Bearing quenching device with rotating wheel type buffering structure

A technology of buffer structure and quenching device, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of deformation of thin-walled ferrules, affecting product quality, etc., and achieve the effect of weakening impact force and avoiding collision deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

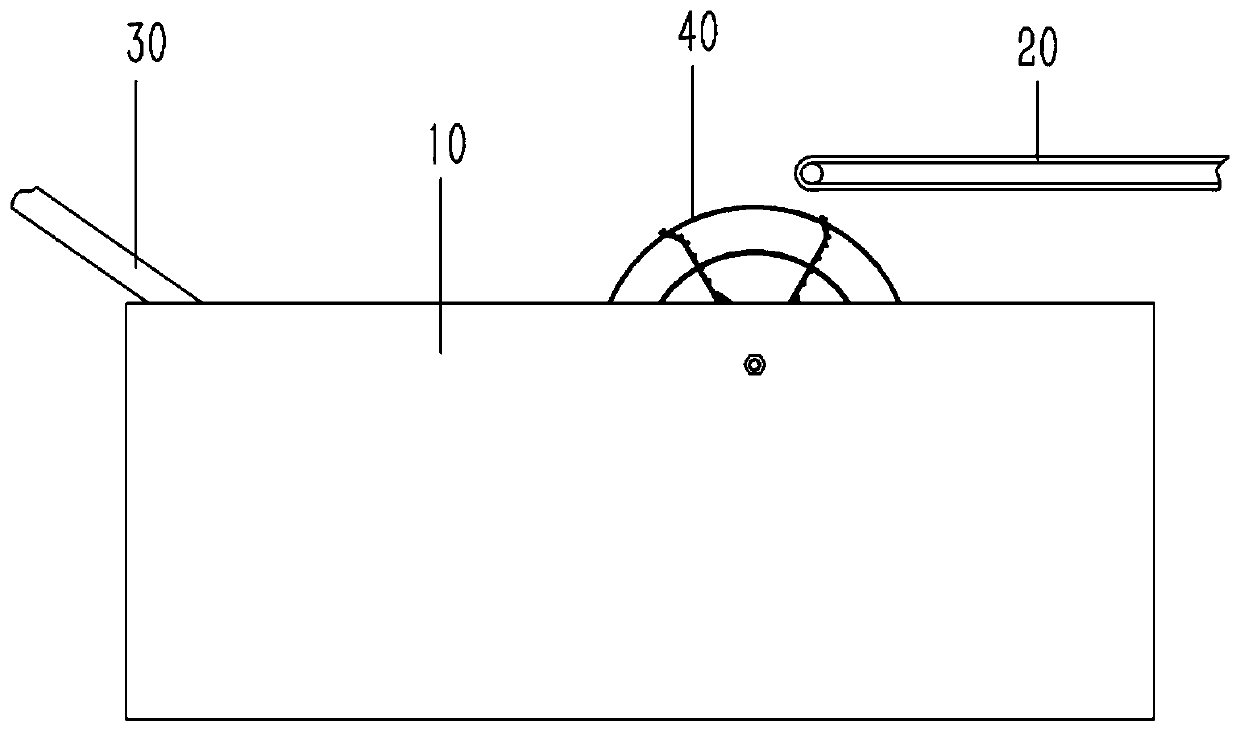

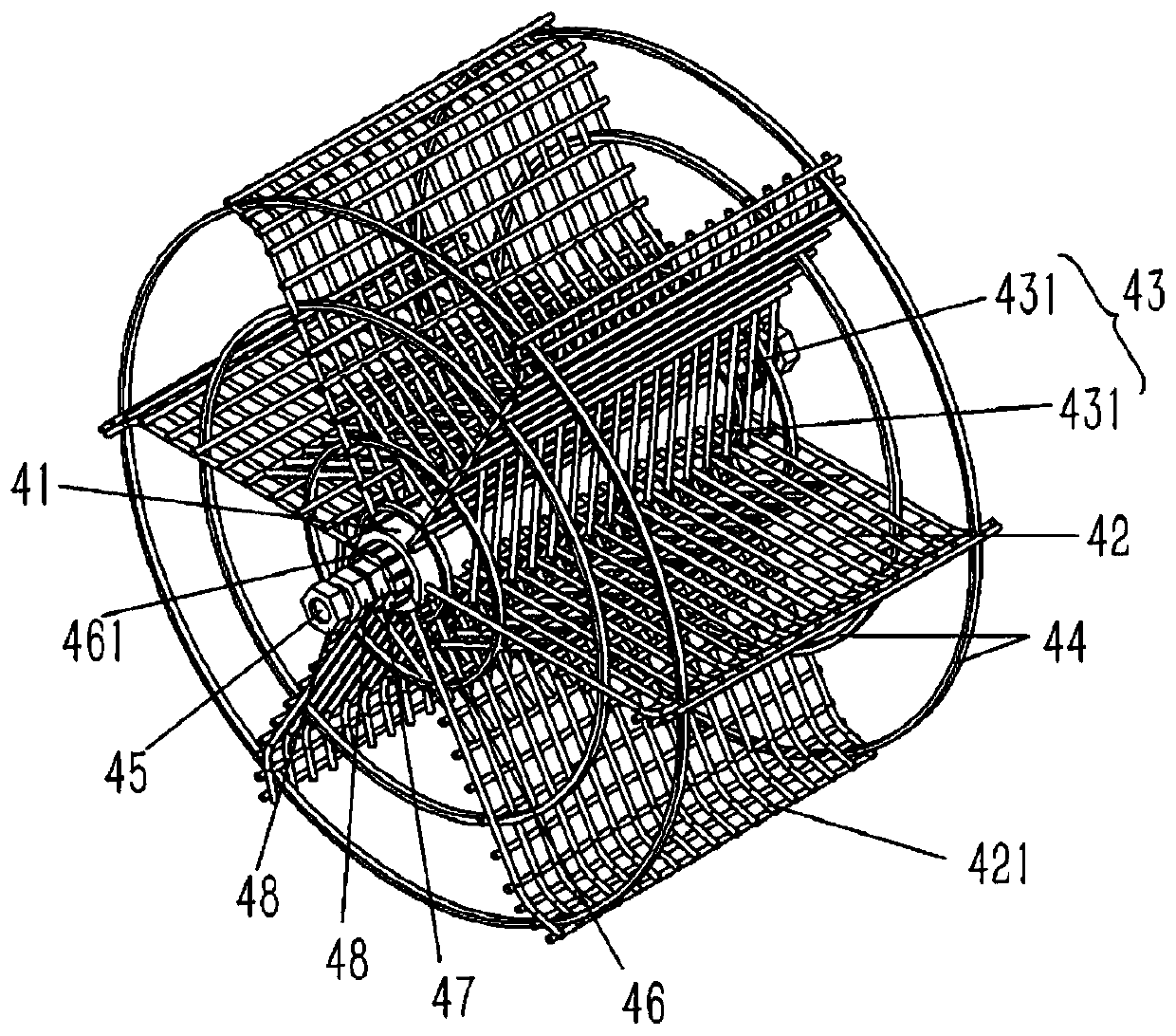

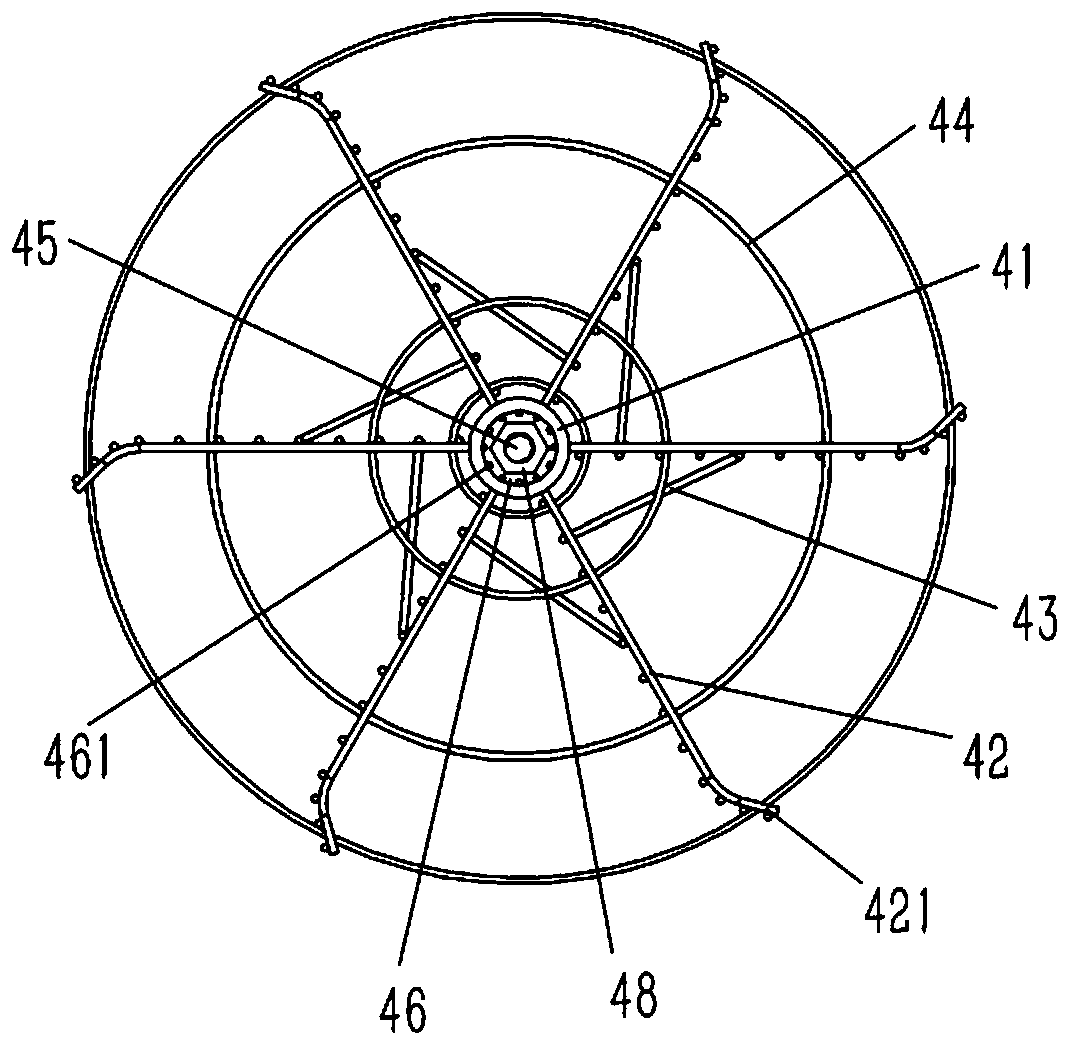

[0019] Example: see Figures 1 to 4 As shown, a bearing quenching device with a wheel-type buffer structure includes a quenching oil tank 10, a horizontal input chain belt 20 is provided above one end of the quenching oil tank 10, and an oblique output chain belt is inserted at the other end of the quenching oil tank 10. 30. A buffer impeller 40 is inserted in the quenching oil tank 10 directly below the output end of the input chain belt 20. The buffer impeller 40 includes a shaft sleeve 41, and a rotating shaft 45 is inserted into the shaft sleeve 41. The two ends of the rotating shaft 45 are plugged and fixed in the quenching oil tank 10. on the side wall; the outer wall of the bushing 41 is fixed with a number of steel mesh buffer blades 42, and the outer side of the buffer blade 42 is bent to form an upwardly inclined deflector 421, and the two buffer blades 42 Several rings of reinforcement rings 44 are fixed on the sides; inclined ribs 43 are fixed between adjacent buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com