Preparation method of modified high-nickel ternary positive electrode material

A positive electrode material, high-nickel technology, applied in the field of preparation of modified high-nickel ternary positive electrode materials, can solve the problem of incomplete matching of coating temperature and sintering temperature, uneven distribution of nickel-manganese oxide precursors, and reduction of lithium ion deintercalation Kinetic properties and other issues, to achieve the effect of accelerating the rapid deintercalation process, good structural reversibility, and improving rate discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

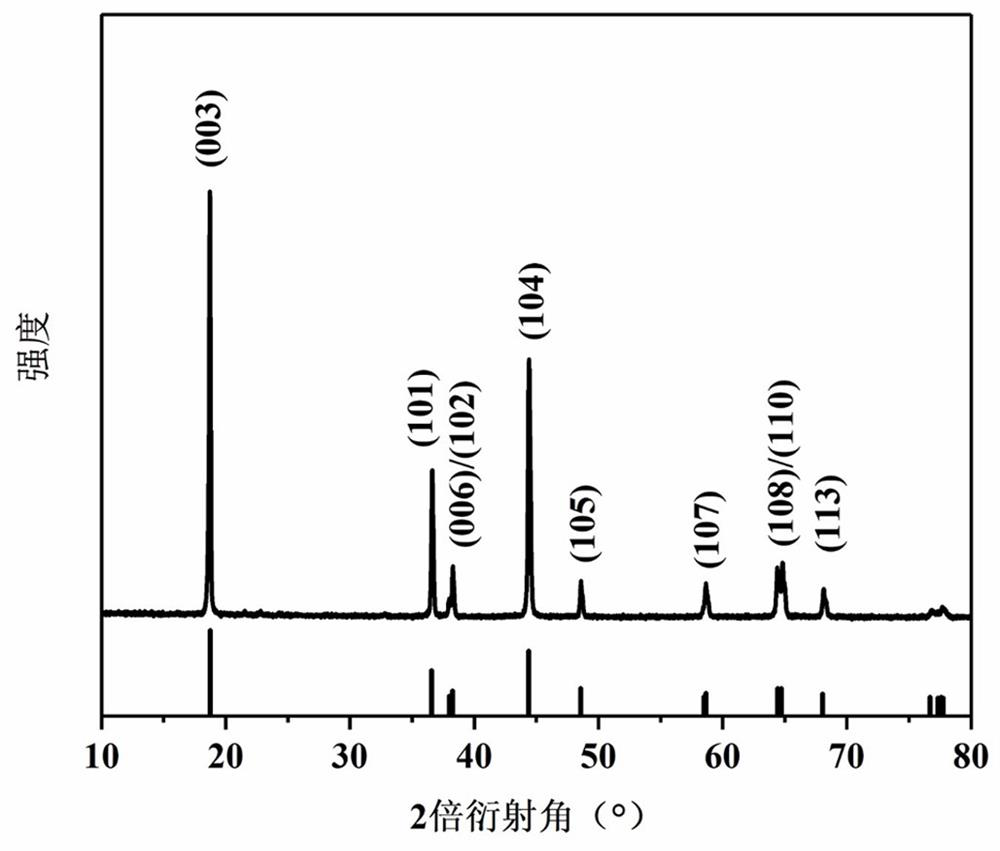

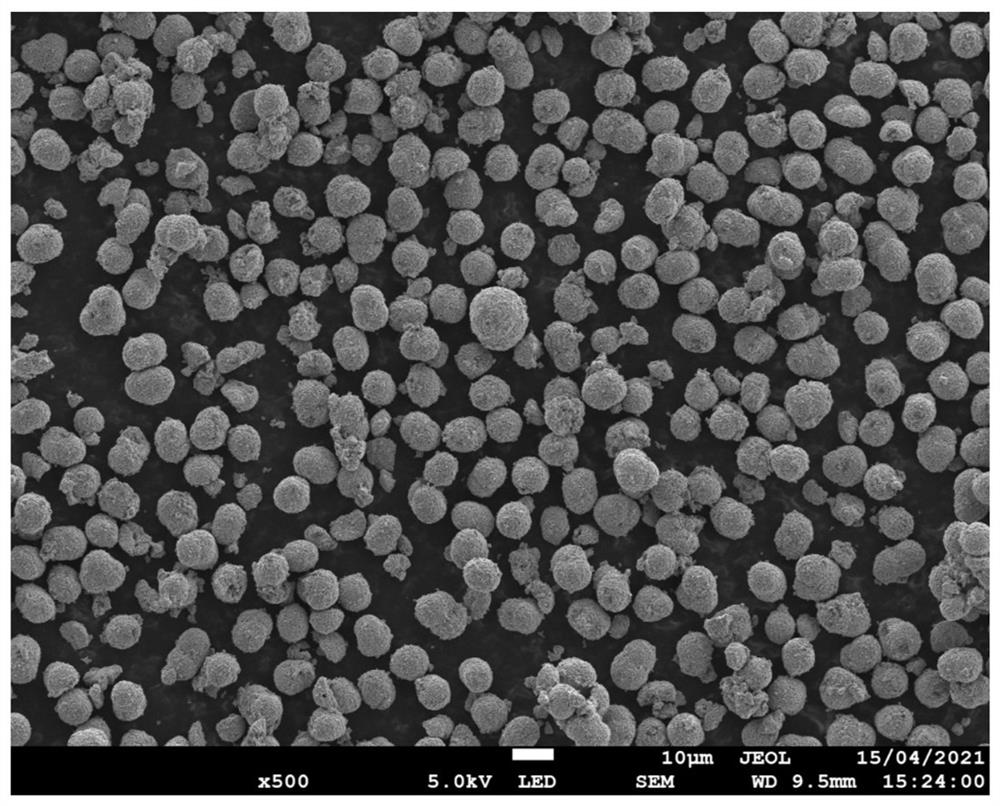

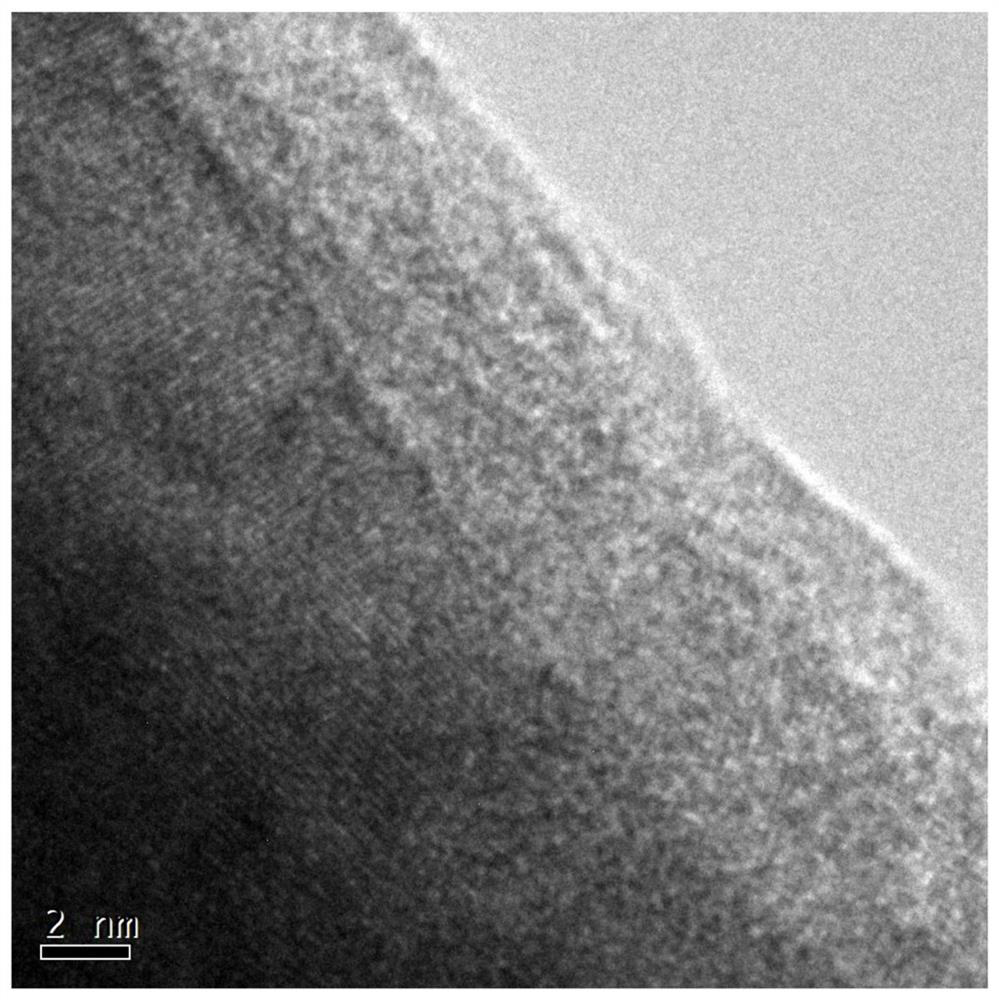

[0047] A modified high-nickel ternary positive electrode material of the present invention, comprising high-nickel ternary positive electrode material LiNi 0.74 co 0.14 mn 0.12 o 2 The matrix, the high-nickel ternary positive electrode material is doped with metal magnesium, and the surface of the magnesium-doped high-nickel ternary positive electrode material is covered with a layer of lithium vanadate coating layer, and the magnesium doping content accounts for 2% of the total transition metals. The lithium vanadate coating layer accounts for 3% of the magnesium-doped high-nickel ternary cathode material; the modified high-nickel ternary cathode material is a spherical secondary particle aggregate with an average particle size of 9 μm, regular shape, and distribution Uniform; the average thickness of the lithium vanadate coating layer is 5nm.

[0048] The preparation method of the modified high-nickel ternary positive electrode material of the present embodiment, the step...

Embodiment 2

[0080] A modified high-nickel ternary positive electrode material of the present invention, comprising high-nickel ternary positive electrode material LiNi 0.74 co 0.14 mn 0.12 o 2 The matrix, the high-nickel ternary positive electrode material is doped with metal magnesium, and the surface of the magnesium-doped high-nickel ternary positive electrode material is covered with a layer of lithium vanadate coating layer, and the magnesium doping content accounts for 3% of the total transition metal. The lithium vanadate coating layer accounts for 5% of the magnesium-doped ternary material; the modified high-nickel ternary material is a spherical secondary particle agglomerate with an average particle size of 9 μm, regular shape and uniform distribution; vanadium The average thickness of the lithium oxide coating layer is 6nm.

[0081] The preparation method of the modified high-nickel ternary positive electrode material of the present embodiment, the steps are as follows:

[...

Embodiment 3

[0089] A modified high-nickel ternary cathode material of the present invention, comprising magnesium-doped high-nickel ternary cathode material LiNi 0.74 co 0.14 mn0.12 o 2 Substrate, magnesium-doped high-nickel ternary positive electrode material The surface of the substrate is covered with a layer of lithium vanadate coating layer, the magnesium doping content accounts for 2% of the total transition metal, and the lithium vanadate coating layer accounts for 2% of the magnesium-doped ternary material. The modified high-nickel ternary cathode material is a spherical secondary particle aggregate with an average particle size of 9 μm, regular shape and uniform distribution; the average thickness of the lithium vanadate coating layer is 5nm.

[0090] The preparation method of the modified high-nickel ternary positive electrode material of the present embodiment, the steps are as follows:

[0091] (1) The preparation process of the nickel-cobalt-manganese hydroxide precursor is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com