Elastic sheet assembly and electronic equipment

A technology of shrapnel and components, applied in the direction of circuits, contact parts, electrical components, etc., can solve problems such as poor spring connection accuracy, contact position offset, collision, etc., to achieve enhanced stability and reliability, avoid collision deformation, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment proposes a preferred shrapnel assembly, which can be formed by bending a metal sheet with good electrical conductivity, which can be used to electrically connect the circuit board and the pressing member. The shrapnel assembly of this embodiment includes a shrapnel and a shrapnel bracket, The shrapnel is electrically connected to the circuit board and the pressing member respectively, the shrapnel is fixedly installed on the shrapnel support, and the shrapnel support is detachably connected to the circuit board.

[0032] Since the shrapnel of the shrapnel component is firmly fixed on the shrapnel bracket, when the shrapnel is squeezed, it will not deviate, so that the contact positions of the shrapnel with the pressing member and the circuit board will not shift, which is beneficial to the circuit The connection between the plate and the pressing member enhances the stability and reliability of the connection between the two. In addition, the shrapnel br...

Embodiment 2

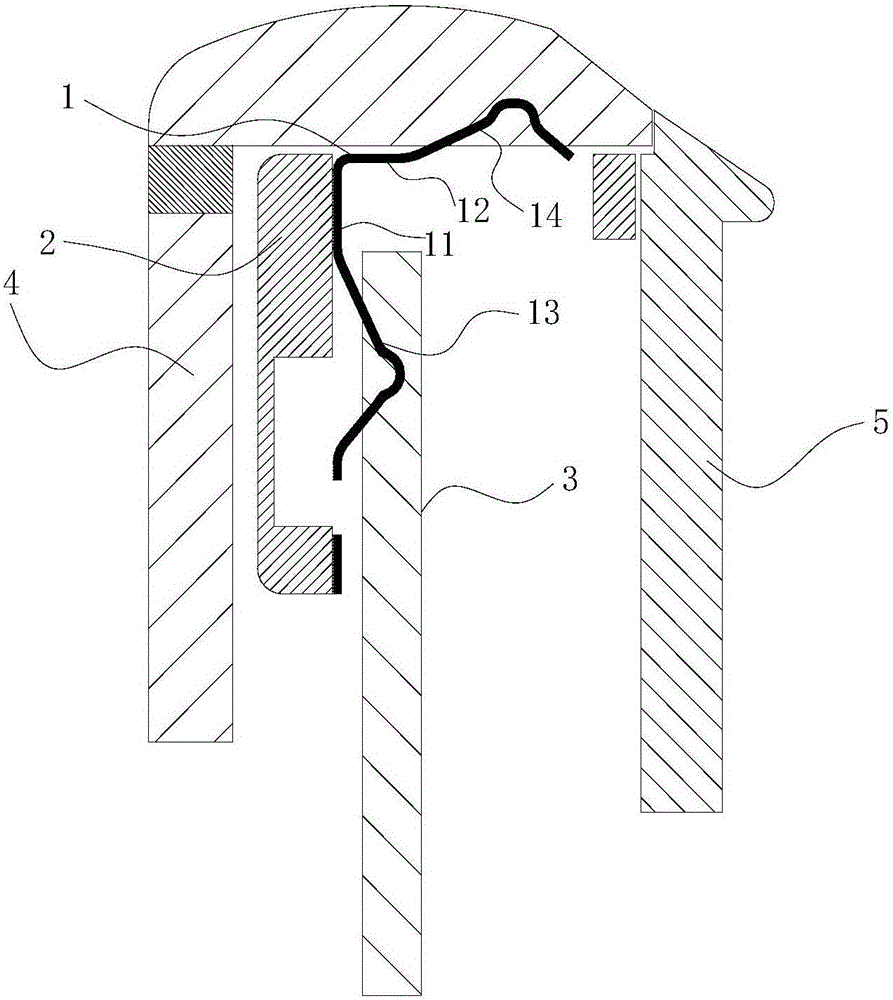

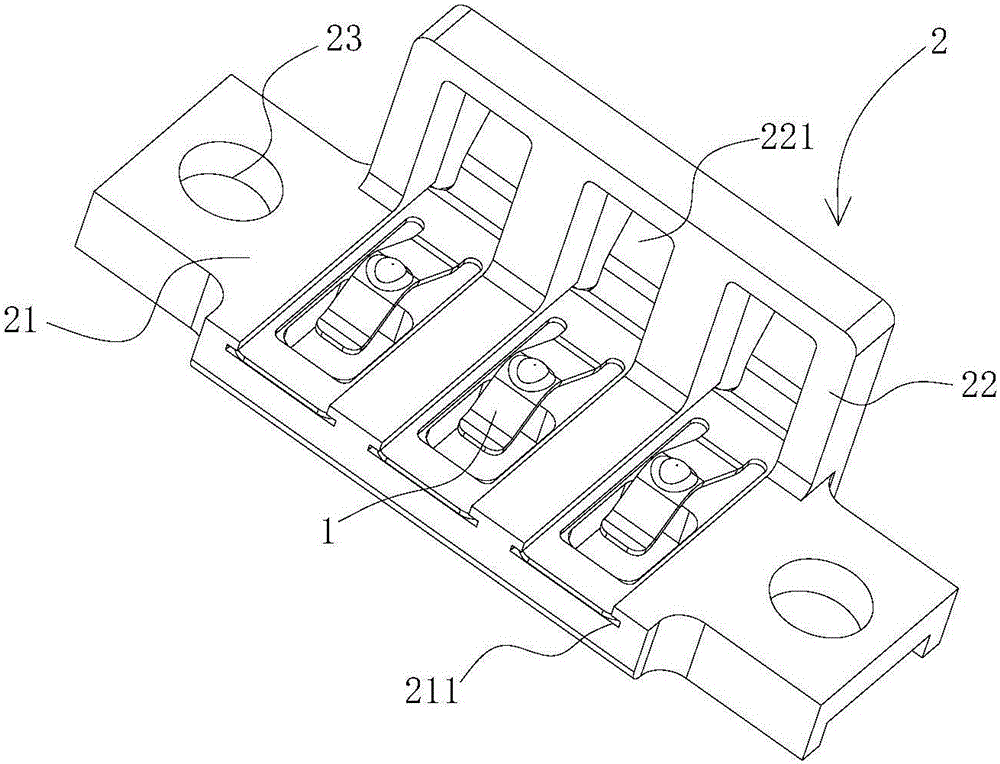

[0034] This embodiment is a further optimization based on the structure of the shrapnel assembly described in Embodiment 1, and proposes another more preferable shrapnel assembly, such as Figure 1 to Figure 3 As shown, the shrapnel assembly includes a shrapnel 1 and a shrapnel bracket 2, the shrapnel 1 is electrically connected to the circuit board 3 and the pressing member 4 respectively, the shrapnel 1 is fixedly installed on the shrapnel bracket 2, and the shrapnel bracket 2 is detachably connected to the circuit board 3 .

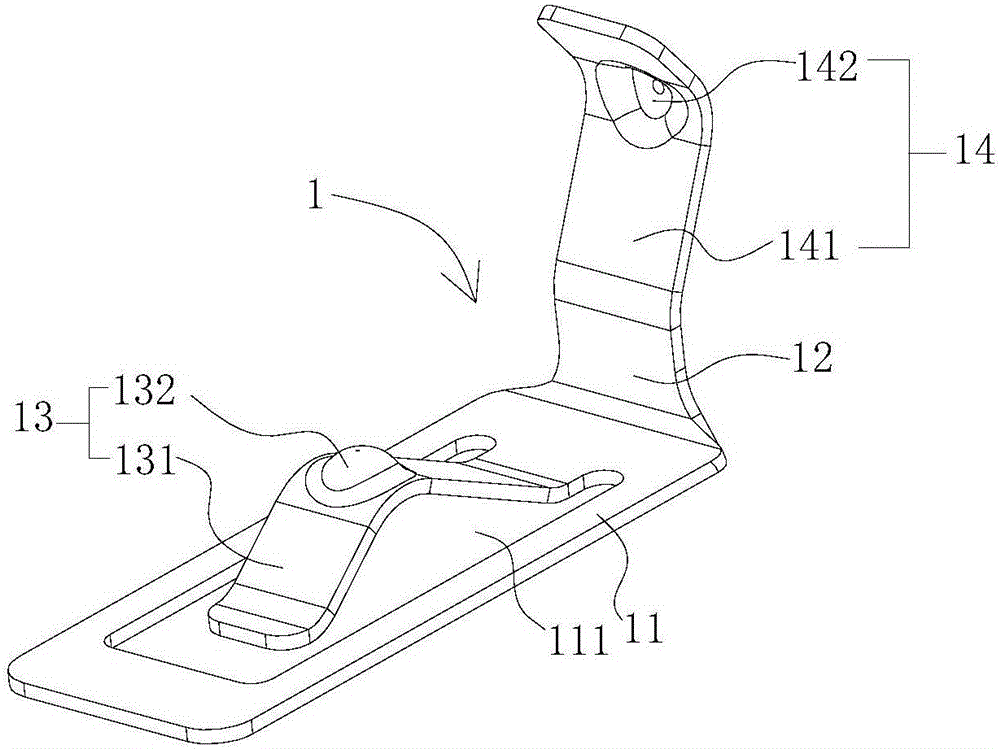

[0035] In this embodiment, specifically, as image 3 As shown, the shrapnel 1 is L-shaped as a whole, and is formed by stamping and bending a metal sheet with good electrical conductivity. The elastic piece 1 includes a fixed portion 11 , a connecting portion 12 that is at an angle to the fixed portion 11 , a first elastic portion 13 and a second elastic portion 14 . Wherein, the fixing portion 11 is in the shape of a rectangular plate, and a first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com