Tapered connecting piece

A technology of conical connectors and cones, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of hidden safety hazards in daily production, leakage of flue gas from steel plate walls, corrosion of expansion joints, etc. Achieve the effect of reducing purchase and welding costs, eliminating leakage points, and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

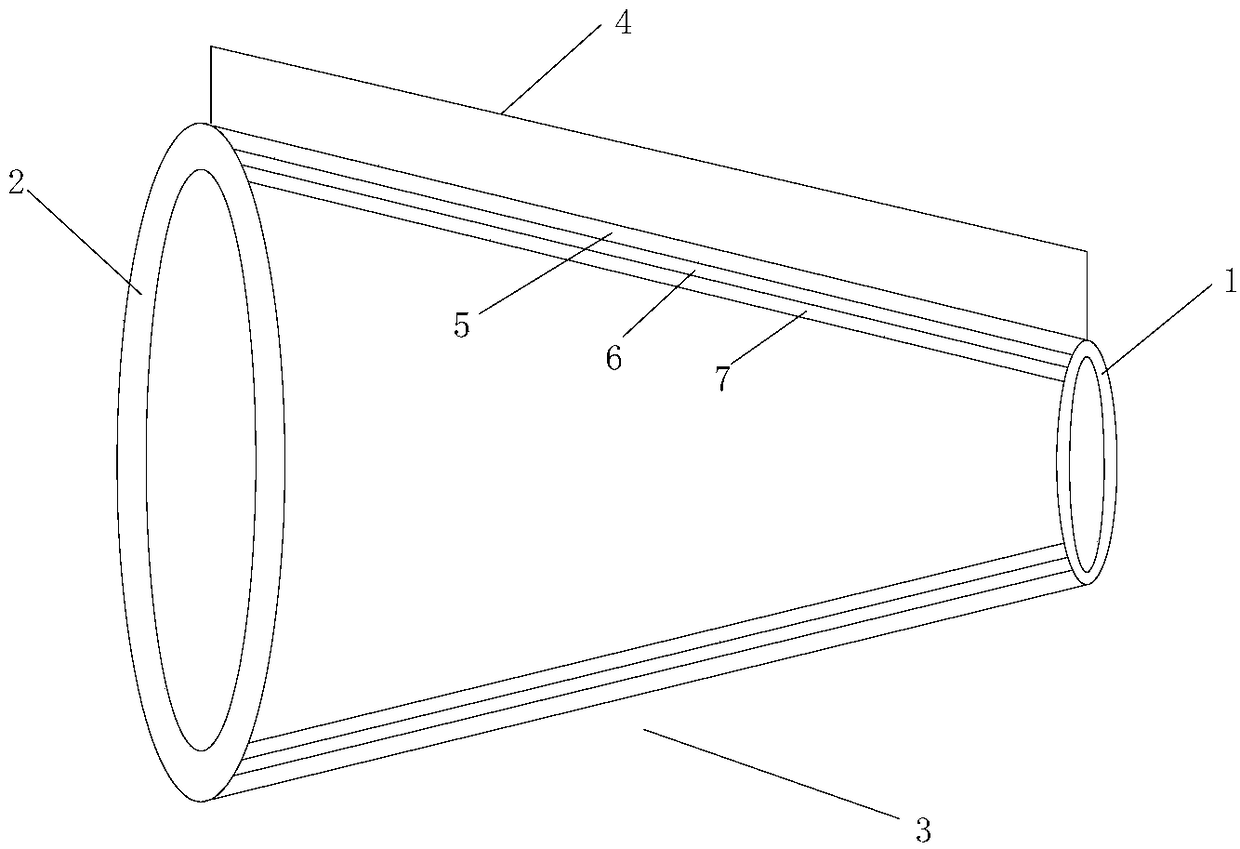

[0010] like figure 1 The conical connector shown includes a top flange 1, a bottom flange 2, and a cone 3 connected between the top and bottom flanges. The cone 3 is provided with a lining, and the lining is insulated by nano-micropores in turn. The backing layer 5 made of board material, the tiled layer 6 of gas-blocking aluminum foil, and the inner layer 7 of heat-insulating bricks, the backing layer 5, the tiled layer 6, and the inner layer 7 are filled with high-temperature resistant ceramic fibers. The cone is provided with a rain cover 4; between the top flange 1, the bottom flange 2 and the cone 3, an alumina fiber ring is provided.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com