A kind of preparation method of 3dpc/co/coo lithium battery negative electrode material

A technology of negative electrode material and composite material, applied in the field of preparation of 3DPC/Co/CoO lithium battery negative electrode material, can solve the problems of poor cycle performance, low conductivity, unstable structure, etc. The effect of structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

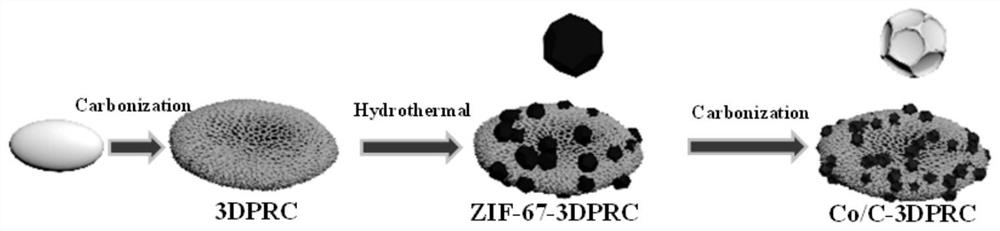

[0047] Embodiment 1: A method for preparing a 3DPC / Co / CoO lithium battery negative electrode material according to this embodiment is carried out according to the following steps:

[0048] 1. Synthesis of 3D porous carbon 3DPC

[0049] In a tube furnace, feed argon gas to carbonize edible rice flakes, the carbonization temperature is 850-950°C, and the heating rate is 8-12°C / min, to obtain three-dimensional porous carbon 3DPC;

[0050] 2. Synthesis of 3DPC / Co-MOFs precursor materials

[0051] Co(NO 3 ) 2 ·6H 2 O was dissolved in methanol solution and stirred for 10 min to obtain Co(NO 3 ) 2 ·6H 2 O methanol solution; Dimethylimidazole was dissolved in methanol solution and stirred for 10min to obtain dimethylimidazole methanol solution; Co(NO 3 ) 2 ·6H 2 O methanol solution and dimethylimidazole methanol solution were mixed and stirred at a constant rate for 10 min to obtain a mixed solution; the mixed solution and three-dimensional porous carbon 3DPC were added to a ...

specific Embodiment approach 2

[0054] Specific embodiment two: the difference between this embodiment and specific embodiment one is: Co(NO 3 ) 2 ·6H 2 Co(NO 3 ) 2 ·6H 2 The molar ratio of O to 2-MeIM in 2-MeIM methanol solution is 1:20-1:43. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0055] Specific embodiment three: the difference between this embodiment and specific embodiment one is: Co(NO 3 ) 2 ·6H 2 Co(NO 3 ) 2 ·6H 2 The molar ratio of O to 2-MeIM in 2-MeIM methanol solution is 1:30 to 1:40. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com