Hot-melt pressure sensitive adhesive for waterproof rolls, and preparation method thereof

A technology of hot-melt pressure-sensitive adhesive and waterproof membrane, applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive type, etc. Adhesive ability, improved adhesion, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

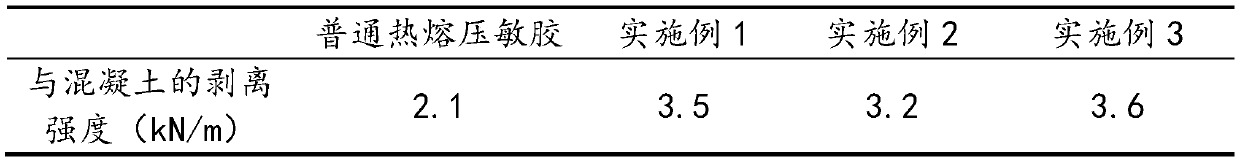

Examples

preparation example Construction

[0042]The embodiment of the present invention provides a hot-melt pressure-sensitive adhesive for waterproof coiled material and its preparation method, comprising: components containing the following content: thermoplastic elastomer: 5-30%; saturated thermoplastic elastomer: 5-15%; Viscose resin: 25-50%; Plasticizer: 15-40%; Silicone additive: 0.5-5%; Stabilizer: 0.5-5%. Wherein, the thermoplastic elastomer is at least one of polystyrene-butadiene-styrene (SBS) and polystyrene-isoprene-styrene (SIS); the saturated thermoplastic elastomer is polystyrene-hydrogenated One of butadiene-styrene (SEBS) and polystyrene-hydrogenated isoprene-styrene (SEPS), the content of styrene in the above-mentioned block copolymers is all controlled at 15%-30%. The main cohesion and elasticity are provided by the thermoplastic elastomer and the saturated thermoplastic elastomer as the skeleton material of the adhesive, and the present invention optimizes such properties through the compounding of...

Embodiment 1

[0064] Heat the reactor to 140°C, add 30 parts of paraffin oil, start stirring, raise the temperature to 160°C, add 30 parts of SIS, 5 parts of SEBS, 1 part of pentaerythritol β-dodecylthiopropionate, 2,6- 2 parts of di-tert-butyl-p-cresol were stirred to dissolve, and 30 parts of C5 petroleum resin and 10 parts of terpene resin were added in batches. After it is completely melted, add 4 parts of silicone additives, 0.5 parts of 2-(2'hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, and stir to mix evenly. The volatile gas is discharged under reduced pressure for half an hour, and the material is discharged and cooled to obtain a hot-melt pressure-sensitive adhesive for waterproof coiled material.

Embodiment 2

[0066] Heat the reactor to 150°C, add 25 parts of naphthenic oil, start stirring, raise the temperature to 160°C, add 20 parts of SIS, 5 parts of SBS, 10 parts of SEPS, β(3,5-di-tert-butyl-hydroxyphenyl ) 0.5 parts of pentaerythritol propionate, 1 part of 2,5-di-tert-butylhydroquinone, stir to dissolve, add 10 parts of C5 petroleum resin, and 25 parts of terpene resin in batches. After it melted completely, add 2 parts of silicone additive, 2-[4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl]-5-( 1 part of octyloxy)phenol, stir to make it evenly mixed. The volatile gas is discharged under reduced pressure for half an hour, and the material is discharged and cooled to obtain a hot-melt pressure-sensitive adhesive for waterproof coiled material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com