Patents

Literature

107results about How to "Avoid discontinuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

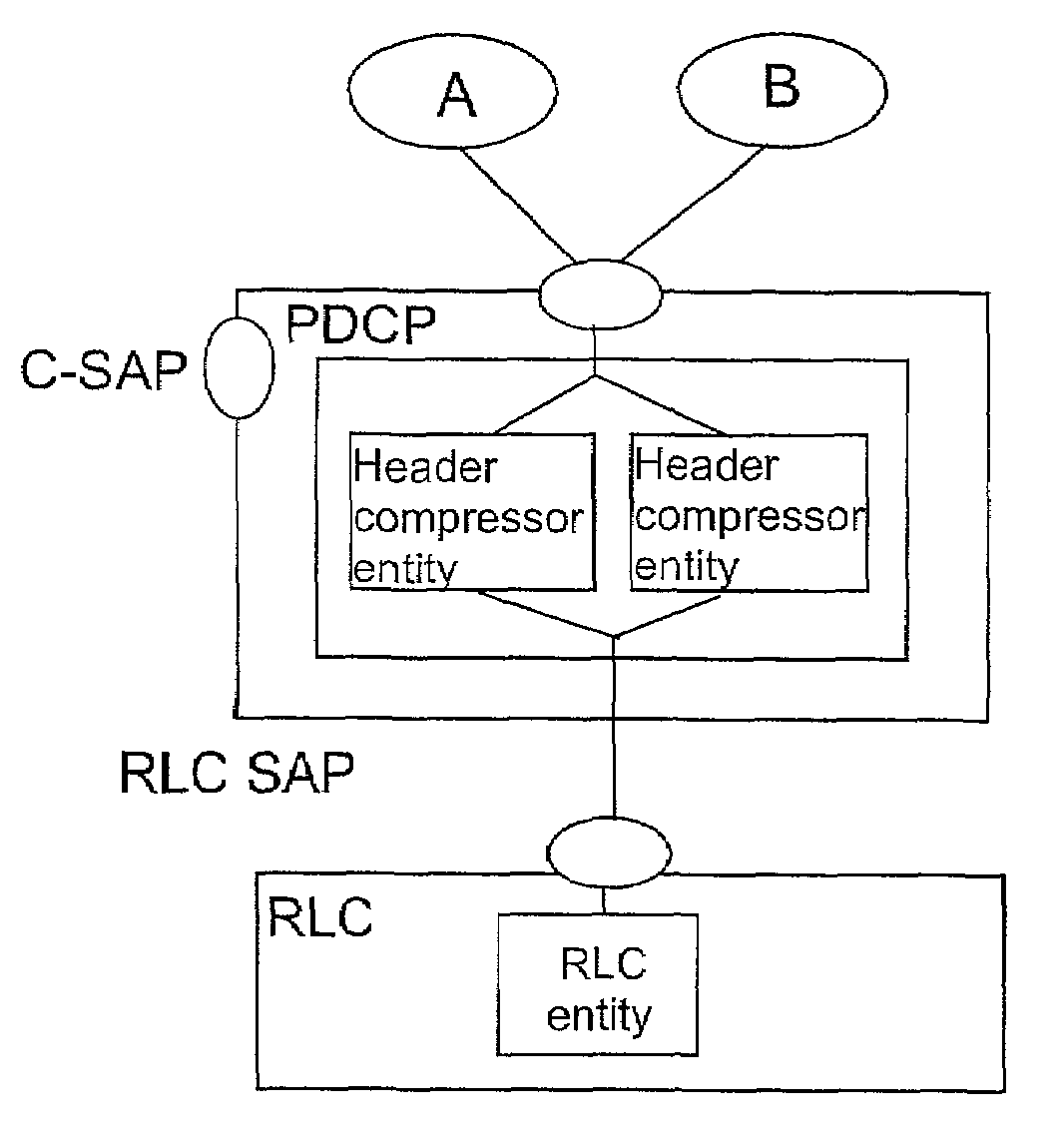

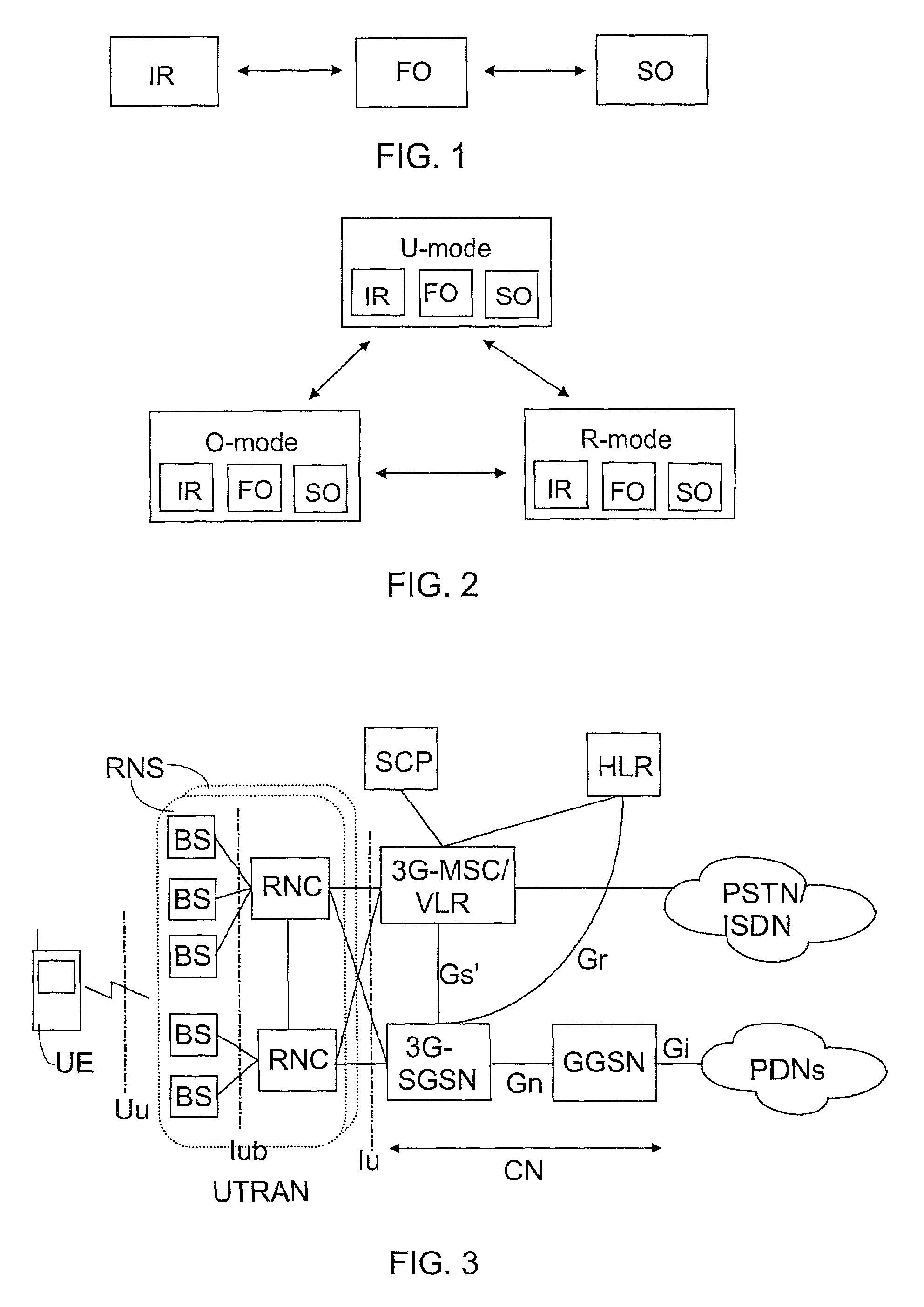

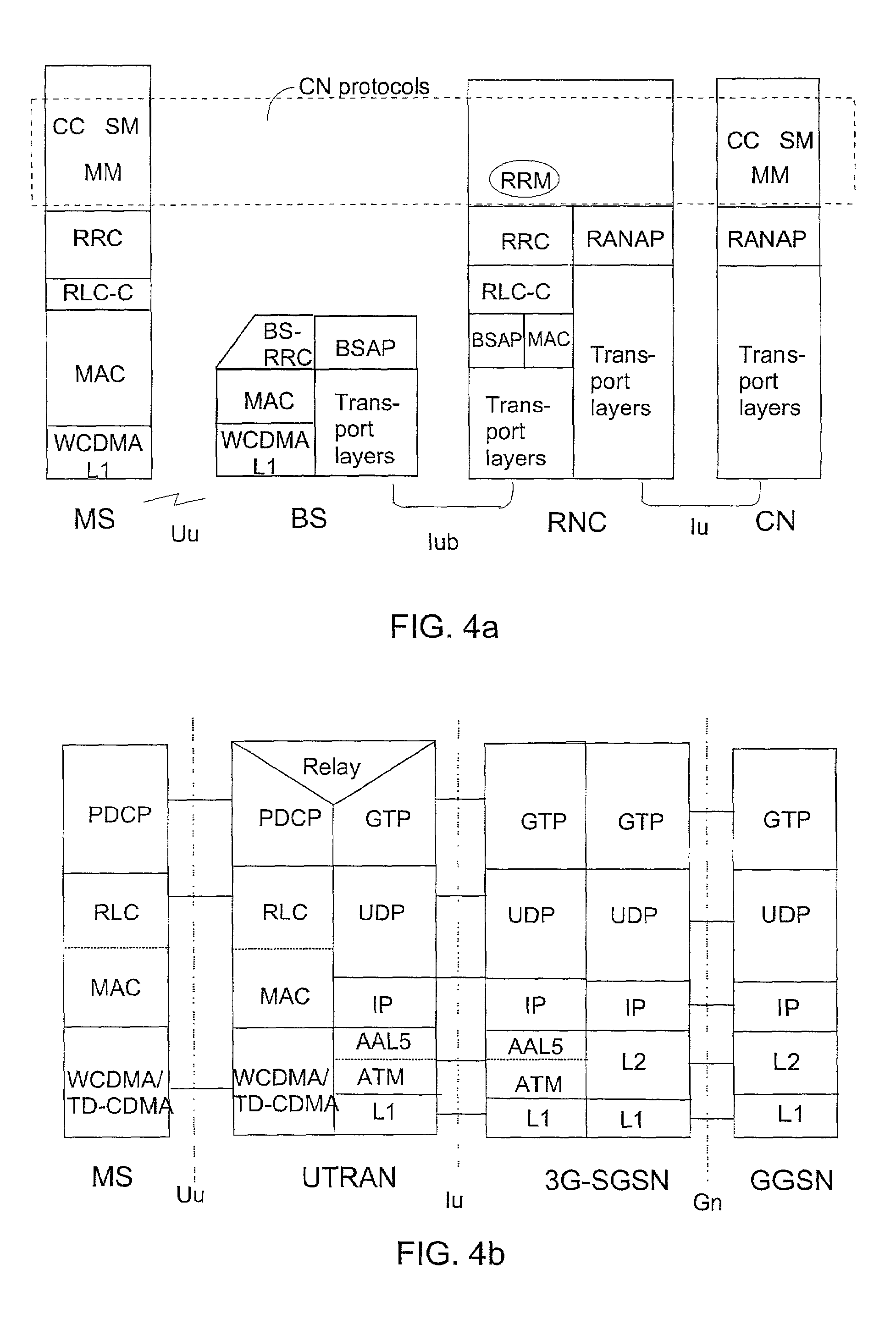

Defining header field compression for data packet connection

ActiveUS7035287B2Simple structureAvoid dataNetwork traffic/resource managementCode conversionNetwork packetData transmission

A method of defining header field compression for a data packet connection and a header field compression system, in which a context for controlling the operation of a compressor and decompressor is defined as one parameter of the connection. A length is defined for a context identifier used in identifying data packet connections for data transmission between the compressor and decompressor, said length defining the maximum number of data packet connections transmitted on one connection. Each data packet connection is identified by its own context identifier. The parameters of the connection are defined in such a manner that at least the number of header fields of data packet connections allowed by the defined context identifier length can be compressed despite the fact that the number of data packet connections allowed by said context identifier length is exceeded.

Owner:NOKIA TECHNOLOGLES OY

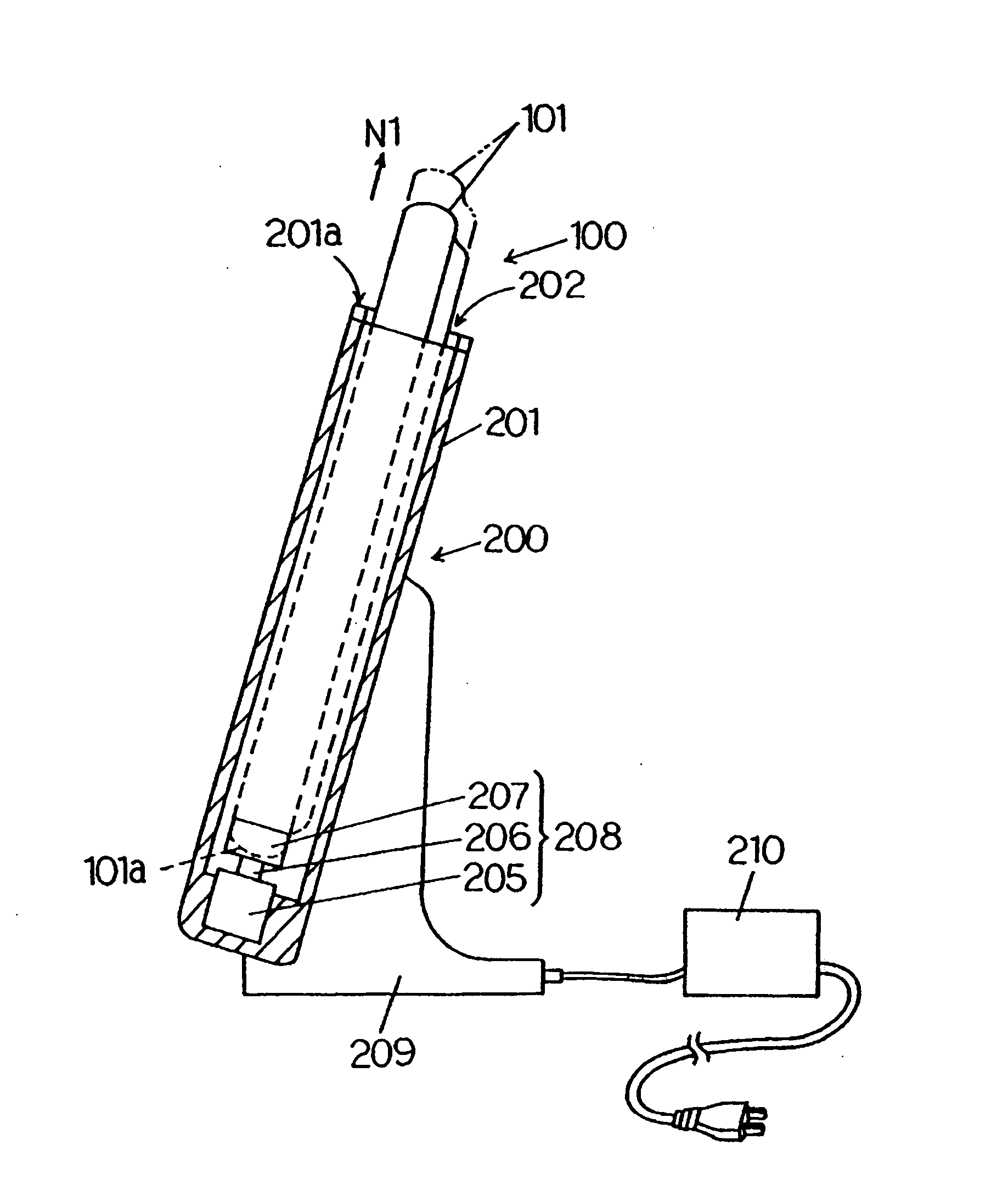

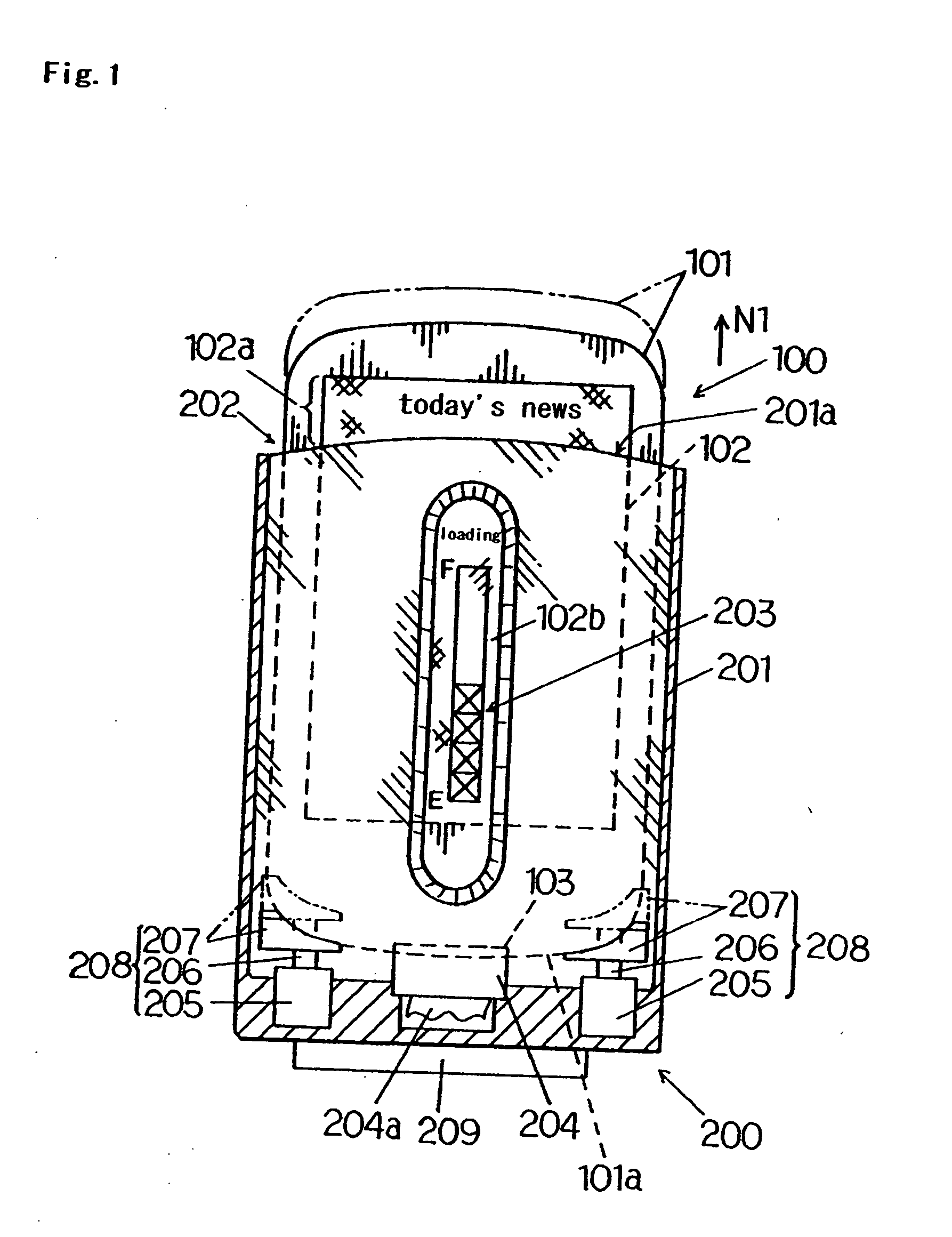

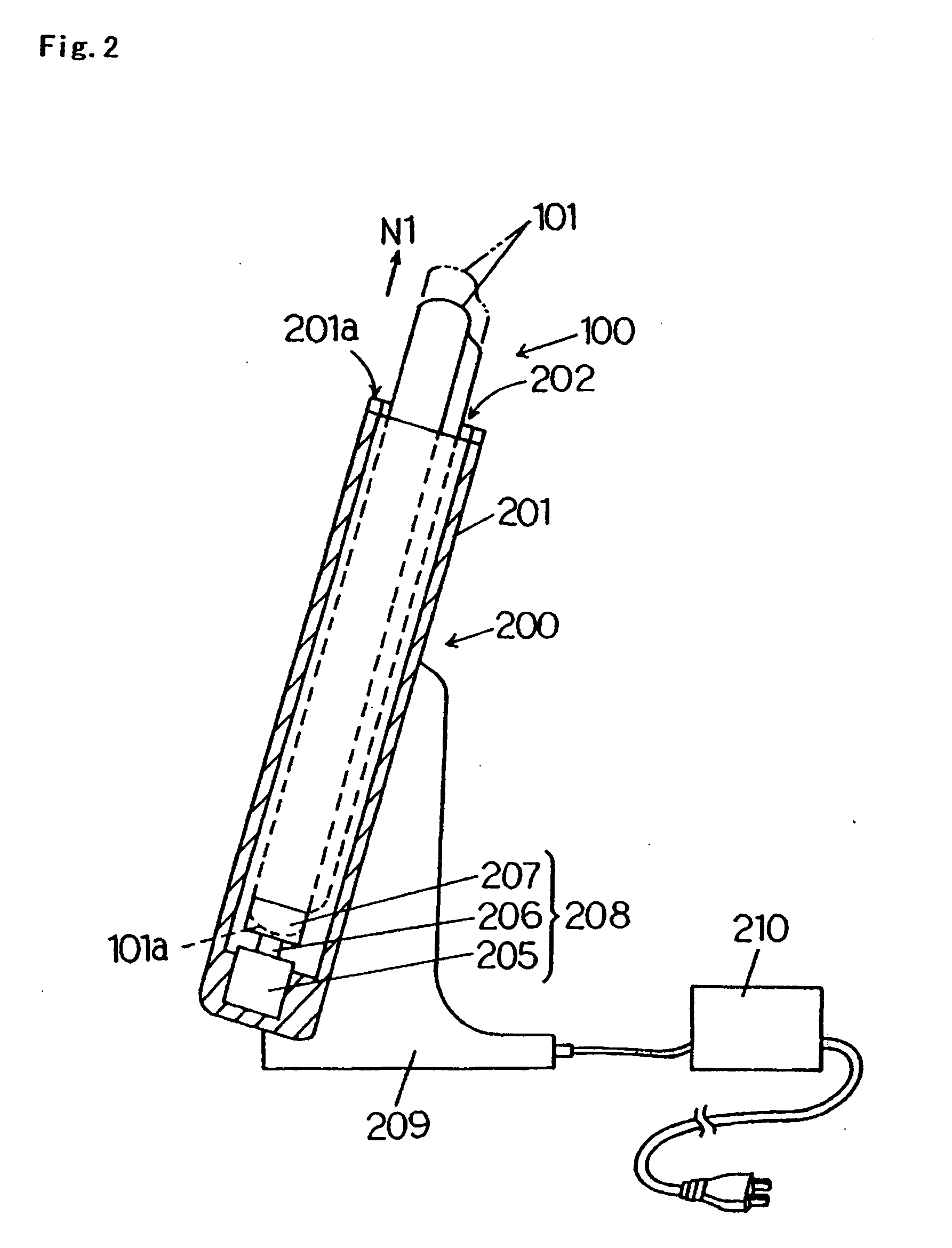

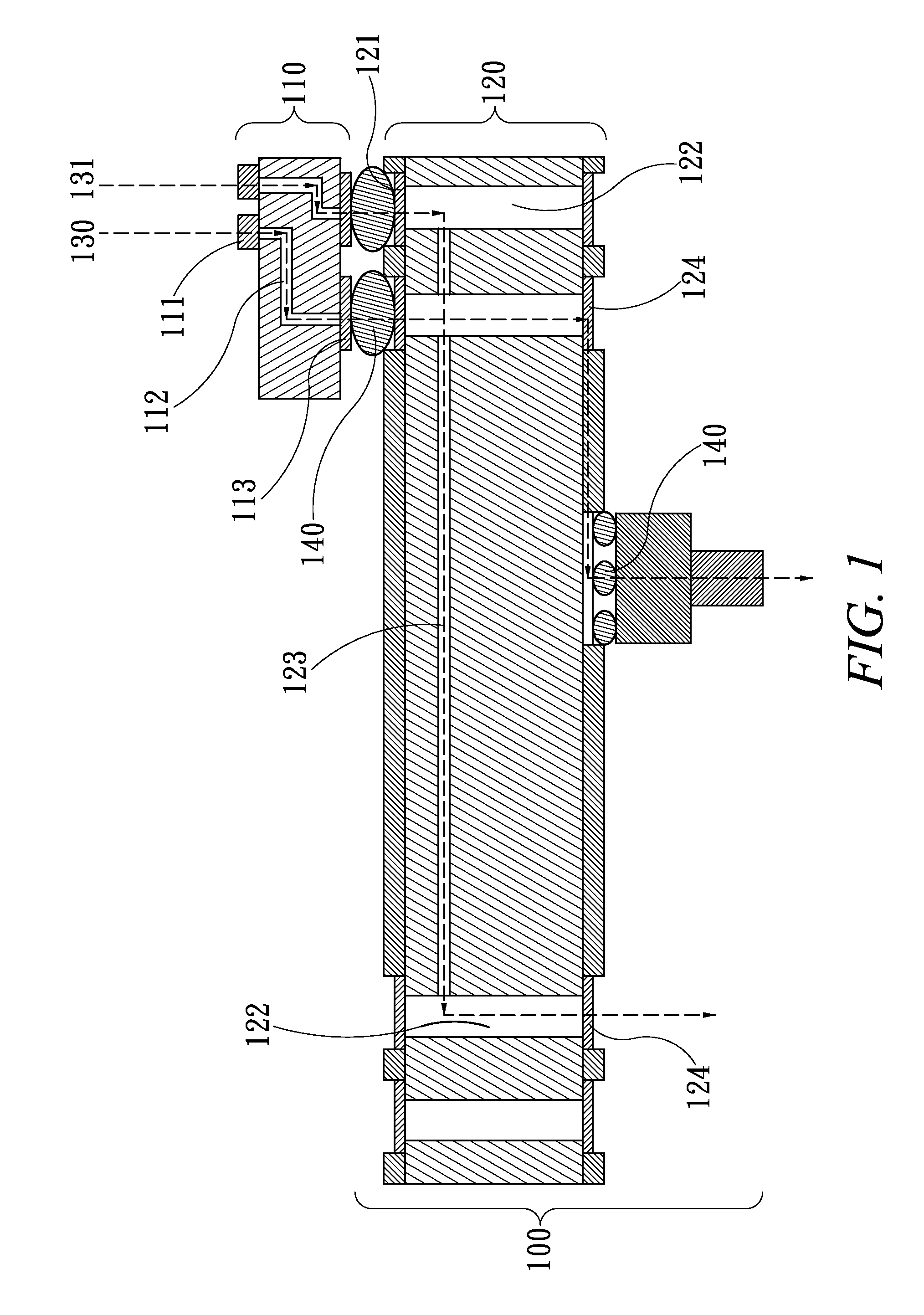

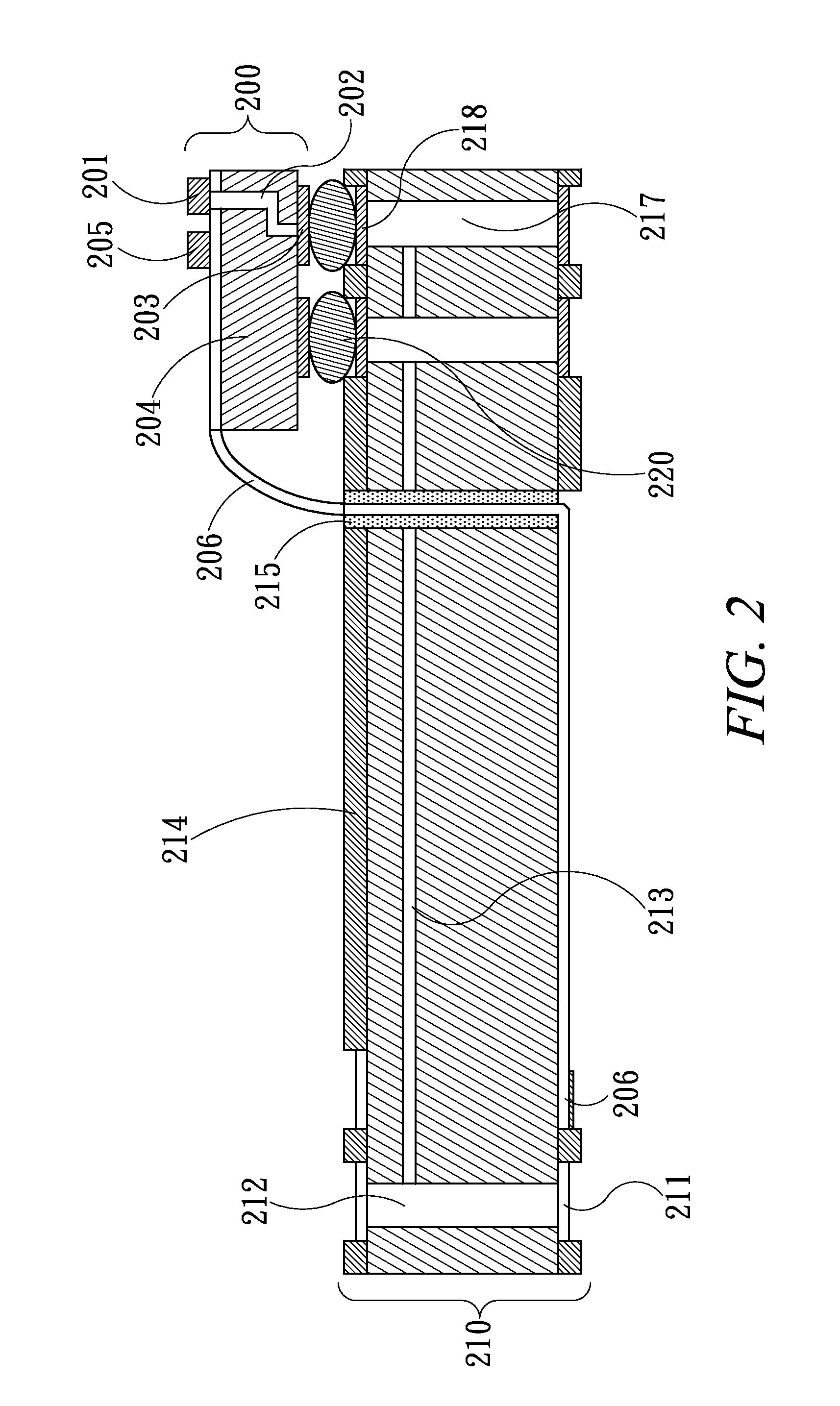

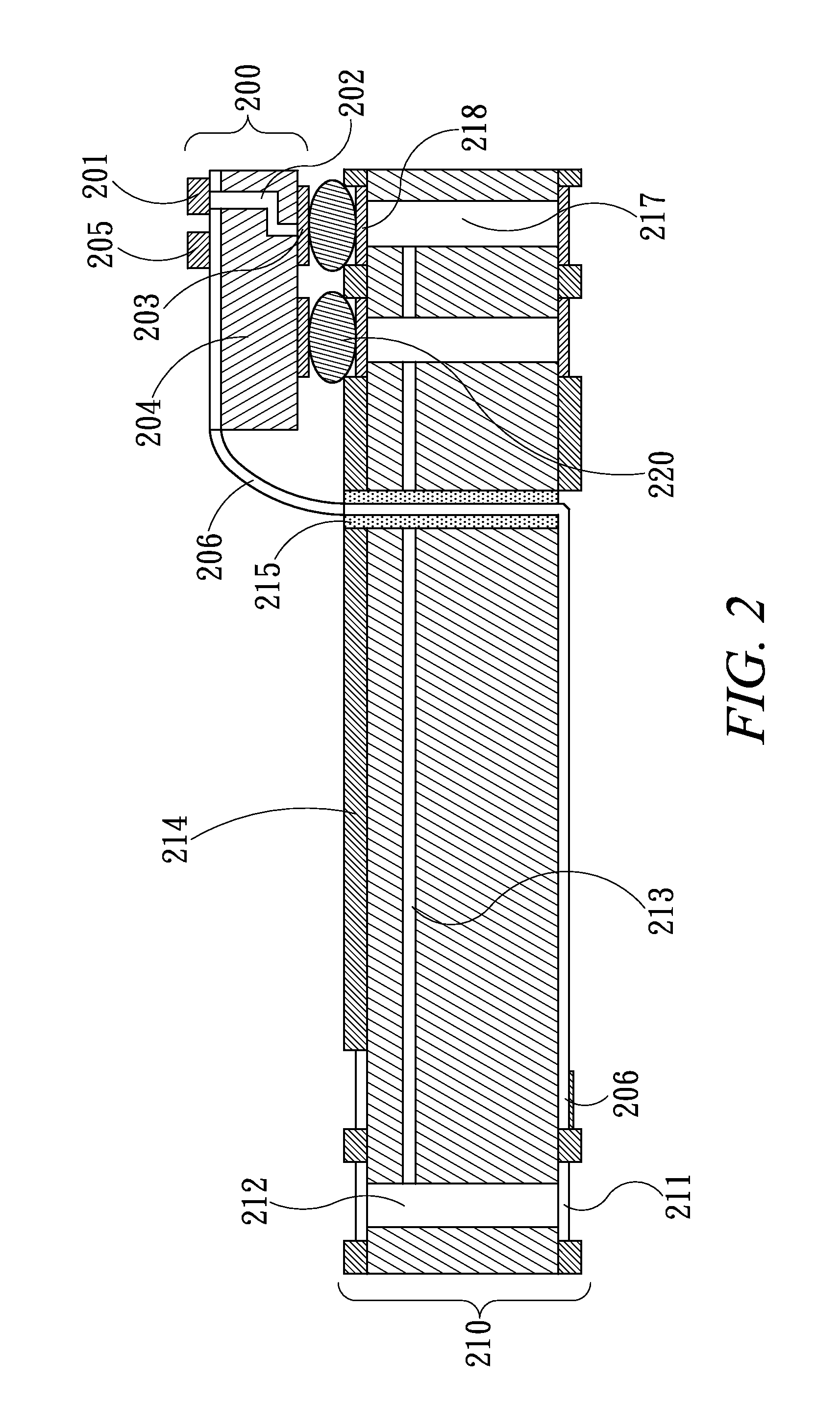

Mounting device for mobile information terminal, and mobile information terminal

ActiveUS20070142097A1Avoid accidental ejectionReduce processing stepsBatteries circuit arrangementsSubstation equipmentElectrical connectionEngineering

A mounting device includes a case that has an insertion inlet for a mobile information terminal, a connector that establishes electrical connection to the mobile information terminal inserted in the insertion inlet, and an ejection mechanism that ejects the mobile information terminal after completion of processing through the connector. After the completion of the processing, by an action of the ejection mechanism, the mobile information terminal is popped up from the mounting device, and a user is understandably notified of the completion of the processing.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

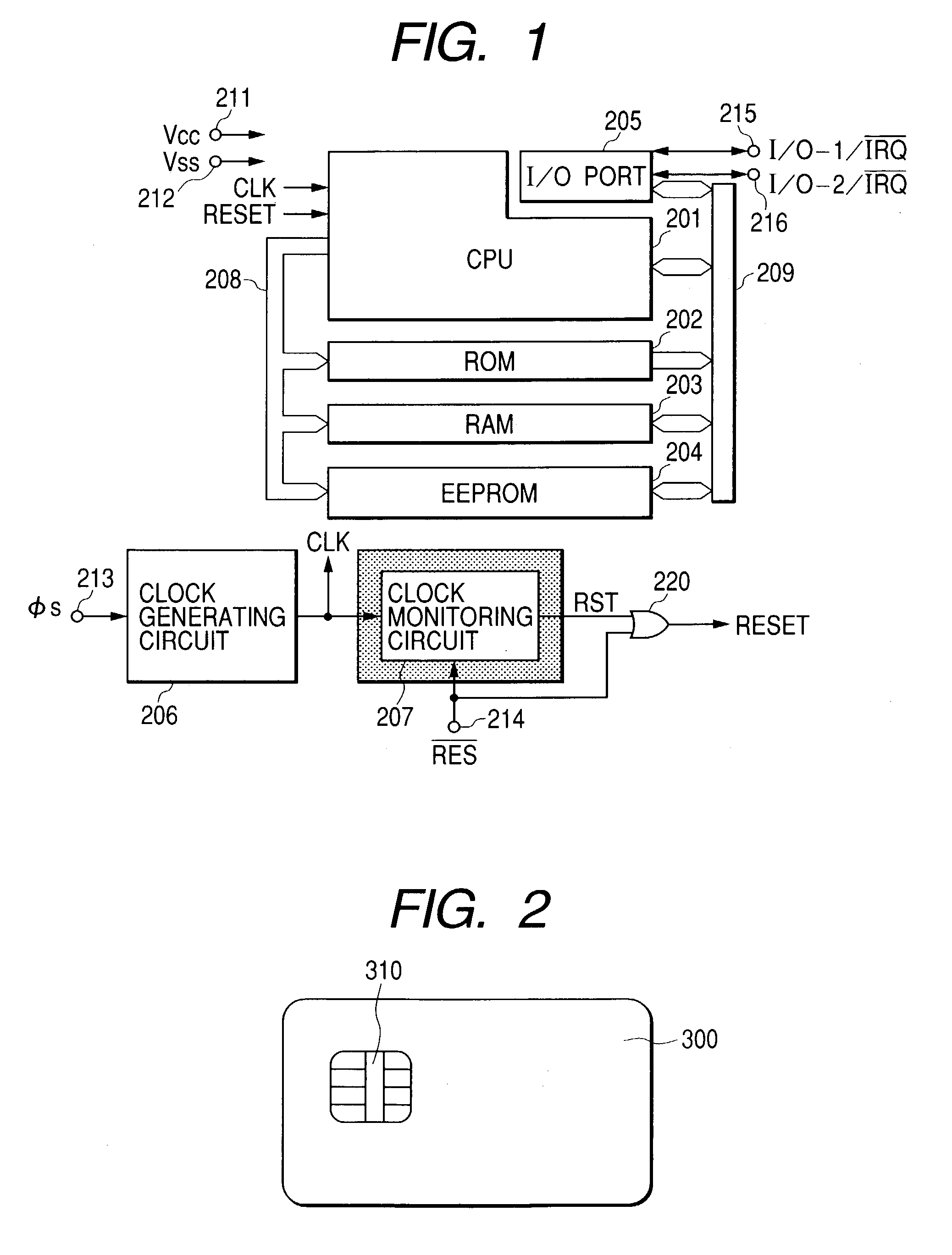

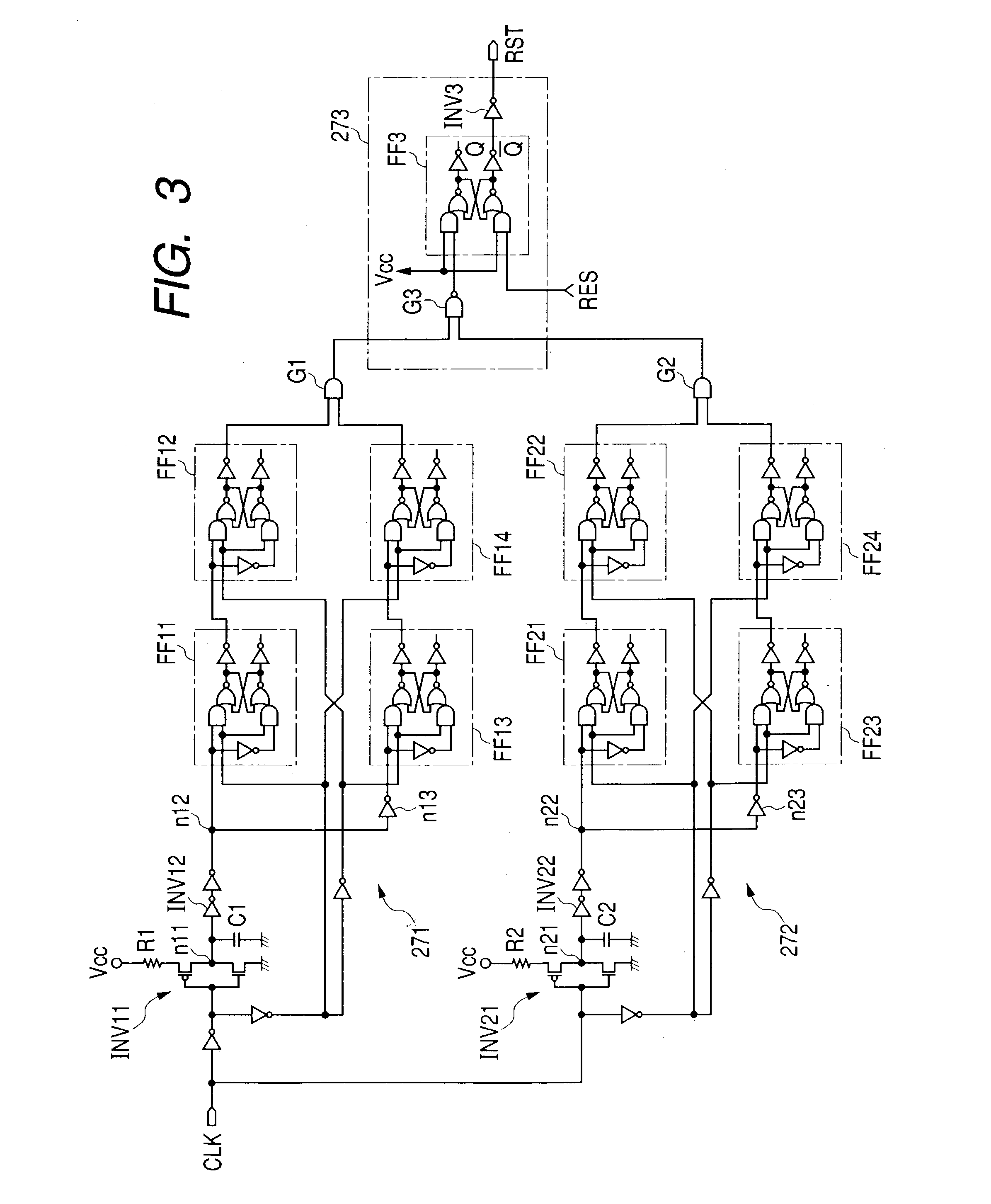

System for monitoring a period of an operation clock signal of a CPU and stopping operations of the CPU when the period is out of a predetermined allowable range

InactiveUS7080001B2Easy to monitorEasy to findVolume/mass flow measurementDigital data protectionMicrocomputerCountermeasure

There is provided a technology for preventing disabling of function of a clock monitoring circuit by a hacker in a microcomputer for IC card provided with a clock monitoring circuit as a countermeasure for a hacker. In the microcomputer for IC card provided with the clock monitoring circuit, the clock monitoring circuit is given the function to perform the detecting operation twice during one cycle, namely at the timings of rise and fall of the clock.

Owner:RENESAS ELECTRONICS CORP +1

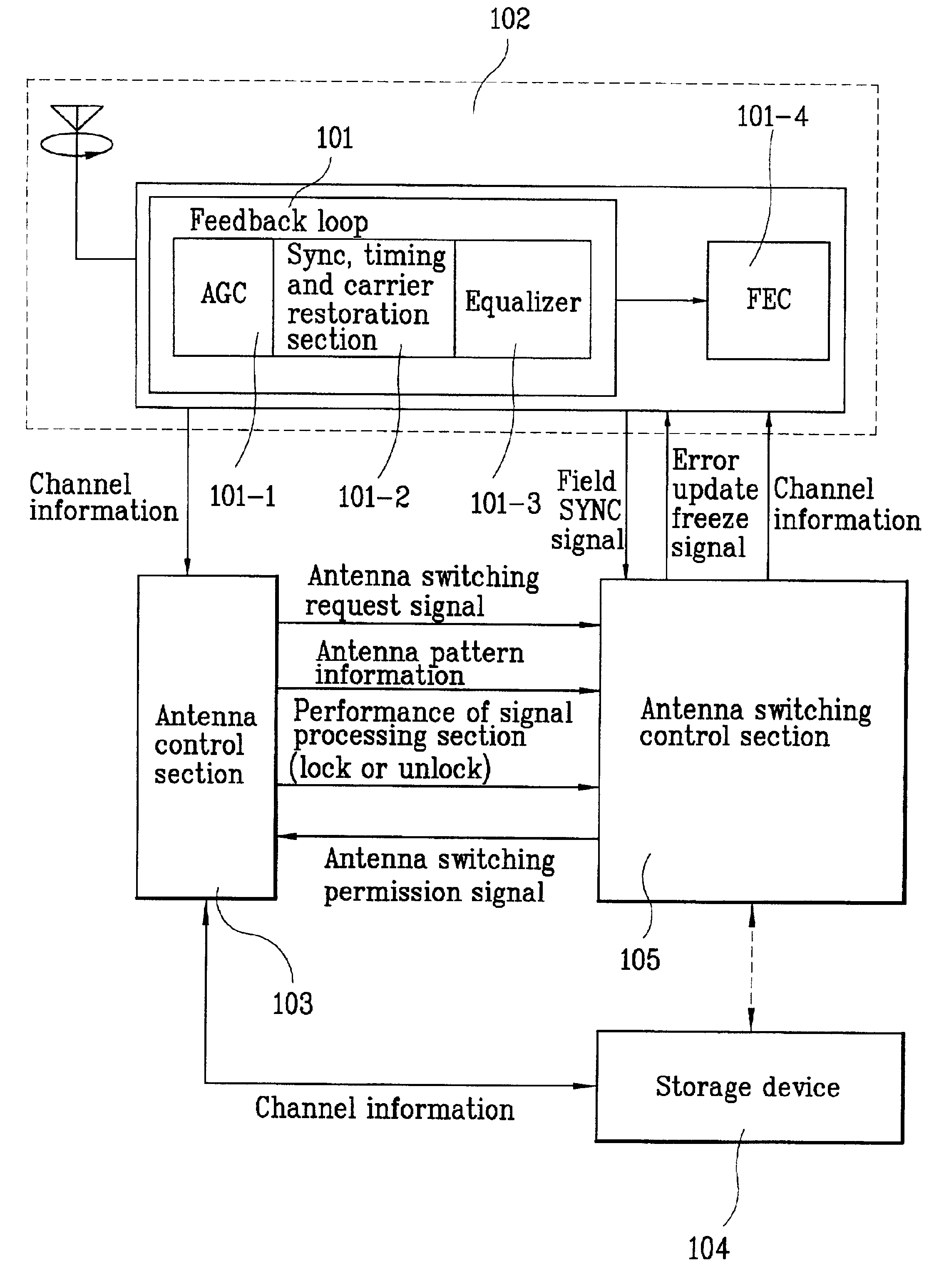

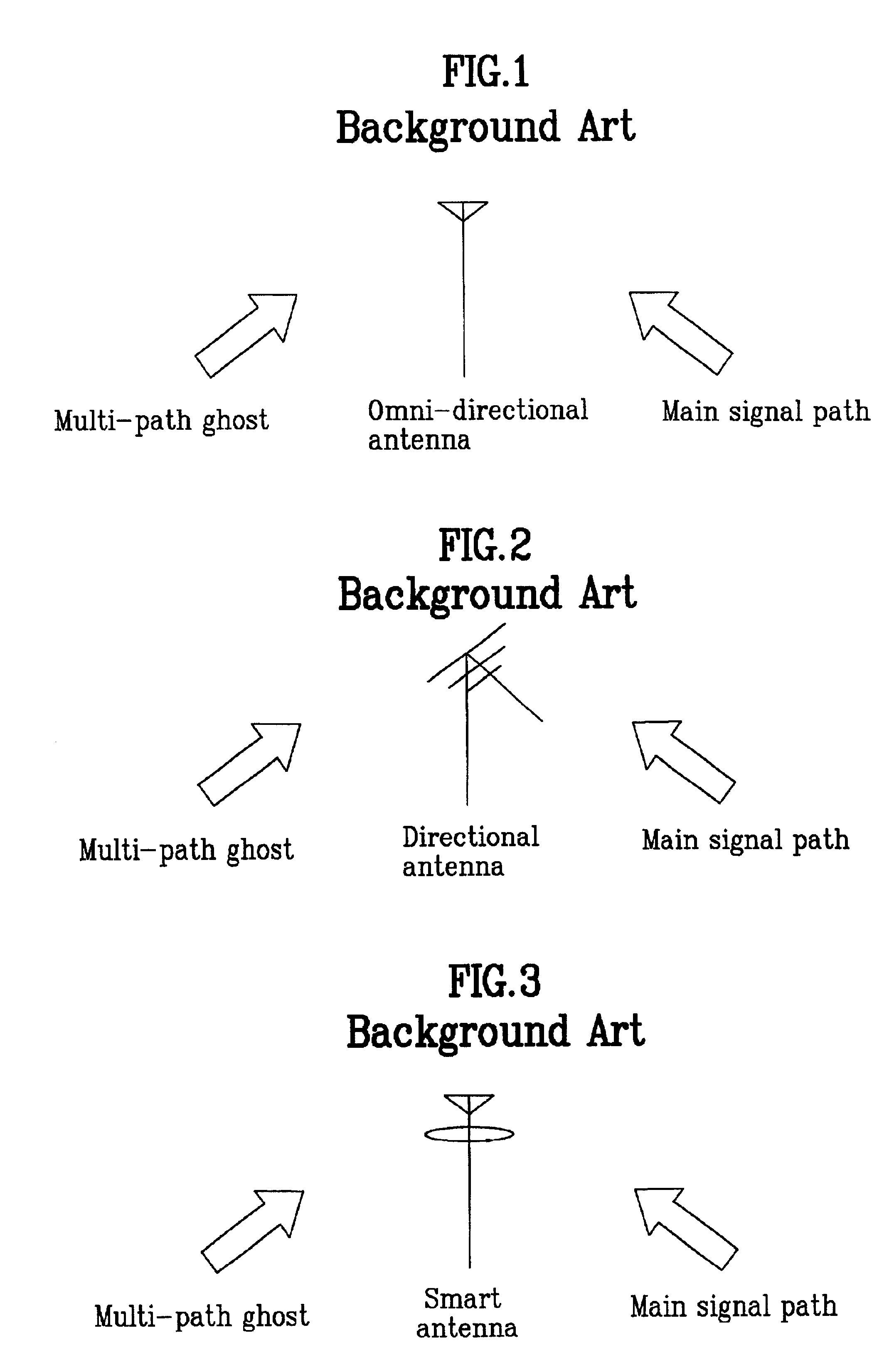

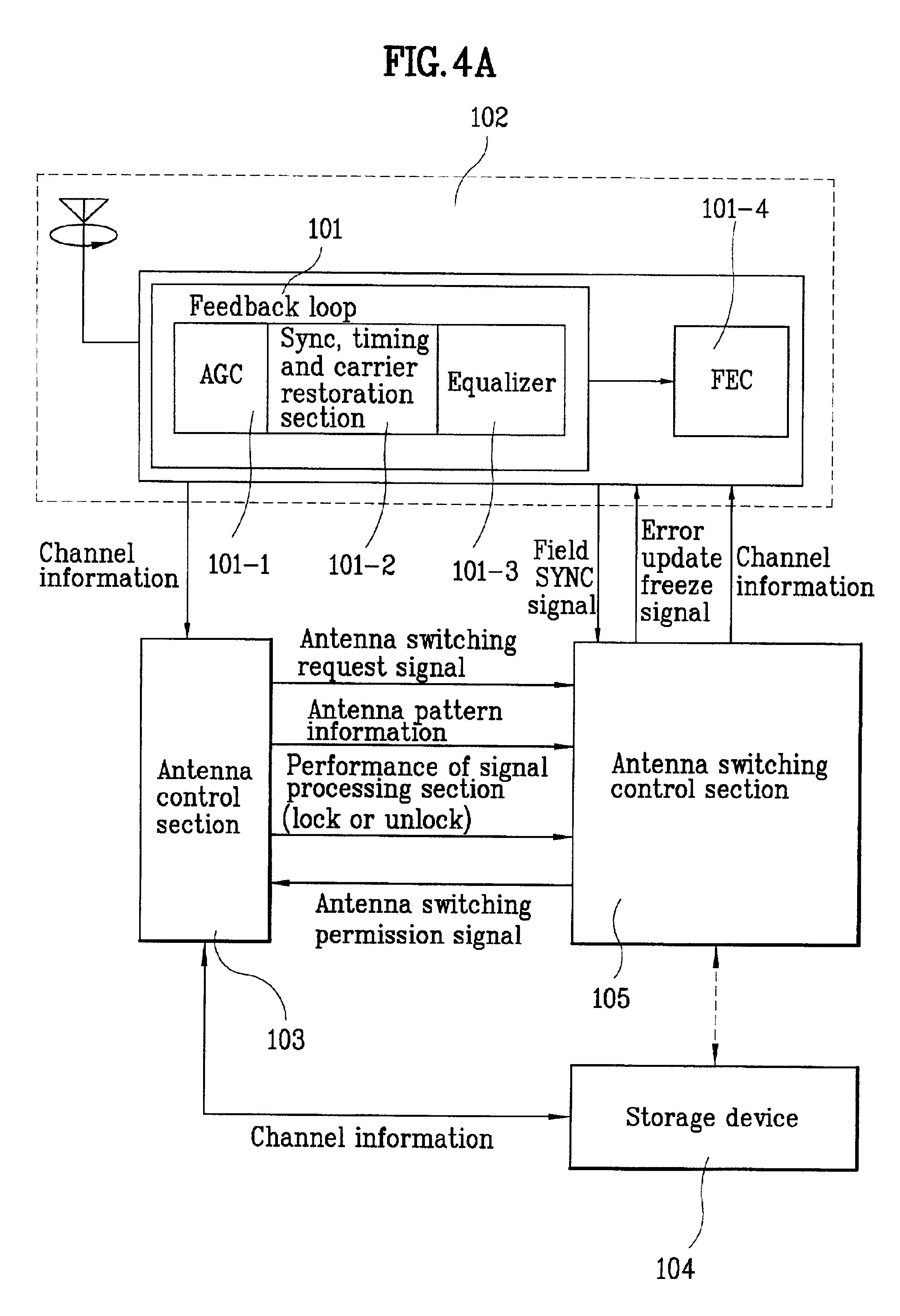

Digital television receiver and antenna control method therein

InactiveUS6867819B2Avoid discontinuationAvoid abnormal stateTelevision system detailsAntenna supports/mountingsControl signalDigital audio broadcasting

A digital television receiver and antenna control method in the digital television receiver are disclosed. The digital television receiver includes and antenna having directivity according to a control signal for switching patterns of the antenna. A receiving section receives and processes channel signals for digital television broadcasting through the antenna. An antenna control section generates the control signal for switching the patterns of the antenna based on channel information according to the received channel signal. An antenna switching control section switches the patterns of the antenna during a sync signal period of the received channel signal when the control signal is generated.

Owner:LG ELECTRONICS INC

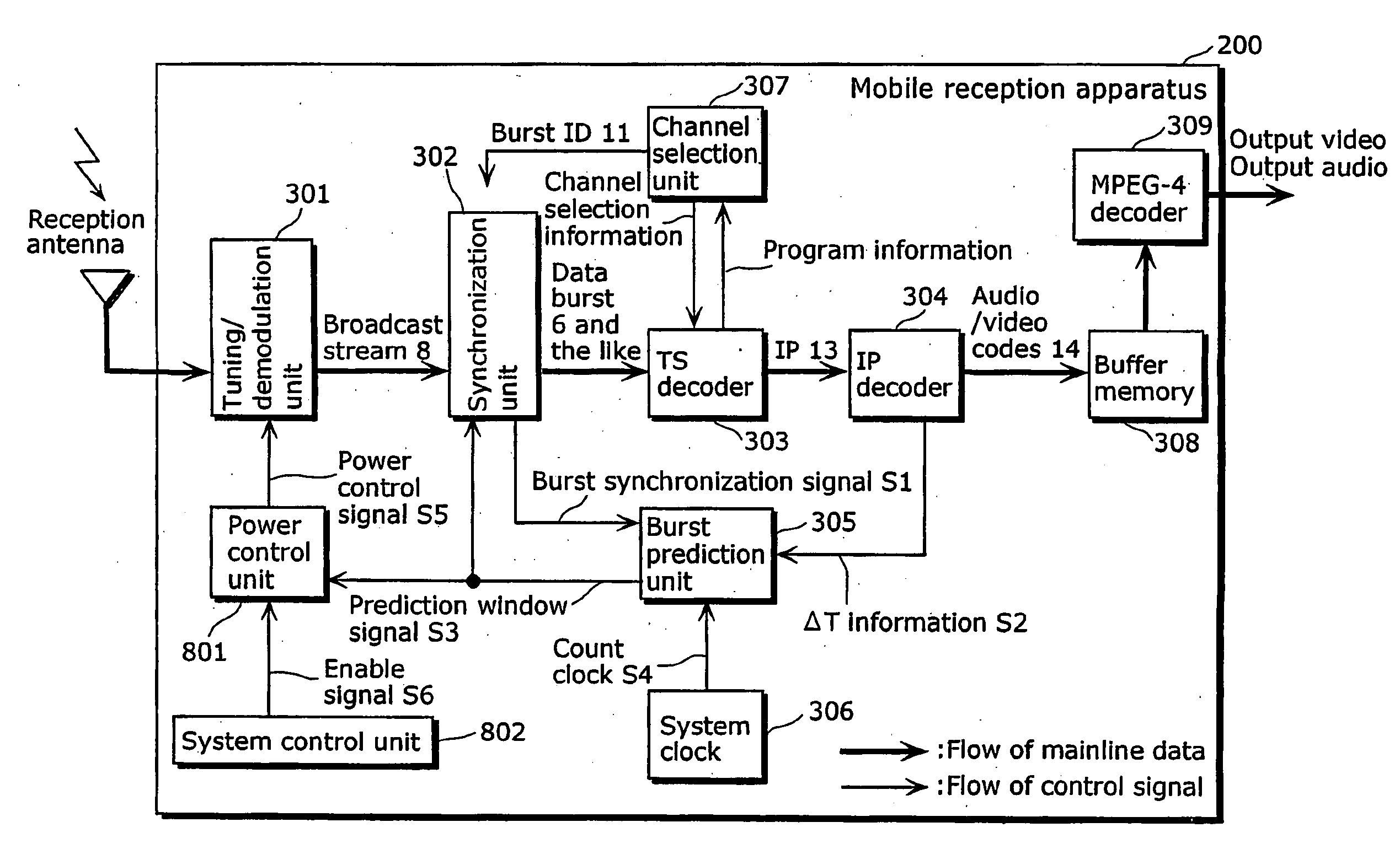

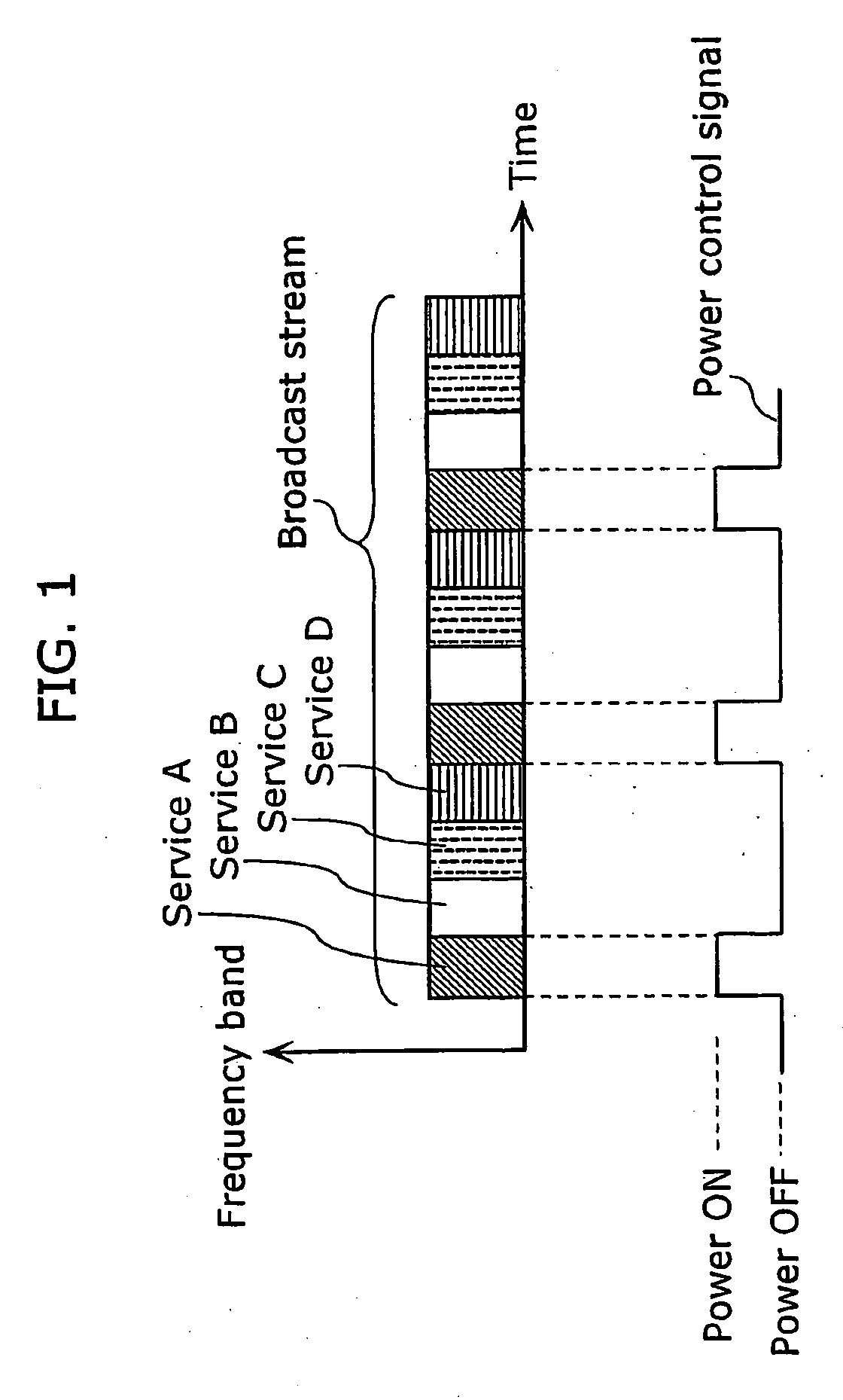

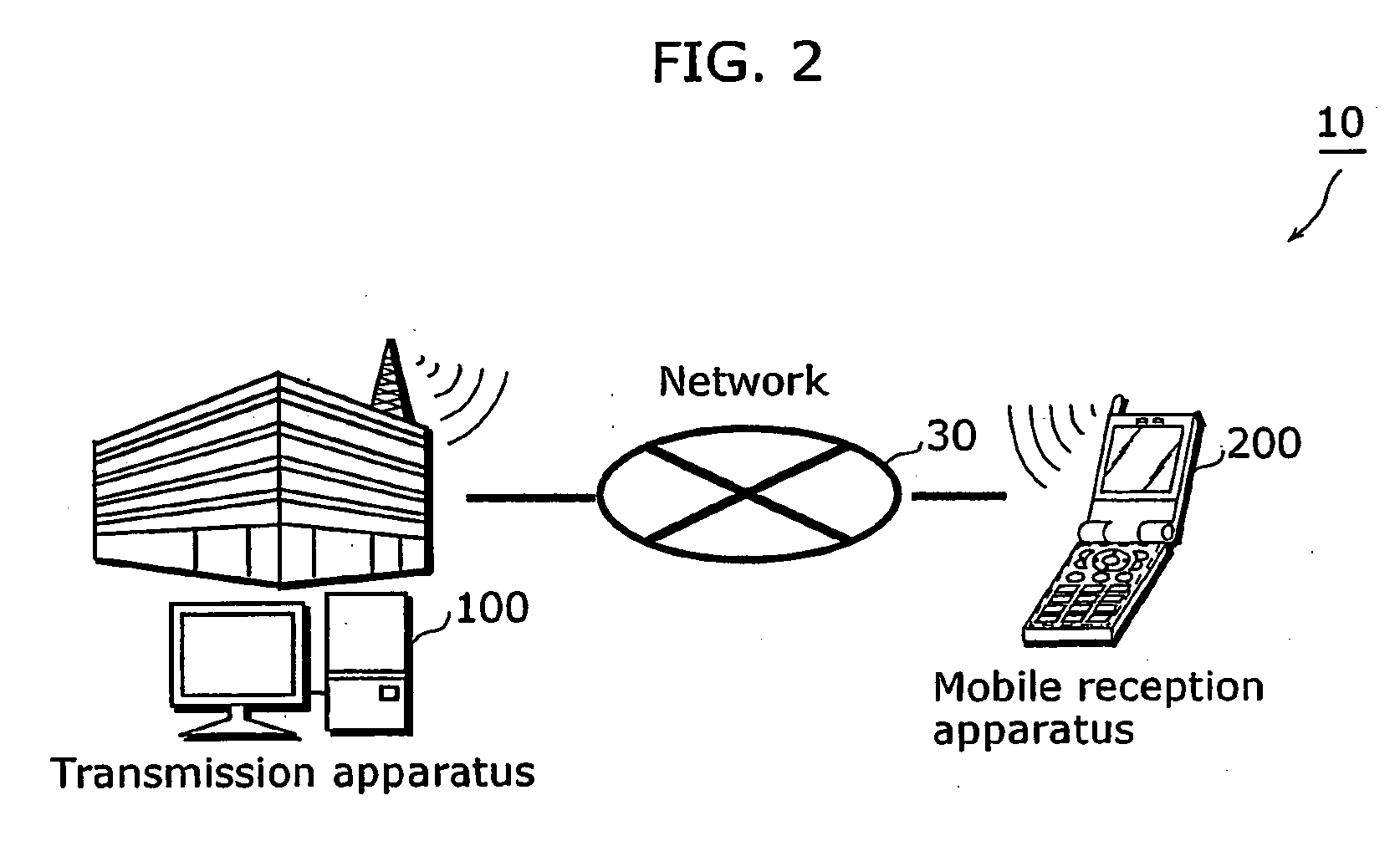

Digital Broadcasting System and Digital Broadcast Transmission and Reception Method

ActiveUS20080276287A1Inhibition of reproductionIncrease probabilityPulse modulation television signal transmissionResource management arrangementsMultiplexingBroadcast transmission

The present invention is a digital broadcasting system for transmitting and receiving, via a network, a broadcast stream created from a broadcast source. The digital broadcasting system includes: a hierarchical coding unit (2) which codes the broadcast source depending on a characteristic of the broadcast source and generates, from the coded broadcast source, a first layer code and a second layer code which can respectively be used for reproduction of the broadcast source; a synthesis unit (5) which generates data bursts, each of which includes the generated first layer code and second layer code; a multiplexing unit (7) which creates the broadcast stream by multiplexing the generated data bursts; a transmission unit (9) which transmits the created broadcast stream to the network; a tuning / demodulation unit (301) which receives the transmitted broadcast stream; a synchronization unit (302) which extracts, from the received broadcast stream, at least one of the first layer code and the second layer code; and a TS decoder (303) which reproduces the broadcast source using the extracted code.

Owner:SOVEREIGN PEAK VENTURES LLC

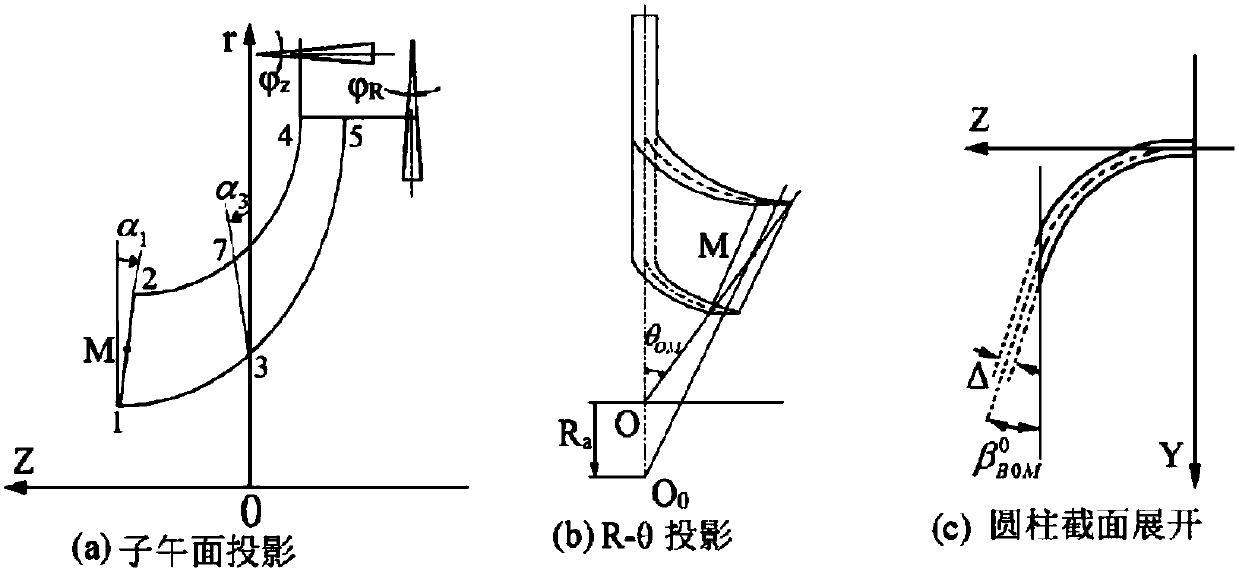

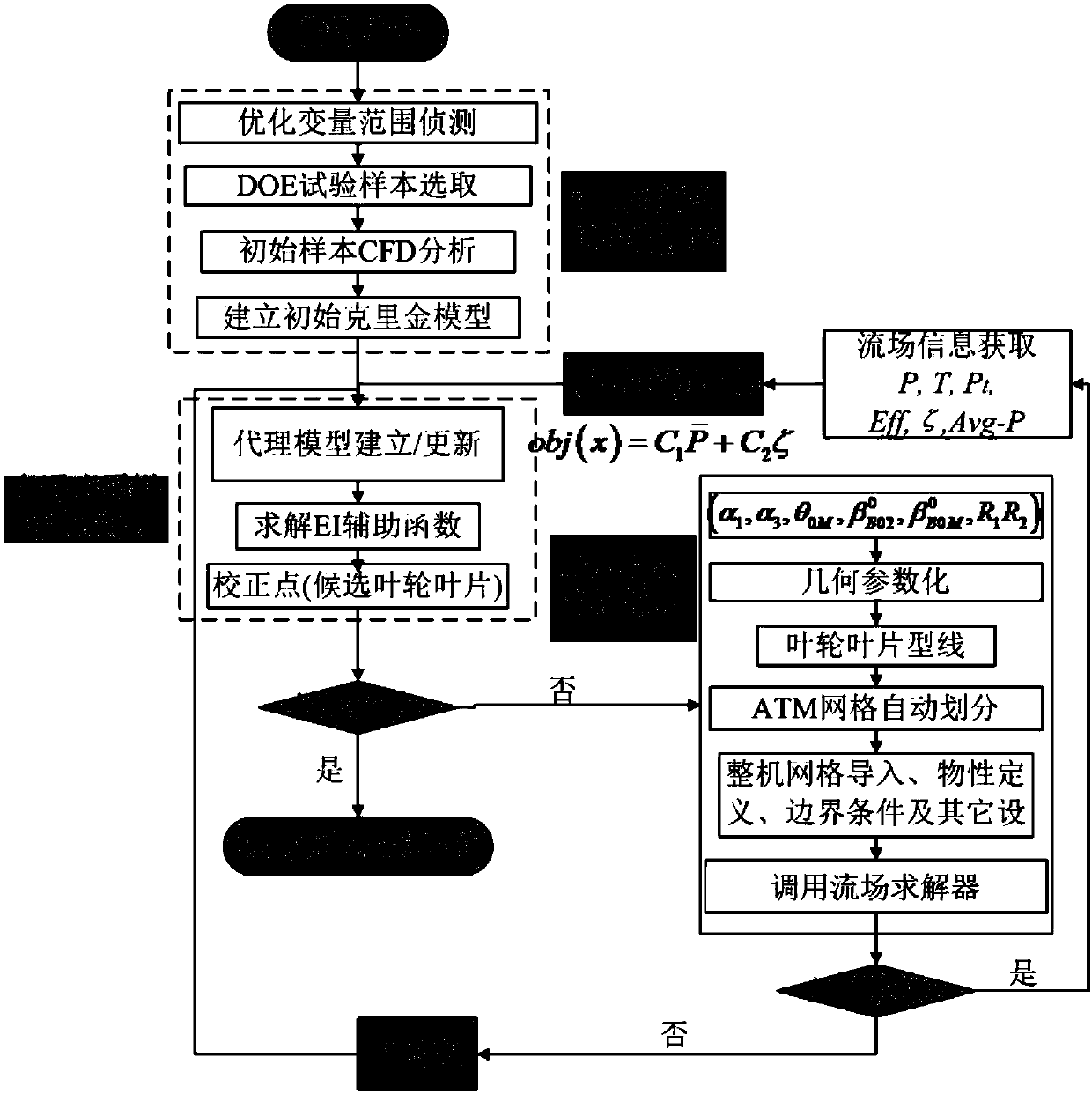

Effective control method for vortex cavitation flowing in low-temperature liquid expander

ActiveCN108561195AImprove performanceImprove operational reliabilityMachines/enginesSafety/regulatory devicesImpellerEngineering

The invention discloses an effective control method for vortex cavitation flowing in a low-temperature liquid expander. The effective control method comprises the steps of researching of the low-temperature liquid expander vortex cavitation mechanism considering the low-temperature fluid thermal-mechanical effect, impeller geometrical parameter sensitivity analysis for vortex cavitation flowing inthe low-temperature liquid expander, characterization presentation of complex vortex cavitation flowing in the low-temperature liquid expander, construction of a flow field optimizing objective function and flow field optimizing control variables with the purpose of controlling vortex cavitation flowing, and parallel solving of a vortex cavitation flowing optimizing control problem. According tothe effective control method, the performance and operation reliability of the low-temperature liquid expander can be effectively improved.

Owner:XI AN JIAOTONG UNIV

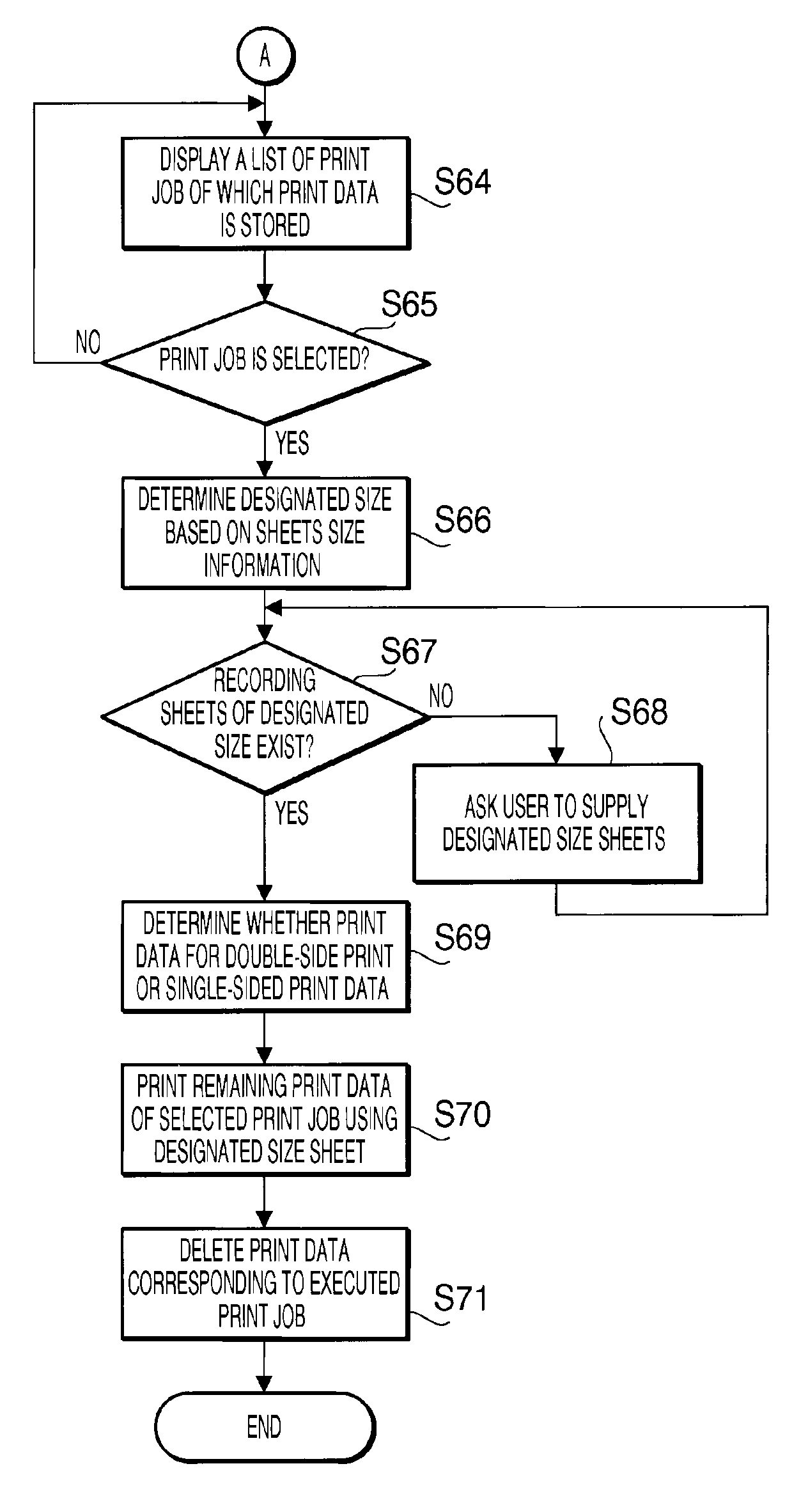

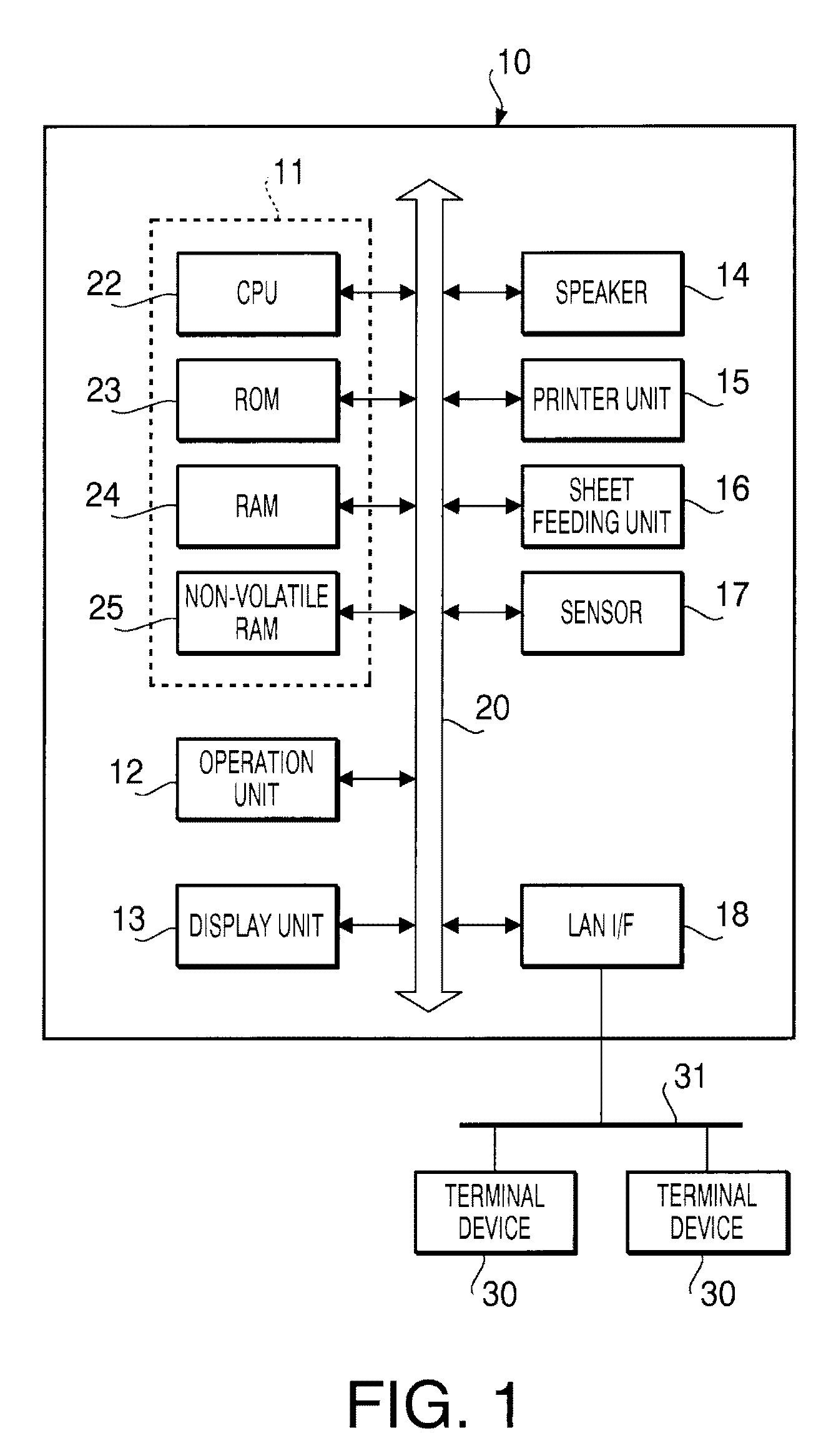

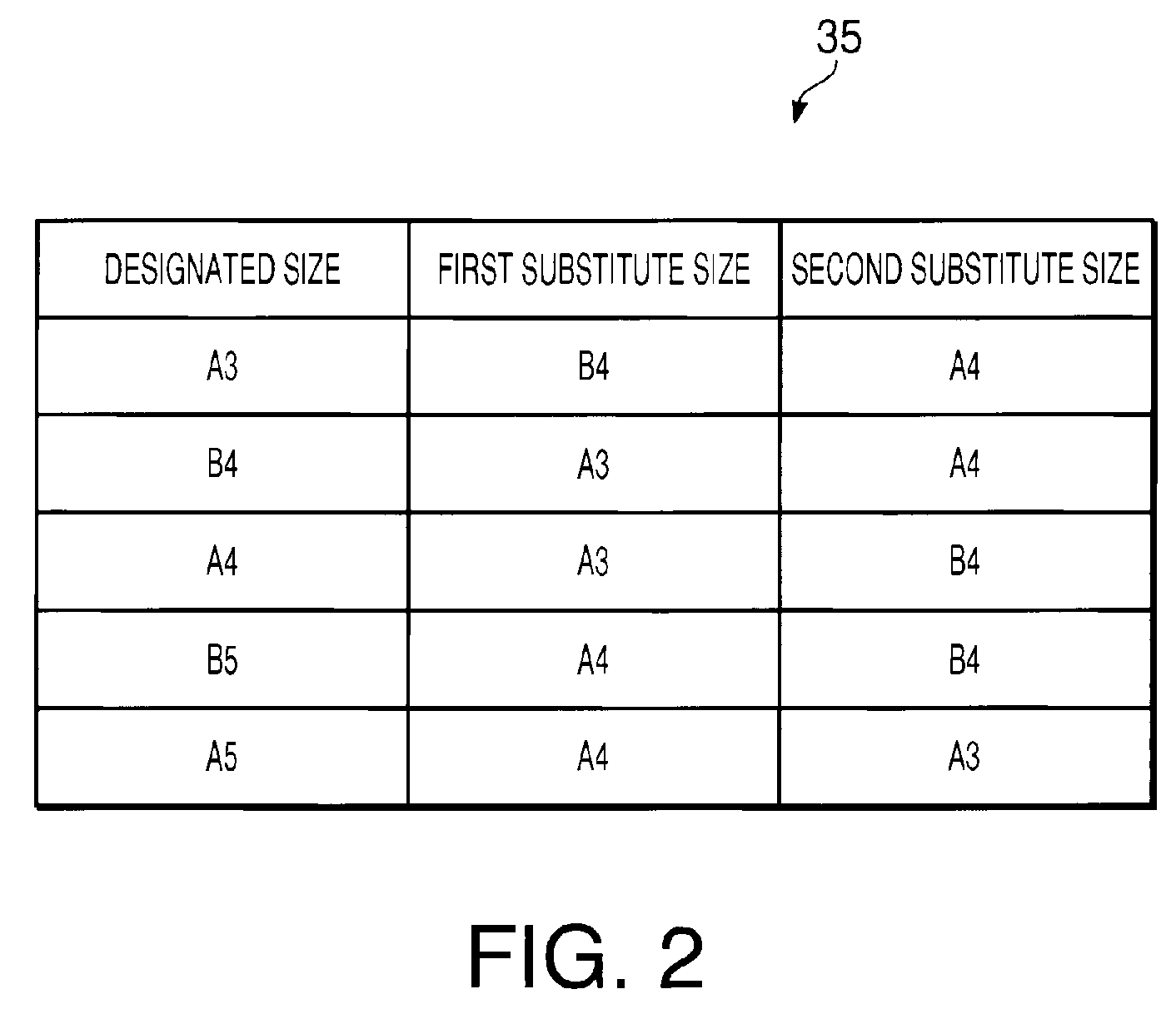

Image forming device

Owner:BROTHER KOGYO KK

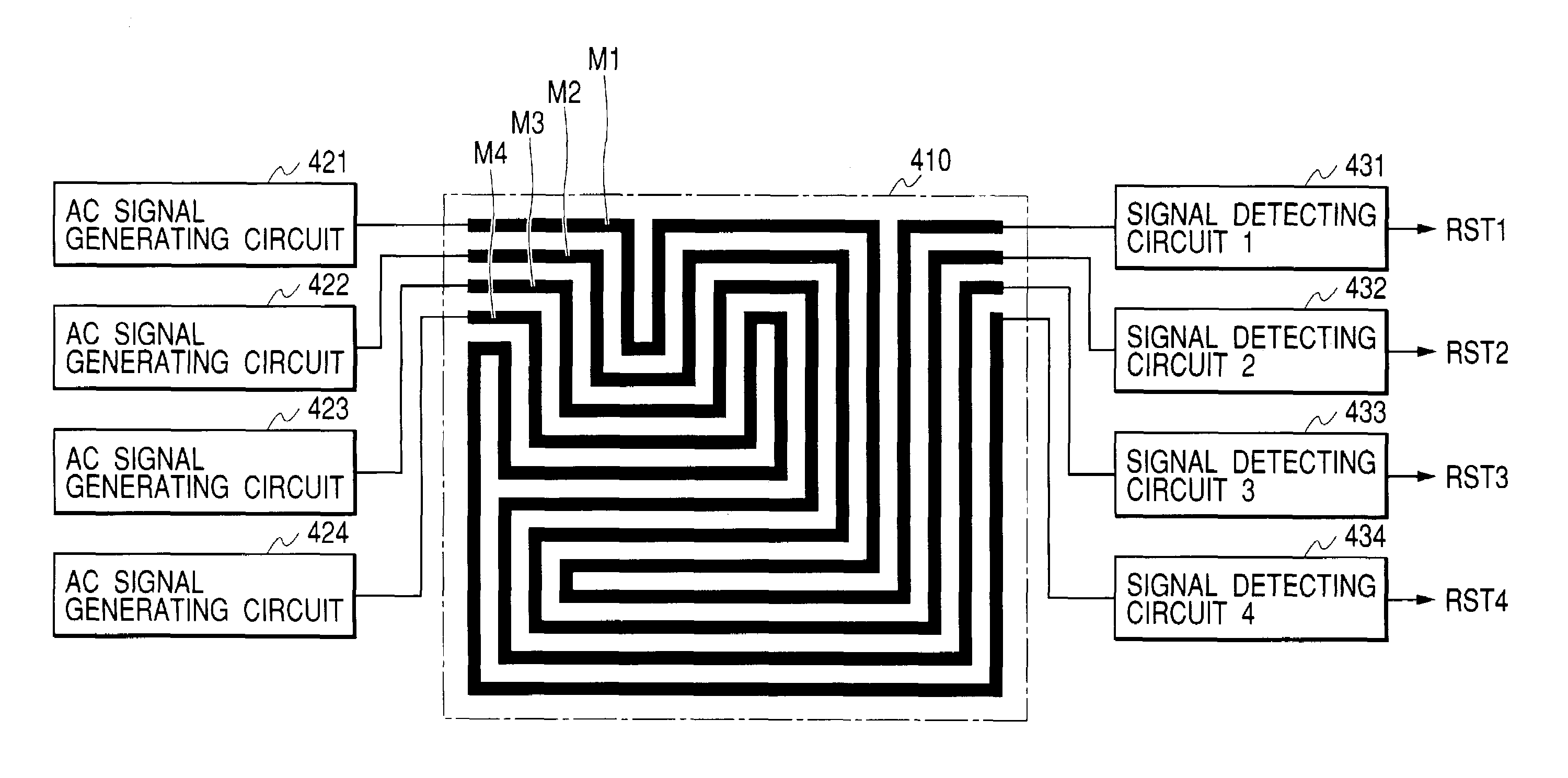

IC Test Substrate for Testing Various Signals

ActiveUS20110025357A1Ensure integritySatisfies requirementElectrical measurement instrument detailsIndividual semiconductor device testingEngineeringIc testing

The present invention provides on IC test substrate for testing various signals, a combined flexible and rigid PCB included in the structure is applicable to perform a mission including for example: stabilizing power input / output, signal transfer by a connector; general, power, and high frequency signal transmission in preserved integrity state.

Owner:CHUNGHWA PRECISION TEST TECH

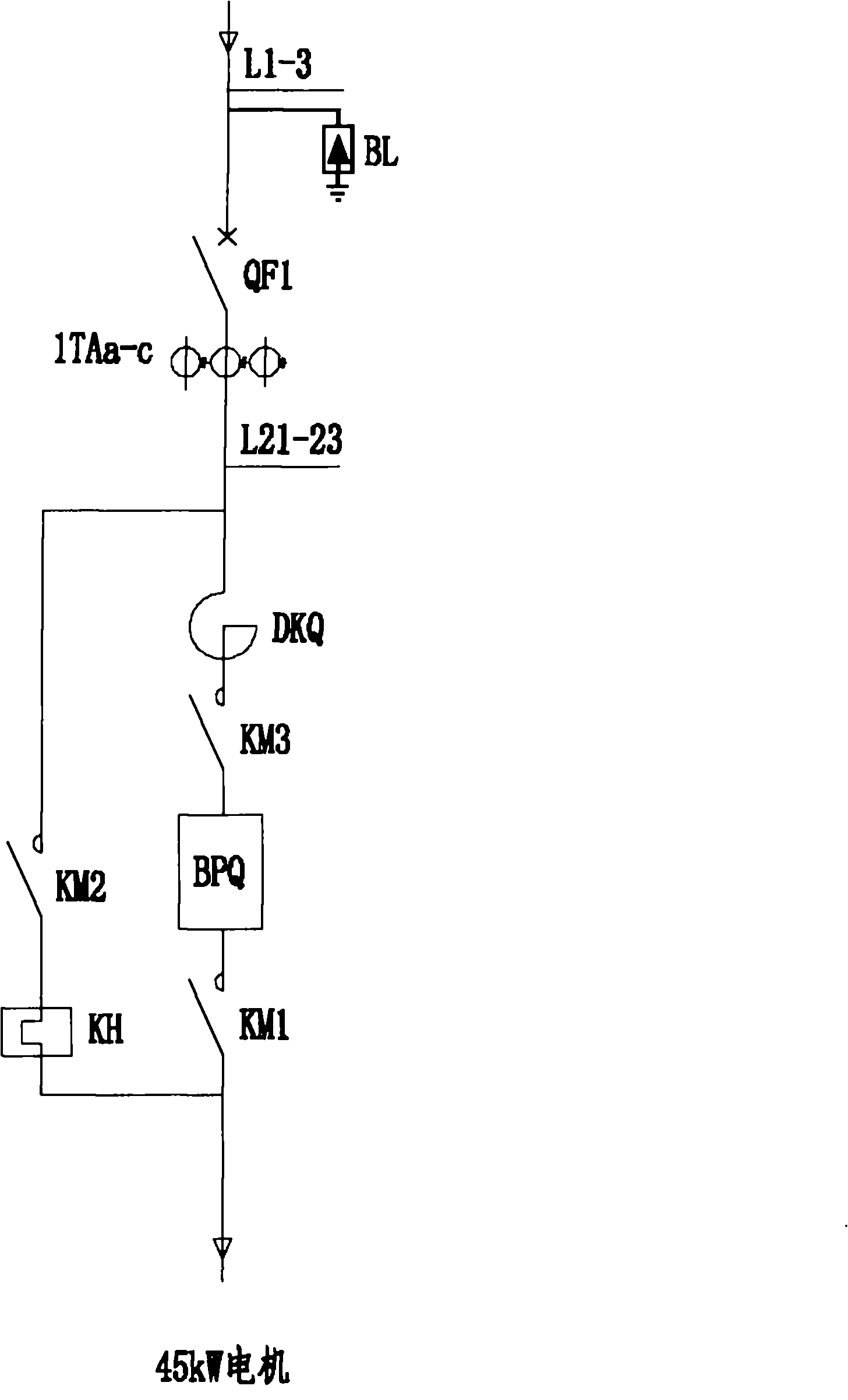

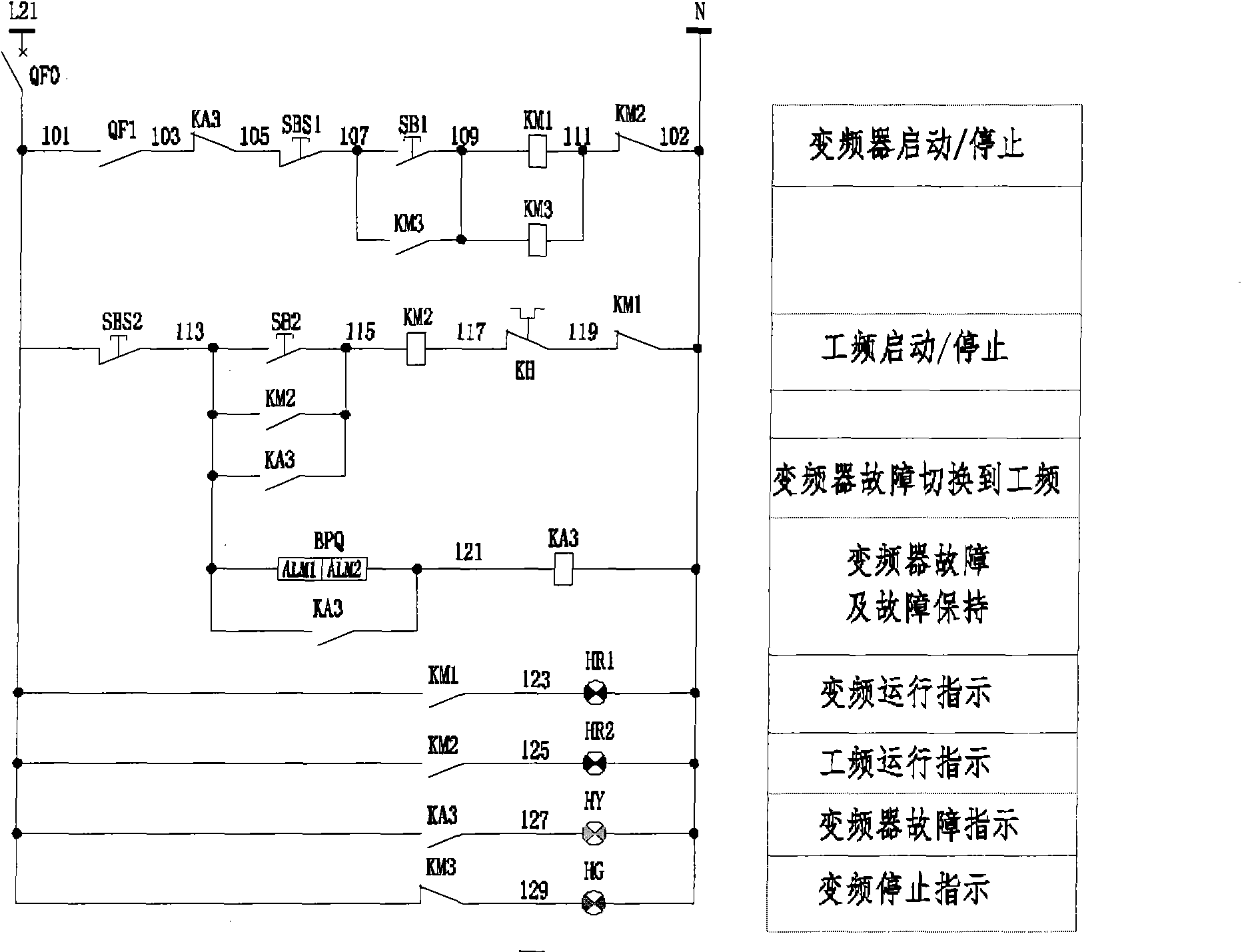

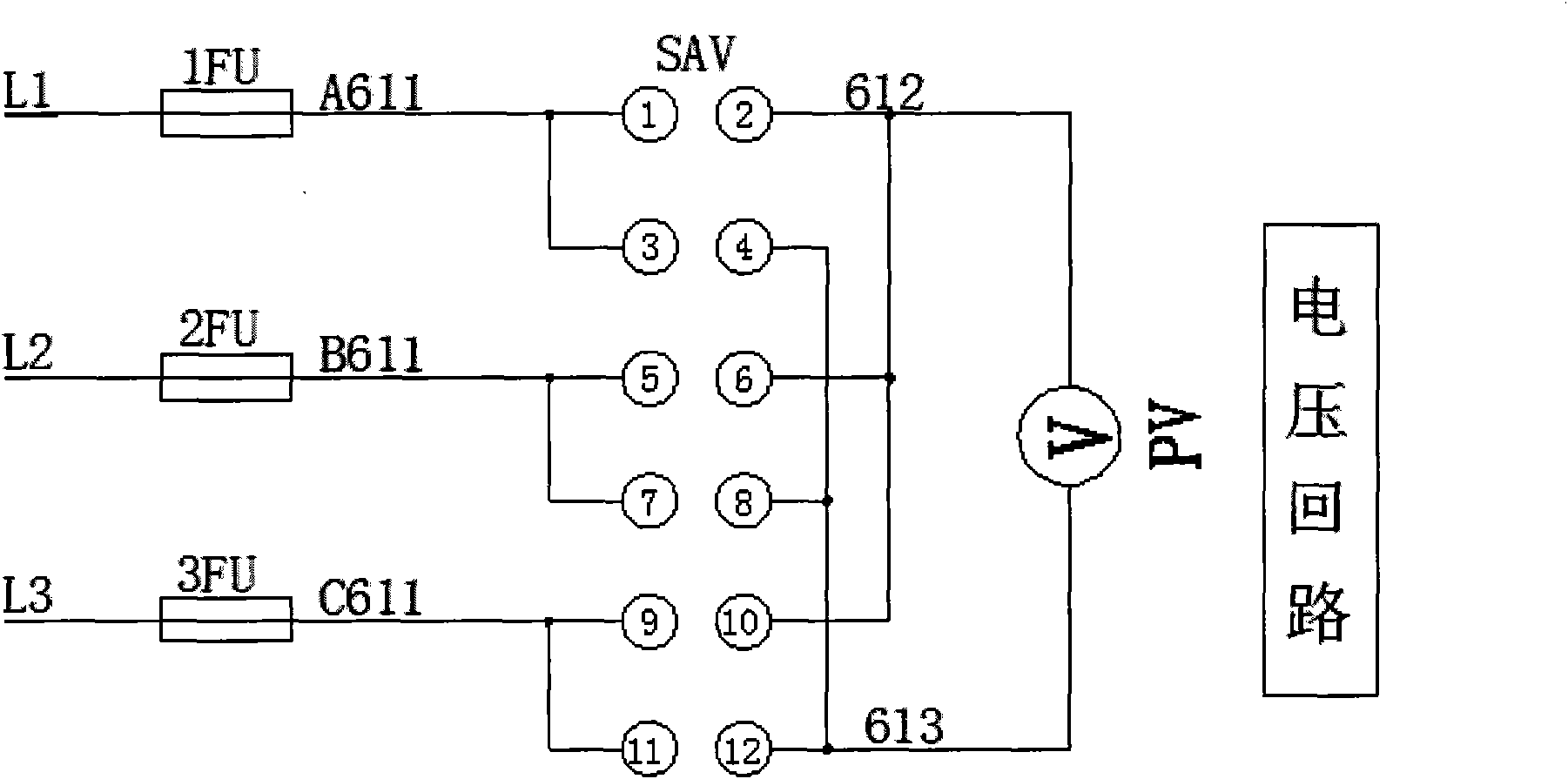

Frequency converting and energy saving device of oil pumping machine

InactiveCN101777762AIncrease productionImprove pump efficiencyReactive power adjustment/elimination/compensationReactive power compensationFrequency changerPower factor

The invention relates to a frequency converting and energy saving device of an oil pumping machine in the technical field of electronic control. The device comprises a breaker, a frequency converter, a current transformer, an input reactor, a first contactor, a second contactor, a third contactor and a thermal relay, wherein an external power supply is connected with the breaker, after the external power supply is controlled by the breaker, the external power supply is divided into two paths of circuits through the current transformer, and one path of the circuit is a frequency conversion loop, while the other path of the circuit is a power frequency loop; the frequency conversion loop firstly passes through the input reactor and then enters the frequency converter through the third contactor, and after the frequency conversion loop is subjected to frequency conversion through the frequency converter, the frequency conversion loop enters the first contactor; the power frequency loop comprises the second contactor and the thermal relay which are connected in series; and the whole power frequency loop and the frequency conversion loop are connected in parallel. The frequency converter is added in a control cabinet of the oil pumping machine so as to improve the output and the pump efficiency of an oil well, compensate the power factor, avoid impacts to power grid equipment when a motor is started and realize arbitrary jig frequency regulation and segmental rotating speed control.

Owner:上海德力西集团有限公司

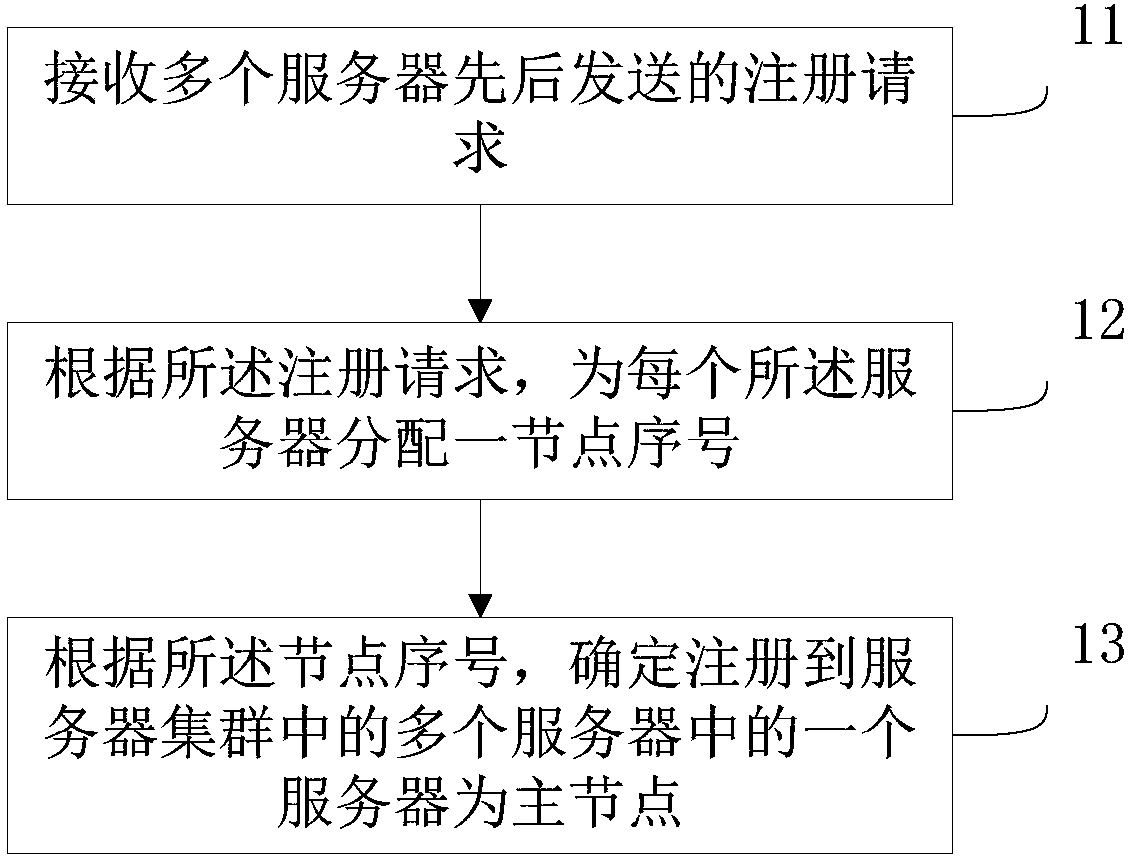

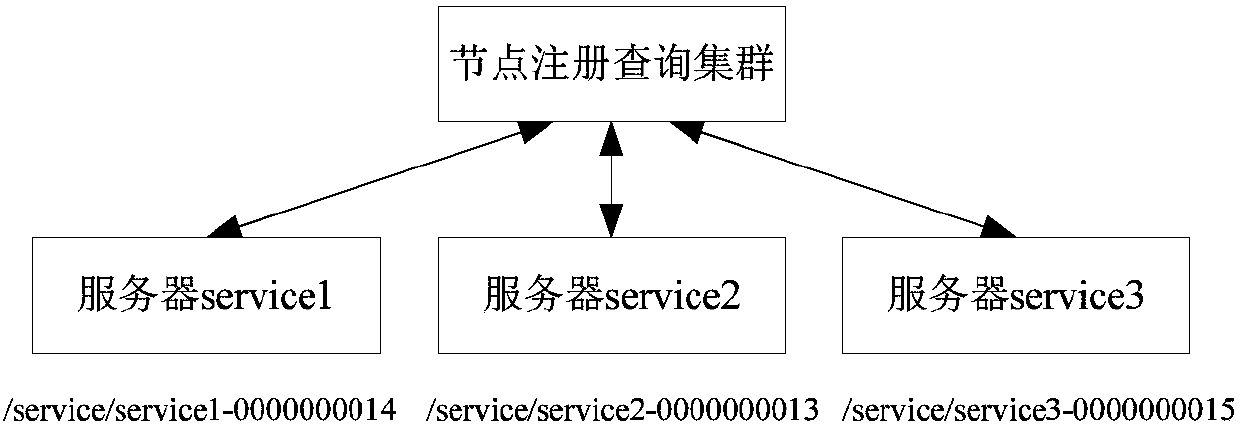

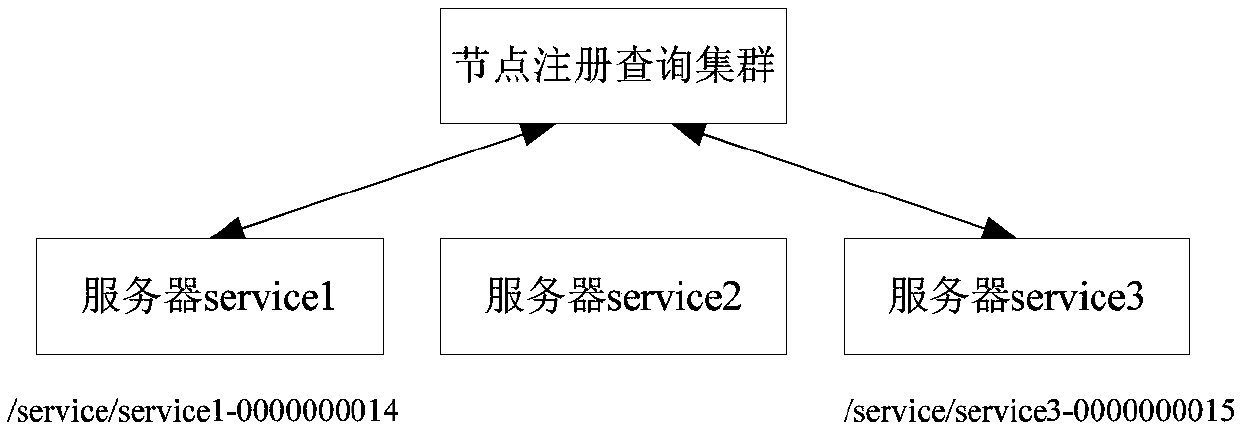

Method and device for determining master node in server cluster and server cluster

The embodiment of the invention provides a method and device for determining a master node in a server cluster and the server cluster. The method includes the following steps: receiving registration requests sent by multiple servers successively; assigning a node sequence number to each server according to the registration requests; and determining a server in the multiple servers registered to the server cluster as the master node according to the node sequence numbers. According to the scheme of the invention, the problems that service systems are out of service and cannot provide online services to the outside in the case that a single server has a single point of failure, and data corruption or result errors may be further caused when the multiple servers simultaneously work to processthe same piece of data can be avoided.

Owner:CHINA MOBILE COMM LTD RES INST +1

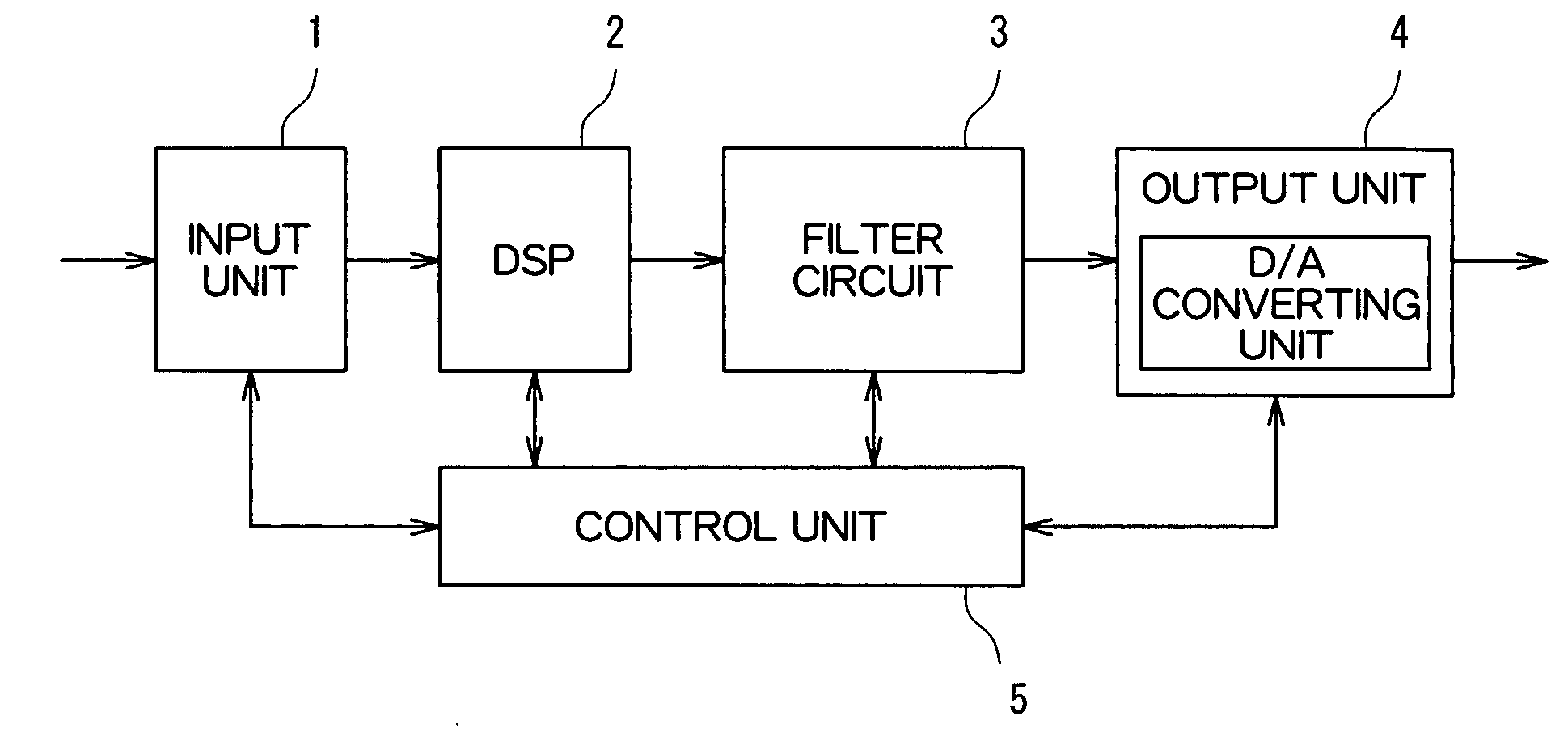

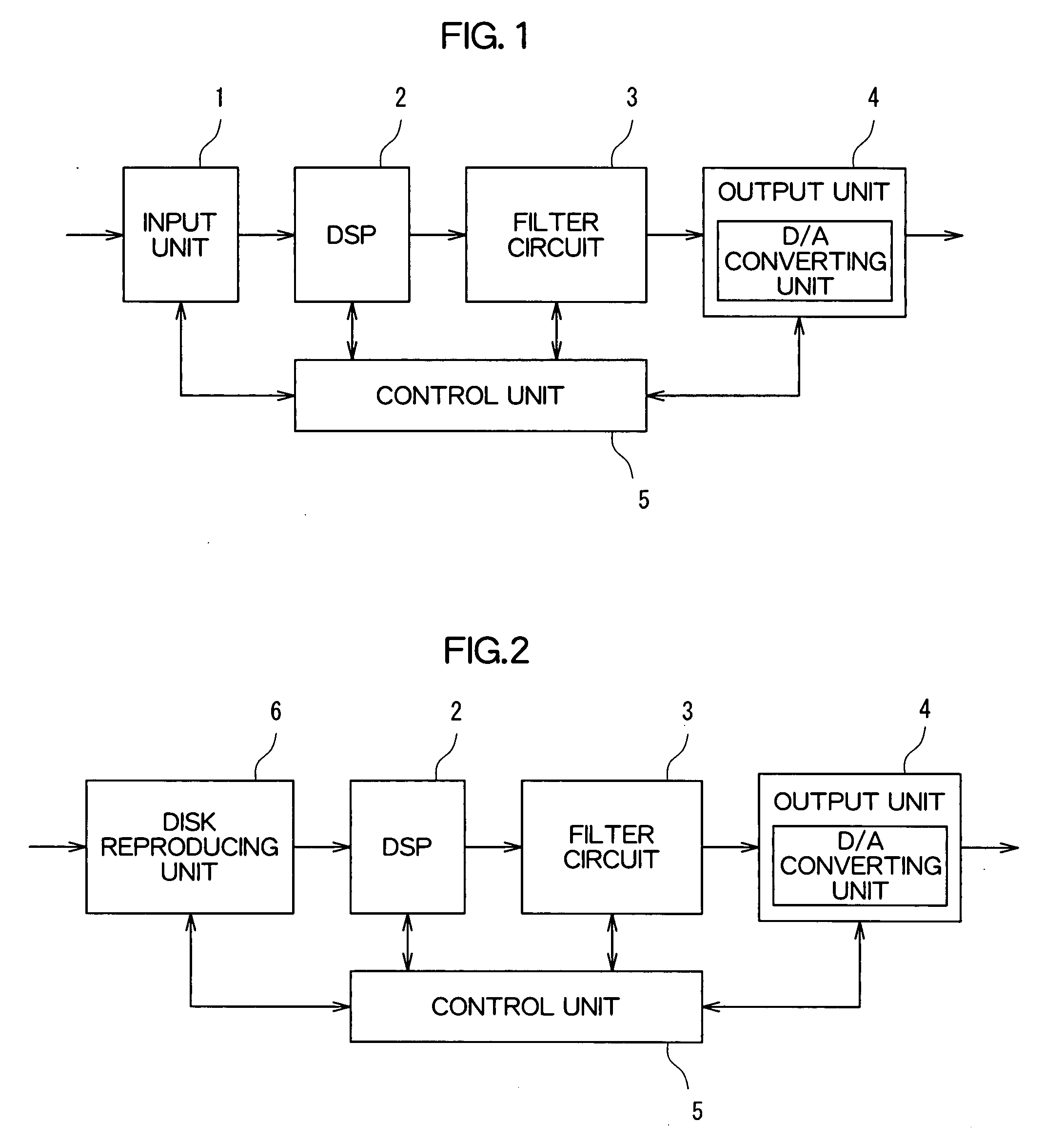

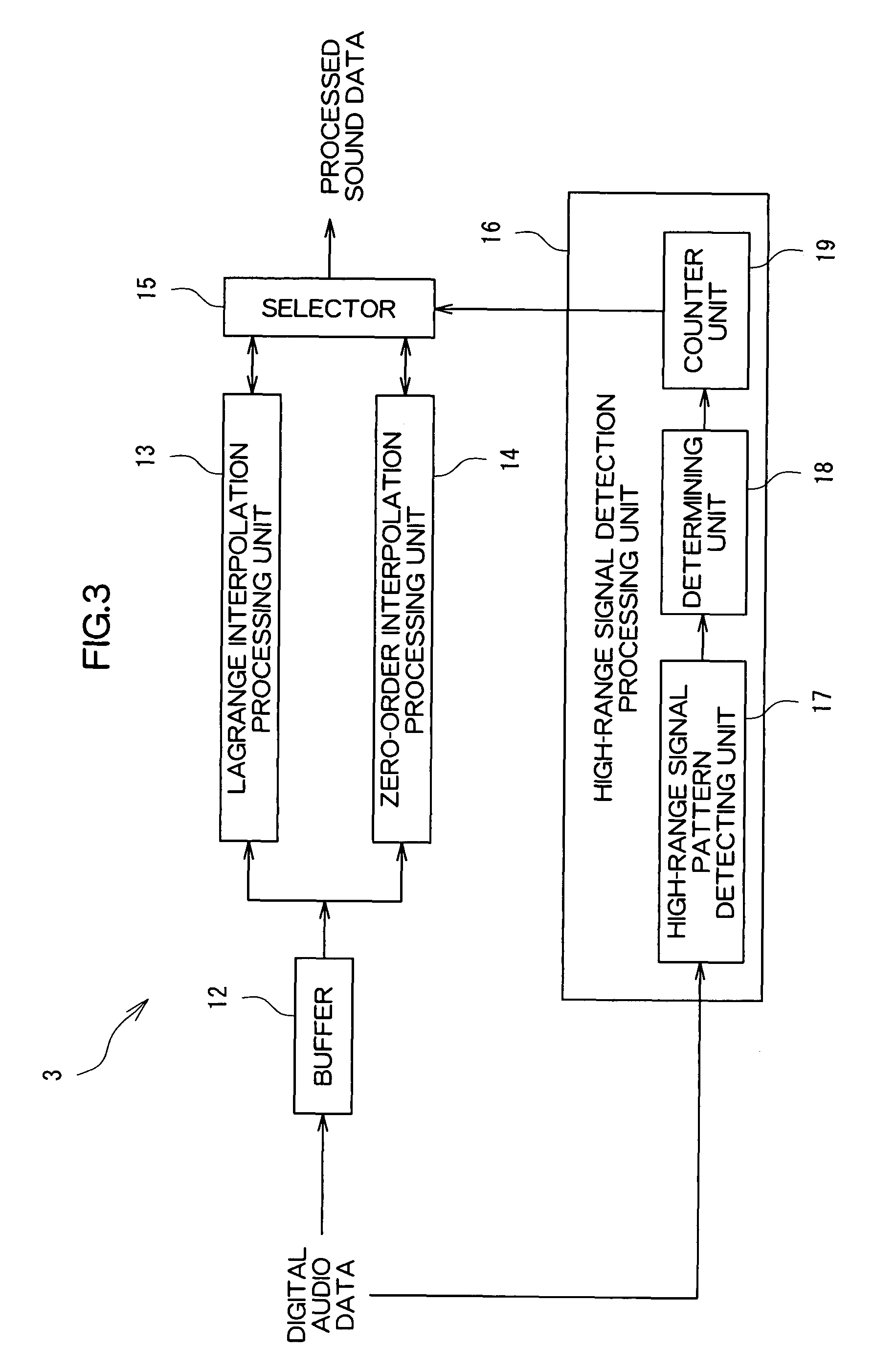

Auto Signal Output Device

ActiveUS20080288094A1Avoid signalingAvoid discontinuationAnalogue/digital conversionModification of read/write signalsElectrical polarityOutput device

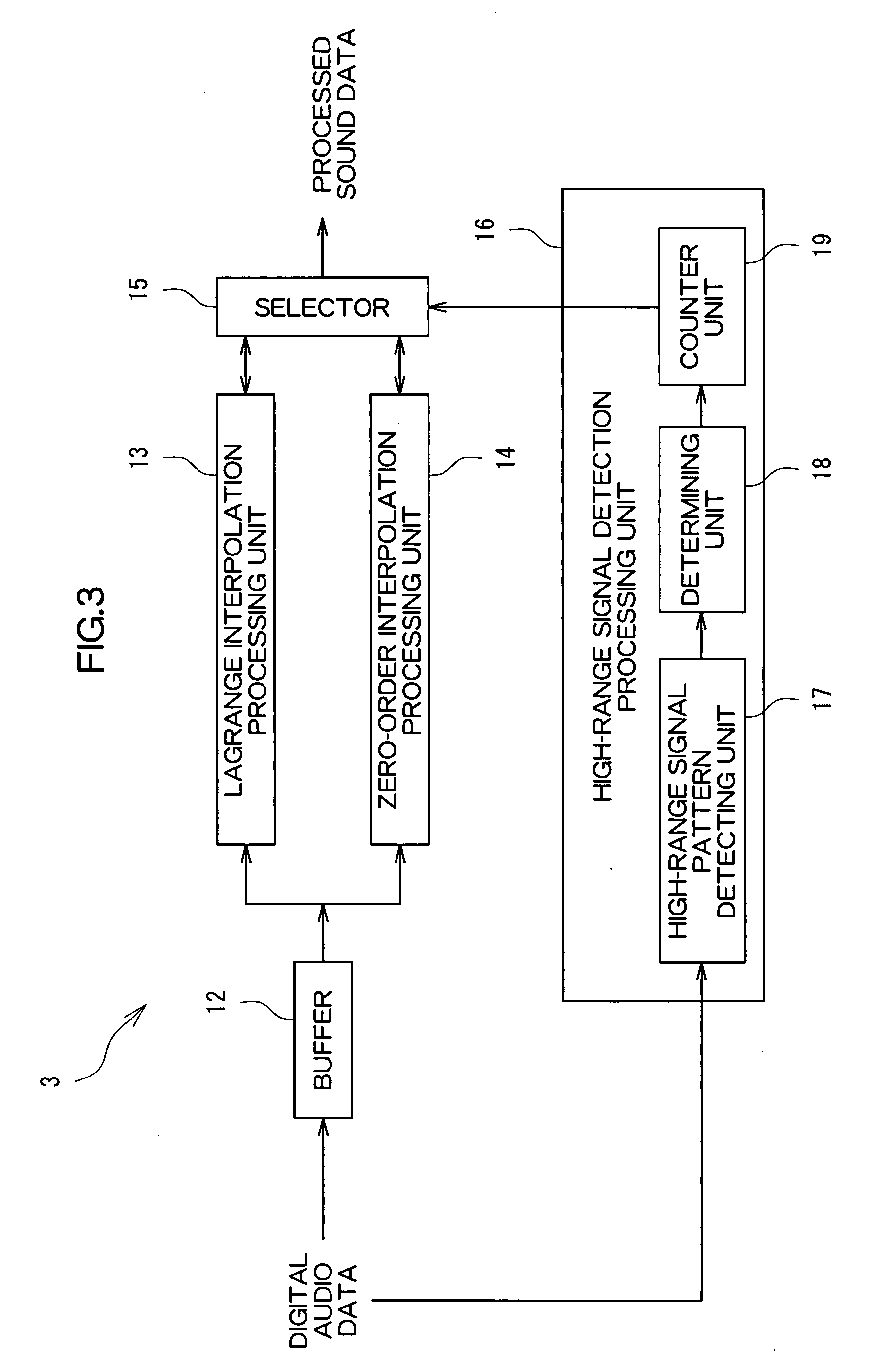

The present invention relates to an audio signal output device for outputting based on a digital audio signal. A judging unit judges the frequency of reversals in polarity of the digital audio signal. A selecting unit switches an output of the audio signal output device between an output based on a first interpolated digital audio signal obtained by interpolating the digital audio signal by way of a first interpolation processing and another output based on a second interpolated digital audio signal obtained by interpolating the digital audio signal by way of a second interpolation processing in response to a judgment result made by the judging unit.

Owner:D & M HOLDINGS INC

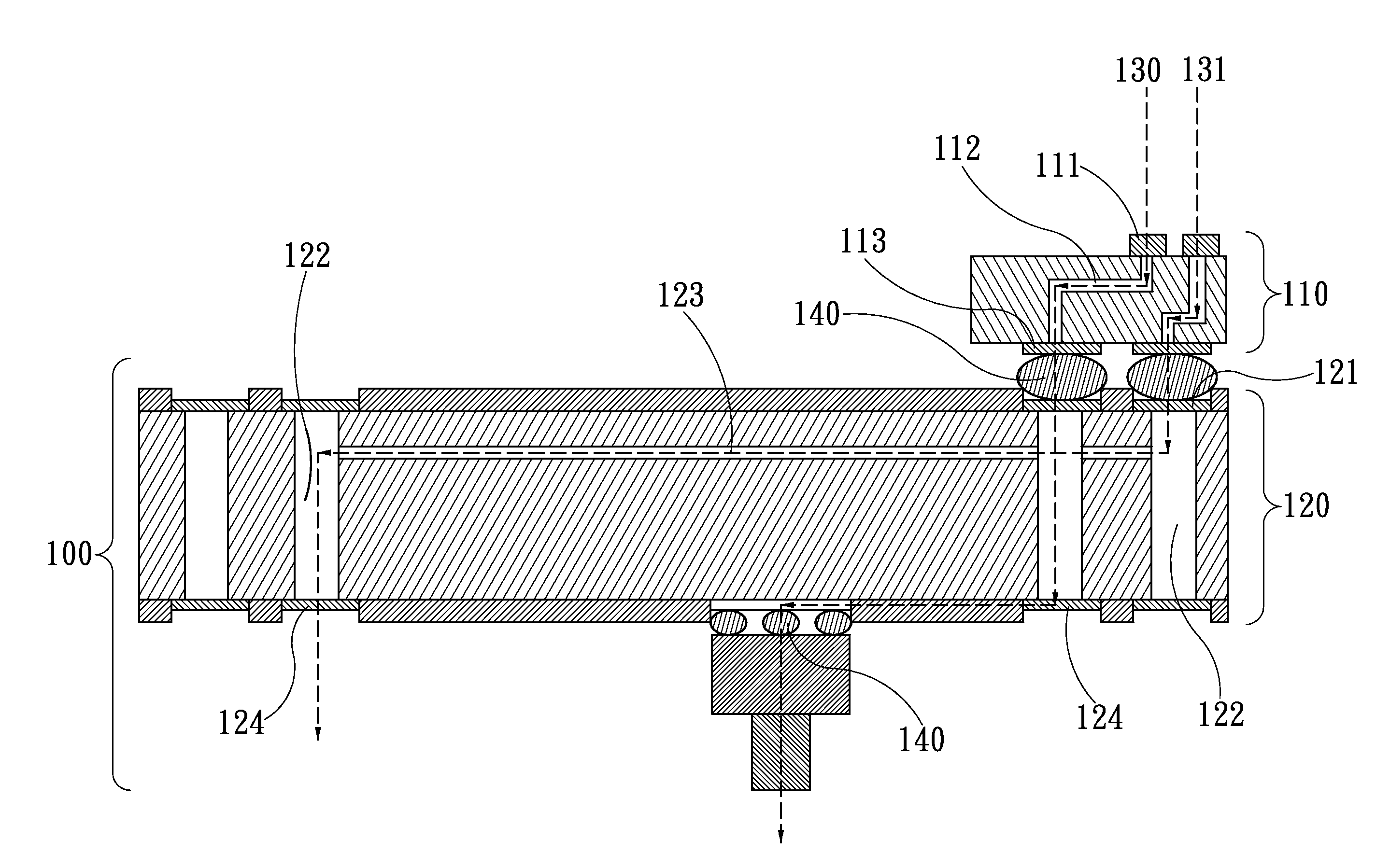

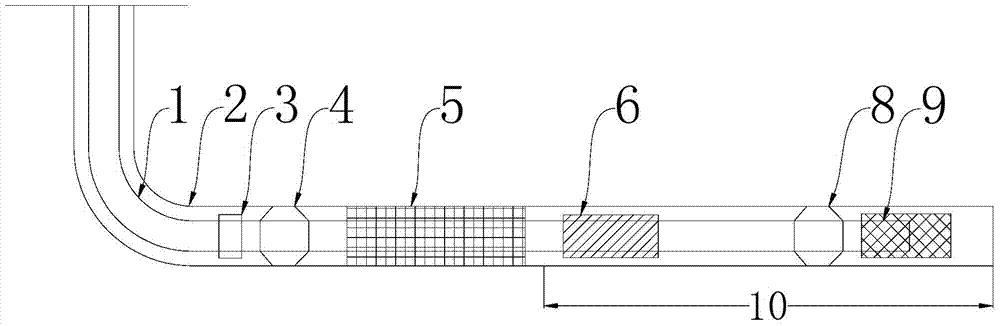

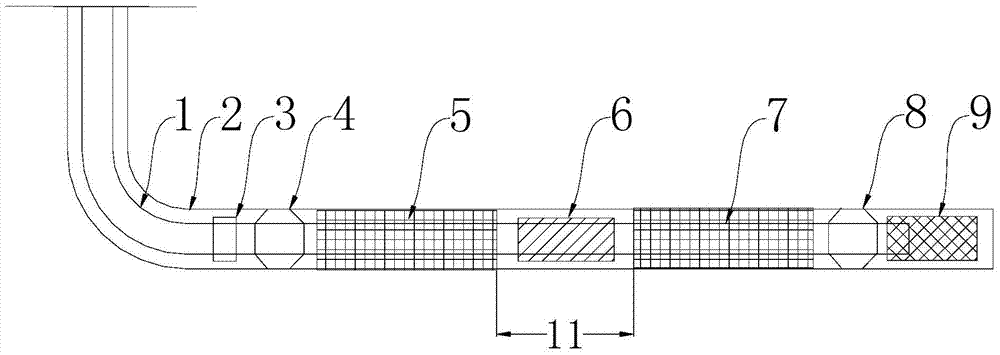

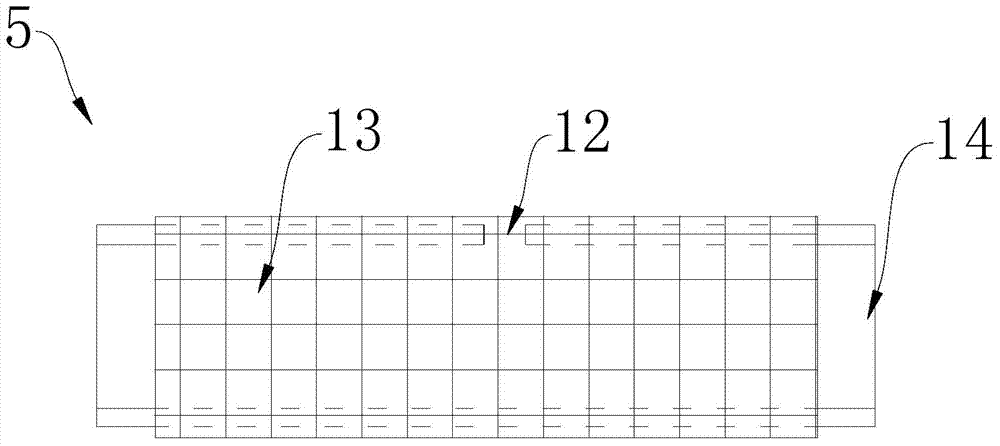

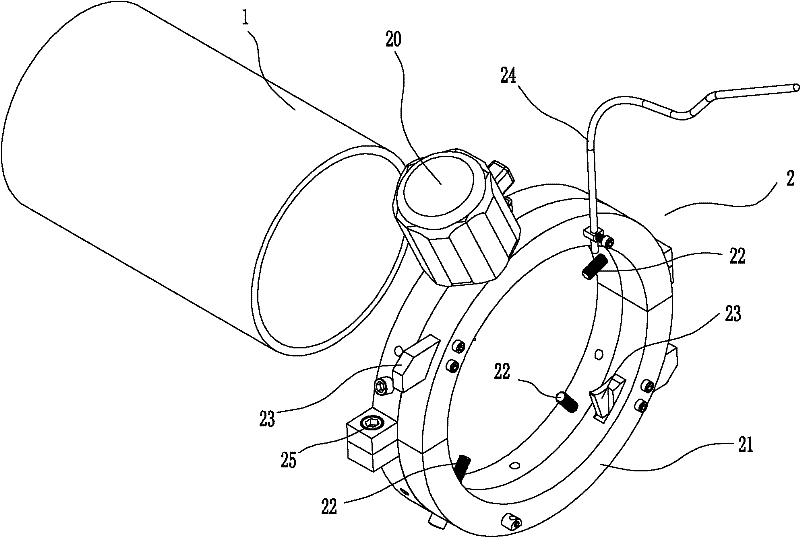

Pipe column for horizontal well

InactiveCN104120997AReduce harmAffect production capacityDrilling rodsSealing/packingPetroleum engineeringConstant pressure

The invention discloses a pipe column for a horizontal well. The pipe column comprises an oil pipe, a first centering guide, a first packer, a constant pressure valve, a second centering guide and a ball seat, wherein the first centering guide, the first packer, the constant pressure valve, the second centering guide and the ball seat are sequentially arranged on the oil pipe in a sleeved mode, and the ball seat is used for blocking off the oil pipe. The first packer comprises a first center pipe and a first rubber sleeve, wherein the first center pipe is communicated with the oil pipe and provided with a first flow guide hole for applying pressure on the first rubber sleeve. The inlet end of the constant pressure valve is communicated with the oil pipe. The inner diameter of the first rubber sleeve of the first packer is 58-62 mm, and the length of the first rubber sleeve of the first packer is 950-1200 mm. According to the pipe column, after pressure is applied on the interior of the oil pipe, the first packer is downed and sealed so that a water exit interval and an oil interval can be effectively separated, and then the constant pressure valve is opened to inject a chemical blocking agent in a set direction to block off the water exit interval. According to the pipe column, water exploration can be carried out, the water exit interval and the oil interval can be effectively separated, the influence of the chemical blocking agent on the oil interval is reduced, and water control and oil increase of the horizontal well are achieved.

Owner:PETROCHINA CO LTD

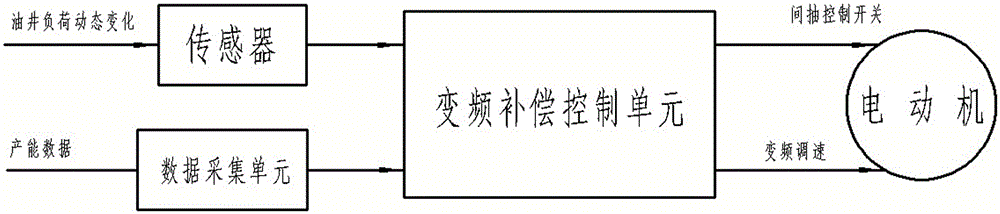

Frequency-conversing compensating and energy saving control apparatus of oil pumping unit in oil fields

InactiveCN105007022AIncrease productionImprove reliabilityAC motor controlFluid removalFrequency changerClosed loop feedback

The invention discloses a frequency-conversing compensating and energy saving control apparatus of an oil pumping unit in oil fields. The apparatus is composed of a motor, a sensor, a data acquisition unit, and a frequency-conversing compensating control unit. The sensor and the data acquisition unit transmit the collected data signals to the frequency-conversing compensating control unit. The shut down or starting of the motor is controlled by the frequency-conversing compensating control unit through a discontinuously-pumping control switch, and the speed of the motor is changed by frequency conversion and speed regulation. The frequency-conversing compensating control unit is controlled by a closed loop feedback system, and is composed of a frequency converter, a programmable logic controller (PLC), a temperature control module, a position detection module, a brake module, an operation panel and a parameter adjusting panel. The energy saving effect is realized by controlling the discontinuously-pumping and frequency conversion and speed regulation of the motor of the oil pumping unit through the frequency-conversing compensating control unit. The technical scheme of the invention employs the frequency conversion control, ensures the accurate match of an output power of the motor and load demands, and dynamically adjusts the pumping speed according to a real feed flow capability of oil wells. The electric energy is saved, the crude oil output is increased, and the service life of the apparatuses is prolonged.

Owner:安徽钟南电器有限责任公司

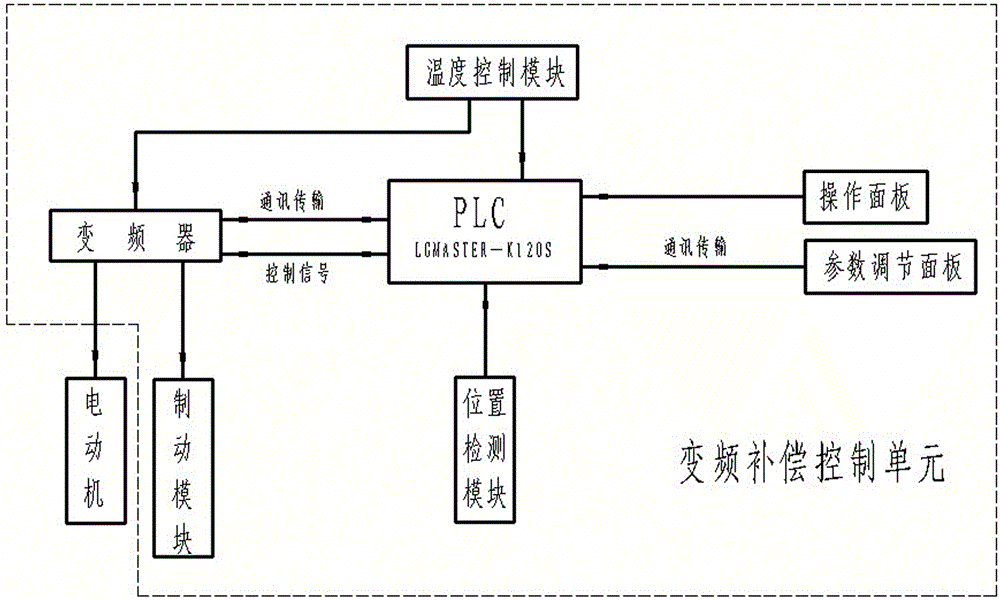

Adaptive interpolation in upsampled audio signal based on frequency of polarity reversals

ActiveUS8160887B2Avoid signalingAvoid discontinuationAnalogue/digital conversionModification of read/write signalsElectrical polaritySelf adaptive

Digital audio sample data are adaptively processed for interpolation based on whether the frequency at which the digital audio signal samples reverse polarity is at least equal to a predetermined threshold, the threshold being determined by their sampling frequency. If so, the digital audio signal samples are subjected to zero-order interpolation, with zero-inserting between the samples followed by lowpass filtering; if not, the samples are subjected to Lagrange (spline) interpolation processing.

Owner:D & M HOLDINGS INC

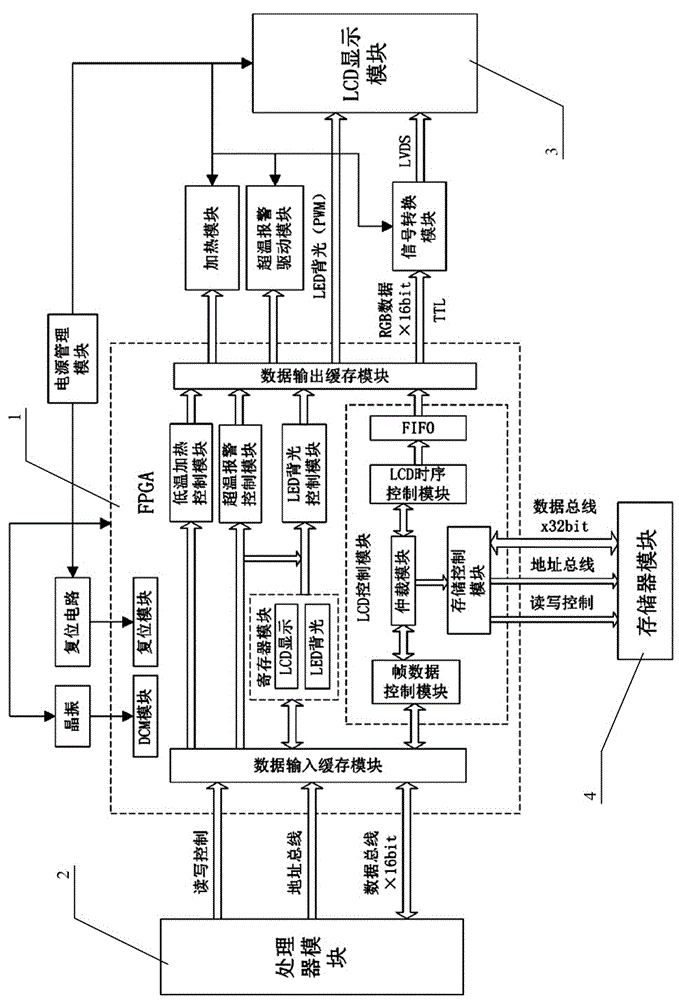

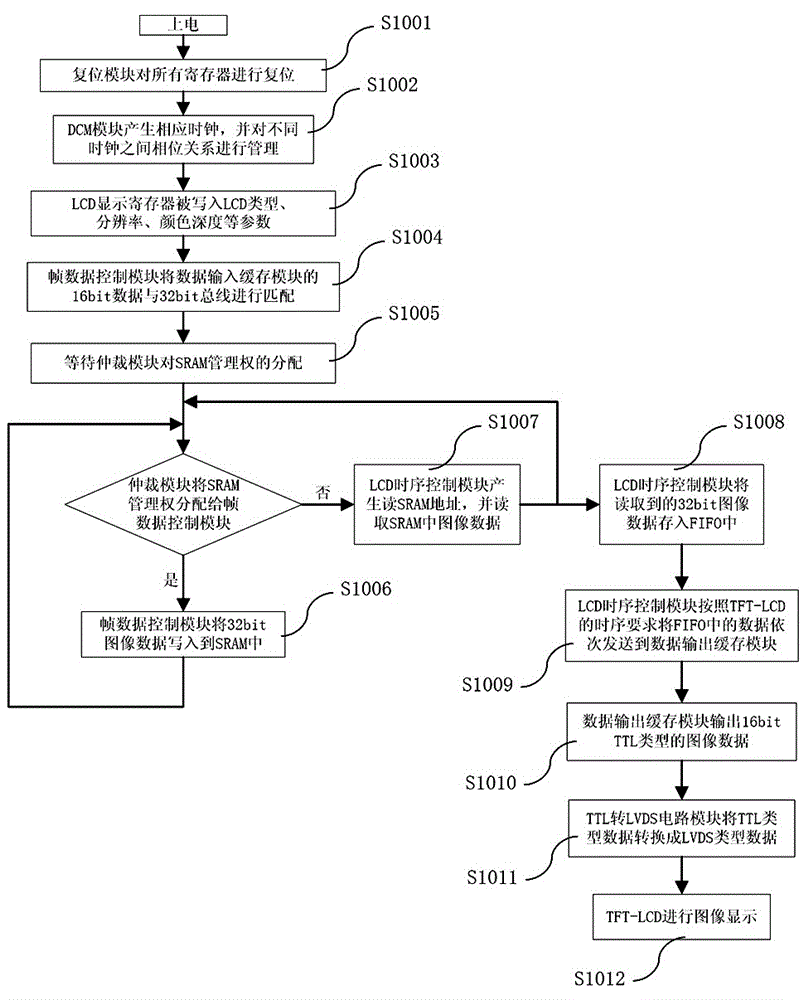

Locomotive vehicle display control apparatus, system and method

ActiveCN106469543AReduce loadSimple structureStatic indicating devicesLocomotivesControl systemProgrammable logic device

The invention discloses a locomotive vehicle display control apparatus, system and method. The apparatus is based on a programmable logic device and comprises an LCD control module used for performing read-write control on data output by a processor module and outputting the data to an LCD display module; a low-temperature heating control module used for driving an external heating module to generate heat to heat the LCD display module when the temperature of the locomotive vehicle display control system is lower than a heating limit value; an over-temperature alarm control module used for driving an external over-temperature alarm driving module to perform over-temperature alarm when the temperature of the locomotive vehicle display control system is higher than a high temperature limit value; and an LED backlight control module used for generating PWM signals according to the change of the ambient brightness and outputting the PWM signals to the LCD display module for brightness adjustment. According to the apparatus, system and method, technical defects that in the prior art, a lot of processor resources need to be occupied, the universality and the practicality are not high, and purchase and halt production risks exist in key devices are overcome.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

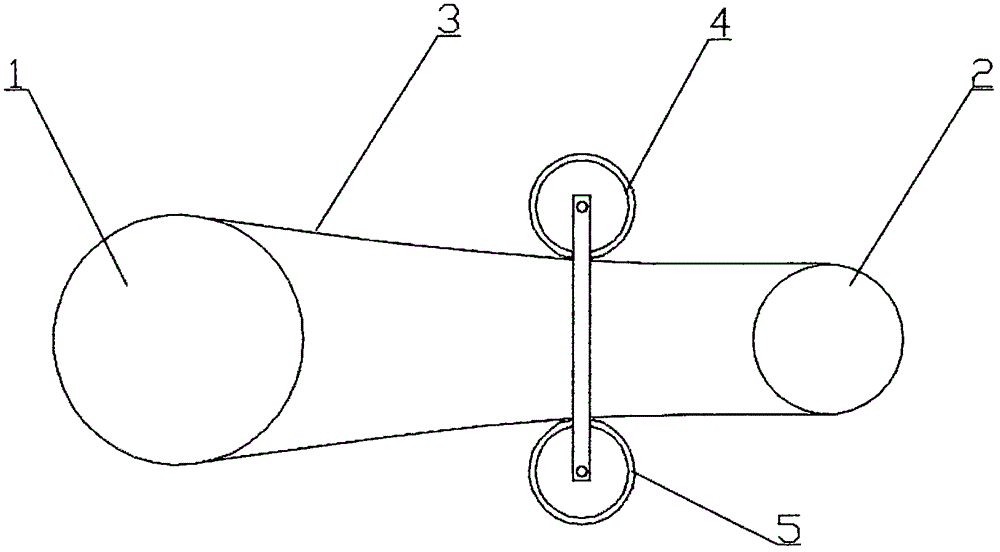

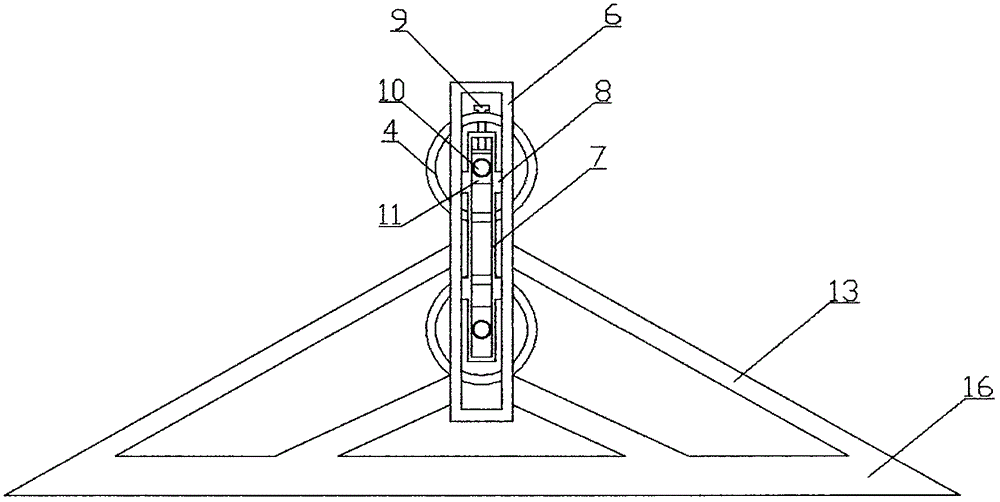

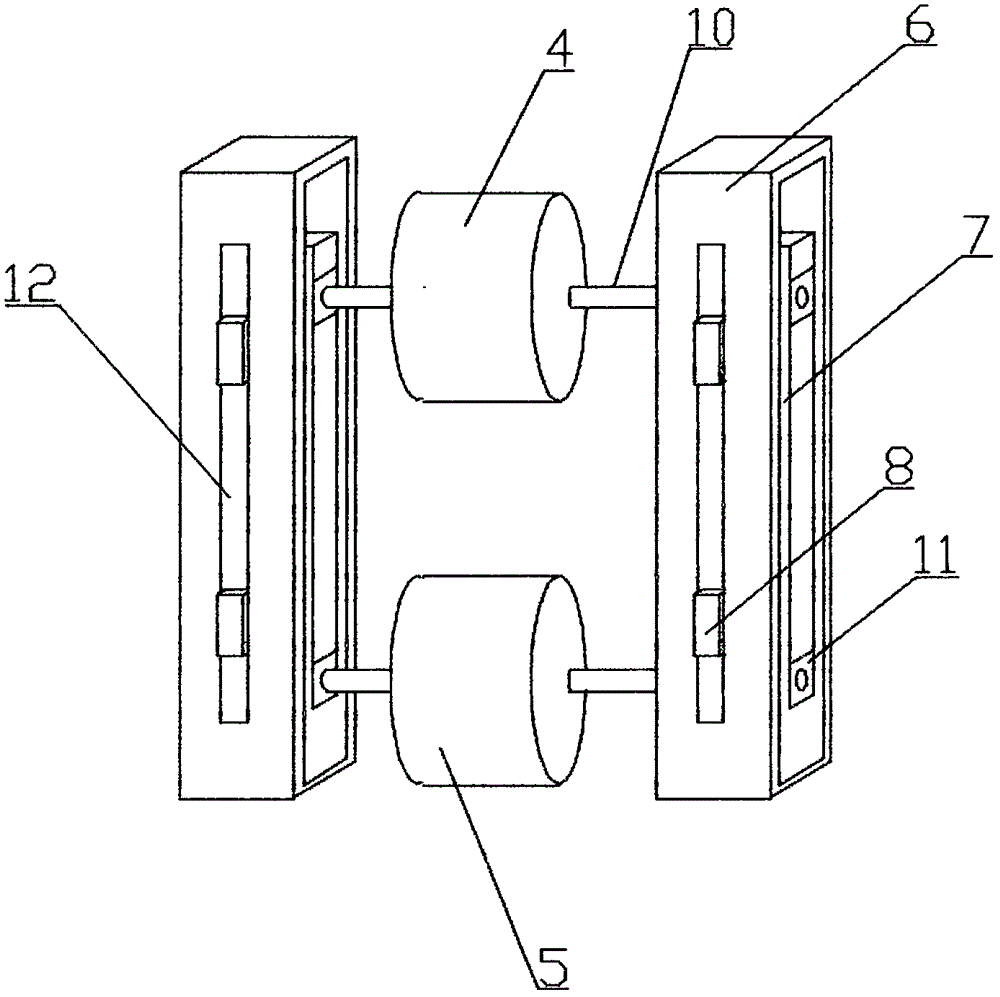

Belt wrap angle adjusting device for pumping unit

The invention discloses a belt wrap angle adjusting device for a pumping unit. The belt wrap angle adjusting device comprises a belt and a belt pressing device. The belt pressing device comprises an upper pressing wheel arranged on the upper side of the belt, and a lower pressing wheel arranged on the lower side of the belt. A wheel track adjusting device used for adjusting the distance between the upper pressing wheel and the lower pressing wheel is arranged between the upper pressing wheel and the lower pressing wheel. The tension degree of the belt is improved through extrusion of the upper pressing wheel and the lower pressing wheel, the wrap angle of the belt on a motor belt wheel and a speed reducer belt wheel is increased, the phenomenon of slippage of the belt is avoided, and oil well halt production due to belt damage caused by belt slippage is avoided.

Owner:东营市鑫瑞达工贸有限公司

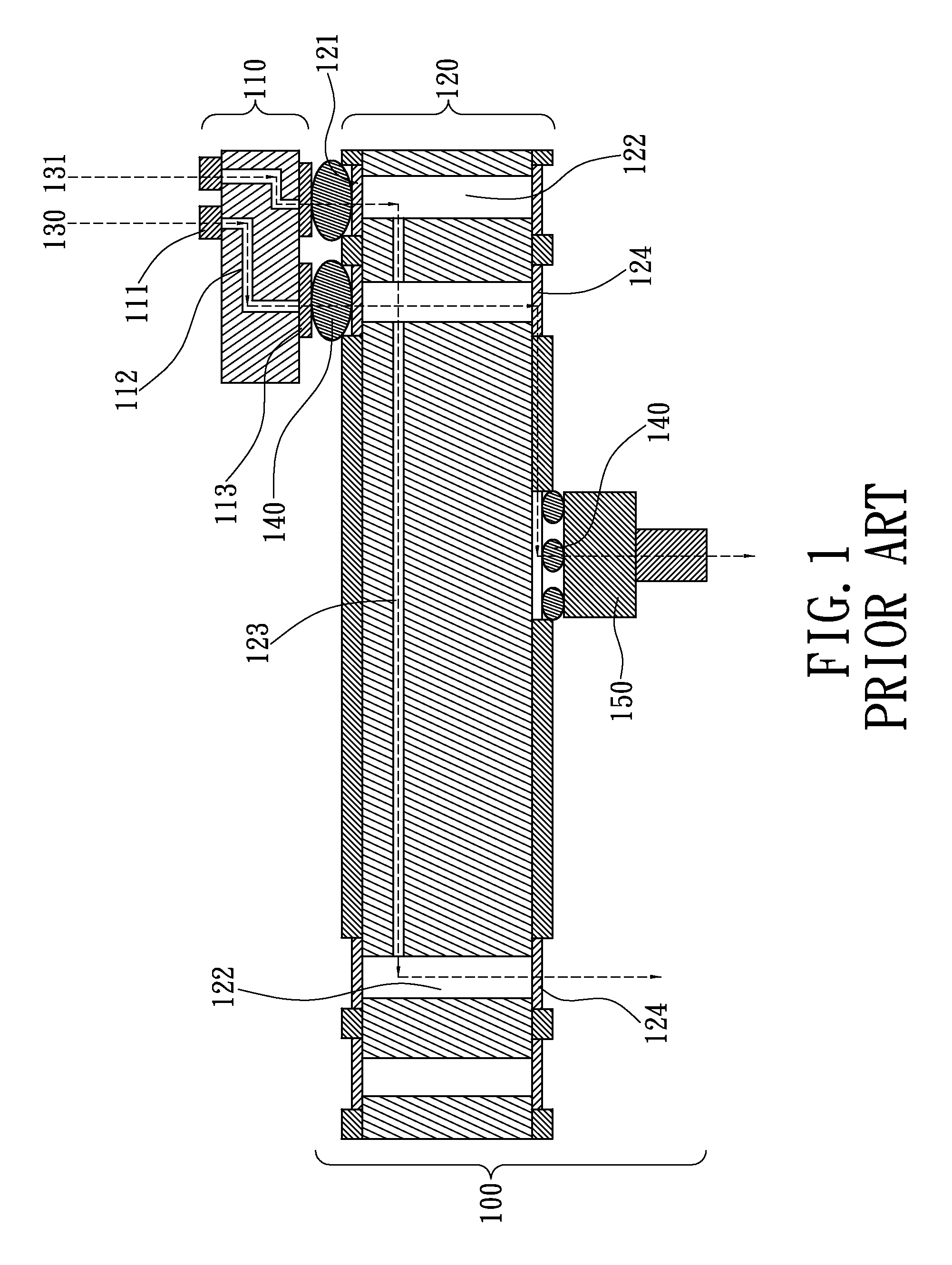

Vertical probe card

ActiveUS8264249B2High impedanceAvoid discontinuationElectrical measurement instrument detailsContactless circuit testingProbe cardEngineering

The present invention provides on IC test substrate for testing various signals, a combined flexible and rigid PCB included in the structure is applicable to perform a mission including for example: stabilizing power input / output, signal transfer by a connector; general, power, and high frequency signal transmission in preserved integrity state.

Owner:CHUNGHWA PRECISION TEST TECH

Insert high-precision stamping and bending die

ActiveCN113696408AAct as a barrierPlay a cleaning roleDirt cleaningCleaning using toolsStructural engineeringBrush

The invention discloses an insert high-precision stamping and bending die. A hydraulic driving rod is fixedly installed at the bottom of a stamping machine, wherein the bottom end of the hydraulic driving rod is fixedly connected with a lifting plate, a stamping block is arranged at the middle portion of the bottom end of the lifting plate, and a stamping die cavity is formed in the position, corresponding to the stamping block, of the top of a machining platform. According to the insert high-precision stamping and bending die, the hydraulic driving rod is used for driving the lifting plate and the stamping block to move downwards, then the stamping block can stamp and cut workpieces so that the workpieces can enter the stamping die cavity, metal contact pins at one sides of the workpieces are bent, part of sweeps can fall off in the stamping processes, a movable baffle plays a role in blocking the bent workpieces, thus sweeps and the workpieces all stay in the stamping die cavity, after the workpieces are taken away, an electric telescopic rod drives the movable baffle to slide towards the interior of a movable groove, and a cleaning brush plays a cleaning role on the surface of the movable baffle, so that the surface of the movable baffle is kept clean, and the sweeps remaining on the surface of the movable baffle can be swept and fall into a collecting box to be stored.

Owner:福益柯汽车系统(上海)有限公司

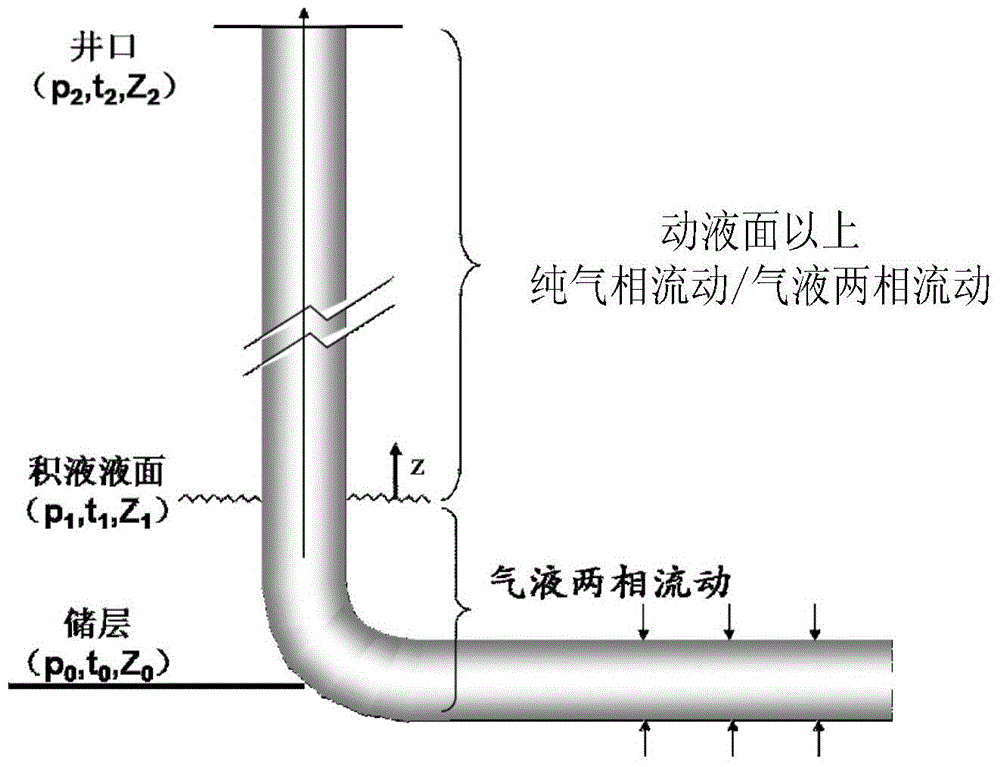

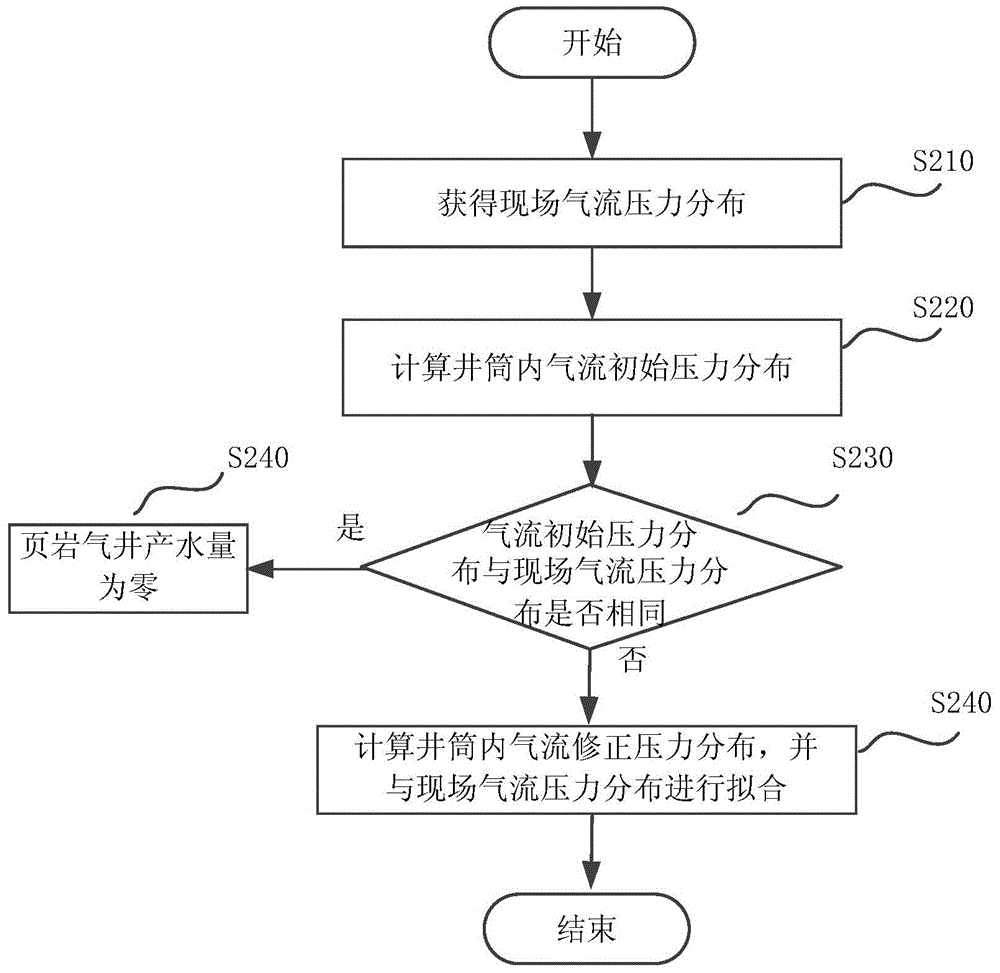

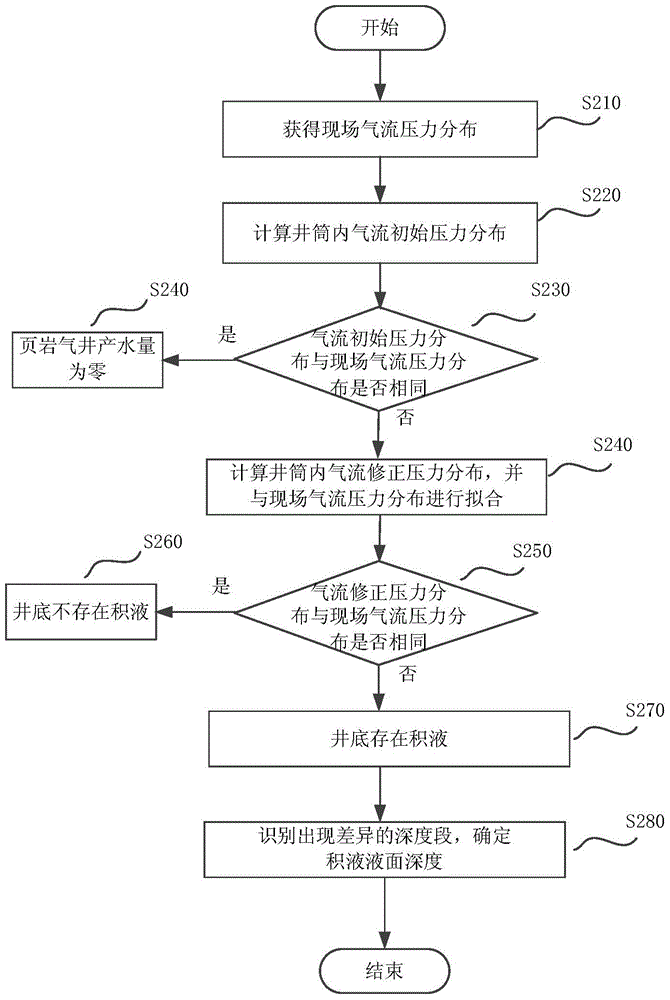

Determination method of producing water for shale gas well, determination method of accumulated liquid and liquid drainage method

ActiveCN106401570ALower bottom hole pressureAvoid discontinuationSurveyFluid removalShale gasProduced water

The invention discloses a determination method of producing water for a shale gas well, a determination method of accumulated liquid and a liquid drainage method.The determination method of producing water for the shale gas well comprises following steps: sampling pressure of airflows at different depths in a shaft on the construction site and obtaining on-site airflow pressure distribution; setting liquid-carrying quantities of airflows at different depths in the shaft as zero and calculating initial airflow pressure distribution in the shaft; comparing whether the initial airflow pressure distribution obtained by calculations is the same as the on-site airflow pressure distribution; determining the water-producing quantity in the shale gas well as zero if it is the same; and setting liquid-carrying quantities of airflows at different depths in the shaft if not, calculating the modified pressure distribution in the shaft, matching the modified airflow pressure distribution obtained by calculations with the on-site airflow pressure distribution and obtaining water producing quantity of the shale gas well. The determination method of producing water for the shale gas well, the determination method of accumulated liquid and the liquid drainage method have following beneficial effects: determinations can be made as to whether accumulated liquid exists in a well bottom of the shale gas well; the height of accumulated liquid in well bottom of the shale gas well can be calculated; and influence of accumulated liquid on production is analyzed.

Owner:CHINA PETROLEUM & CHEM CORP +1

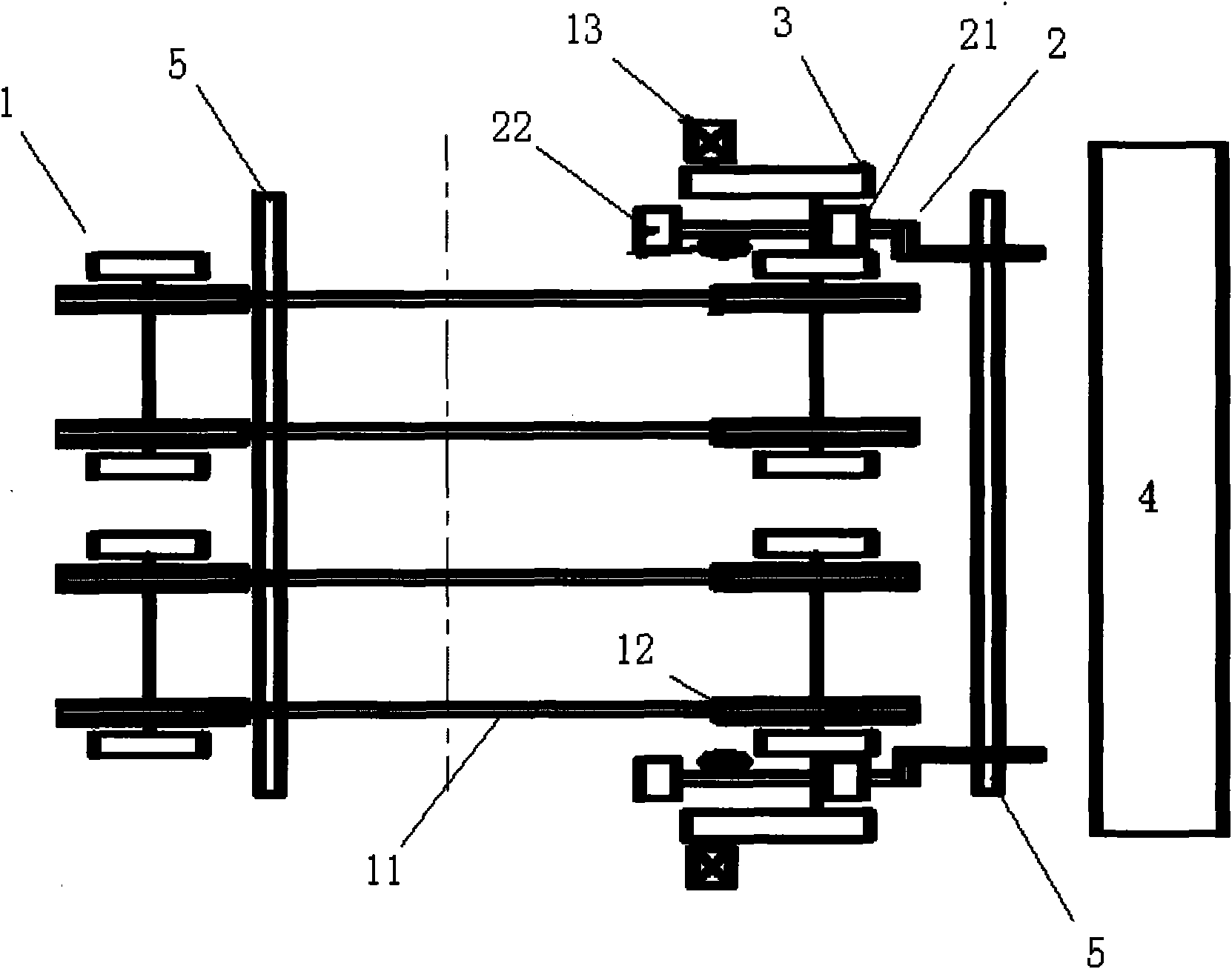

Compact feeding skid steel receiving device

InactiveCN101671775ASmall footprintSolve feeding difficultiesFurnace typesHeat treatment furnacesEngineeringSprocket

The invention discloses a compact feeding skid steel receiving device comprising a steel removing machine and a steel sending machine, wherein the steel removing machine comprises a chain, a chain wheel and an electric motor, the chain is surrounded on the chain wheel, and the chain wheel is connected with the electric motor; the steel sending machine comprises a steel sending skid and an air cylinder, and the rotating shaft of the steel sending skid is connected with the air cylinder; one end of the chain is arranged at a steel billet feeding part, and the other end is matched with a materialreceiving end of the steel sending skid; and a material sending end of the steel sending skid is arranged at the mouth of a heating furnace. The invention has compact structure, effectively saves site areas for factories, and has fewer devices and smooth steel receiving compared with the traditional feeding system.

Owner:NANJING IRON & STEEL CO LTD

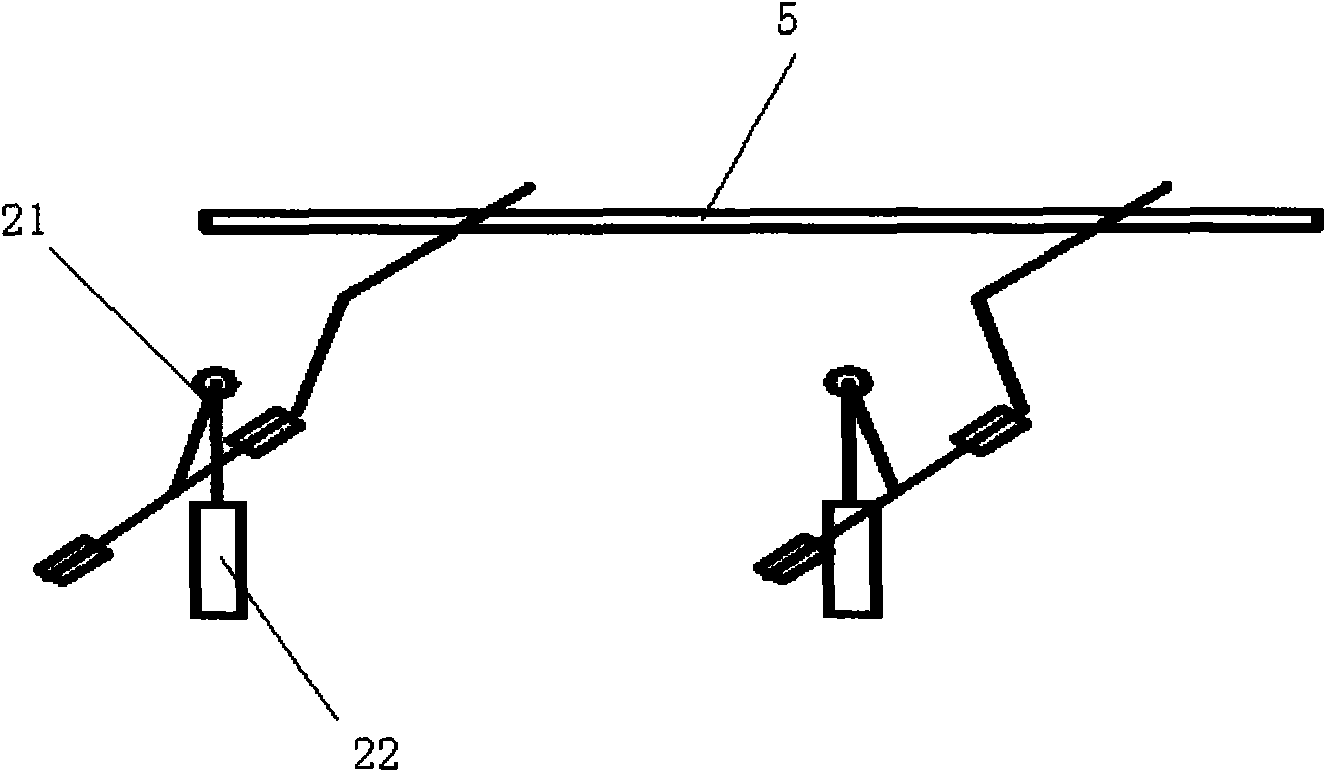

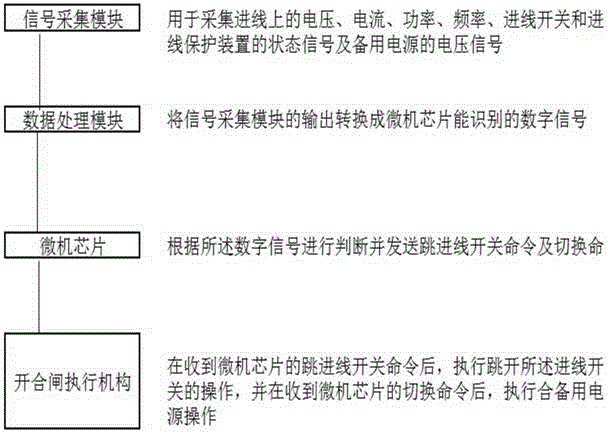

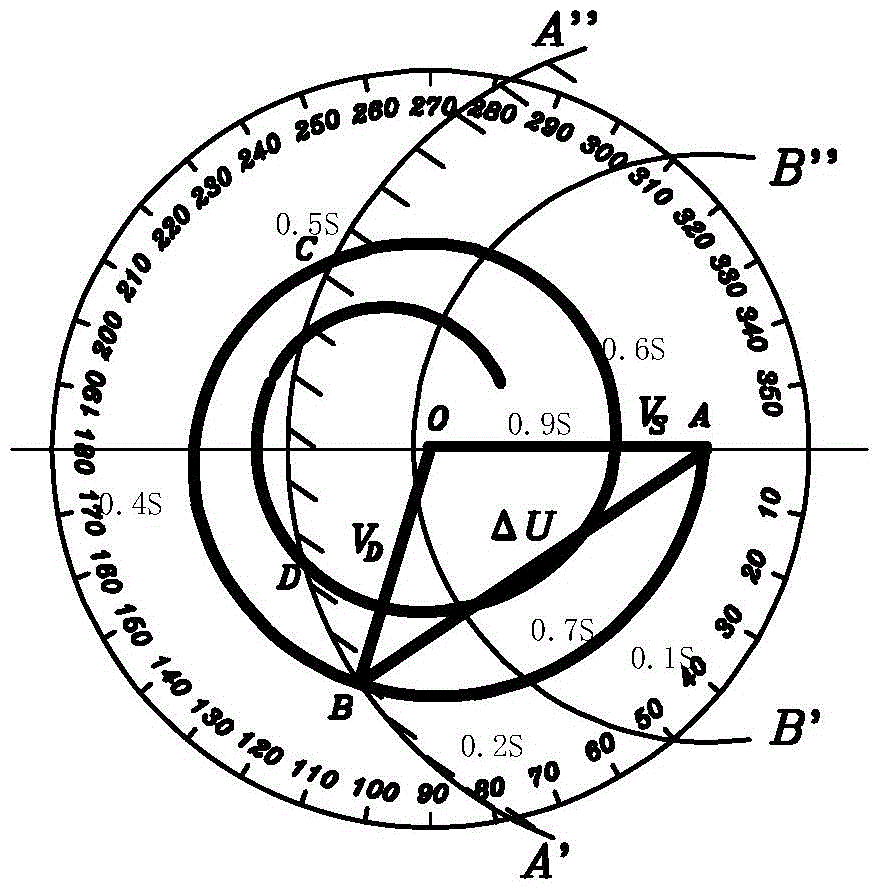

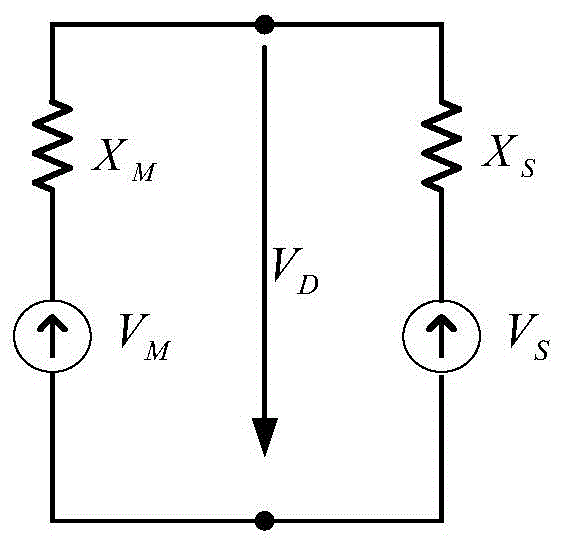

Rapid switching device for 110kV power system of petrochemical enterprises

InactiveCN104539039AProcessing speedDetect fault conditionsPower network operation systems integrationInformation technology support systemMicrocomputerElectric power system

Provided is a rapid switching device for a 110kV power supply system of petrochemical enterprises. The rapid switching device comprises a microcomputer chip, and the microcomputer chip determines whether a reverse power starting condition, a zero-current starting condition, a voltage-loss starting condition, a tripping error starting condition and a protection starting condition are satisfied; if the tripping error condition is satisfied, a switching operation is started, and whether the other conditions are satisfied are further determined successively; if any condition except the tripping error condition is satisfied, an incoming switch tripping command is emitted, the switching operation is started, and whether a rapid switching condition, a same-period capture switching condition, a residual voltage switching condition and a long delay switching condition are satisfied is determined successively; if one of the condition is satisfied, determination is stopped, and a corresponding switching command, namely a rapid switching command or a same-period capture switching command or a residual voltage switching command or a long time delay switching command, is transmitted. Thus, the 110kV power supply system of petrochemical enterprises can be stably switched between a working power supply and a standby power supply.

Owner:CHINA PETROCHEMICAL CORP

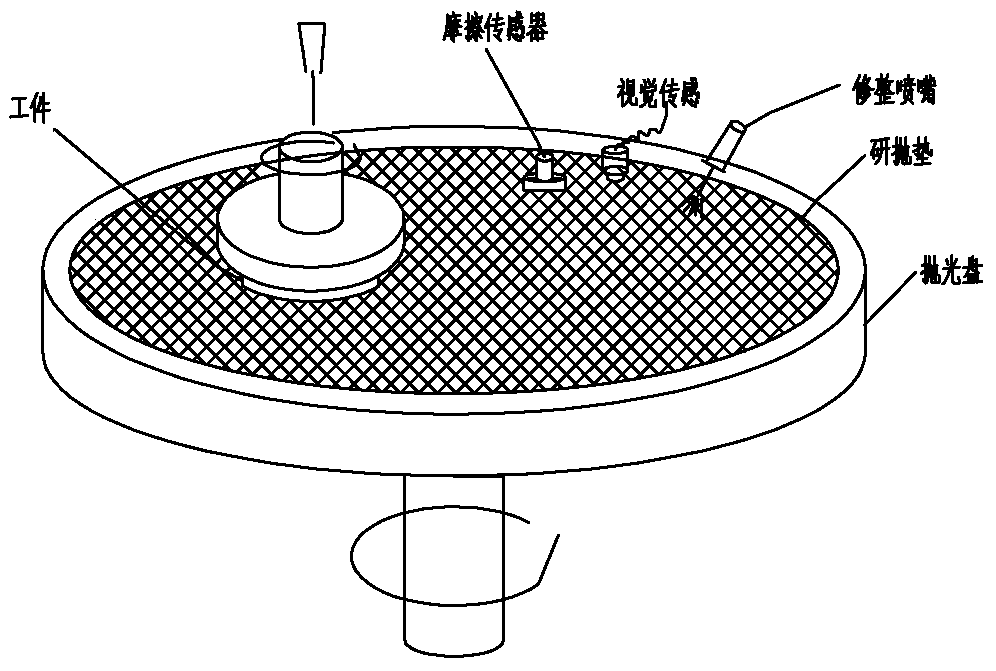

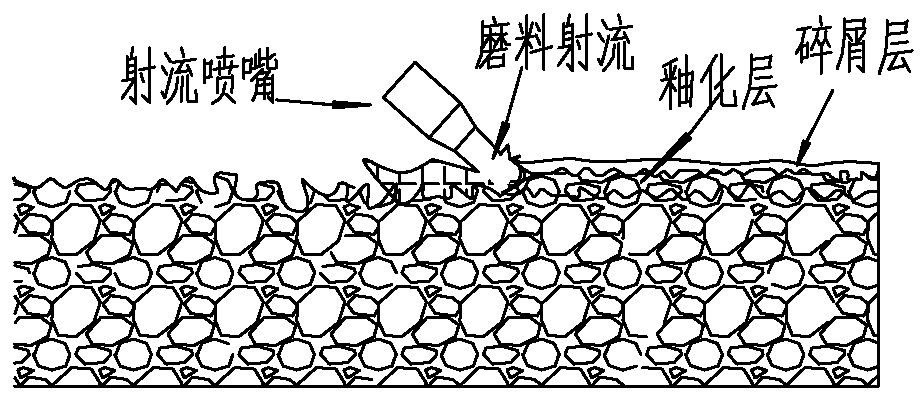

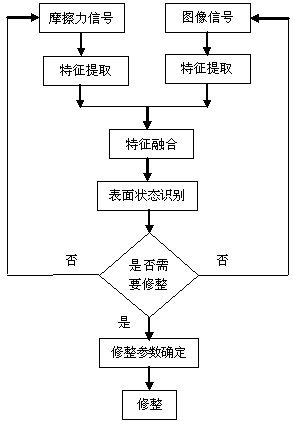

Abrasive jet flow adaptive dressing method for consolidating abrasive polishing pad

ActiveCN108500843AAchieving Adaptive Dressing ControlImprove trimming effectGrinding feed controlAbrasive surface conditioning devicesFeature extractionSelf adaptive

The invention discloses an abrasive jet flow adaptive dressing method for consolidating an abrasive polishing pad. The abrasive jet flow adaptive dressing method for consolidating the abrasive polishing pad is characterized that the abrasive jet flow adaptive dressing method for consolidating the abrasive polishing pad comprises the following steps that firstly, the characteristics of different surface states of the polishing pad, such as a sharp state and a passivation state, are obtained by image recognition; the characteristics of different surface states of the polishing pad are obtained by friction signals; secondly, an artificial neural network is established to obtain the mapping relationship between image and friction characteristics and machining efficiency and quality; and thirdly, on-line measurement of the image, friction signal and feature extraction are carried out in the actual processing, then, according to the processing requirement, self-adaptive judgment is carried out on whether the polishing pad needs to be dressed or not and what kind of dressing parameters are used. The abrasive jet flow adaptive dressing method for consolidating the abrasive polishing pad has high dressing efficiency, can be carried out in time, and can obviously improve the polishing quality.

Owner:HENAN INST OF SCI & TECH

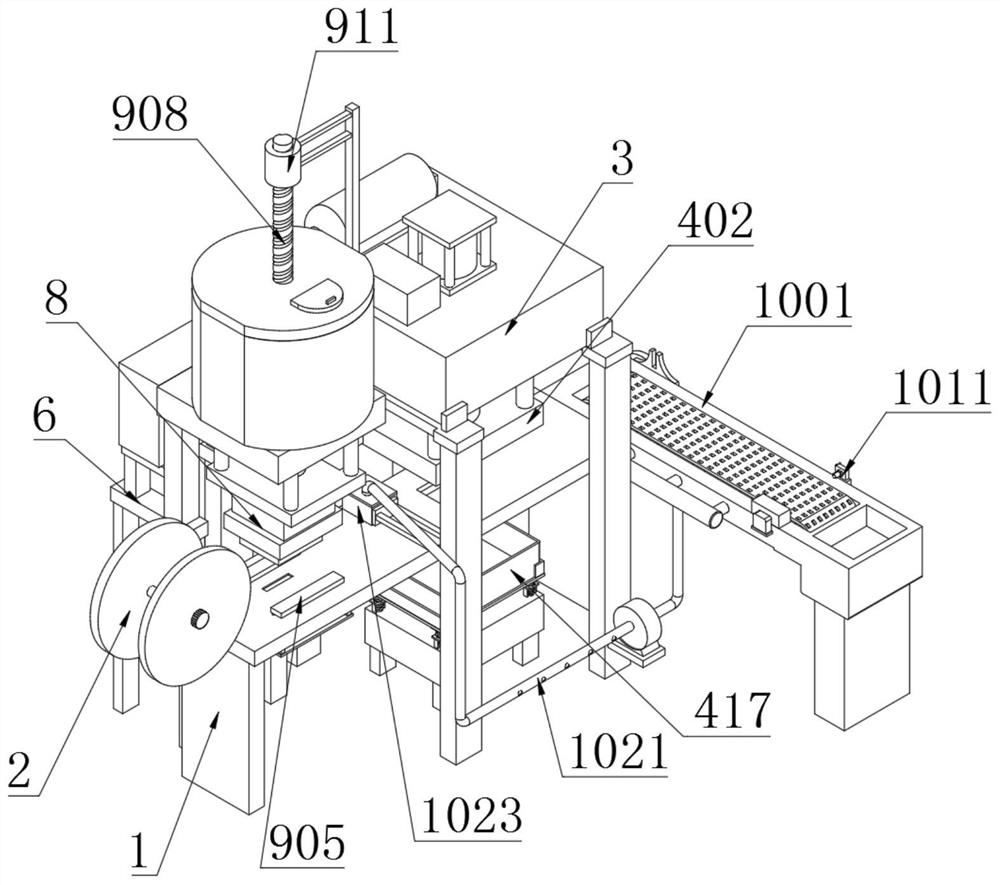

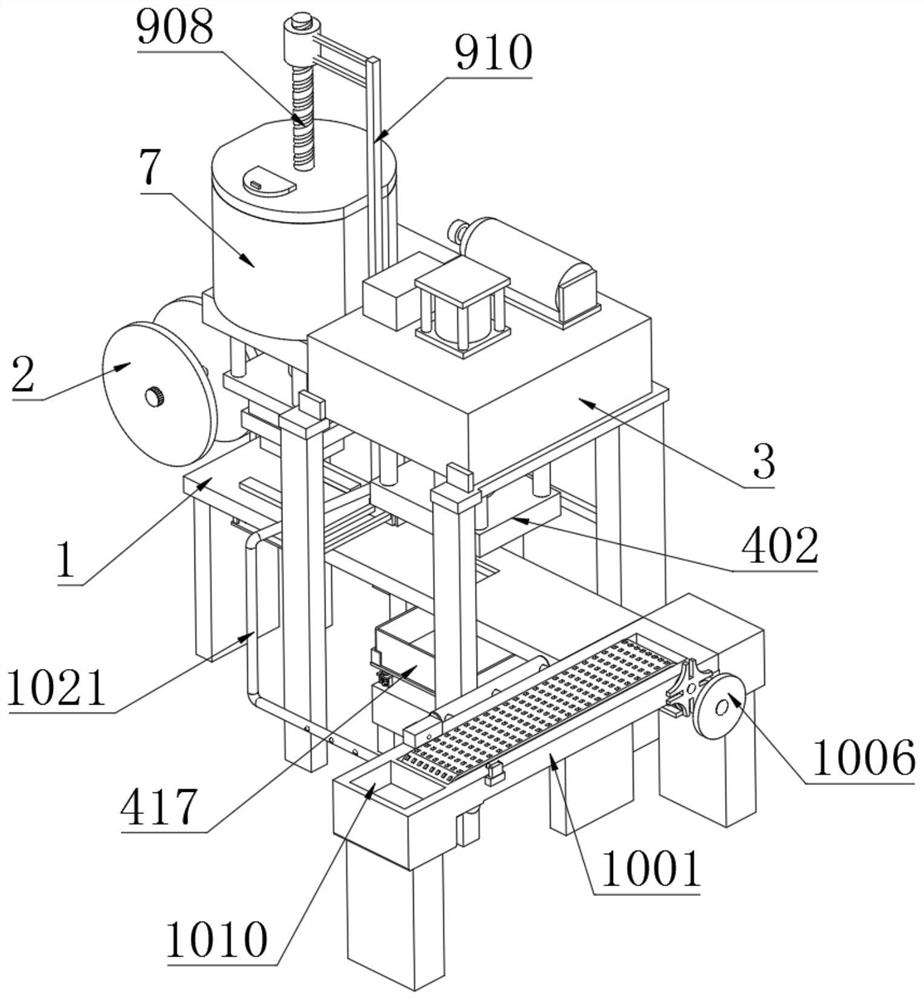

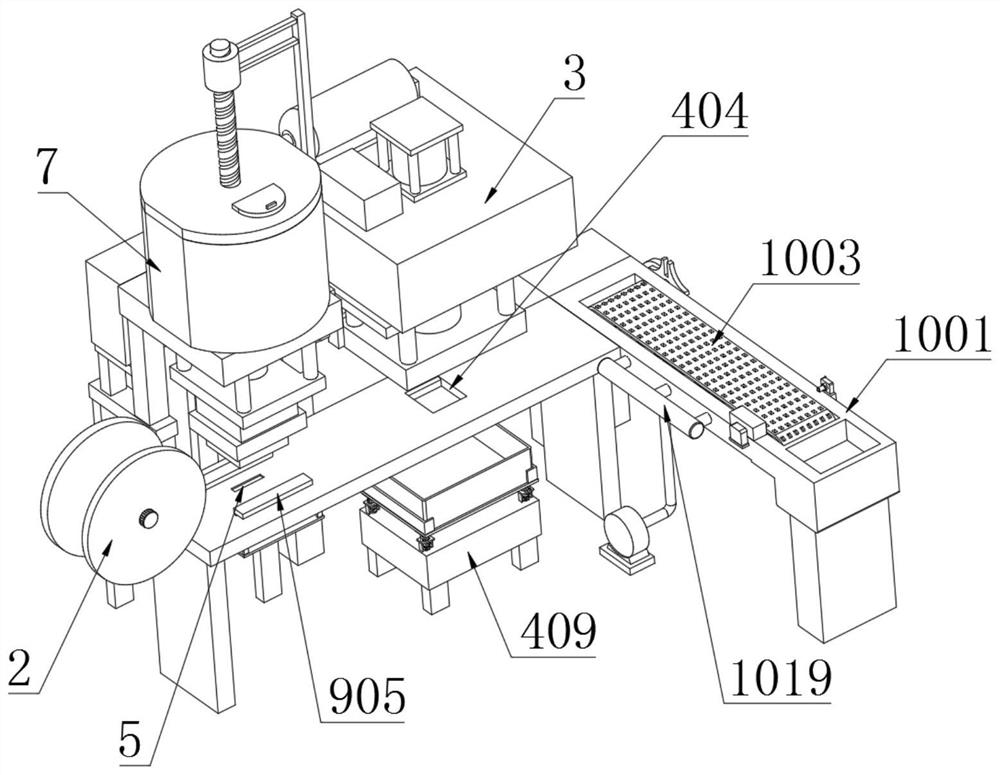

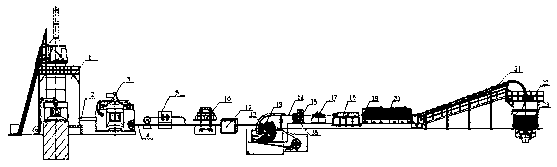

Continuous casting and rolling and boronizing method and device of conductive aluminium alloy rod

The invention discloses a continuous casting and rolling and boronizing method and device of a conductive aluminium alloy rod. The continuous casting and rolling and boronizing method of the conductive aluminium alloy rod comprises the following steps that step 1, industry pure aluminum is heated and melted in a smelting furnace, when the temperature of aluminum melt reaches 730-750 DEG C, the aluminum melt is poured into a holding furnace from the smelting furnace through a flow discharging groove; step 2, alloying components of the aluminum melt in the holding furnace are subjected to purification treatment; step 3, the aluminum melt is discharged through the flow discharging groove and is subjected to continuous feeding of A1-B intermediate alloy wire rod at the end, near the holding furnace, of the flow discharging groove, and thus the aluminum melt makes sufficient contact with the A1-B intermediate alloy wire rod and is reacted with the A1-B intermediate alloy wire rod in the flow discharging groove and enters an online gas-freeing device with a slag discharging hole arranged on the bottom; step 4, the aluminum melt after still standing enters a ceramic filtering device through the flow discharging groove and is filtered, then the filtered aluminum melt enters a horizontal casting system through a casting flow groove and is poured into a continuous casting machine, and aluminium alloy wirebar is formed and the aluminum melt is subjected to continuous separation; and step 5, a aluminium alloy rod is obtained through continuous roll forming, the aluminium alloy rod is cooled by an online cooling device, and then the cooled aluminium alloy rod is winded into a coil rod.

Owner:YANGTZE NORMAL UNIVERSITY

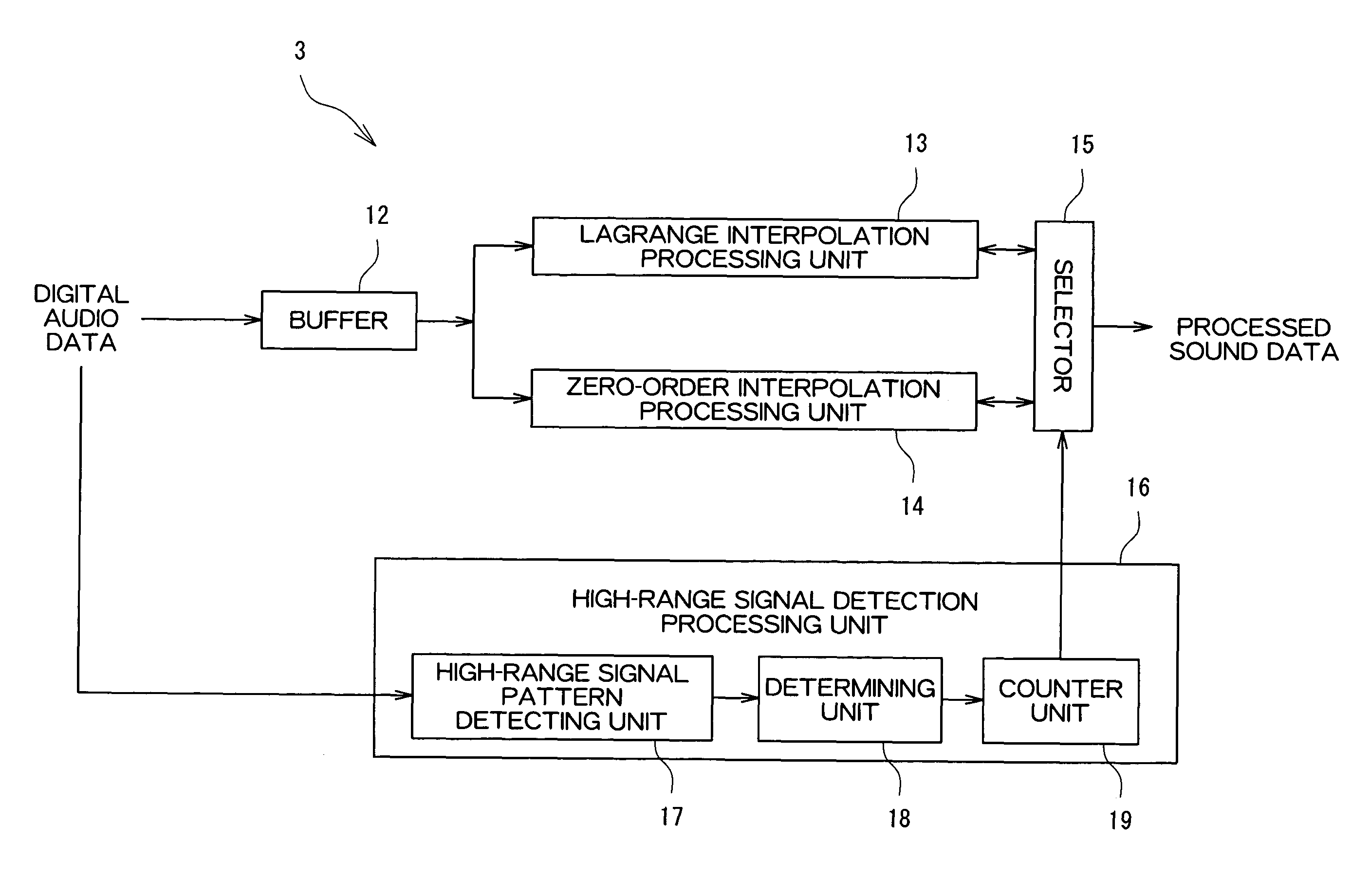

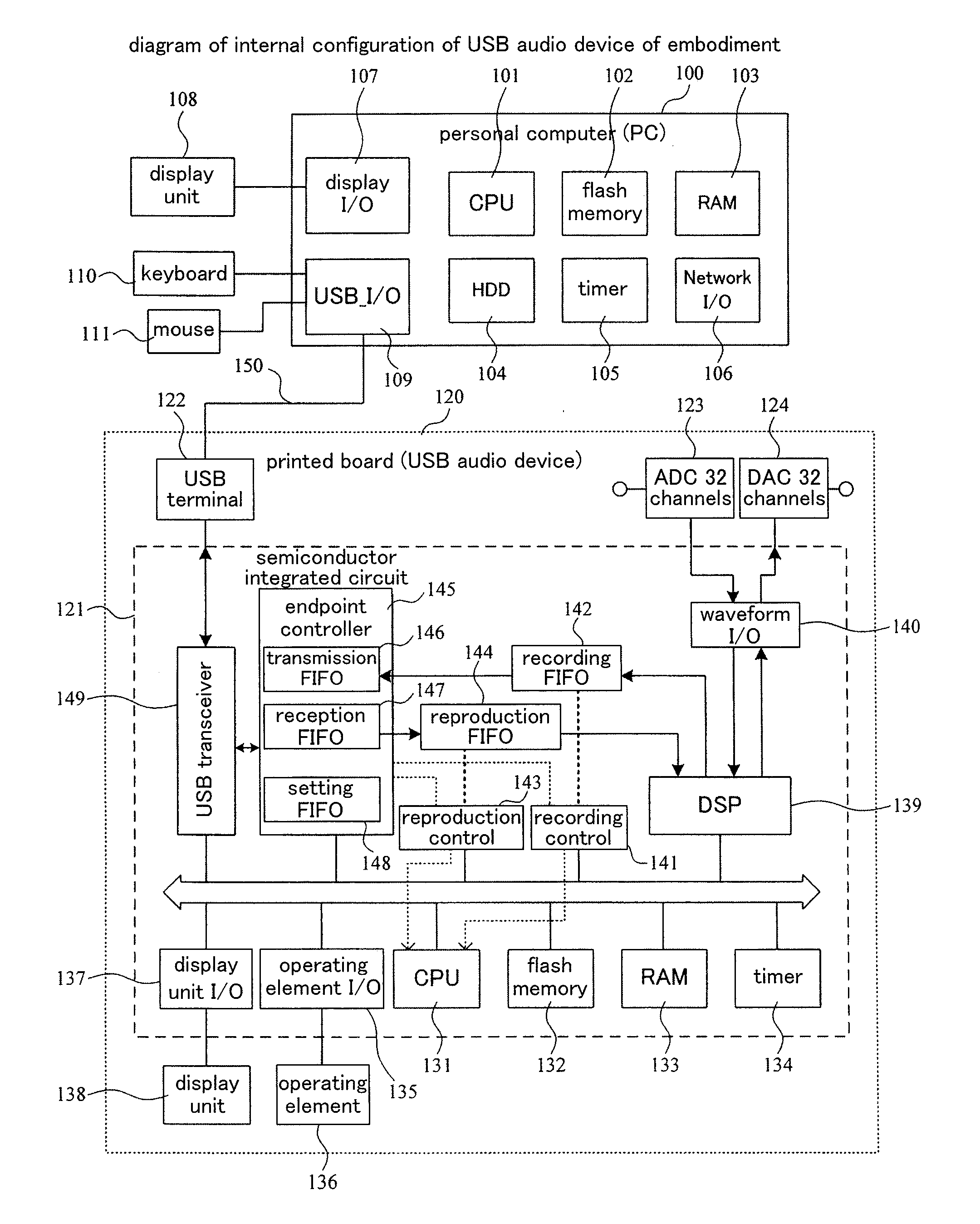

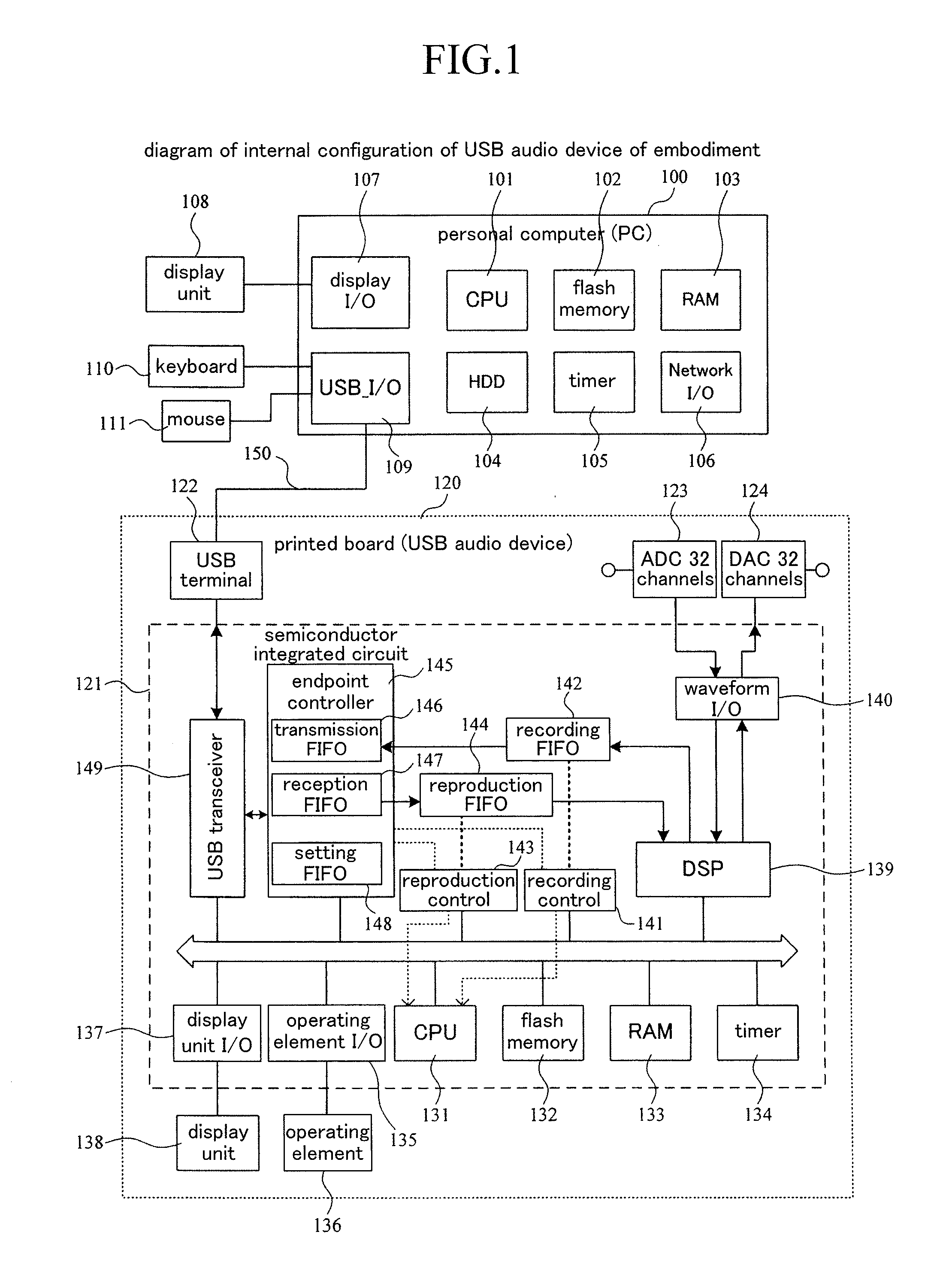

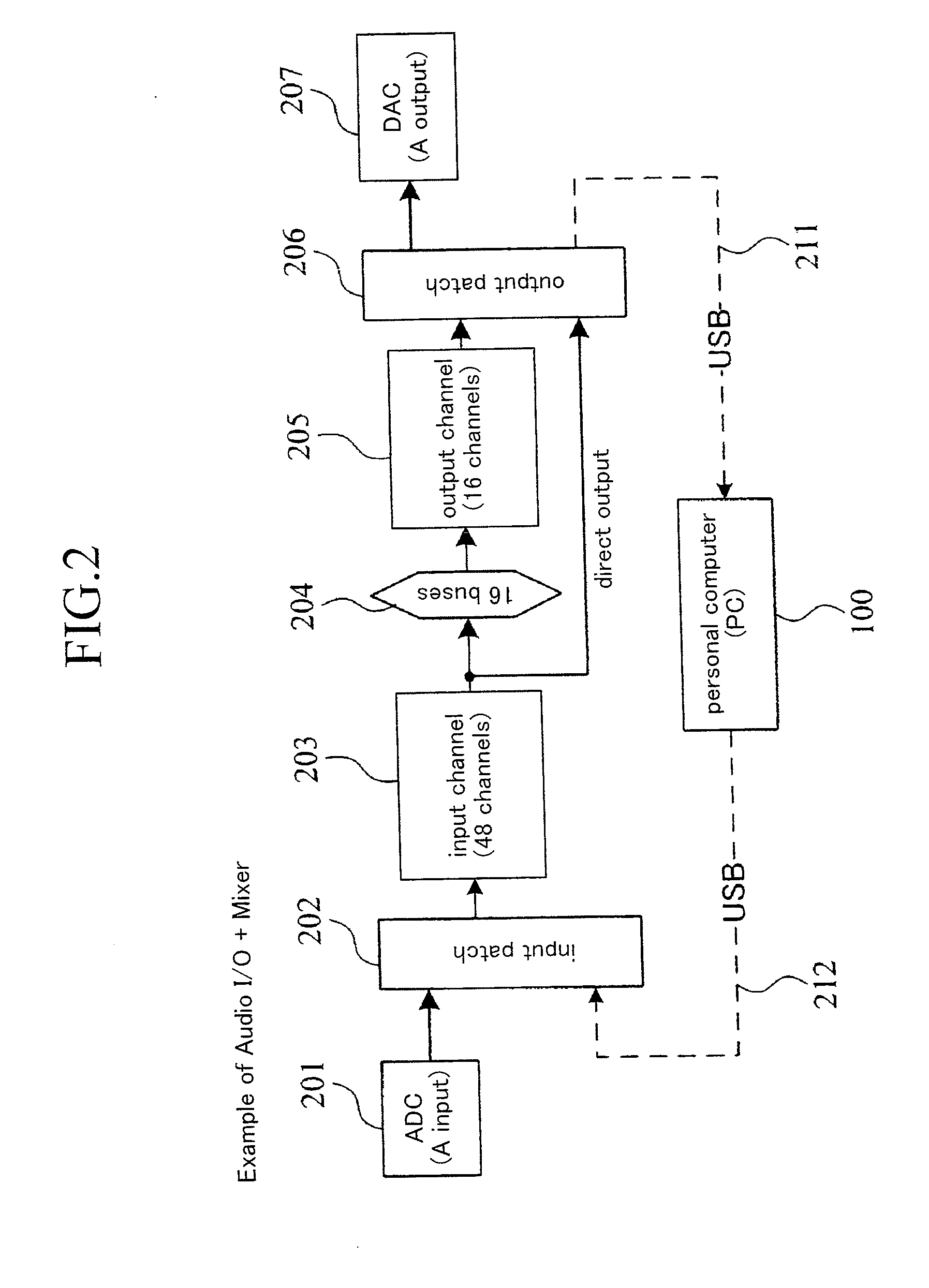

Audio data inputting apparatus and audio data outputting apparatus

InactiveUS20120253491A1Placing burdenAvoid discontinuationSpeech analysisRecord information storageOutput deviceData shipping

As for an audio data outputting apparatus and an audio data inputting apparatus for performing processing on audio data to transfer the audio data at each predetermined frame period, the processing on audio data performed at each frame period is done by hardware other than a CPU so that the CPU will not be interrupted at each frame period. In a case of transfer of audio data from a host to the audio data outputting apparatus, a reproduction control portion controls the data transfer in which a reception buffer and a reproduction buffer are involved, also controlling a receiving portion and a processing portion (DSP). In a case of transfer of audio data from the audio inputting apparatus to the host, a recording control portion controls the data transfer in which a transmission buffer and a recording buffer are involved, also controlling a transmitting portion and a processing portion.

Owner:YAMAHA CORP

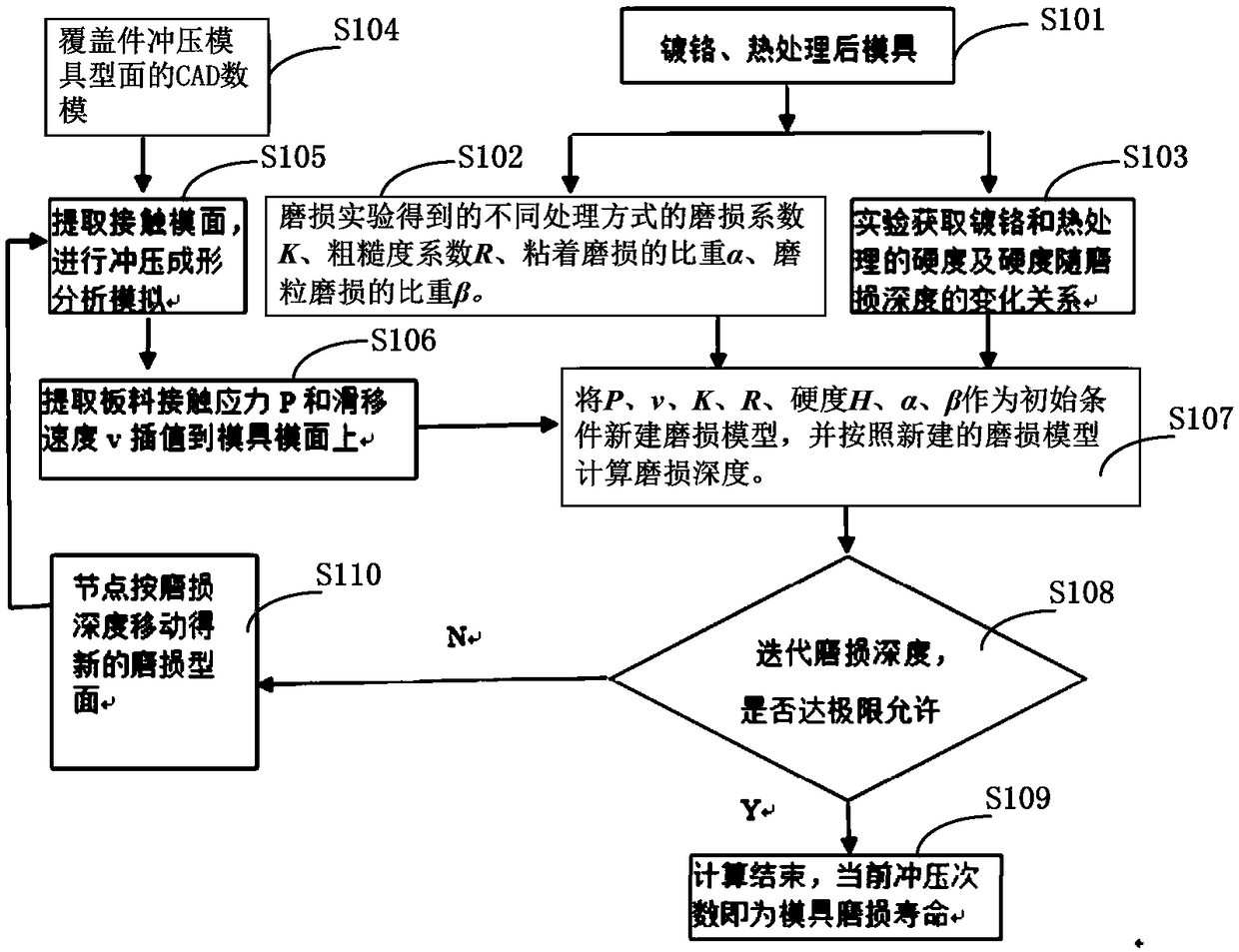

Method for predicting the wear life of stamping dies with full-time wear accumulation

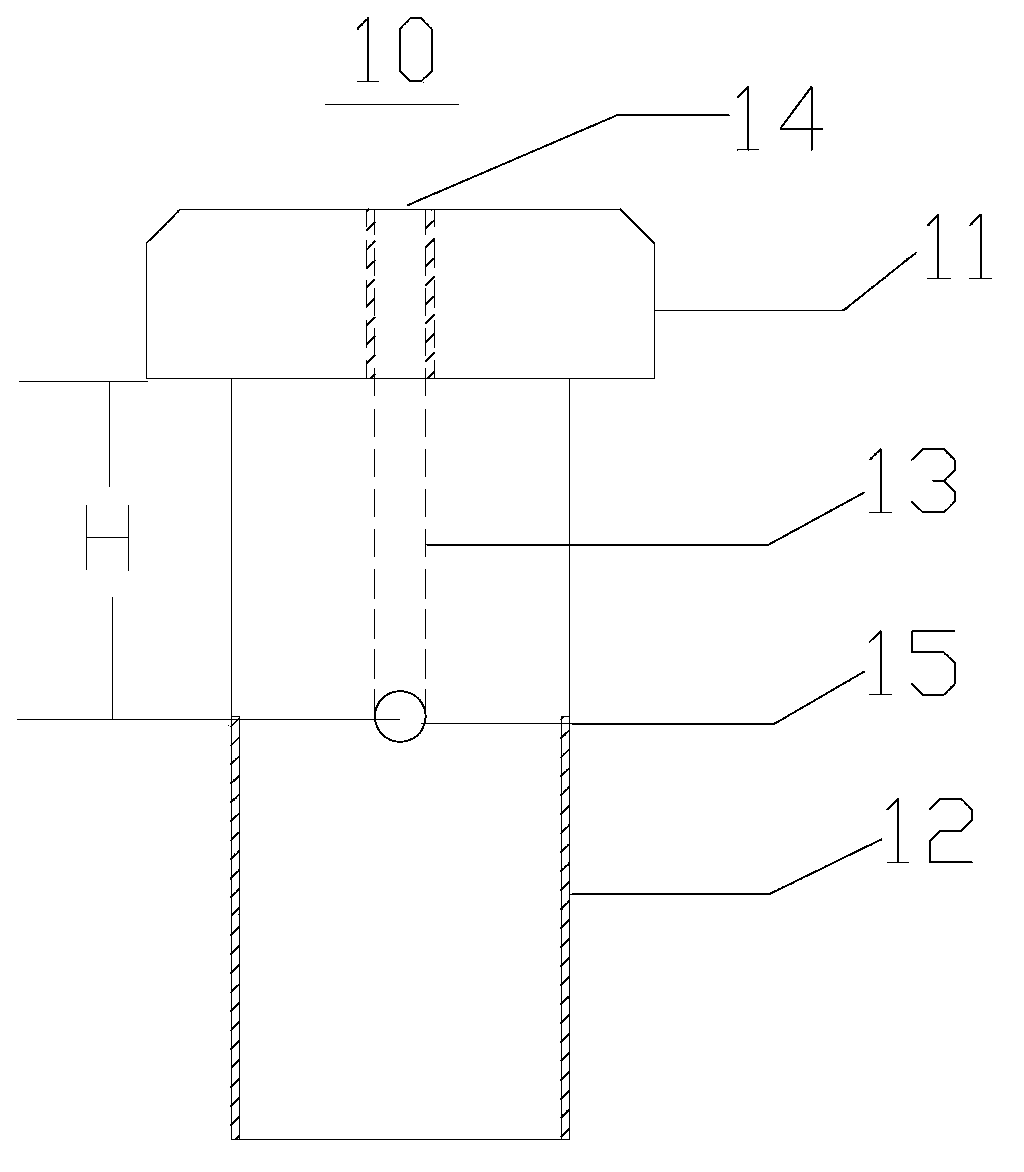

PendingCN109033673AAvoid discontinuationAvoid occupyingGeometric CADDesign optimisation/simulationWear testingHardness

The invention relates to a full-time wear accumulative wear life prediction method of a stamping die, which adopts a wear testing machine to separately measure wear coefficient K, roughness coefficient R, specific gravity alpha of adhesive wear and specific gravity beta of abrasive wear of a plurality of die materials with different treatment modes; through the finite element simulation experiment, the hardness H of the die material and the relationship between the hardness and the wear depth gradient were obtained. According to the die surface CAD digital model of the stamping die, the contact die surface of the stamping die and the stamped sheet metal is extracted, and the contact stress P of the contact die surface and the slip speed v of the stamped sheet metal is extracted relative tothe die through numerical simulation of stamping forming; a new wear model is established and the wear depth is calculated by using the above parameters as boundary conditions. When the wear depth ofthe stamping wear model obtained by iteration reaches the limit allowable value, it is confirmed that the current stamping times is the die wear life. The invention solves the technical problem thatthe prediction accuracy of the traditional Archard model is not high.

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

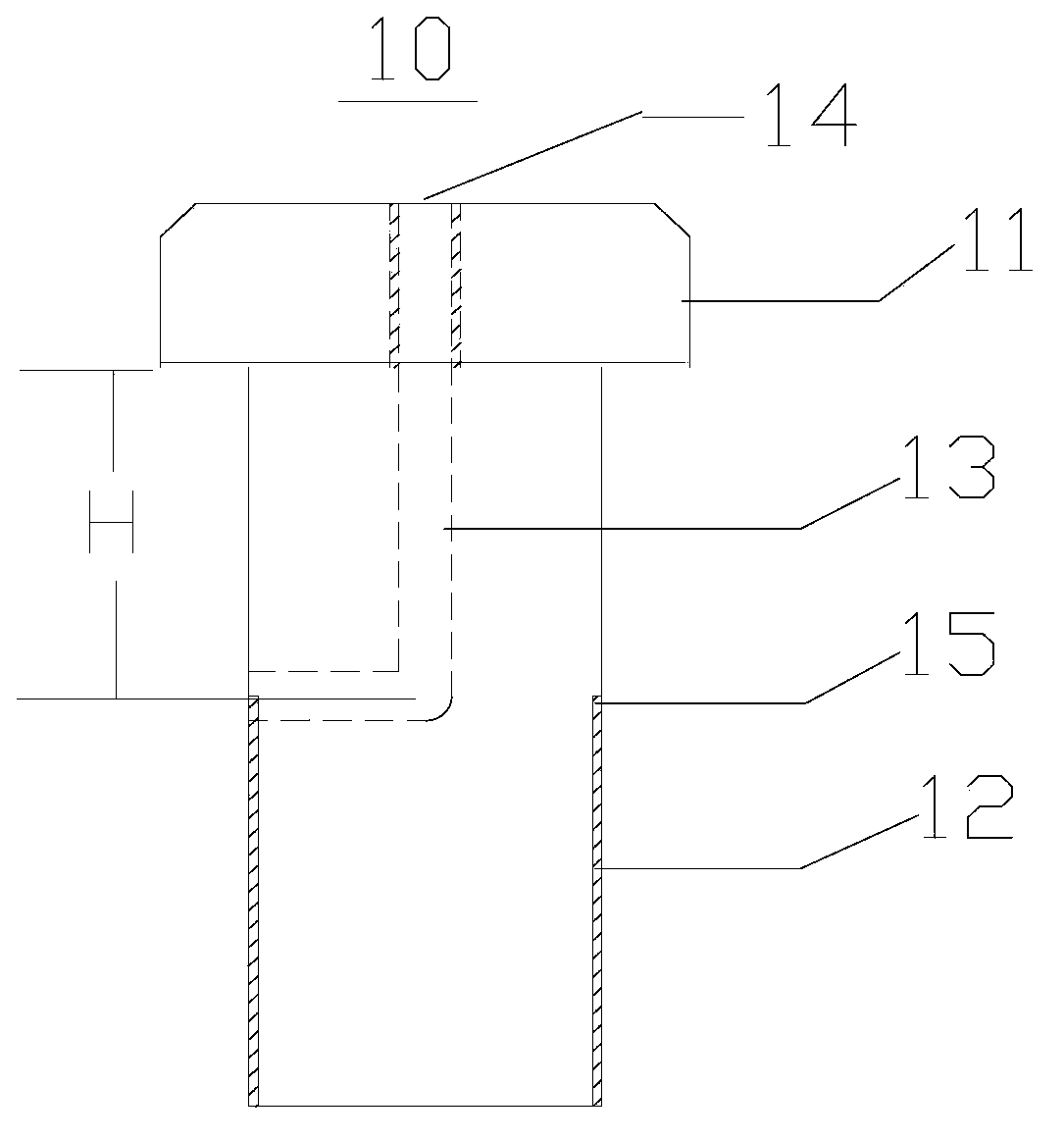

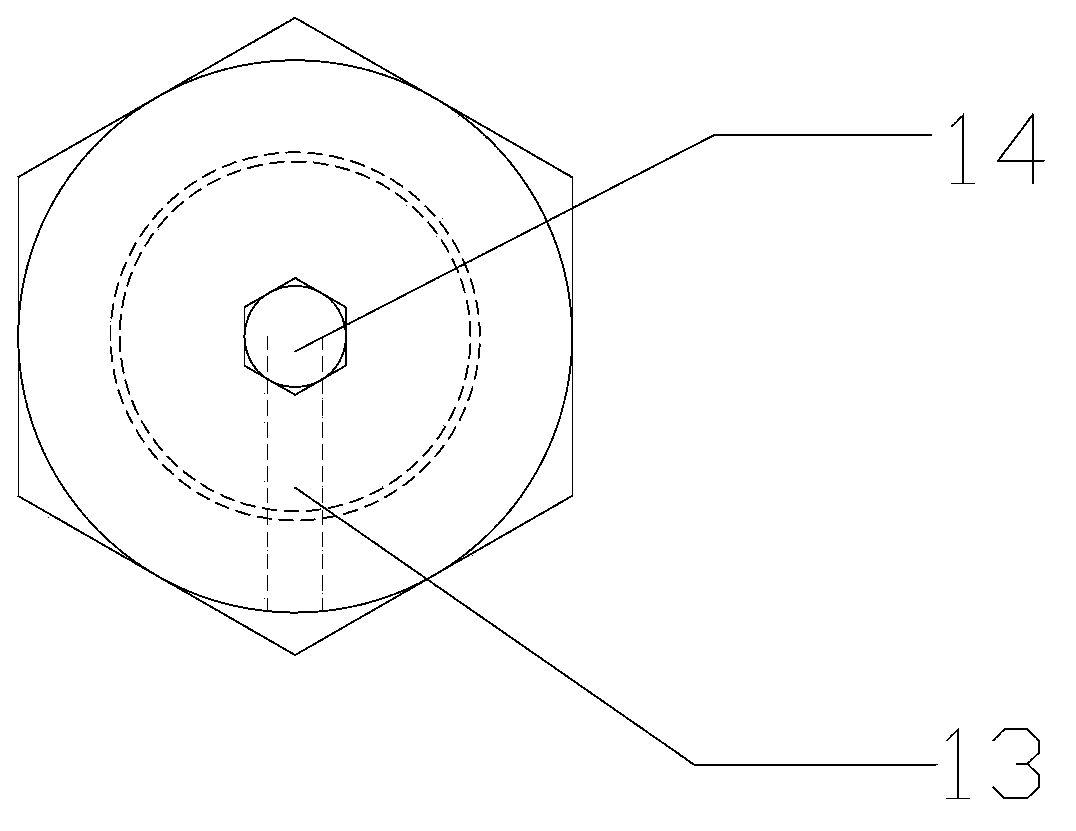

Method and device for plugging leaking point of flange face and sealing gasket of high-pressure equipment

The invention discloses a method for plugging a leaking point of a flange face and a sealing gasket of high-pressure equipment. The method includes the following steps: disposing a glue injection bolt in a bolt hole, and enabling an outlet of an L-shaped hole to be positioned at the leaking point of the flange face and the sealing gasket, wherein the glue injection bolt is provided with the L-shaped hole formed downwards from the head of the glue injection bolt along the axial direction, and the L-shaped hole is a glue injection passage; injecting a sealing agent through the glue injection passage to plug the leaking point; screwing a sealing bolt into the L-shaped hole to seal the glue injection bolt, wherein the sealing bolt is matched with the L-shaped hole. Correspondingly, the invention further discloses a device used in the method. The device comprises the glue injection bolt and the sealing bolt. The glue injection bolt is provided with the L-shaped hole downwards formed from the head of the glue injection bolt along the axial direction, an outlet end of the L-shaped hole is communicated with the outside, and outer diameter of the sealing bolt is matched with inner diameter of the L-shaped hole. The method and the device have the advantages that the leaking point, positioned on the flange face and the sealing gasket, of the high-pressure equipment can be plugged quickly, conveniently and effectively.

Owner:BAOSHAN IRON & STEEL CO LTD

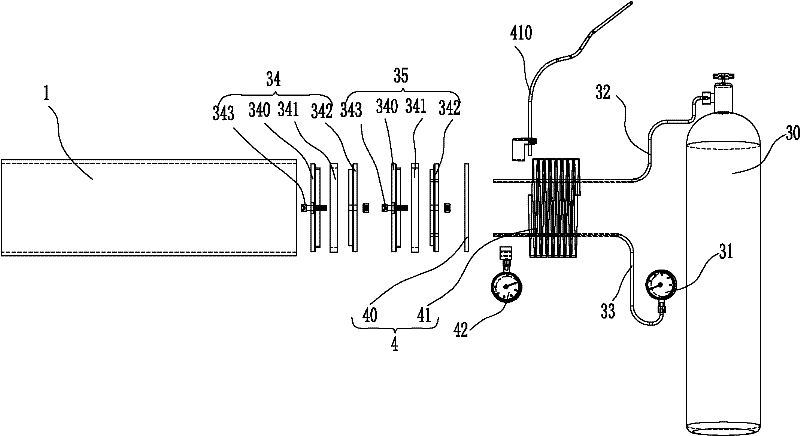

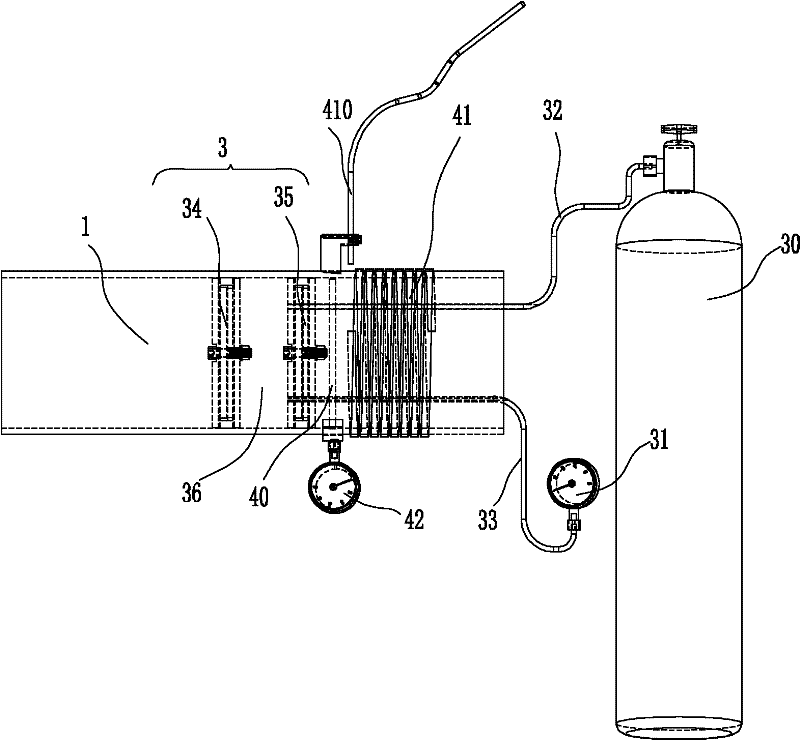

Process and device for welding and cutting flammable-explosive medium pipeline in on-line mode

InactiveCN102229037AAvoid fire and explosionIncreased renovation costsWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringHot Temperature

The invention provides a process and a device for welding and cutting a flammable-explosive medium pipeline in an on-line mode. By adopting the processing process provided by the invention, a ring rotated cutting device is directly used for carrying out low-temperature cutting; and through adopting a double-disc stopper and a heat insulation cooing device, a pressure online detector and a temperature detector can perform real-time detection and monitoring in the cutting process to prevent the pipeline firing and explosion caused by spark and high temperature from happening. By adopting the technology processing steps and the stopper, the economic losses caused by the stopping and cleaning of fammable-explosive medium pipelines, as well as the production halts and cleaning of an enterprise can be integrally avoided and online technical transformation and promotion can be carried out.

Owner:中化珠海石化储运有限公司

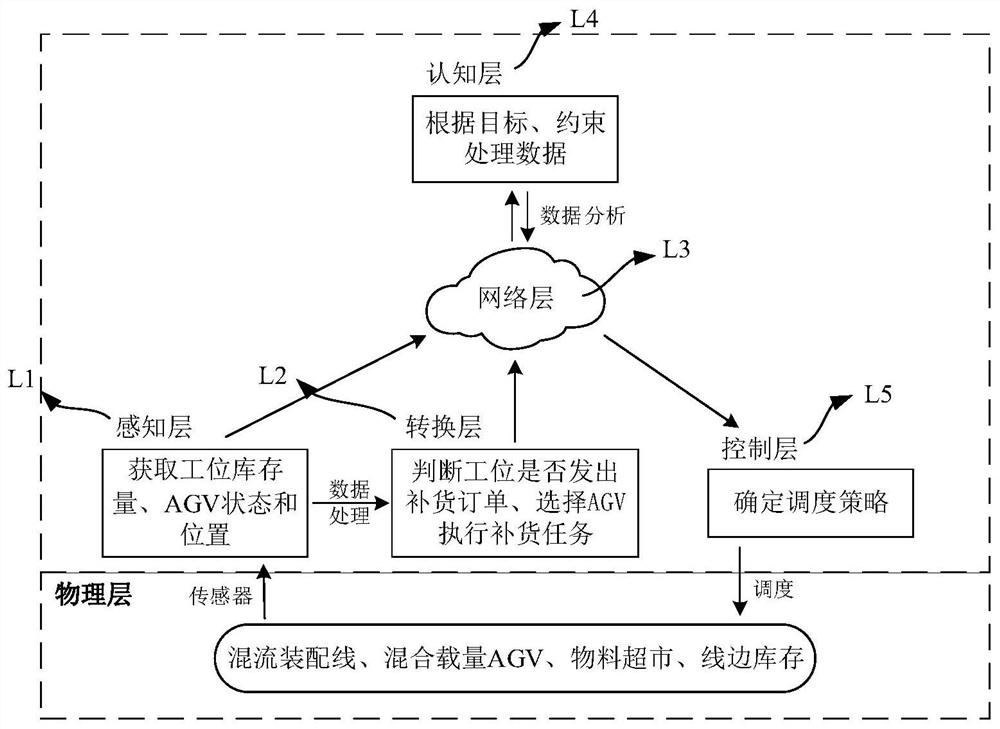

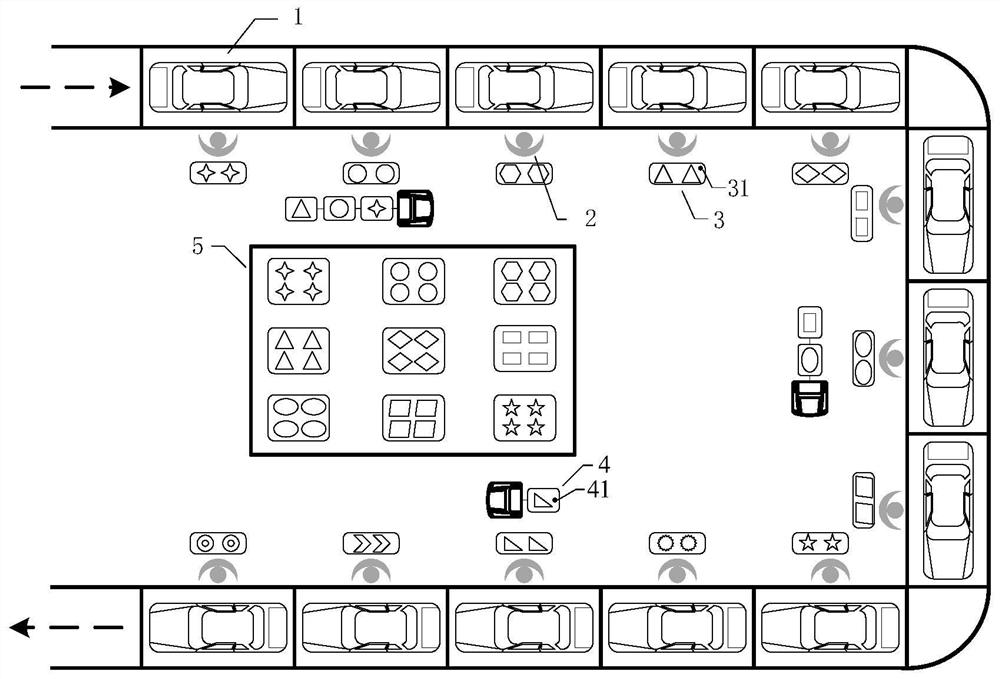

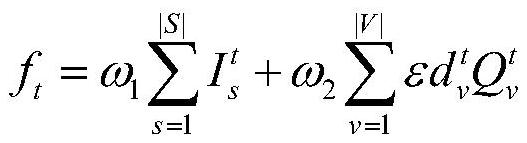

Mixed flow assembly line material distribution method and system based on static half-set strategy

ActiveCN112801483AExcellent delivery strategyReduce inventory levelsDesign optimisation/simulationResourcesControl layerMixed flow

The invention relates to a mixed flow assembly line material distribution method and system based on a static half-set strategy, and the system comprises: a sensing layer which obtains the remaining line side stock of each station and the state and position of a mixed load AGV in real time through a sensor; the conversion layer that is used for converting the data acquired by the sensing layer into useful information, determining whether a station has a replenishment demand or not, and summarizing material demands; the network layer that is connected with other layers to realize data exchange; the cognitive layer that determines an optimal material distribution scheduling strategy through data analysis according to the target function; and the control layer that determines a control strategy according to the cognition result of the cognition layer. Compared with the prior art, the invention considers the real-time inventory of each station, the state and position information of the AGV and the like, and has the advantages of effectively reducing the inventory level of the line side, improving the material distribution efficiency, reducing the operation cost and the like.

Owner:TONGJI UNIV

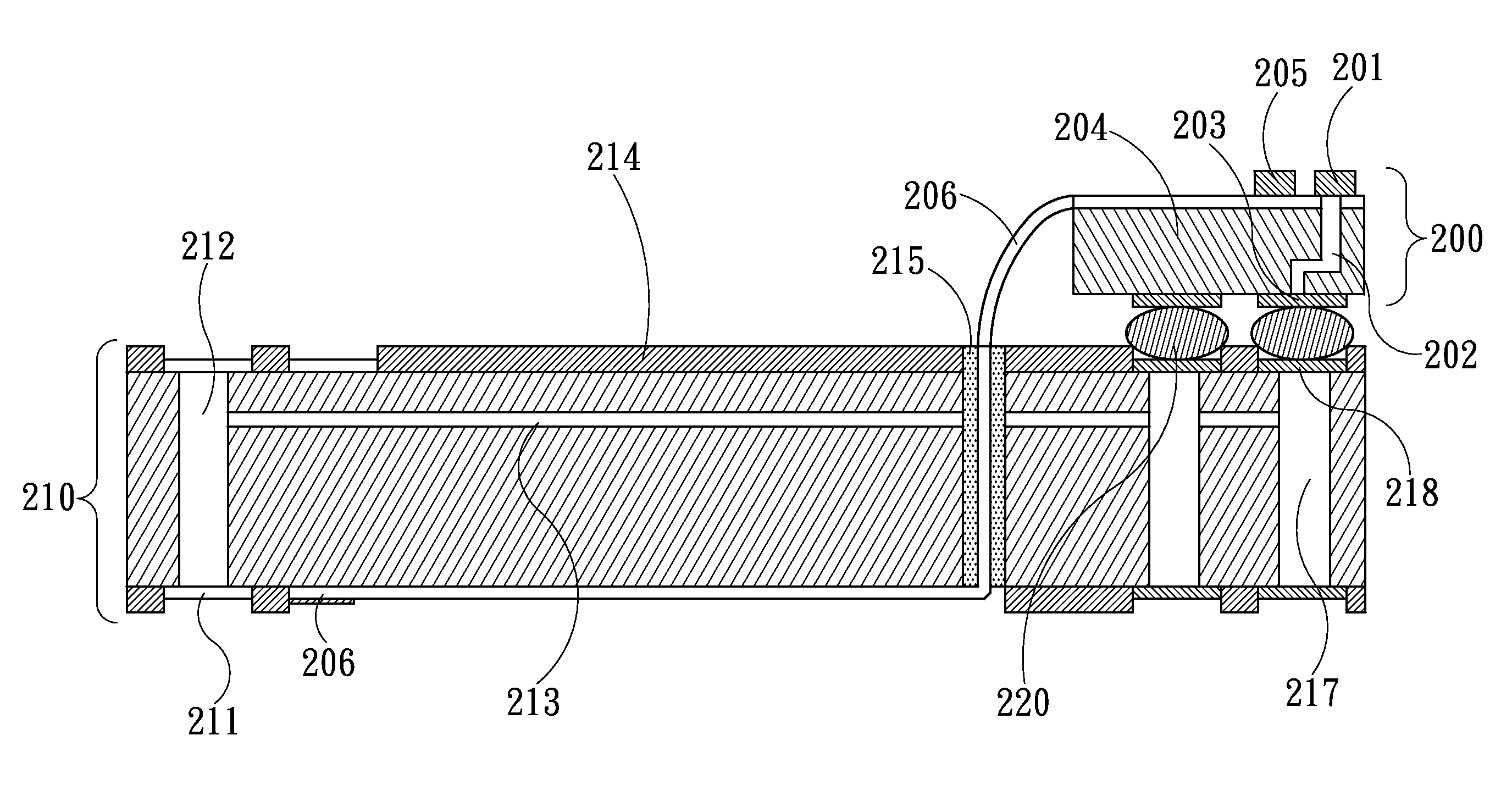

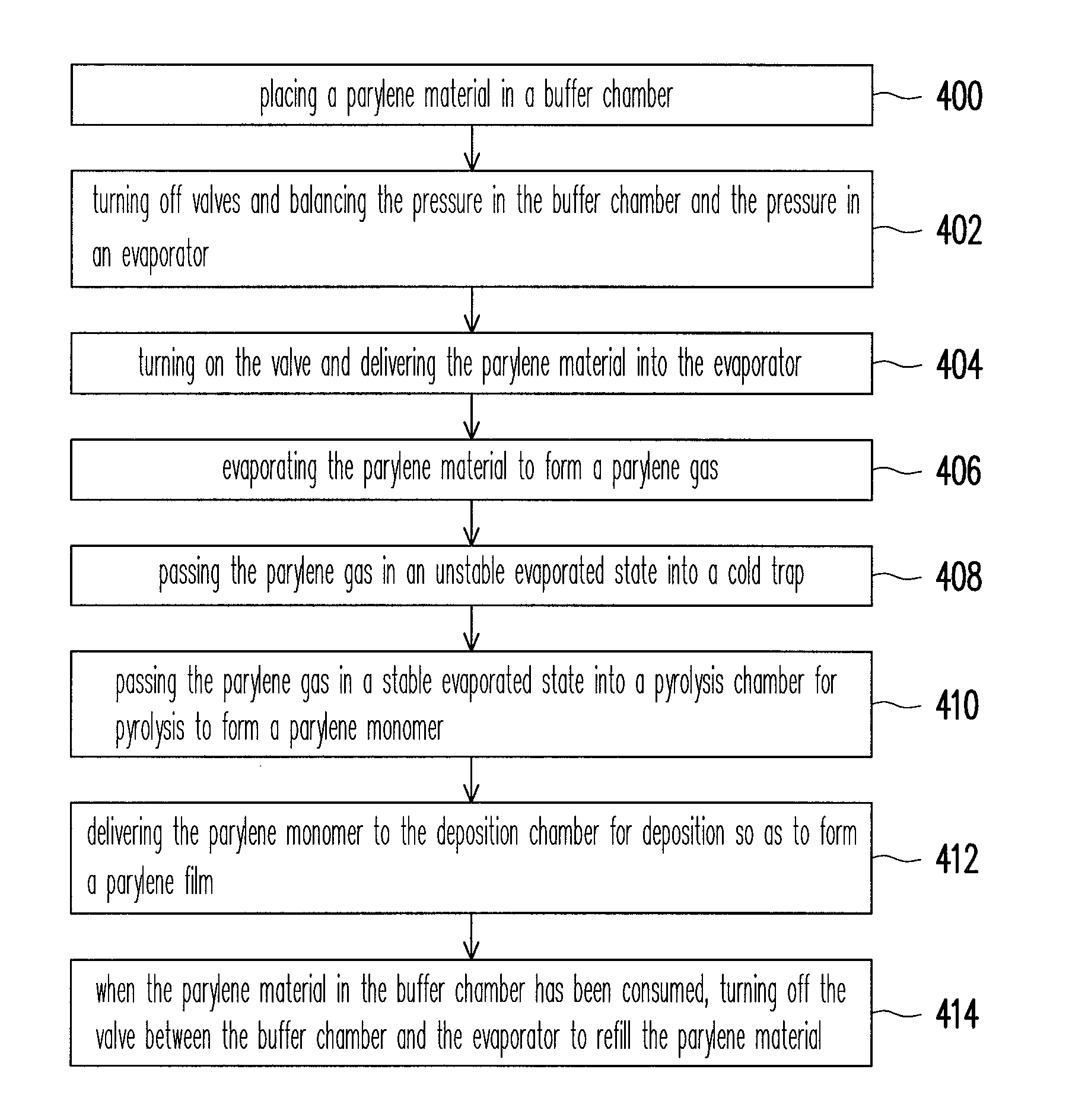

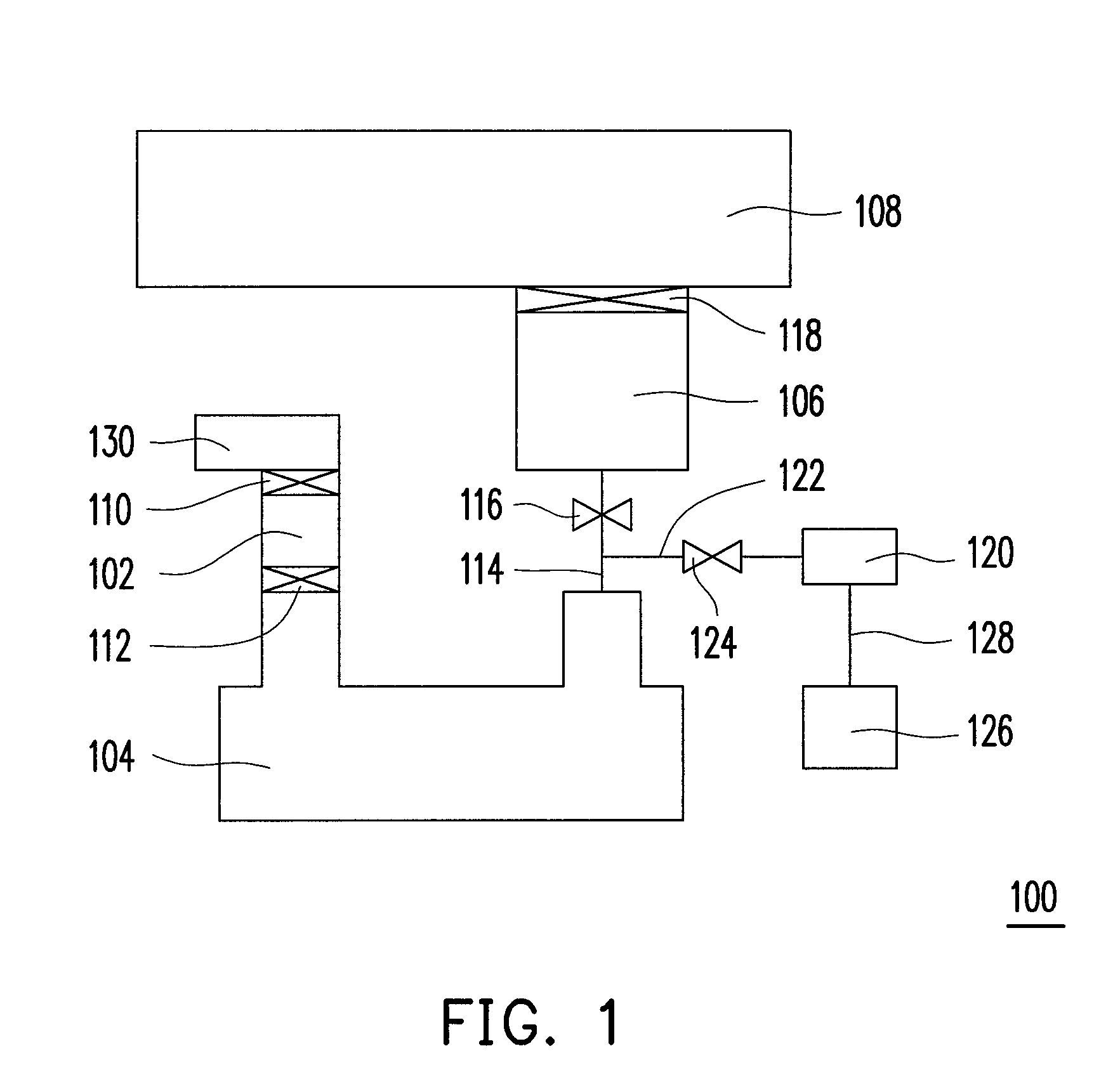

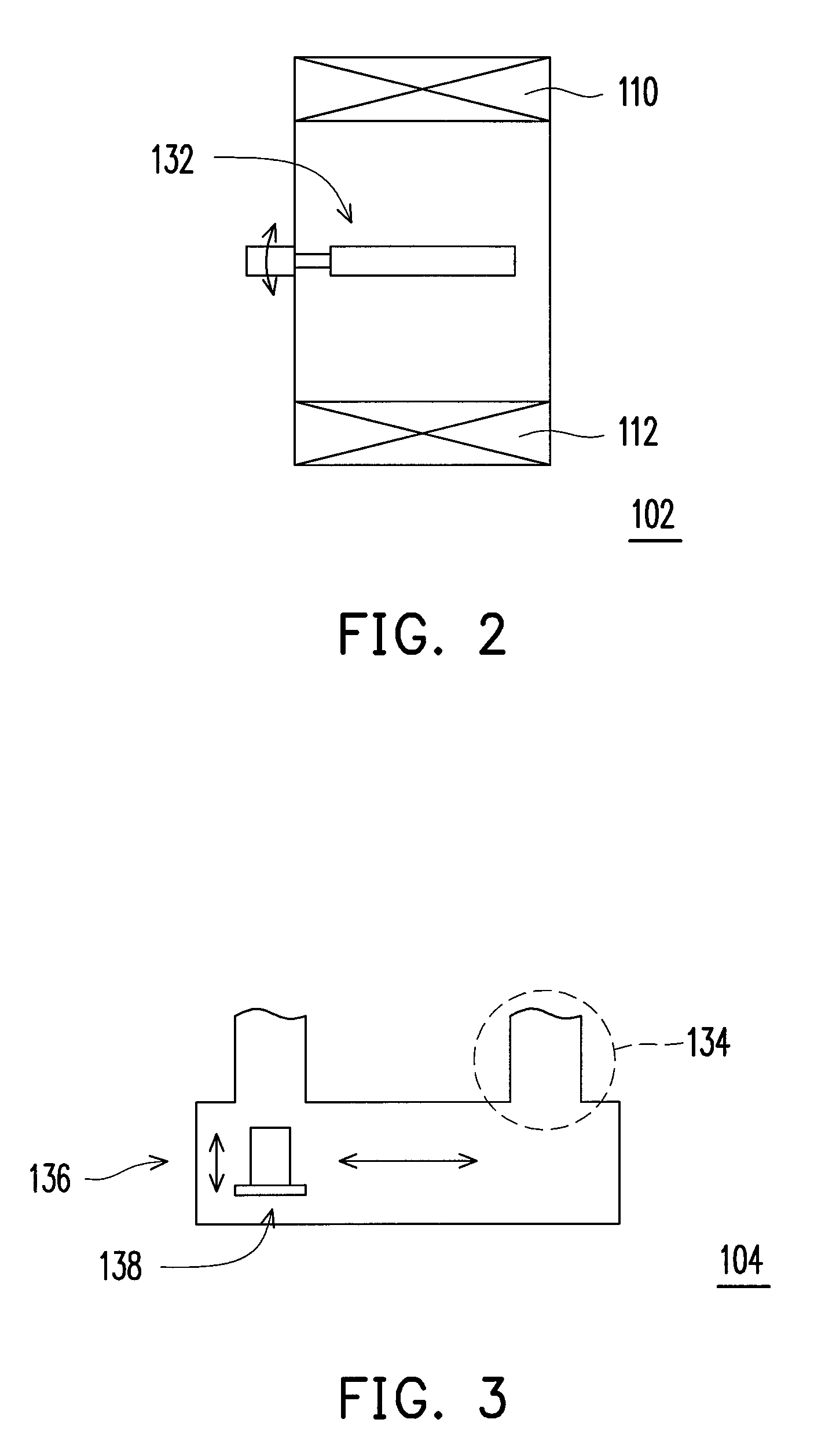

Method of forming parylene film

ActiveUS8889224B2Hinders fabricationAvoid discontinuationLiquid surface applicatorsChemical vapor deposition coatingParyleneEngineering

A method for forming a parylene film is provided, which includes following steps. Providing a chemical vapor deposition apparatus including a buffer chamber having first and second valves and a rotative carrying apparatus, an evaporator connected with the second valve, a pyrolysis chamber connected with the evaporator, and a deposition chamber connected with the pyrolysis chamber. Placing a parylene material in the rotative carrying apparatus of the buffer chamber through the first valve. Turning off the first and second valves and balancing a pressure in the buffer chamber and a pressure in the evaporator. Turning on the second valve and delivering the parylene material into the evaporator. Evaporating the parylene material in the evaporator to form a parylene gas. Pyrolyzing the parylene gas in the pyrolysis chamber to form a parylene monomer. Delivering the parylene monomer to the deposition chamber for deposition so as to form a parylene film.

Owner:IND TECH RES INST

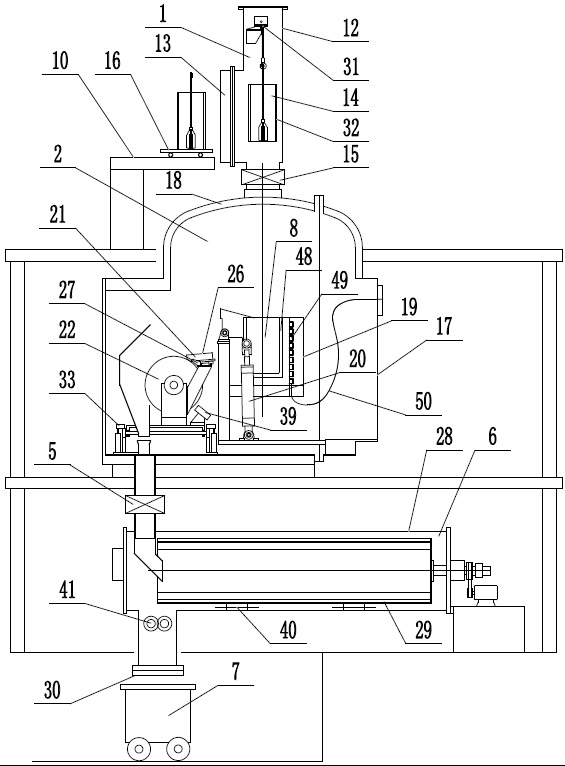

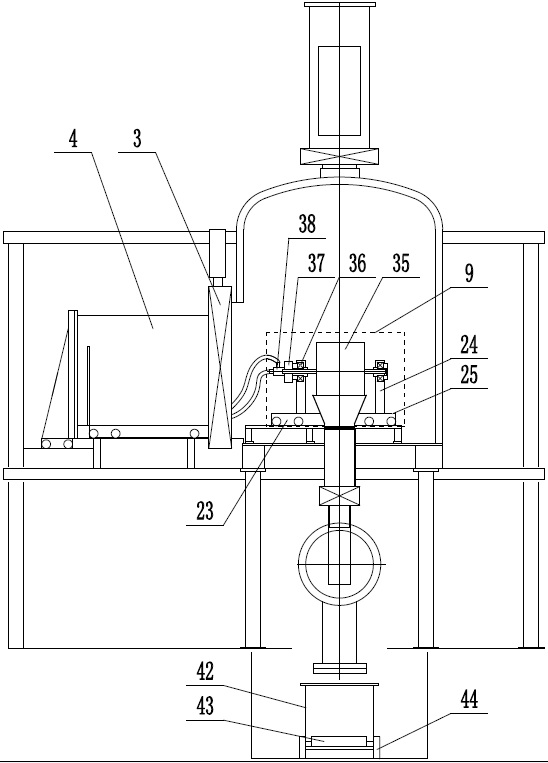

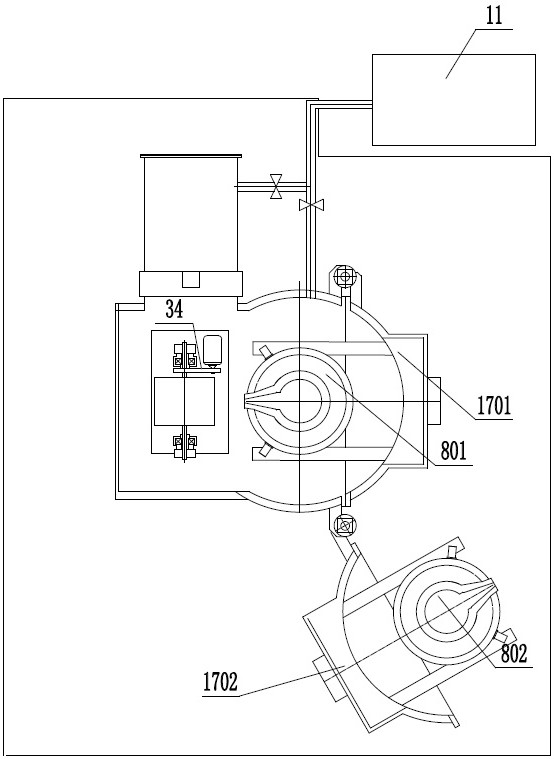

Intelligent vacuum melting and rapid hardening equipment and manufacturing method of rapid hardening alloy

PendingCN112626360AImprove work efficiencyDelay agingInductances/transformers/magnets manufactureSmart controlMaterials science

The invention discloses intelligent vacuum melting and rapid hardening equipment which mainly comprises a vacuum feeding chamber, a vacuum melting chamber, a rotating roller isolating valve, a rotating roller moving chamber, a middle isolating valve, an alloy sheet cooling chamber, an alloy sheet collecting device, a vacuum melting device, a rotating roller device, an operating platform, a vacuum unit and an intelligent console. When the intelligent vacuum melting and rapid hardening equipment works, opening and closing of the vacuum isolating valves among the vacuum feeding chamber, the vacuum melting chamber, the alloy sheet cooling chamber and the rotating roller moving chamber are accurately controlled through the intelligent console, and through cooperative operation of a feeding device, a smelting chamber door, the vacuum melting device, the rotating roller device, a cooling roller, an alloy sheet collecting device and the like, continuous melting and casting, continuous feeding and discharging can be achieved in a vacuum environment. The invention further discloses a method for preparing rapid hardening alloy by adopting the intelligent vacuum melting and rapid hardening equipment.

Owner:SHENYANG CHINANORTH VACUUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com