A virtual replacement method for an electronic product production line

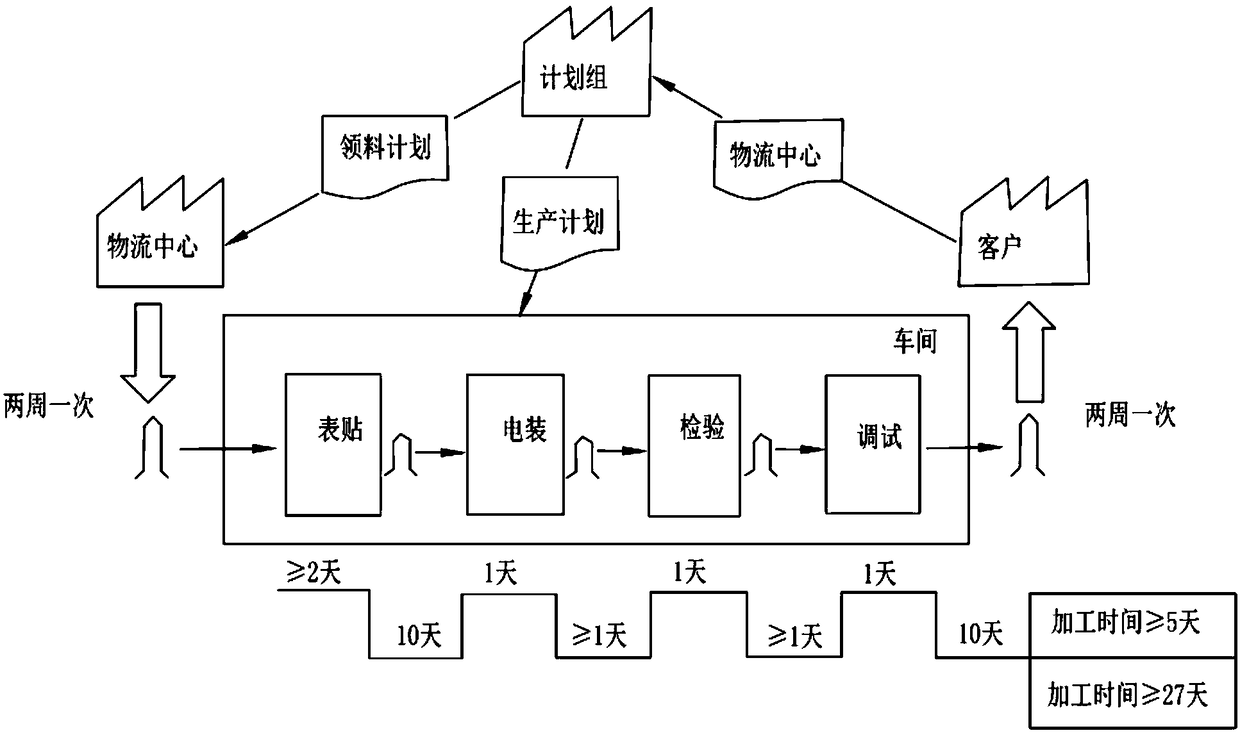

A technology for electronic products and production lines, applied in the field of virtual production change of electronic product production lines, can solve the problems of intensified competition for SMT equipment resources, the inability to switch production lines quickly, and the risk of unqualified batch quality, so as to achieve balanced production and improve equipment utilization. , The effect of improving equipment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

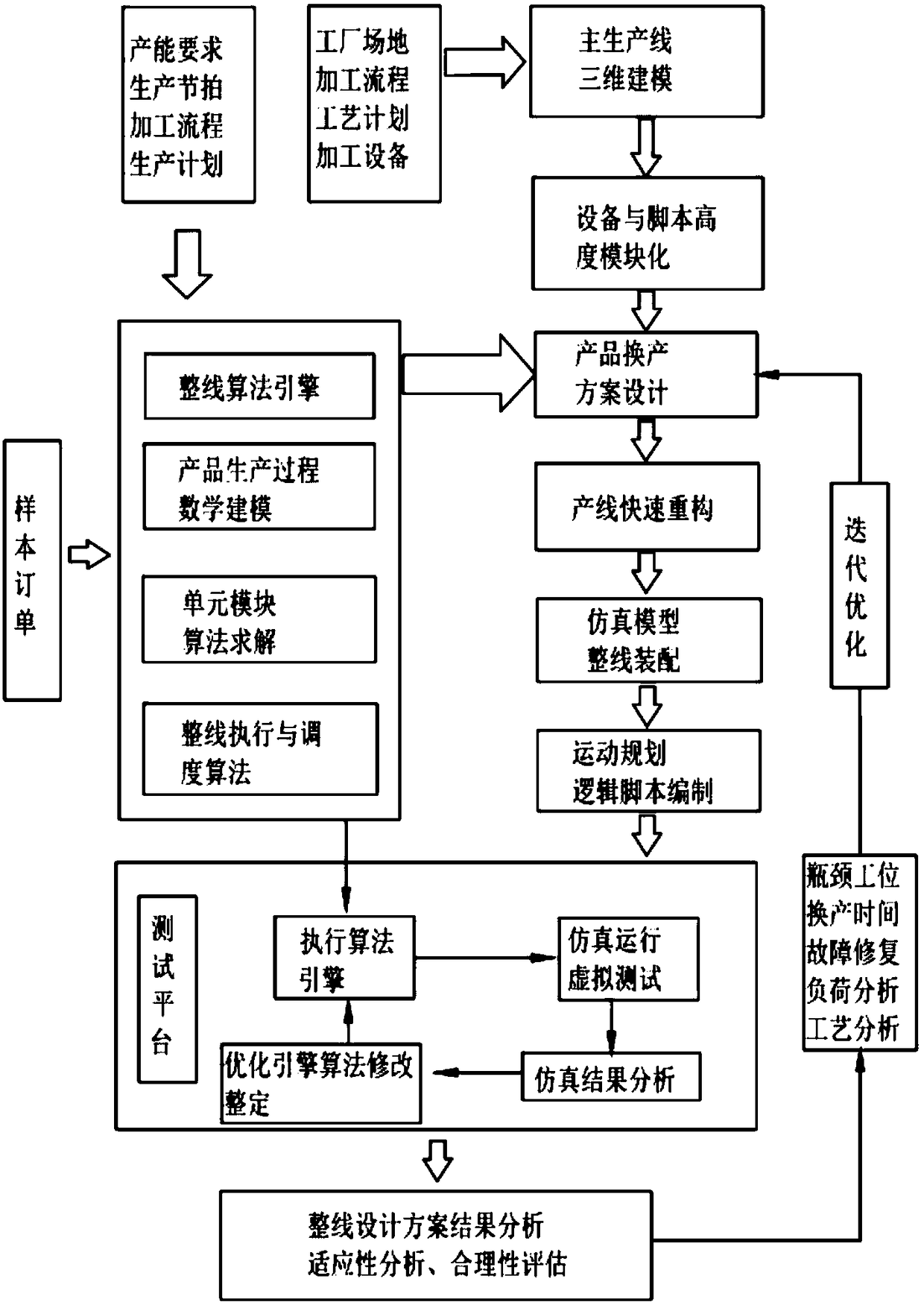

[0039] A virtual replacement method for an electronic product production line, comprising the following steps:

[0040] Step A, according to the layout planning of the mainstream pipeline and the special production platform required for the replacement of electronic products, the simulation system is modeled, and the 3D model library is established in the host computer;

[0041] Step B, encapsulating the action mode and control mode according to the mainstream pipeline and special production platform, defining standardized data interfaces and information interfaces, and encapsulating the established 3D model library after modularization;

[0042] Step C, according to the situation of the sample order, and according to the constraints of the initial production conditions, combined with the three-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com