Intelligent vacuum melting and rapid hardening equipment and manufacturing method of rapid hardening alloy

A vacuum smelting and vacuum technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems affecting production efficiency, life and work stability, waste of rare earth raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

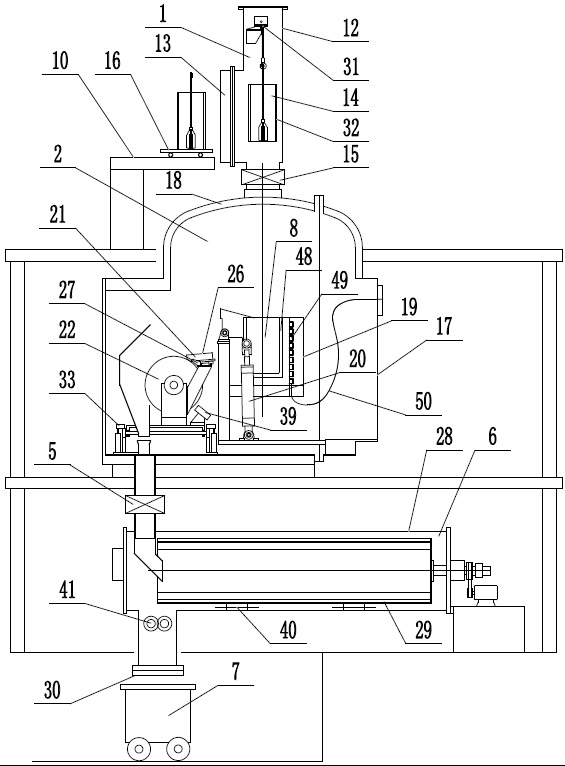

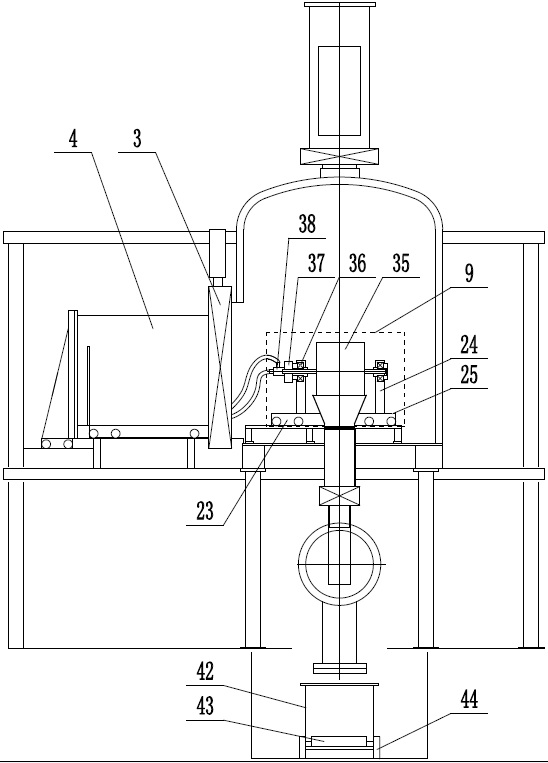

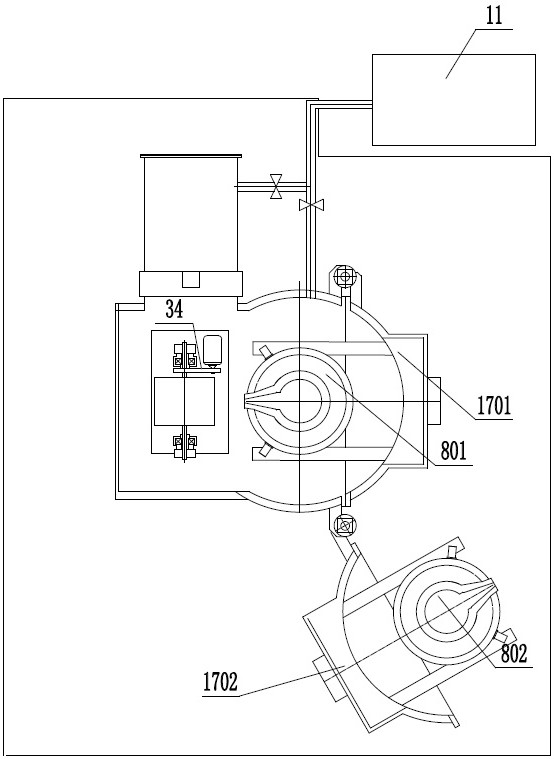

[0037] like Figure 1-3 As shown, in one embodiment of the present invention, the intelligent vacuum smelting quick-setting equipment mainly includes a vacuum feeding chamber 1, a vacuum smelting chamber 2, a rotating roller isolation valve 3, a rotating roller moving chamber 4, an intermediate isolation valve 5, and an alloy sheet Cooling chamber 6, alloy sheet collecting device 7, vacuum melting device 8, rotating roller device 9, operating platform 10 and vacuum unit 11; vacuum feeding chamber 1 includes feeding chamber body 12, feeding chamber door 13, feeding device 14, and vacuum feeding valve 15 and feeding cart 16; the vacuum feeding chamber 1 is arranged above the vacuum smelting chamber 2, the feeding chamber door 13, the feeding chamber body 12 and the vacuum feeding valve 15 form a sealing body, and the feeding device 14 is arranged in the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com