Composite double-sided metal sheet

A composite double-sided, metal plate technology, applied in the field of composite panels, can solve the problems of poor heat insulation effect, PVC foam board is not easy, inconvenient installation, etc., to prevent the expansion of the fire, excellent fire and heat insulation effect, prevent The effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

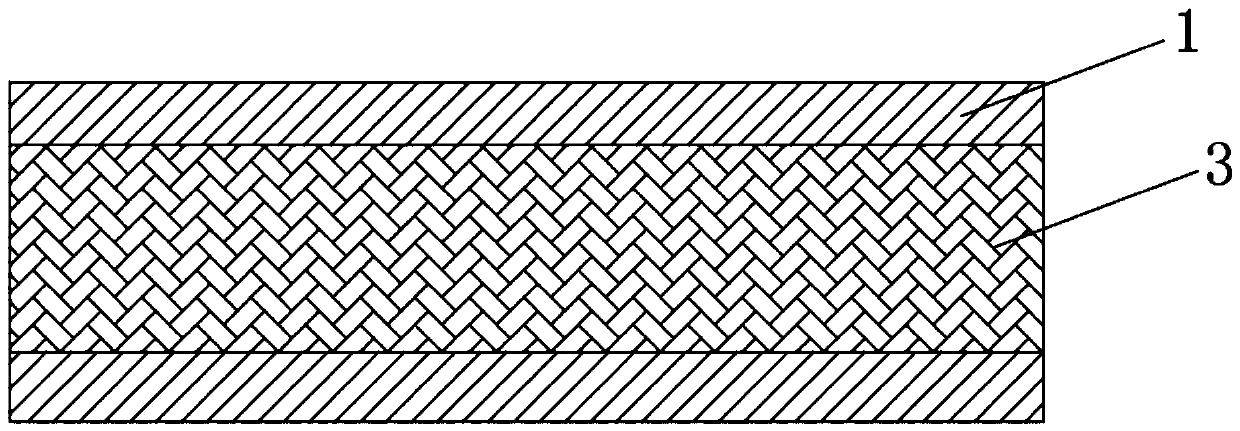

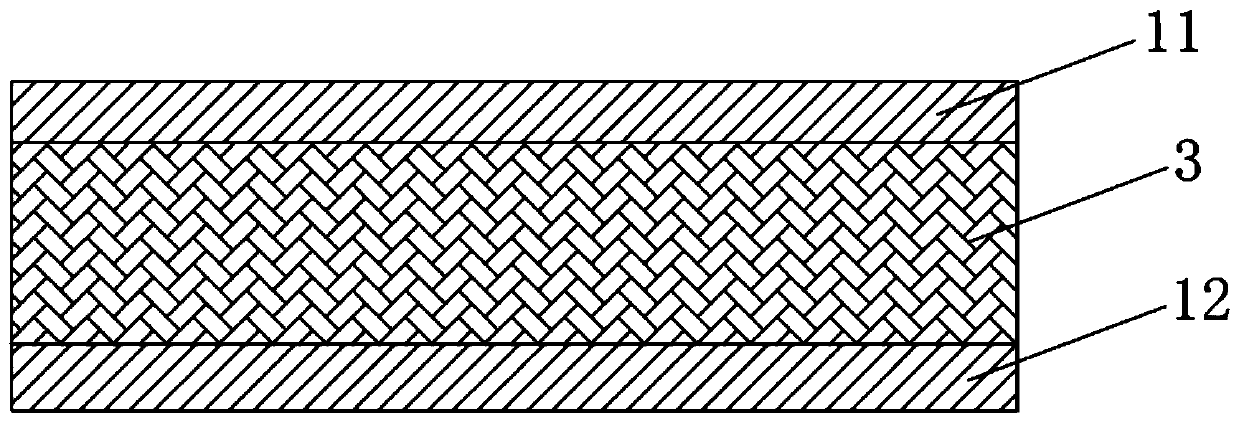

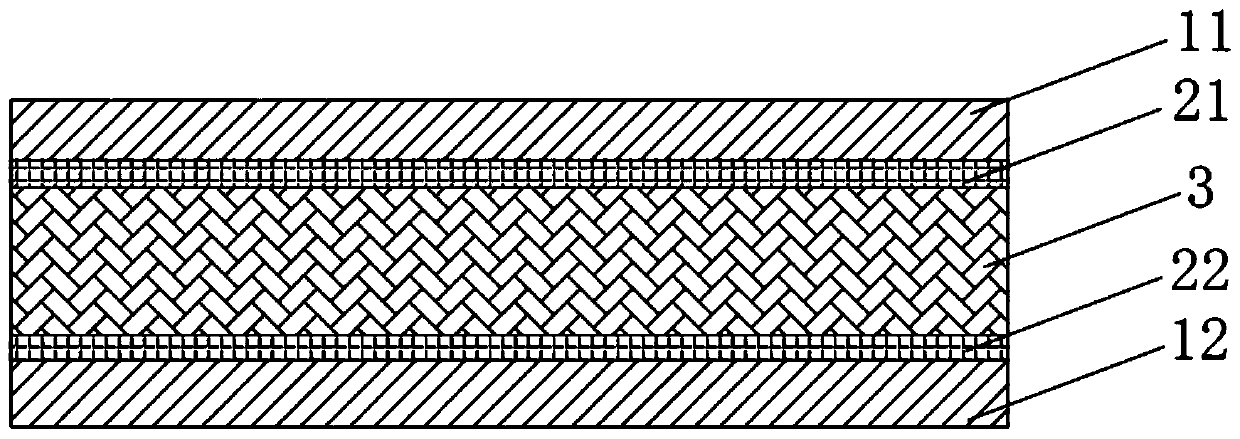

[0026] as attached figure 1 To attach image 3 As shown, the present invention provides a specific embodiment of a composite double-sided metal plate, comprising two metal layers 1 and a wooden layer 3 in the middle; the two metal layers 1 are divided into an upper metal layer 11 and a lower metal layer 12 , Between the upper metal layer 11 and the wooden layer 3 and between the lower metal layer 12 and the wooden layer 3, hot-melt glue or phenolic glue is used to glue and connect them into one body. The present invention also includes a 2-layer insulation layer 2, which is divided into an upper insulation layer 21 and a lower insulation layer 22; the upper insulation layer 21 is arranged between the upper metal layer 11 and the wooden layer 3, and the lower insulation layer 22 is arranged Between the lower metal layer 12 and the wooden layer 3; like this between the upper metal layer 11 and the upper thermal insulation layer 21, between the upper thermal insulation layer 21 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com