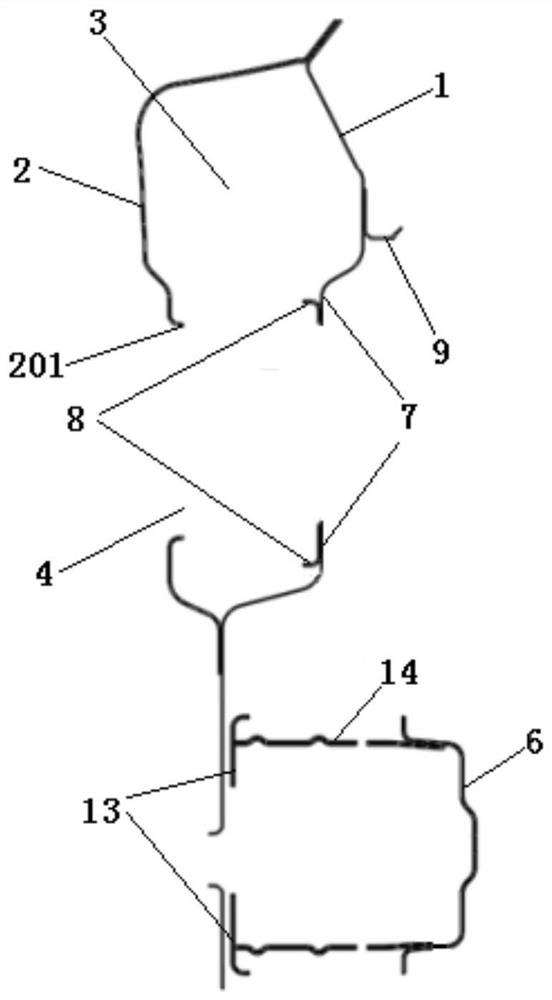

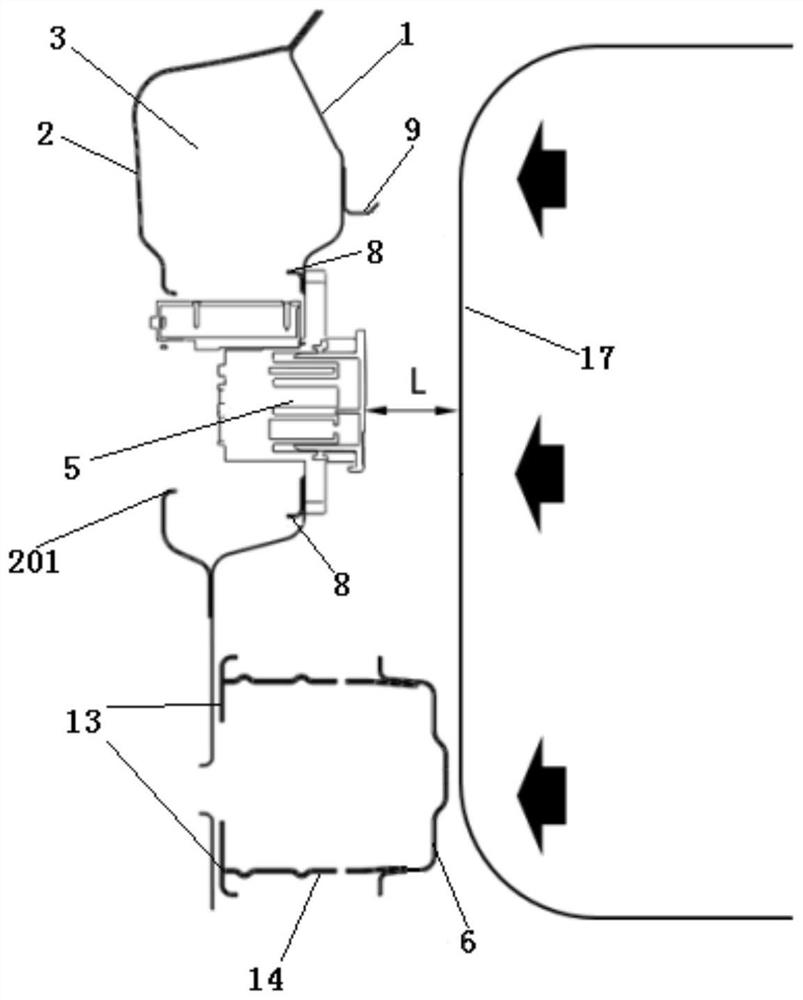

Rear apron board assembly and vehicle

PendingCN113734293AAvoid Collision DeformationAvoid damageSuperstructure subunitsElectric carsElectric vehicle

The invention relates to a rear apron board assembly and a vehicle. The rear apron board assembly comprises a rear apron board outer board and a rear apron board inner board, the rear apron board outer board is connected with the rear apron board inner board, a cavity is formed between the rear apron board outer board and the rear apron board inner board, and a charging port is formed in the rear apron board outer board and the rear apron board inner board in an inside-outside penetrating mode and used for installing a charging base so that the charging base can be contained in the cavity. A rear anti-collision cross beam is installed on the lower portion of the rear apron board outer plate. The invention provides a vehicle. The vehicle includes a rear apron assembly. The problems that an existing electric vehicle charging port base structure is prone to deformation or damage when a vehicle is slightly collided, and charging and normal use cannot be achieved are solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

High-temperature resistant turns bowl

ActiveCN106601465AEven heat dissipationAvoid deformationMagnetic core manufactureEngineeringRejection rate

The invention relates to the field of production of a turns bowl, in particular to a high-temperature resistant turns bowl. The invention aims to provide the high-temperature resistant turns bowl which can be used for preventing from generating a concave-convex point or being deformed during the sintering process of a magnetic core. In the technical scheme, the high-temperature resistant turns bowl comprises a turns bowl main body, wherein a load bearing plate is arranged on the turns bowl main body, a surface of the load bearing plate is coated with zirconium oxide, the thickness of the zirconium oxide is 0.05-1 millimeter, a plurality of limitation grooves are formed in the load bearing plate, a limitation plate is arranged under the turns bowl main body, a plurality of limitation pieces are arranged on the limitation plate and are used for limiting the magnetic core to move or deform during the sintering process, and the limitation pieces penetrate through the limitation grooves and extend out of an upper surface of the load bearing plate. By the high-temperature resistant turns bowl, the concave-convex point, deformation or damage can be prevented from being generated during the sintering process of the magnetic core, and the rejection rate of the magnetic core is reduced.

Owner:宿州市徽腾知识产权咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com