Engine oil-valve operation combination

An engine throttle and control combination technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as unfavorable assembly and product quality control, excess throttle control combination function, and many throttle control combined parts and other problems. The effect of reducing the number of parts, reducing costs, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

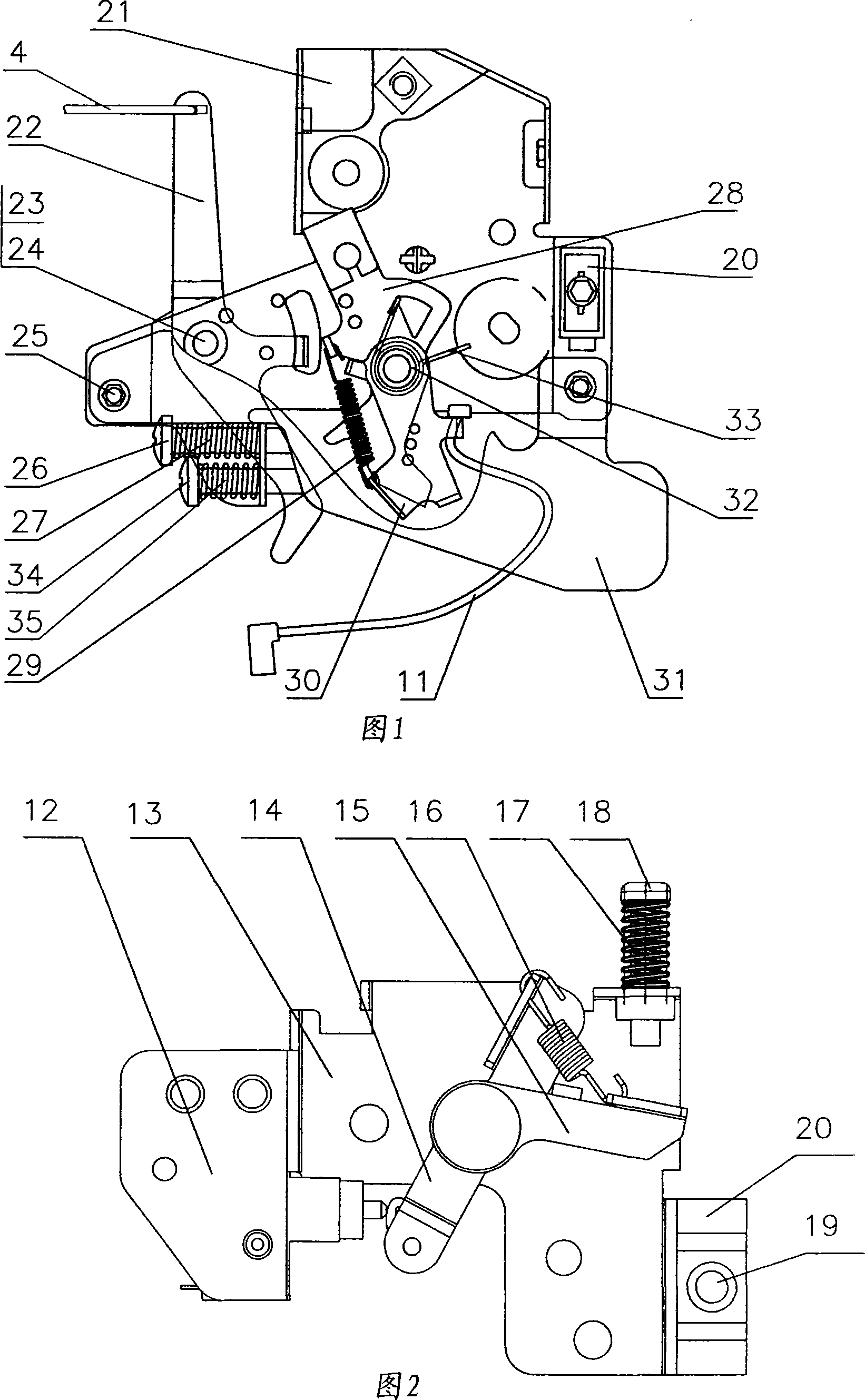

[0021] Referring to Fig. 2, as can be seen from the figure, the present invention comprises a flameout switch 12, an accelerator control combination bracket 13, a joystick 14, a speed regulating spring control handle 15, an adjustment screw 18 and a drag cable pressing plate 20, and the flameout switch 12 is installed in the figure. The left side of the throttle control combination bracket 13 is shown, the adjustment screw 18 is installed on the right side above the throttle control combination bracket 13 shown in the figure through the nut welded on the throttle control combination bracket 13, and a screw is arranged between the adjustment screw 18 and the throttle control combination bracket 13 Back off spring 17. The cable pressing plate 20 is installed on the lower right side of the throttle control combination bracket 13 as shown in the figure through fastening screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com