Large-scale motor assembling and carrying device and assembling and carrying method

A technology of large-scale motors and handling devices, applied in hoisting devices, conveyors, mechanical conveyors, etc., can solve the problems of destroying the quality of the galvanized layer on the surface of the parts, affecting the overall appearance of the product, and bumping and deforming the parts, so as to ensure the quality and surface The effect of flatness, saving manpower and time resources, and avoiding collision and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

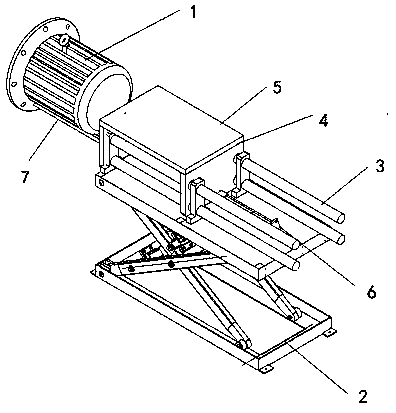

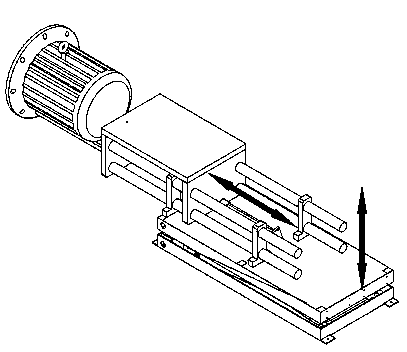

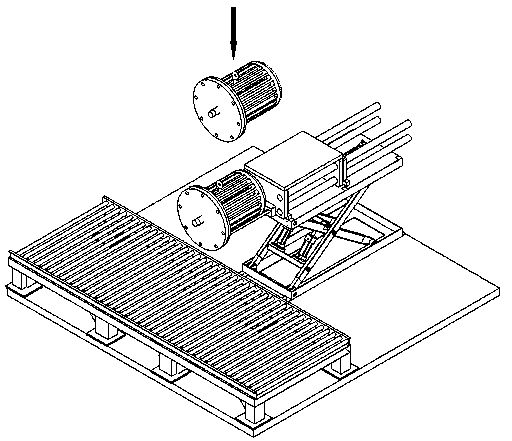

[0032] The present invention discloses a large-scale motor assembly and transportation device and a corresponding assembly and transportation method suitable for use in the assembly process of a flange-type B5 structure motor, specifically as follows.

[0033] Such as Figure 1~Figure 2 As shown, a large-scale motor assembly and handling device is set on one side of the conveyor belt.

[0034] The conveyor belt is used for conveying the machined parts of the fan, and the machined parts of the fan include a cylindrical fan casing, and a motor installation area for placing the motor 1 is arranged inside the cylindrical fan casing, and the motor installation area The central axis of is the central axis of the fan machined part.

[0035] A feeding end and a discharging end are arranged on the conveying material belt, and the conveying material belt moves from the feeding end to the discharging end, and at the feeding end and the discharging end of the conveying material belt A m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com