Method and device for plugging leaking point of flange face and sealing gasket of high-pressure equipment

A technology for sealing gaskets and high-pressure equipment, which is applied in flange connections, mechanical equipment, pipes/pipe joints/fittings, etc., and can solve the problems of inability to meet the normal production requirements of iron and steel making, difficult to maintain, and long maintenance cycles. , to achieve the effect of simple and easy implementation, low cost of manufacturing equipment, and improved production capacity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

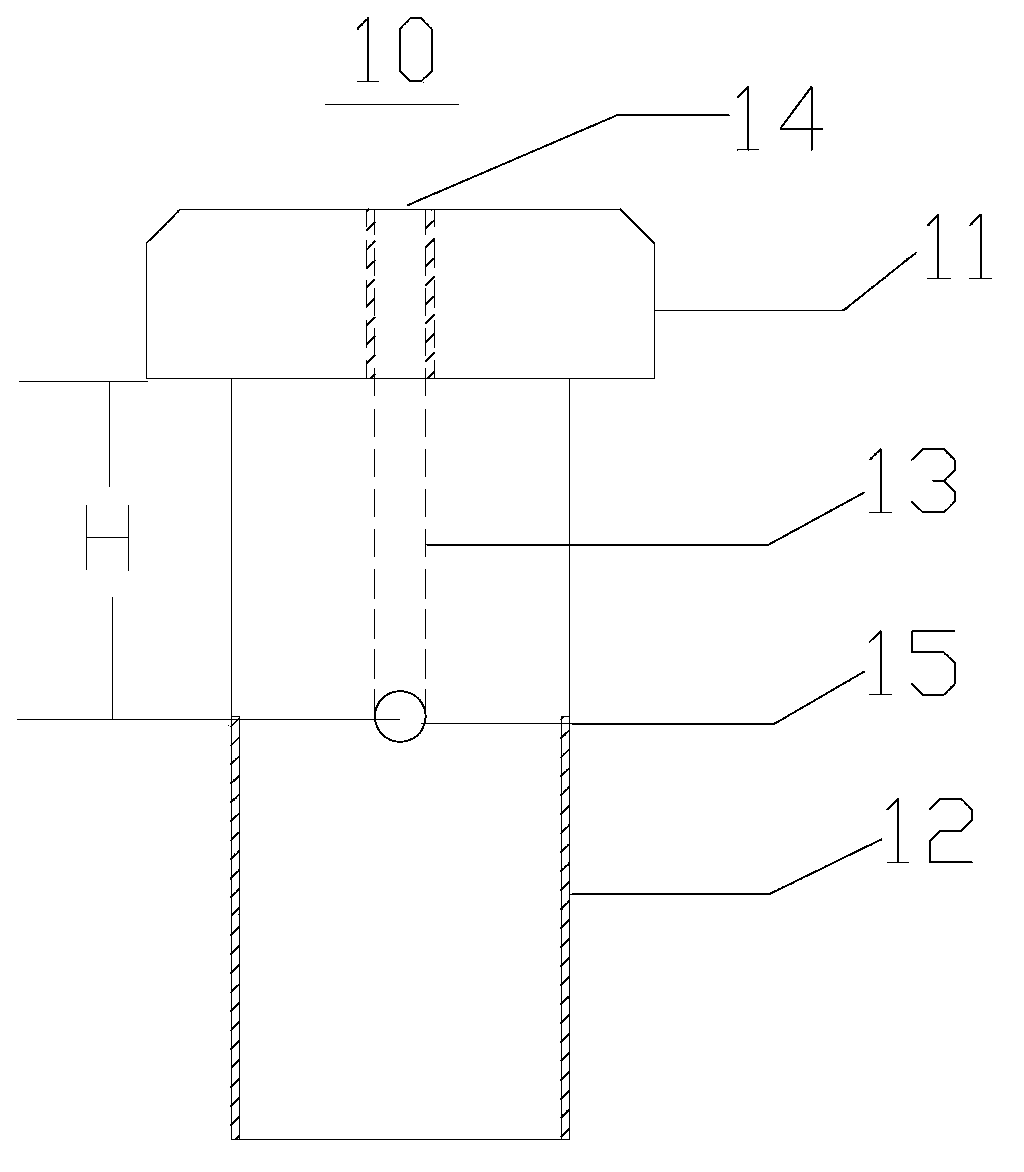

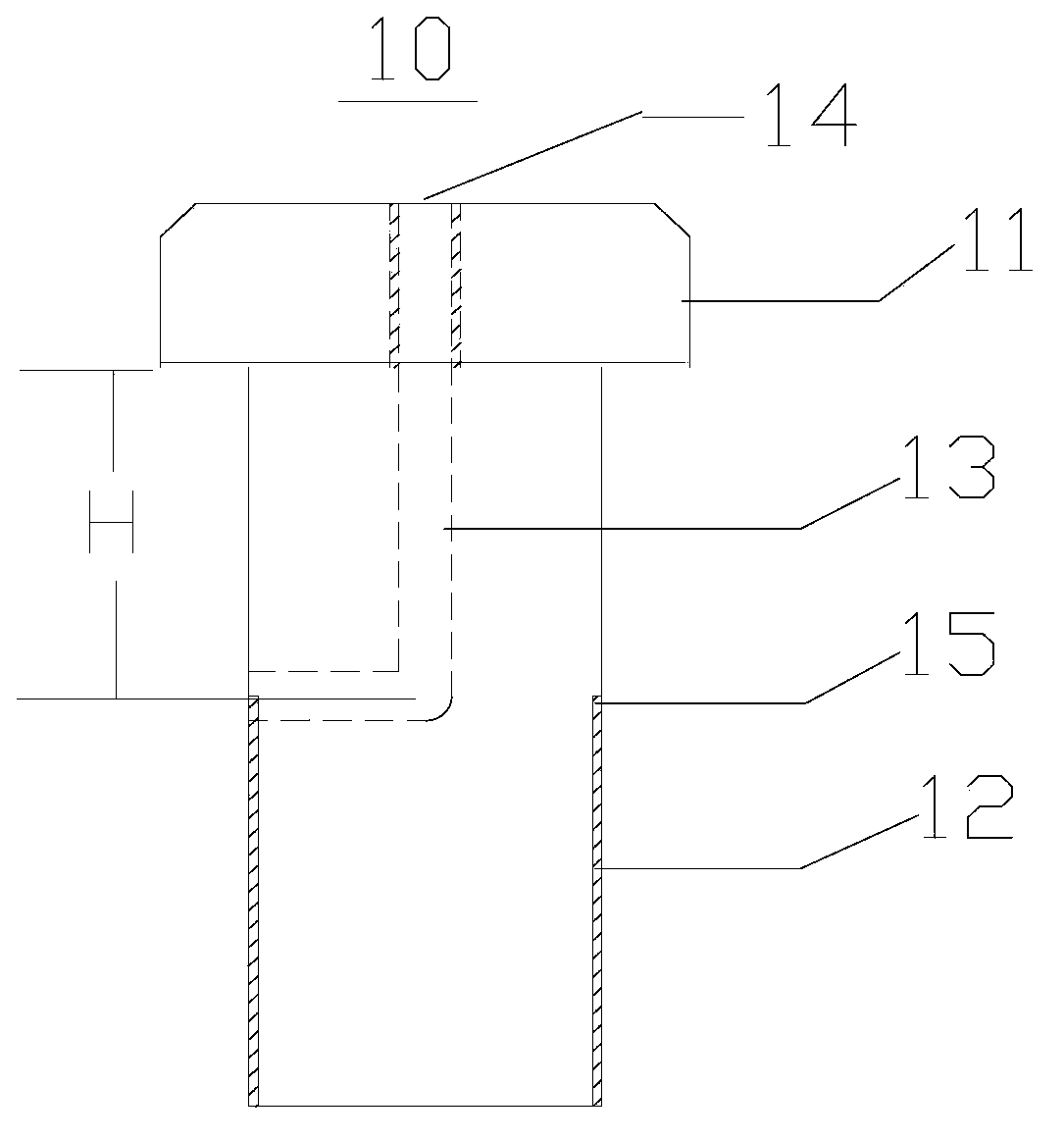

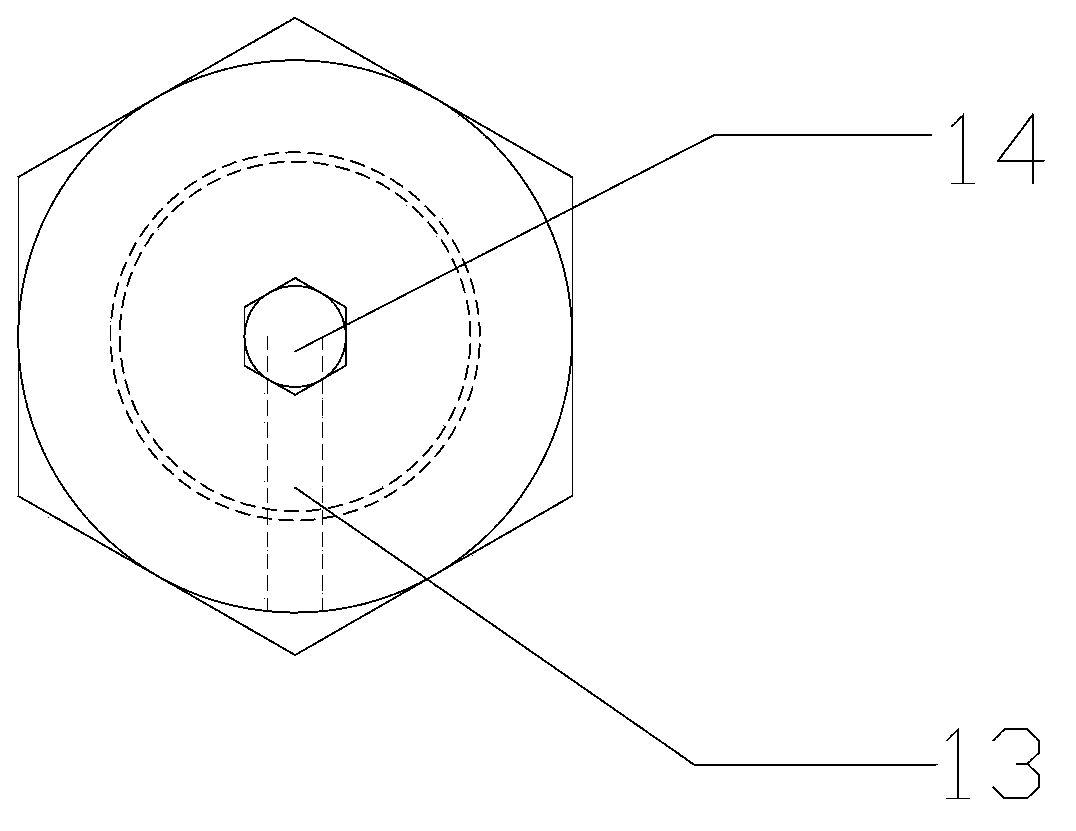

[0028] The method and device for sealing the leakage of the flange surface of the high-pressure equipment and the sealing gasket according to the present invention will be further described according to the specific embodiments and the accompanying drawings, but the specific embodiments and related descriptions do not constitute a reference to the present invention. Improper limitation of technical solutions.

[0029] Follow the steps below to seal the flange surface of the high-pressure equipment and the leakage point of the sealing gasket:

[0030] (1) Judging the location of the leakage point according to the on-site sound and ash emission;

[0031] (2) On the outside of the flange surface of the leakage point, weld the angle iron or flat iron to the flange, so that a sealed space is formed between the angle iron or flat iron, the flange surface and the bolts to prevent leakage in the subsequent steps. The sealant is squeezed and leaked, wherein the length of the angle iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com