Composite single-surface metal board

A metal plate, single-sided technology, applied in the field of composite boards, can solve the problems of PVC foam boards, such as difficulty, poor heat insulation effect, inconvenient installation, etc., achieve excellent fire prevention and heat insulation effects, prevent the expansion of the fire, and prevent collisions deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

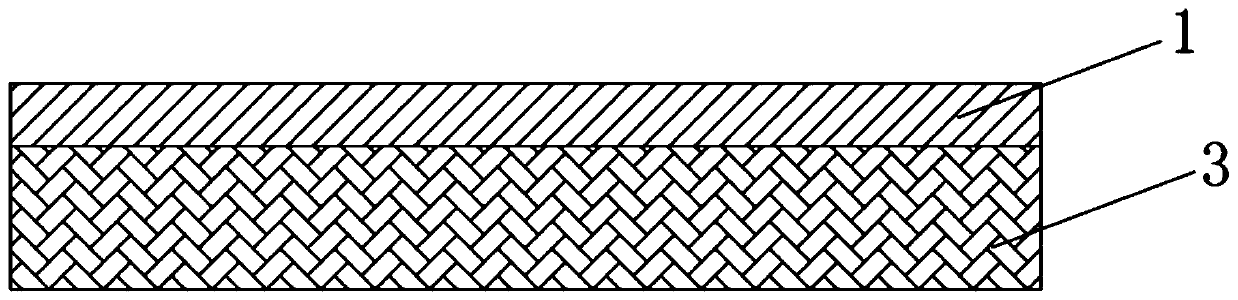

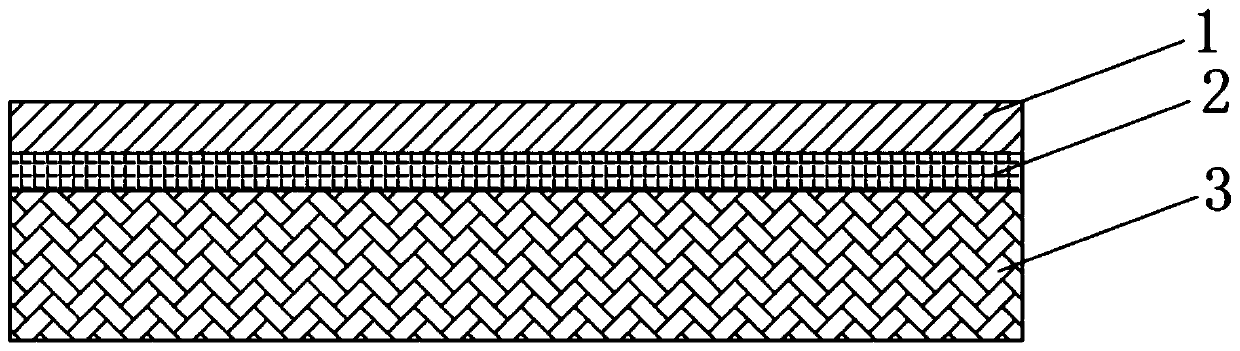

[0024] as attached figure 1 to attach figure 2 As shown, the present invention provides a specific embodiment of a composite single-sided metal plate, including a wooden layer 3, and a metal layer 1 is arranged on the surface of the wooden layer 3; Glue or phenolic glue is glued and connected into one. The present invention also includes a layer of insulation layer 2, the insulation layer 2 is arranged between the metal layer 1 and the wood layer 3, between the metal layer 1 and the insulation layer 2 and between the insulation layer 2 and the wood layer 3 all adopt hot melt Glue or phenolic glue is glued and connected into one.

[0025] Wherein, the thermal insulation layer 2 is made of glass wool, rock wool board, polyurethane material thermal insulation fireproof board or thermal insulation board. The thickness of the metal layer 1 ranges from 0.1 mm to 2 mm. The thickness range of the wood layer 3 is 8mm-60mm. The wooden layer 3 adopts plywood, particle board or lami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com