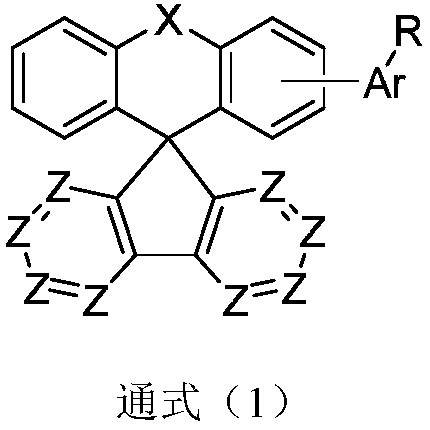

Compound with aza-spirofluorene structure as mother nucleus and application of compound on organic electroluminescent devices

A compound and organic compound technology, applied in the application field of organic electroluminescent devices, can solve problems such as performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

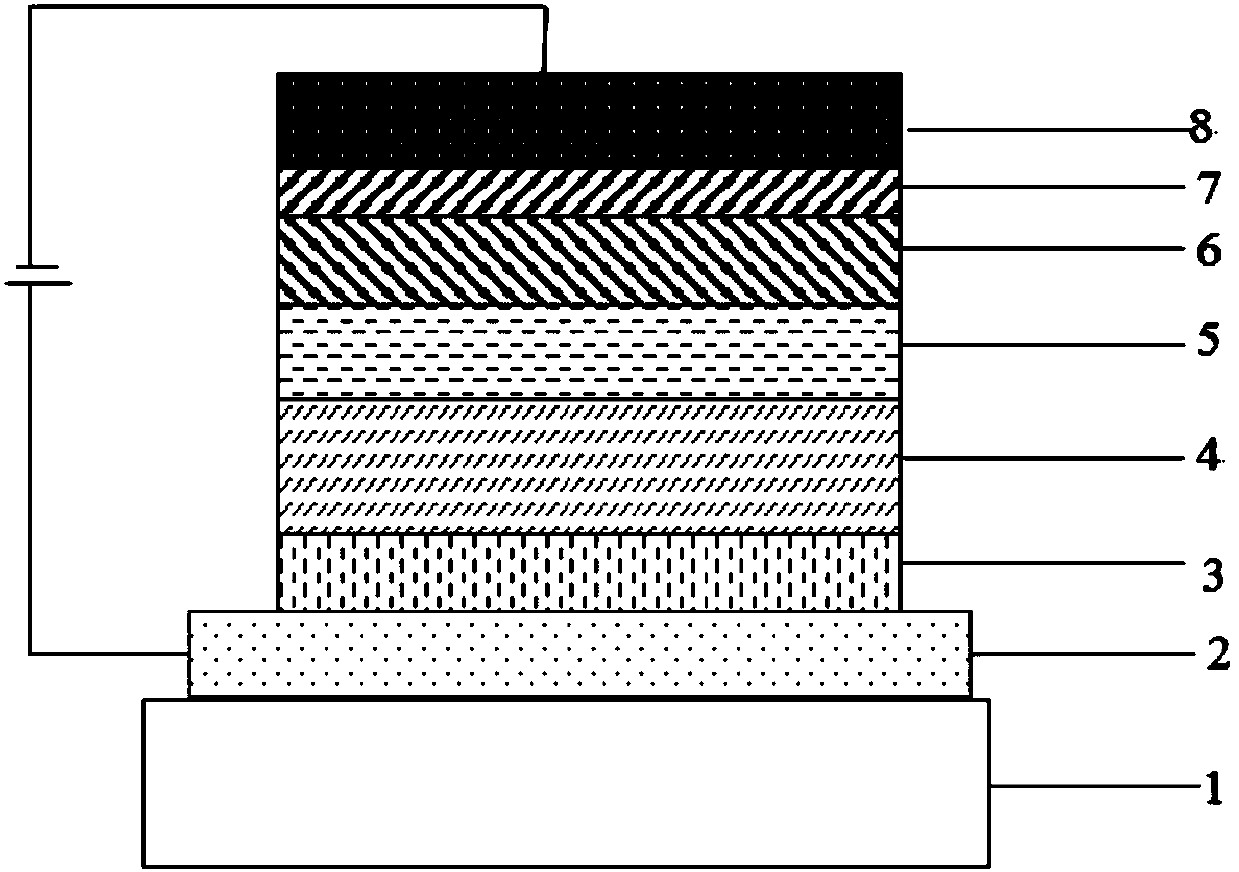

Method used

Image

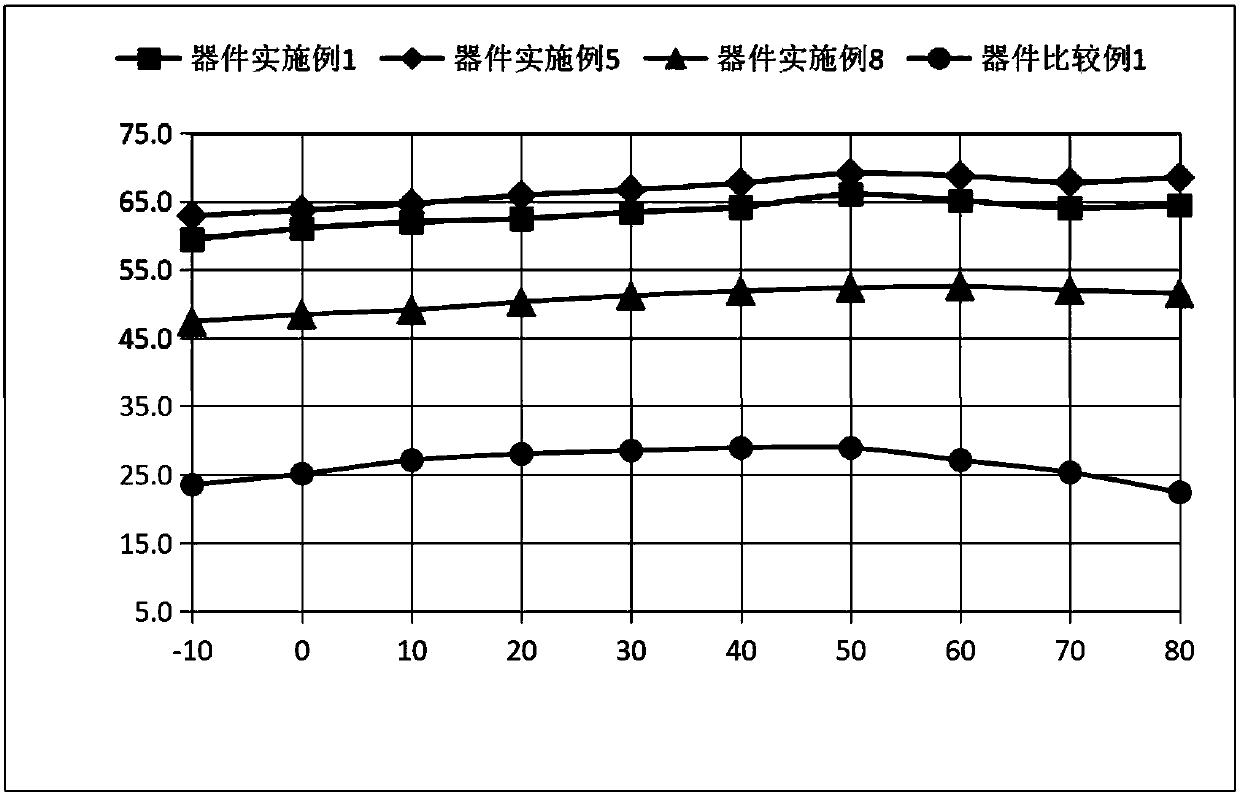

Examples

Embodiment 1

[0053] Embodiment 1: the synthesis of compound 1

[0054]

[0055] In a 500mL three-neck flask, under nitrogen protection, add 0.03mol raw material A-1, 0.03mol raw material B-1, 250mL toluene and stir to mix, then add 0.09mol potassium tert-butoxide and 0.09mol triphenylphosphine, 0.0015mol Pd 2 (dba) 3 , heated to 110°C, reflux reaction for 24 hours; naturally cooled to room temperature, filtered, and the filtrate was subjected to vacuum rotary evaporation (-0.09MPa, 85°C), and passed through a neutral silica gel column to obtain compound 1. The HPLC purity was 99.3%, and the yield was 76.3%;

[0056] Elemental analysis structure (molecular formula C 44 h 29 N 3 O): theoretical value C, 85.83; H, 4.75; N, 6.82; tested value: C, 85.81; H, 4.76; N, 6.81. MS m / z: 615.28[M+H] + , theoretical value: 615.74.

Embodiment 2

[0057] Embodiment 2: the synthesis of compound 15

[0058]

[0059]

[0060] In a 500mL three-neck flask, under nitrogen protection, add 0.03mol raw material B-2, 0.03mol p-dibromobenzene, 250mL toluene and stir to mix, then add 0.09mol potassium tert-butoxide and 0.09mol triphenylphosphine, 0.0015mol Pd 2 (dba) 3 , heated to 110°C, and refluxed for 24 hours; naturally cooled to room temperature, filtered, and the filtrate was subjected to reduced-pressure rotary evaporation (-0.09MPa, 85°C), and passed through a neutral silica gel column to obtain intermediate C-1;

[0061] In a 250mL three-neck flask, under the protection of nitrogen, add 0.02mol intermediate C-1, 0.03mol biboronic acid pinacol ester, 0.05mol potassium carbonate, 0.002mol Pd 3 (PPh) 4 and 100ml of toluene / water (volume ratio=5:1), stir and mix, heat to 80°C, react for 24 hours, take a sample point plate, it shows that there is no intermediate C-1 remaining, and the reaction is complete; naturally coo...

Embodiment 3

[0064] Embodiment 3: the synthesis of compound 27

[0065]

[0066]

[0067] In a 500mL three-neck flask, under the protection of nitrogen, add 0.03mol raw material B-3, 0.03mol m-dibromobenzene, 250mL toluene and stir to mix, then add 0.09mol potassium tert-butoxide and 0.09mol triphenylphosphine, 0.0015mol Pd 2 (dba) 3 , heated to 120°C, and refluxed for 24 hours; naturally cooled to room temperature, filtered, and the filtrate was subjected to reduced-pressure rotary evaporation (-0.09MPa, 85°C), and passed through a neutral silica gel column to obtain intermediate C-2;

[0068] In a 250mL three-neck flask, under the protection of nitrogen, add 0.02mol of intermediate C-2, 0.03mol of pinacol borate, 0.05mol of potassium carbonate, 0.002mol of Pd 3 (PPh) 4 and 100ml toluene / water (volume ratio = 5:1), stir and mix, heat to 80°C, react for 24 hours, take a sample point plate, it shows that there is no intermediate C-2 remaining, and the reaction is complete; naturally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com