Method for replacing water seal of floating access door

A replacement method and door water seal technology, which are applied in water conservancy projects, ship lifting devices, marine engineering and other directions, can solve the problems of complicated replacement methods, difficult flatness measurement, and difficulty in applying force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

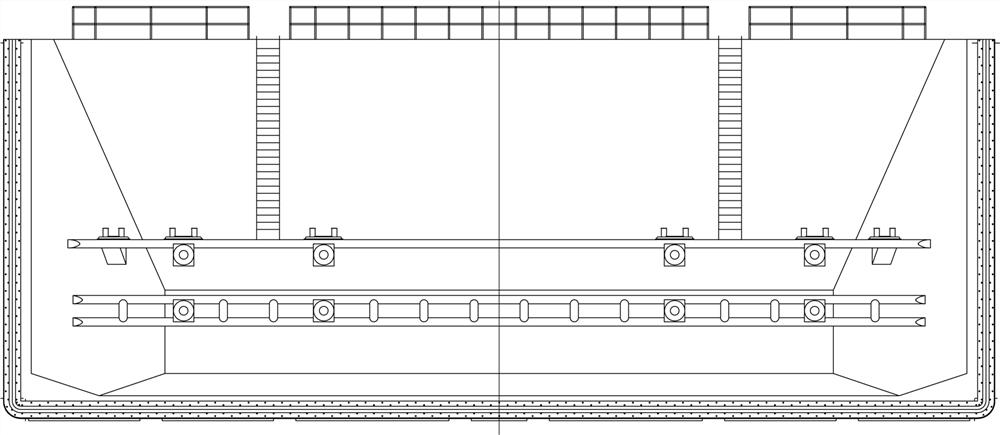

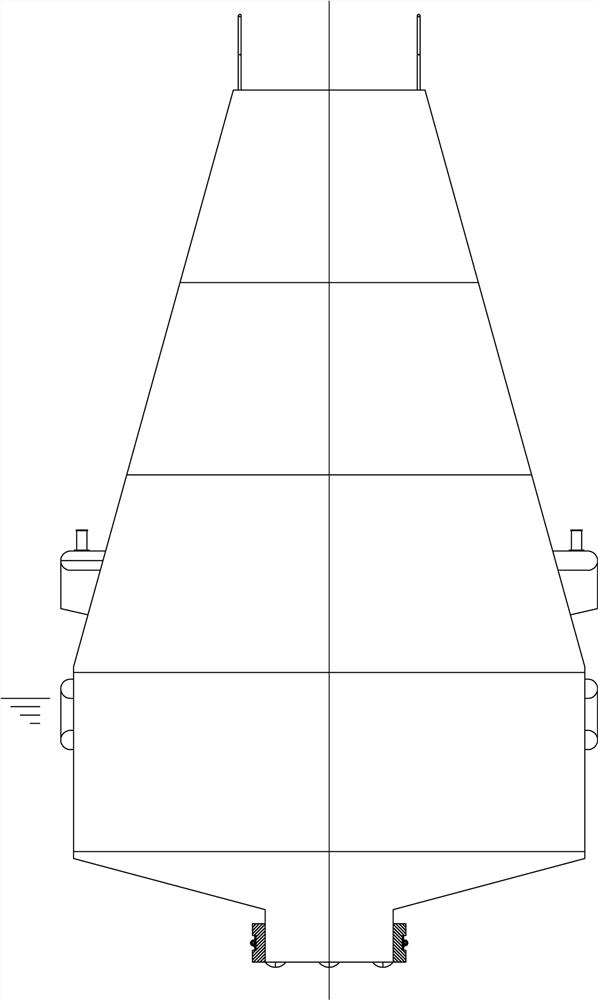

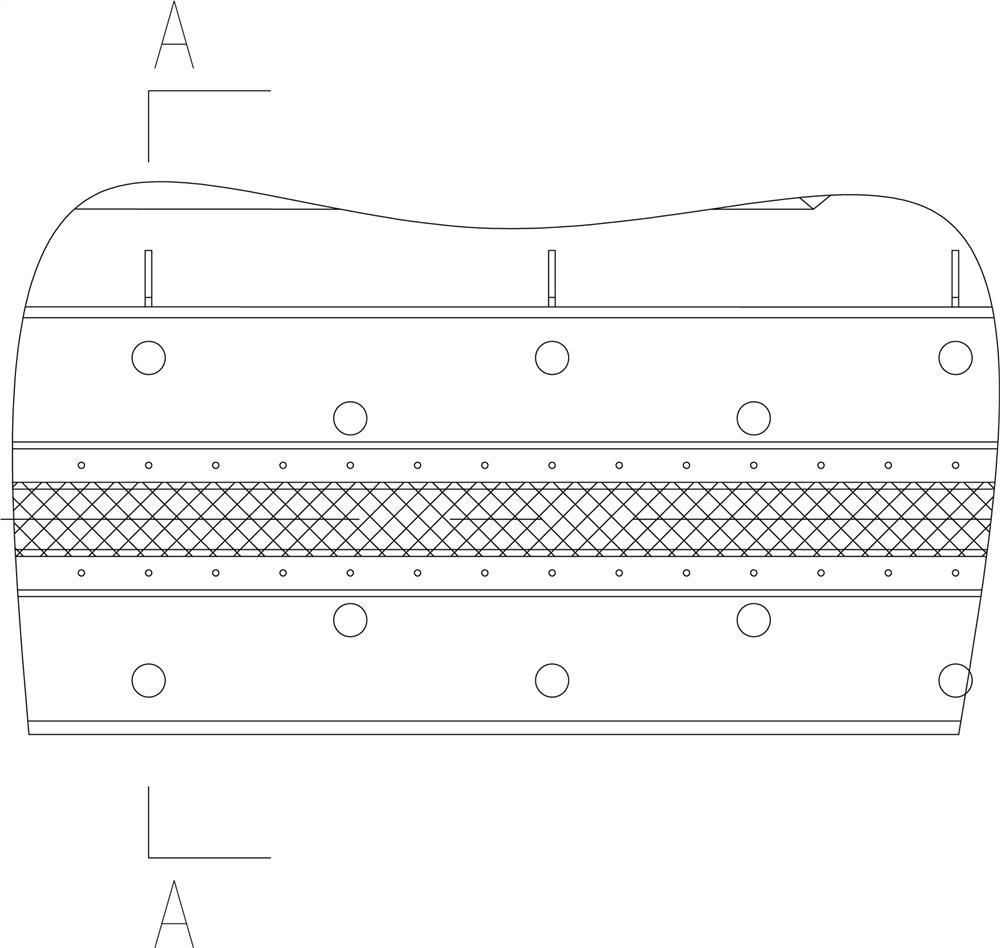

[0042] Such as Figure 1~Figure 12 Among them, a method for replacing a water seal of a floating inspection door includes the following steps:

[0043] S1, remove the wood screw 13 on the surface of the water stop plate 5 in the wood water stop groove, then remove the water stop plate 5 and the rubber water stop 4; remove the wooden plug on the original fastening bolt 1 of the wood 9 7. Then remove the fastening nut 2;

[0044] Further, when disassembling the fastening nuts 2, the disassembly sequence of the multiple fastening nuts 2 is to remove the fastening nuts 2 at the top of the floating door, and remove them one by one in the downward direction;

[0045] S2, remove multiple sections of vertical beams sequentially by prying up, and then remove the horizontal beams with a removal tool;

[0046] S3, after removing all the original beams 9, correct or replace the fastening bolts 1 inside the bearing groove 8, then polish the bearing groove 8 and the fastening bolts 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com