Multi-row dropping head device with pressure-dividing disc special for preparing big dropping pill of over 100mg

A pressure divider and dripper technology, which is applied in the direction of making medicines into special physical or taking forms, can solve the problems of easy collision and deformation, increase the resistance of liquid medicine, and reduce production efficiency, so as to prevent collision deformation , Reduce processing difficulty, reduce the effect of liquid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, dripper device

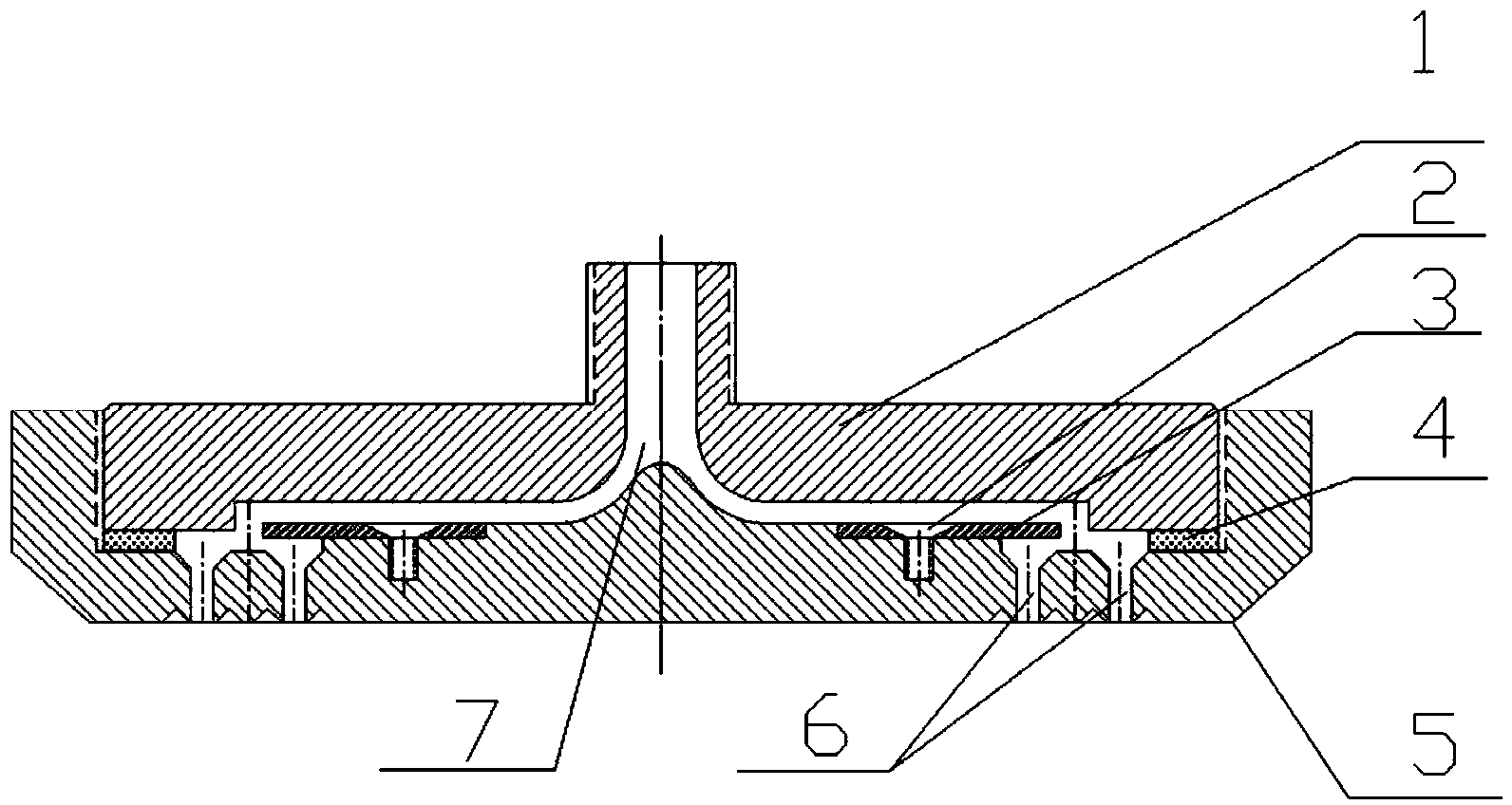

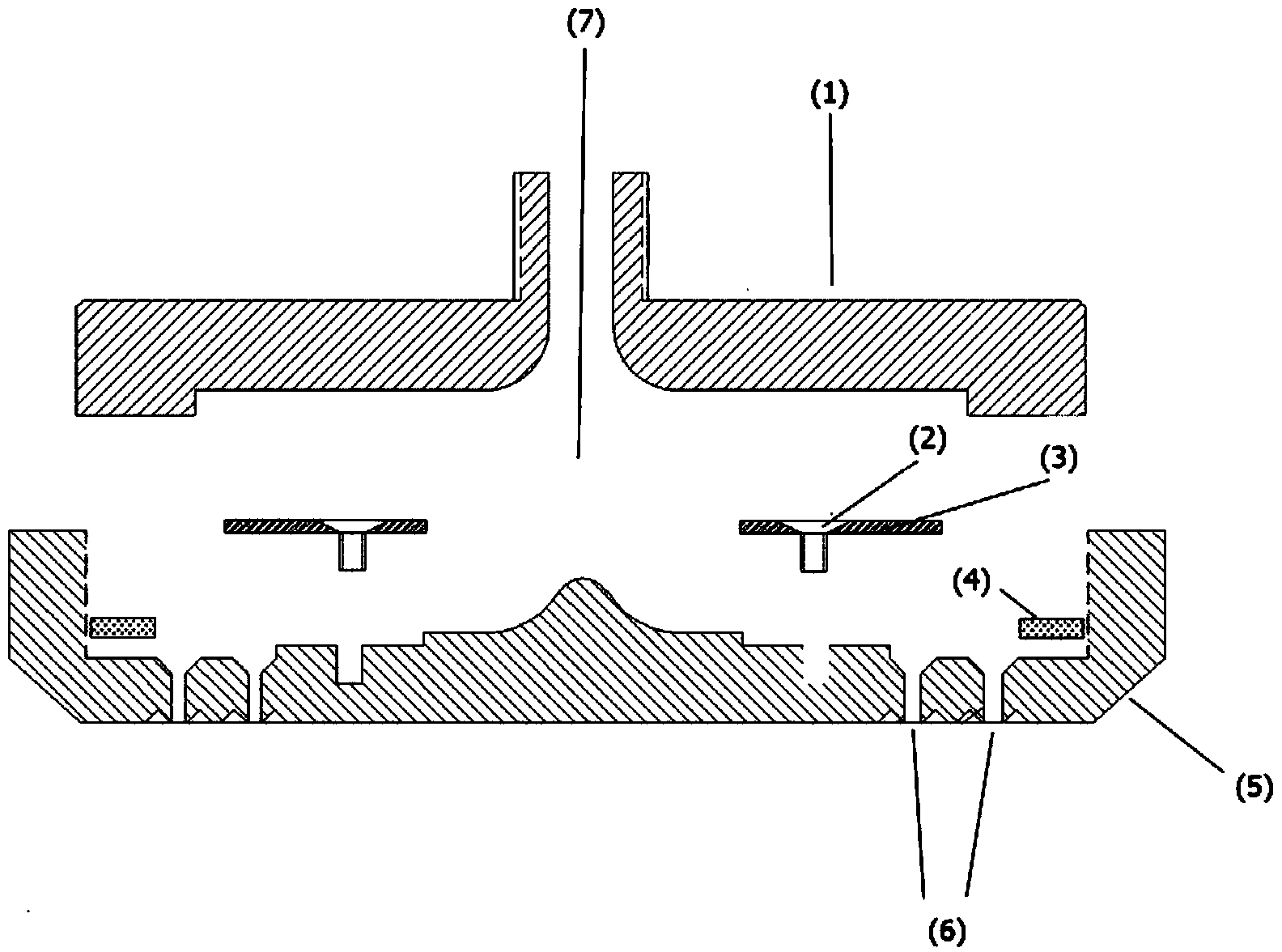

[0034] The dripper device involved in the present invention mainly consists of an upper cover (1) of the dripper device, a fixed plug (2), a medicinal liquid pressure plate (3), a rubber pad (4), a lower cover of the dripper device (5), The drip nozzle of the inner ring, the drip nozzle of the outer ring (6), and the liquid medicine flow area (7) are composed.

[0035] The connection relationship of its various components is as follows: between the dripper device upper cover (1) and the dripper device lower cover (5) is the liquid medicine flow area (7), and the liquid medicine pressure plate (3) passes through the fixing bolt (2) Installed on the lower cover (5) of the dripper device, rubber pads (4) are installed on both sides of the lower cover (5) of the dripper device, and the lower cover (5) of the dripper device is provided with an inner ring drip nozzle and Outer ring drip-tip (6).

[0036] Wherein, the drip nozzles of the inner ...

Embodiment 2

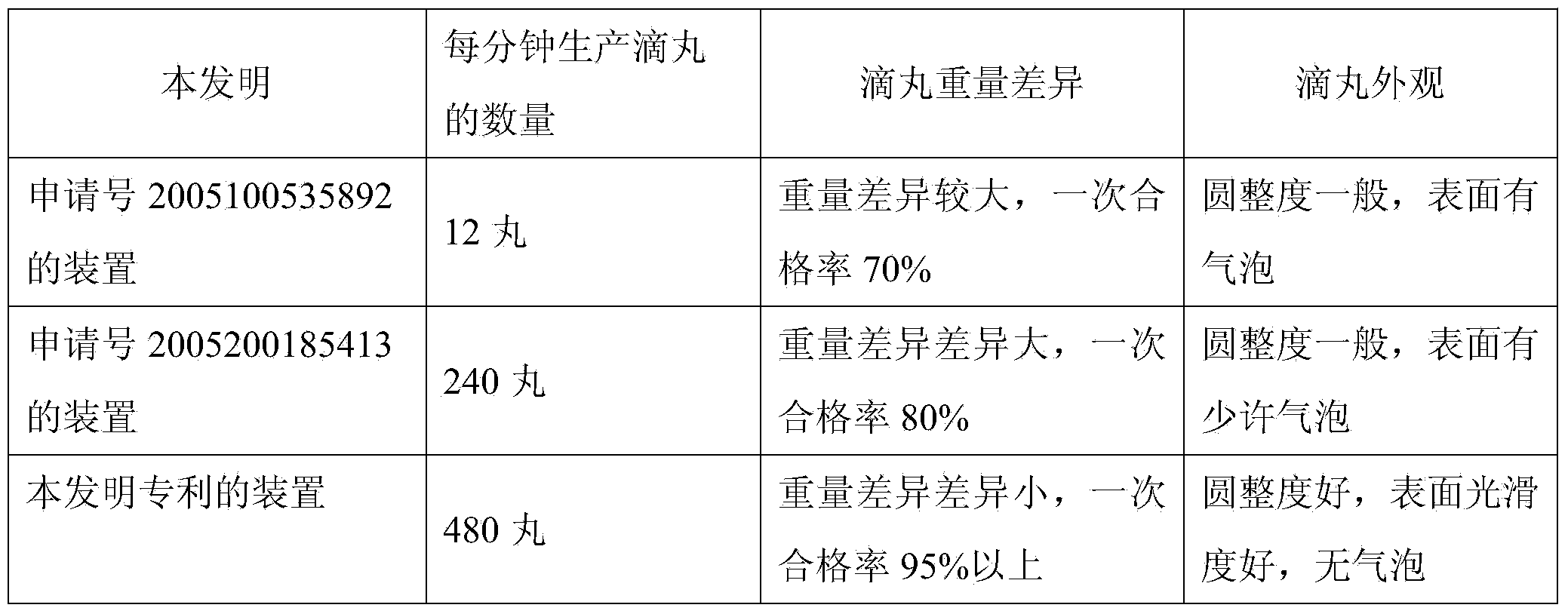

[0038] Embodiment 2, performance comparison of different dripper devices

[0039] The dripper device of the present invention is compared with existing devices, and its performance is investigated.

[0040] experimental method:

[0041]On the same dripping pill machine, use the drip tray of application number 2005100535892, the drip tray of application number 2005200185413 and the drip tray of the patent of the present invention to drip the same medicinal liquid respectively, and the results are as follows:

[0042] Test Results:

[0043]

[0044] Experimental result shows: the quantity that the present invention produces drop pill per minute is obviously more than existing device, and production speed is fast, and cost is low; Small difference in pellet weight, complete appearance, moderate viscosity and so on.

Embodiment 3

[0045] The preparation process of embodiment 3, dropping pills

[0046] Adopt the currently commercially available dripping pill machine, and its dripper device adopts the double-row dripper device with liquid medicine dividing plate of the present invention to produce Liuwei Dihuang dripping pills, the specification is 300mg)

[0047] Take the prepared liquid of Liuwei Dihuang dripping pills, put them in the drip irrigation of the dripping pill machine, and seal the drip irrigation. The dripper device of the present invention (the installation method of the dripper device: first fix the medicinal liquid pressure plate on the lower cover of the dripper, place a silicone sealing ring on the lower cover of the dripper, install the dripper on the lower cover of the dripper, Connect the upper cover of the dripper and the lower cover of the dripper to make it sealed, that is) connected to the drip irrigation, open the stirring paddle in the drip irrigation, so that the liquid medic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com