Mixed flow assembly line material distribution method and system based on static half-set strategy

An assembly line and material technology, applied in the field of mixed-flow assembly line material distribution based on static semi-complete strategy, can solve the problems of unsatisfactory distribution efficiency and cost control, achieve efficient material distribution methods, reduce line-side inventory levels and energy consumption costs, The effect of meeting the needs of flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

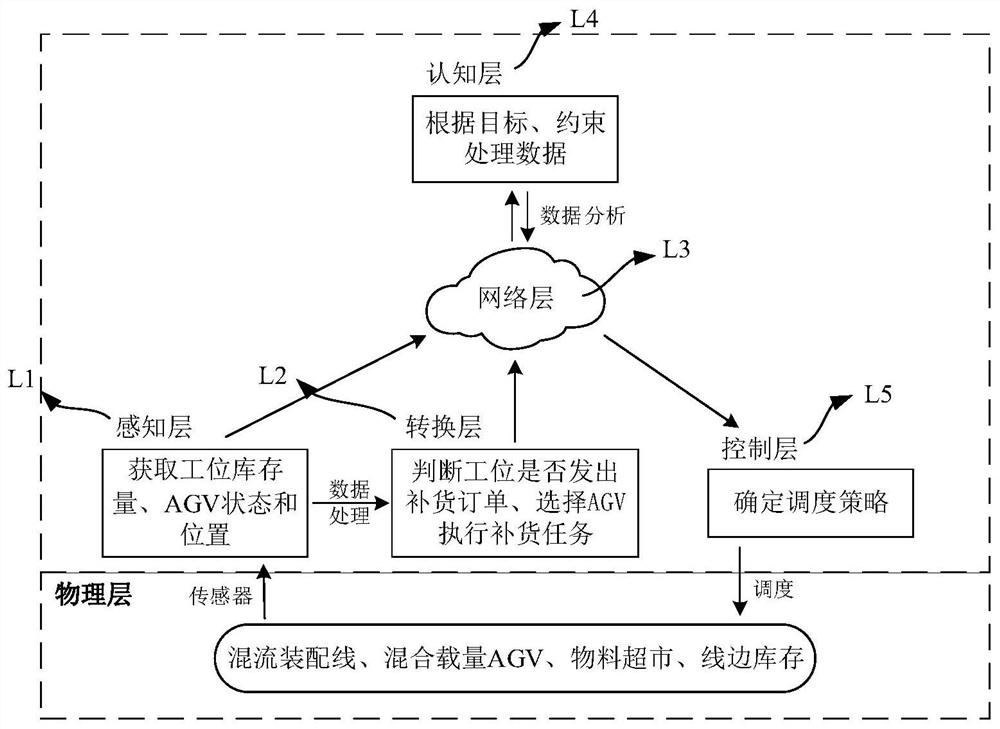

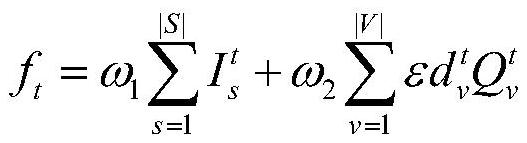

[0049] This embodiment provides a method for material distribution in a mixed-flow assembly line based on a static semi-complete strategy, including the following steps:

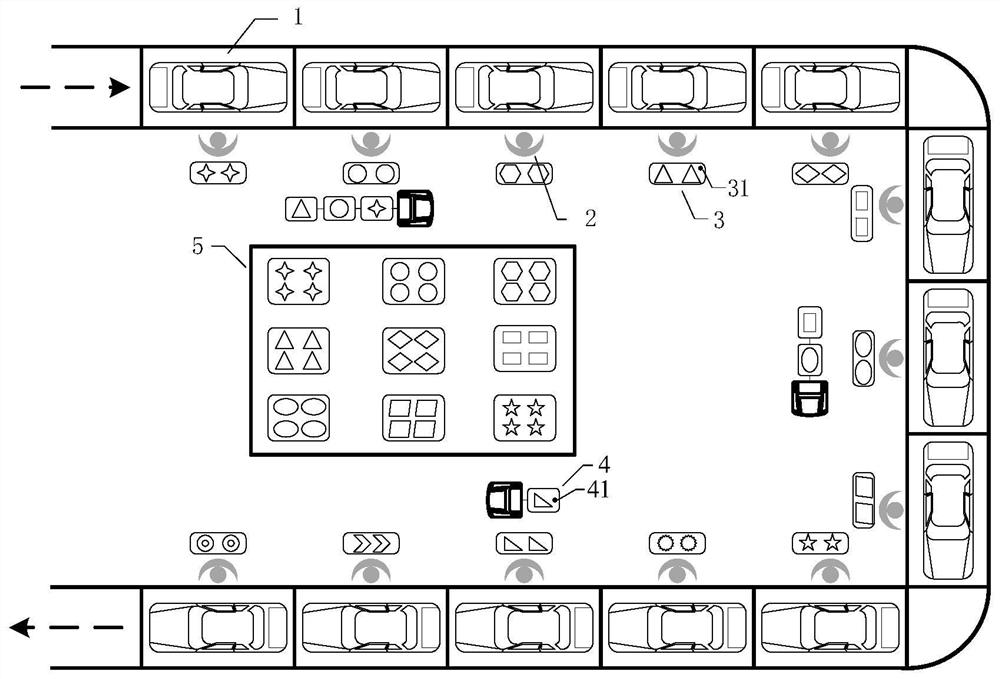

[0050] S1: Build the physical layer based on the static semi-complete strategy. The physical layer includes the bin preparation area, workstations and AGVs with mixed loads. The bin preparation area stores multiple bins, and the bins are used to store materials; the static semi-complete strategy is specific To: sort and assemble materials and store them in corresponding material boxes. When it is necessary to distribute materials to stations, the AGV with mixed load takes out several material boxes from the material box preparation area, and traverses the work required for refilling. AGV (Automated Guided Vehicle) refers to a transport vehicle equipped with automatic navigation devices such as electromagnetic or optical, capable of driving along a prescribed navigation path, with safety protection and various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com