Insert high-precision stamping and bending die

A stamping and bending, high-precision technology, applied in the field of workpiece stamping, can solve the problems of waste of resources, the workpiece cannot be used normally, and the residue of waste chips, etc., to achieve the effect of easy placement and installation, and avoid excessive overflow of waste chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

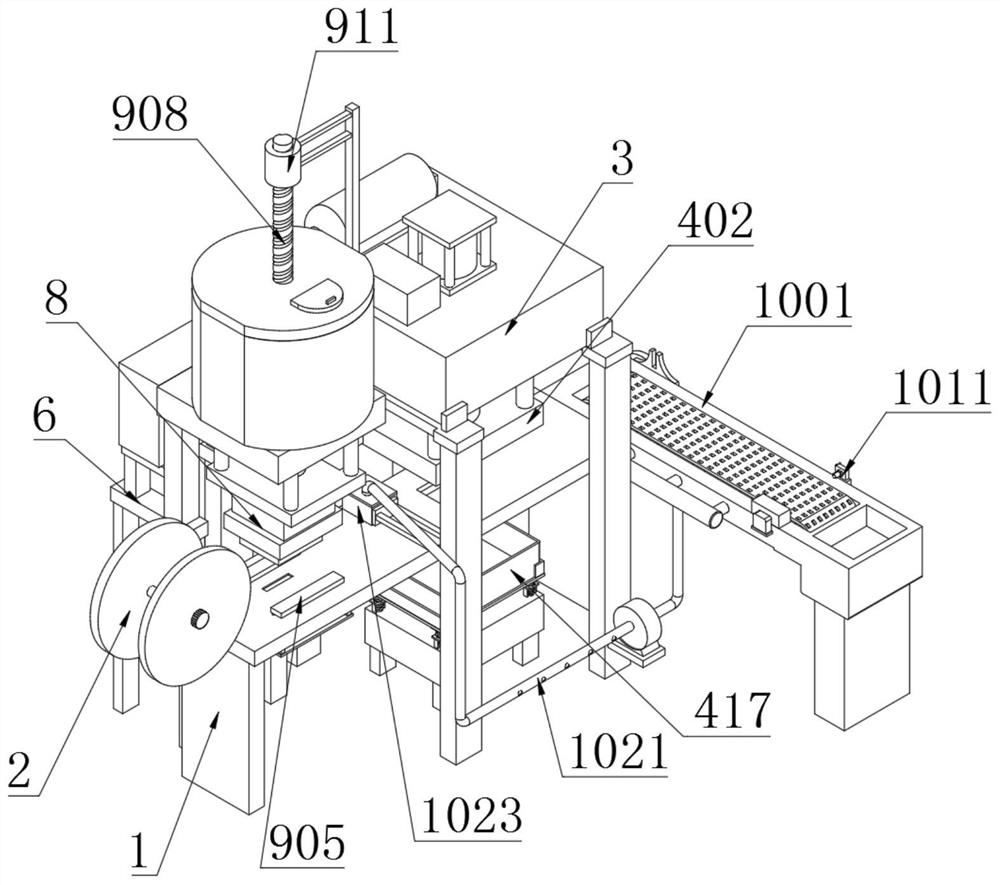

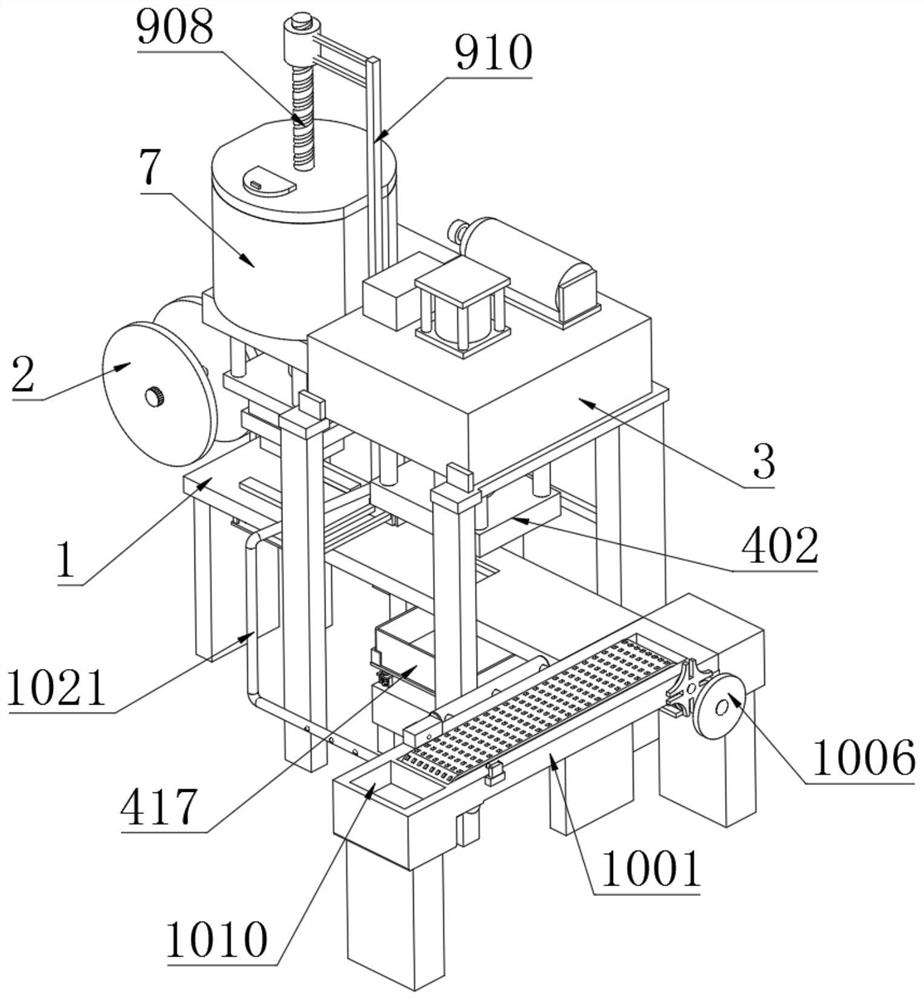

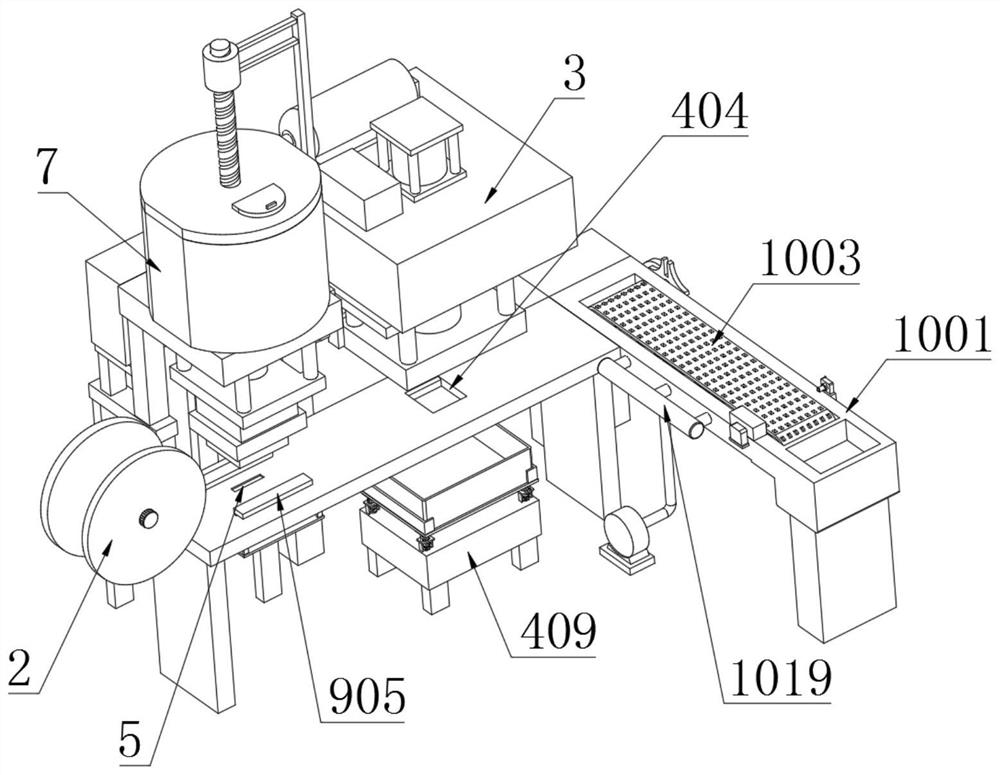

[0038] Example: Figure 1-10 As shown, the present invention provides a technical solution, an insert high-precision stamping bending mold, including a machining platform 1, one end of the machining platform 1 fixedly mounted, a raw material placement frame 2, a side fixed mounting of the machining platform 1 There is a punching machine 3, and the stamping and waste collecting mechanism 4 is fixed at a lower position of the punching machine 3 such that the scrap produced during the punch bending process is left on the active baffle 407, and the waste is discharged into the collection box 417 When the scorpion is accomplished to a certain extent, the staff will be reminded by the buzzer 412;

[0039] The stamping and waste collecting mechanism 4 includes a hydraulic drive rod 401, a lifting plate 402, a punching block 403, a stamping cavity 404, a movable tank 405, an electric telescoping rod 406, a movable baffle 407, a cleaning brush 408, a fixed station 409, a support frame 410 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com