Equipment for enabling copper pipe to pass through fin of condenser

A condenser and copper tube technology, which is applied in the field of air-conditioning condenser processing equipment, can solve problems such as low production efficiency and safety, inability to realize mass production, and difficulty in passing copper tubes in sequence, so as to reduce labor costs and equipment loss, overcome cumbersome and unsafe factors, and improve the effect of equipment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

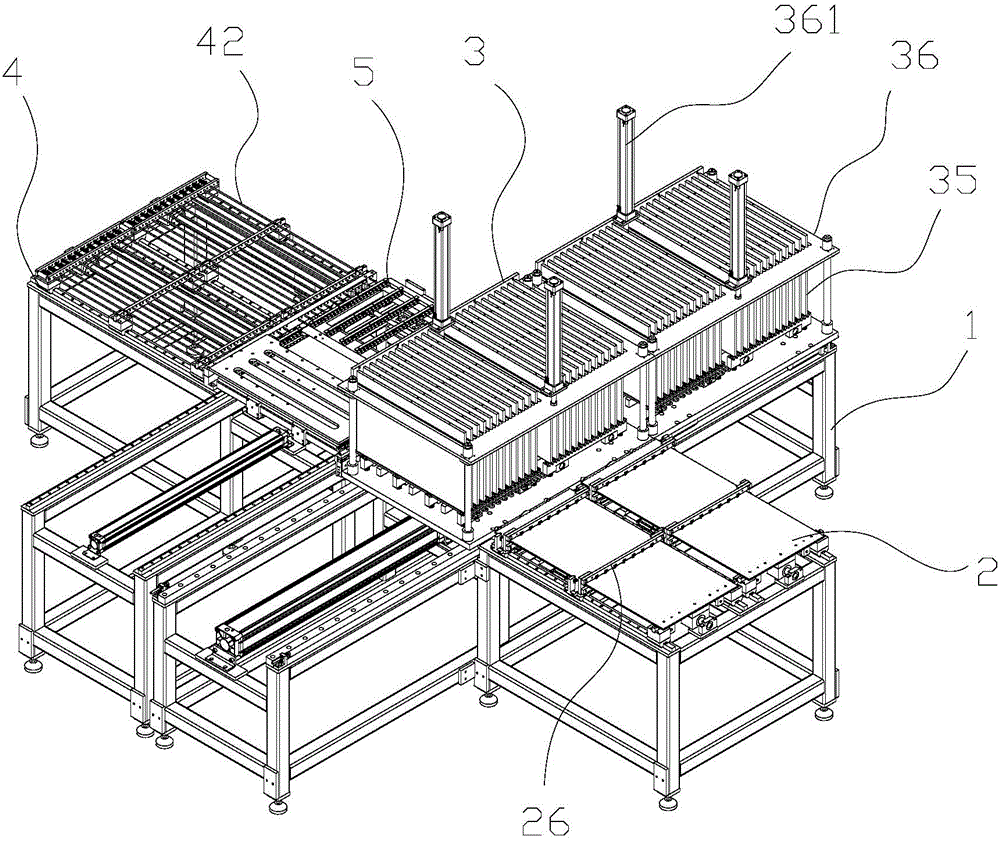

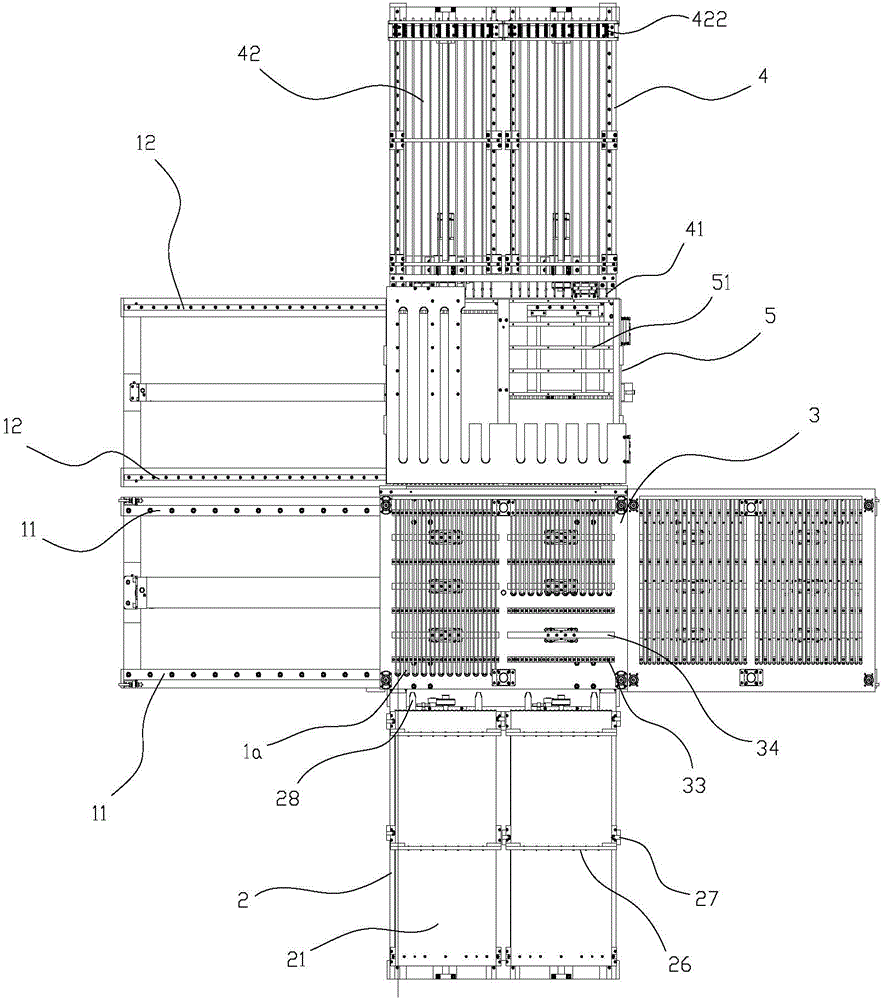

[0054] Refer to attached figure 1 to attach figure 2 As shown, a device for condenser fins to pass through copper tubes, including a bracket 1 and a push plate drive system 2 located on the bracket 1, a copper tube collector 3, a fin collector pan 5 and a traction device 4 .

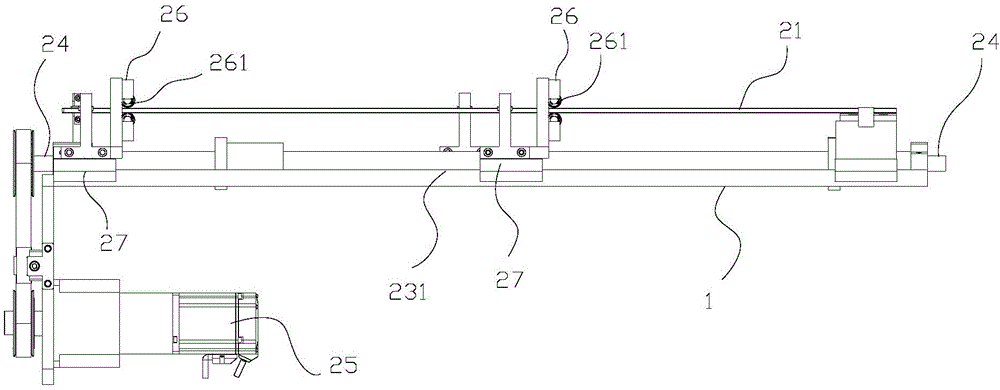

[0055] Refer to attached image 3 to attach Figure 8 As shown, the push pedal drive system 2 includes a push pedal 21 , a push pedal guide mechanism, a screw rod 24 and a motor 25 . The length c of the push plate 21 is greater than the length d of the copper pipe 1a it pushes, and the front end of the push plate 21 has a corrugated structure. The wave structure is formed by connecting the first arc segment 211 and the second arc segment 212 at intervals in sequence, the transition between the first arc segment 211 and the second arc segment 212 is smooth, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com