Automatic slitting machine for arc-shaped paperboard

A technology of arc and cardboard, which is applied in the field of automatic cutting machine for arc cardboard, can solve problems such as collision and deformation of arc cardboard, and achieve the effect of tight connection of actions and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

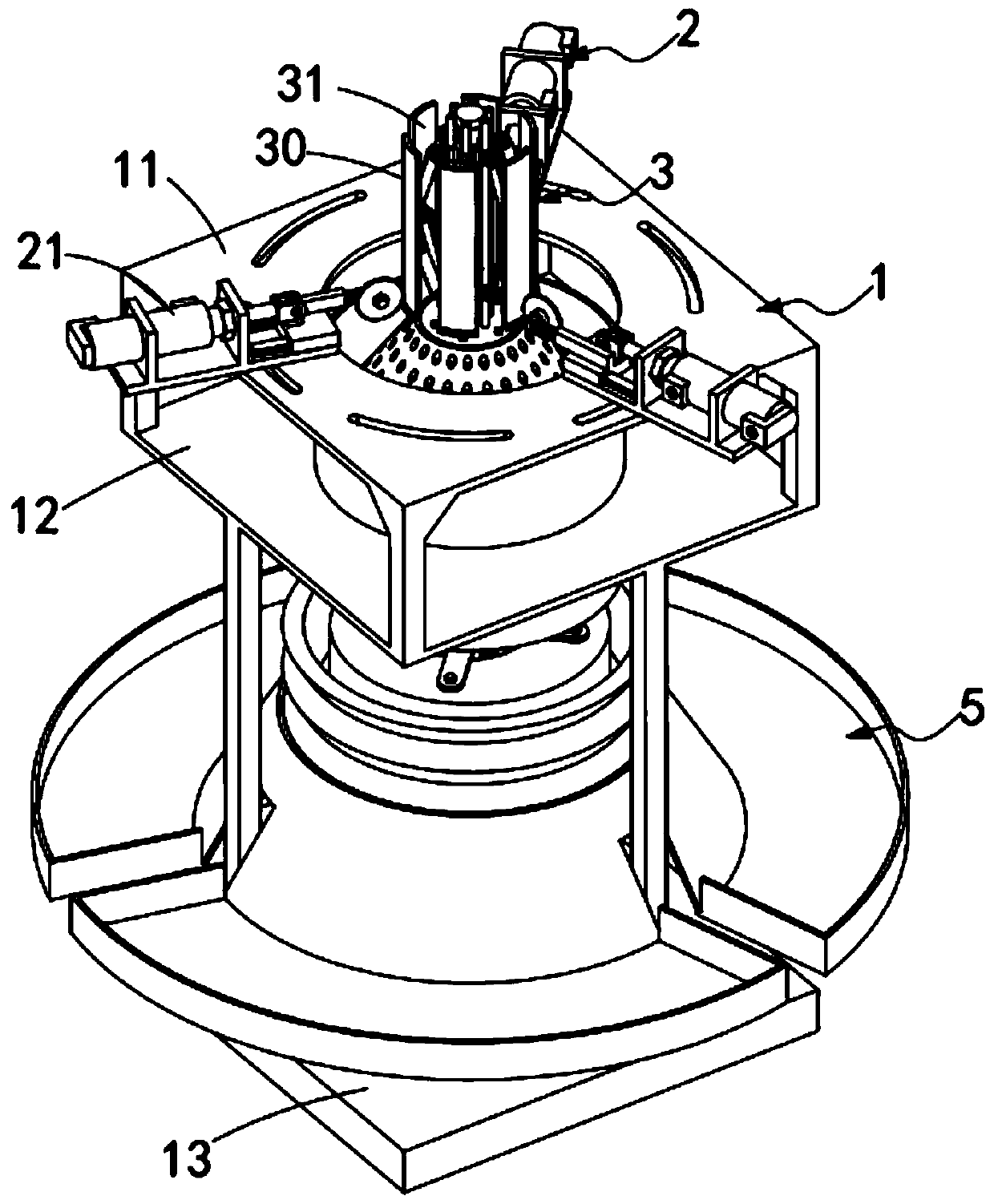

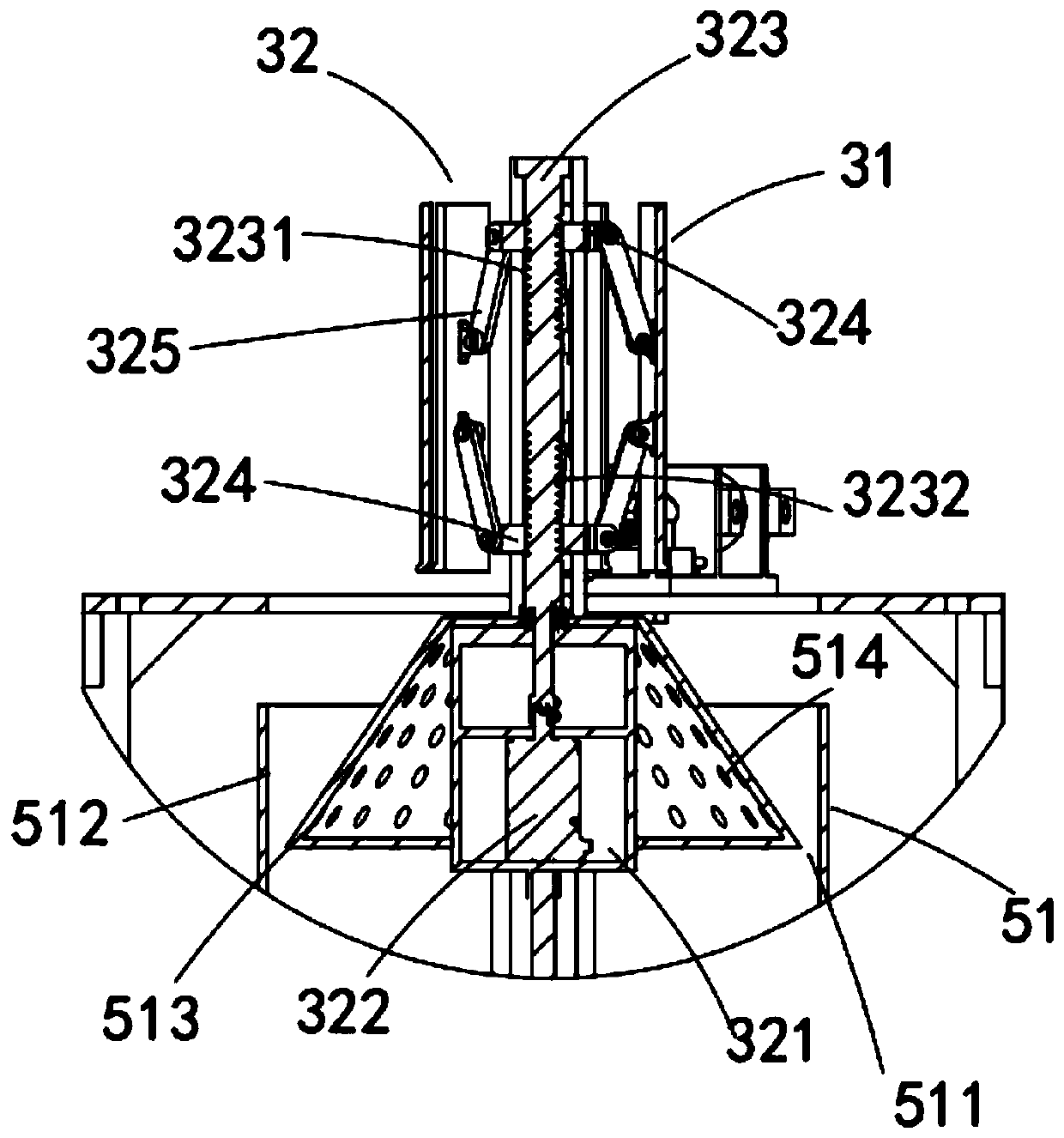

[0069] Such as Figure 1 to Figure 3 As shown, a high-quality curved cardboard automatic slitting machine, including:

[0070] Frame 1, the frame 1 is a frame-shaped setting, which includes a first mounting plate 11 at the top, a second mounting plate 12 at the middle and a third mounting plate 13 at the bottom;

[0071] Cutting mechanism 2, described cutting mechanism 2 is installed on the described first mounting plate 11, and it comprises several cutting assemblies 21 that are equidistantly arranged along the axis circle of described first mounting plate 11, and this cutting assembly 21 All point to the center of the first mounting plate 11;

[0072] The material receiving mechanism 3, the material receiving mechanism 3 is installed on the axis of the frame 1, it rises and falls along the axis of the frame 1 and penetrates the first mounting plate 11 and the second mounting plate 12 to set , and the material receiving mechanism 3 includes a number of material receiving pl...

Embodiment approach

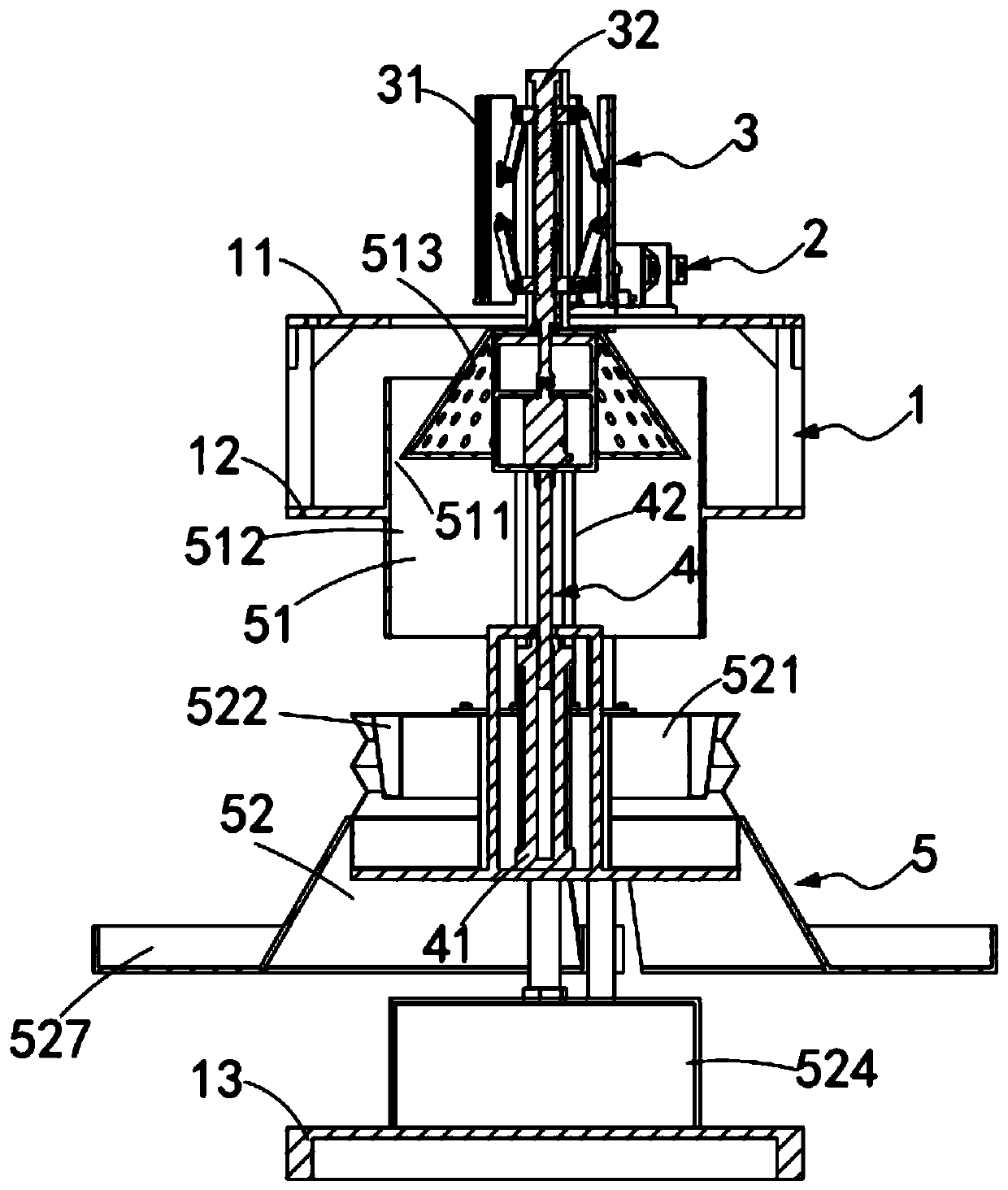

[0101] Such as figure 2 and Figure 10 As shown, as a preferred embodiment, the lifting mechanism 4 includes:

[0102] Lifting the cylinder 41, the lifting cylinder 41 is vertically arranged between the second mounting plate 12 and the third mounting plate 13, and its cylinder shaft 411 pushes the material receiving mechanism 3 vertically upward; and

[0103] The guide rod 42 is equidistantly arranged around the axis of the lifting cylinder 41 , its upper end is fixedly connected with the material receiving mechanism 3 , and its lower end slides through the frame 1 .

[0104] Further, the guide assembly 51 includes:

[0105] A guide tube 512, the guide tube 512 is vertically installed at the center of the second mounting plate 12, and the material receiving mechanism 3 is arranged up and down in the inner circumferential side wall of the guide tube 512; and

[0106] The guide platform 513, the guide platform 513 is fixedly connected with the material receiving mechanism 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com