A kind of composite lithium-ion battery diaphragm and preparation method thereof

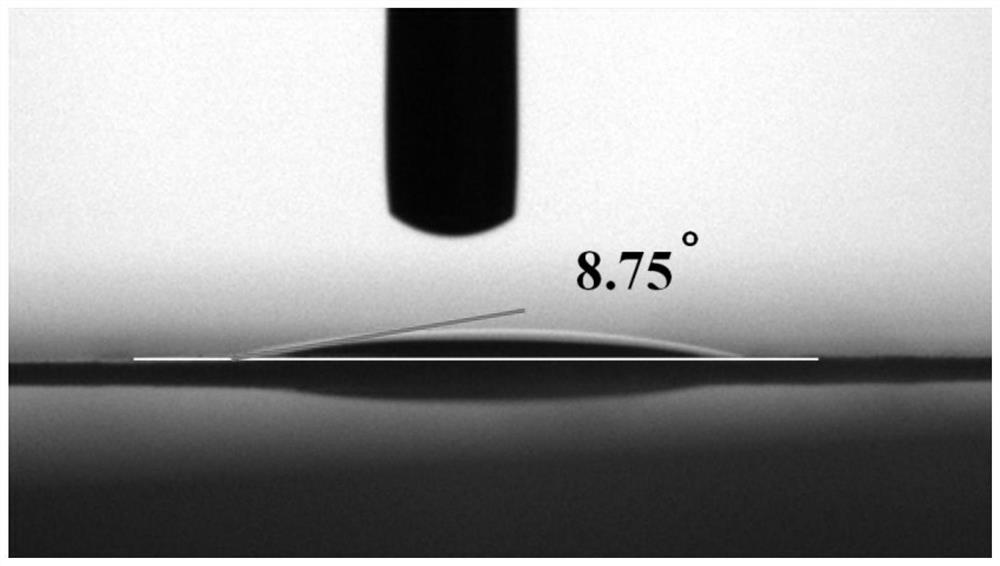

An ion battery, composite lithium technology, applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc., can solve the impact of battery safety performance and electrochemical performance, inorganic nanoparticles easily fall off, diaphragm It can improve the electrochemical cycle performance and safety performance, inhibit the collapse of the cathode material structure, and achieve the effect of excellent wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of above-mentioned composite lithium-ion battery separator, comprises the following steps:

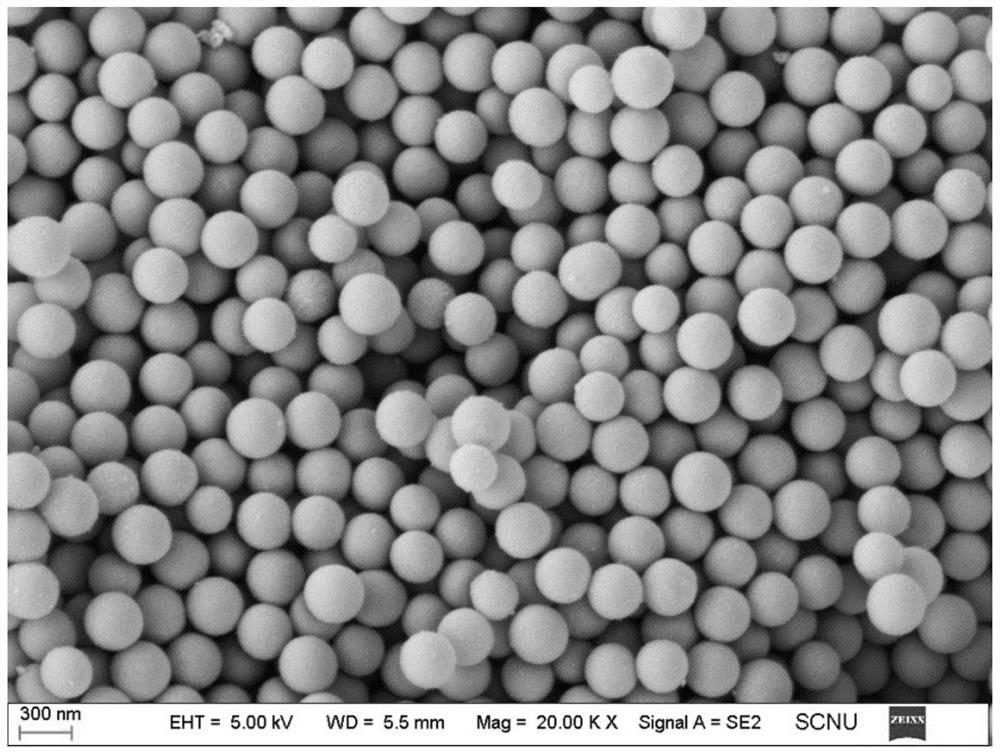

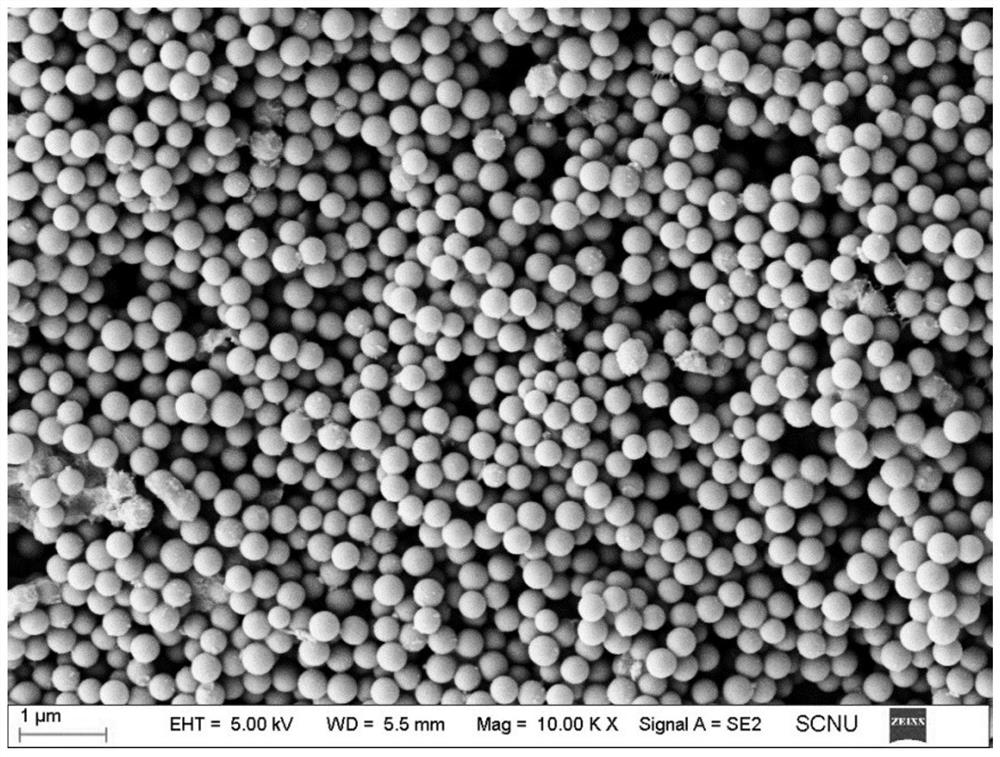

[0039] 1) adding the tetraethyl orthosilicate-ethanol mixed solution into the ammonia-ethanol-water mixed solution, fully reacting to obtain the nano-silica dispersion;

[0040] 2) Add γ-methacryloxypropyltrimethoxysilane into the nano-silica dispersion liquid, fully react, then separate the solid from the liquid, wash and dry the solid product to obtain vinyl silica nanoparticles ;

[0041] 3) Add 1-vinylimidazole, styrene, initiator and vinyl silica nanoparticles into the solvent, fully react, then separate solid and liquid, wash and dry the solid product to obtain imidazole-based silica nanoparticles ;

[0042] 4) Dispersing imidazole-based silica nanoparticles and organic polymers in a solvent to obtain a casting liquid, then immersing the polyolefin-based film in the casting liquid, fully soaking, taking out and drying to obtain a composite lithium-...

Embodiment 1

[0061] A kind of composite lithium-ion battery diaphragm, its preparation method is as follows:

[0062] 1) Mix 82.8mL ethanol and 8.4mL tetraethyl orthosilicate evenly to obtain tetraethyl orthosilicate-ethanol mixed solution, mix 16.2mL concentrated ammonia water with a mass fraction of 25%, 28.8mL ethanol and 45mL distilled water, Obtain the ammonia water-ethanol-water mixture, and then add the tetraethyl orthosilicate-ethanol mixture into the ammonia-ethanol-water mixture at a constant speed while stirring, and stir at room temperature for 12 hours to obtain a nano-silica dispersion;

[0063] 2) Slowly add 4g of γ-methacryloxypropyltrimethoxysilane dropwise into the nano-silica dispersion, stir at room temperature for 24 hours, centrifuge at high speed, wash the centrifuged solid product with ethanol and distilled water several times, and then Dry at 120°C for 24 hours to obtain vinyl silica nanoparticles;

[0064] 3) Add 0.8mL of 1-vinylimidazole, 0.8mL of styrene, 0.04g...

Embodiment 2

[0073] A kind of composite lithium-ion battery diaphragm, its preparation method is as follows:

[0074] 1) Mix 124.2mL ethanol and 6mL tetraethyl orthosilicate evenly to obtain tetraethyl orthosilicate-ethanol mixed solution, mix 24.3mL concentrated ammonia water with a mass fraction of 25%, 43.2mL ethanol and 67.5mL distilled water, Obtain the ammonia water-ethanol-water mixed solution, and then add the tetraethyl orthosilicate-ethanol mixed solution into the ammonia-ethanol-water mixed solution at a constant speed while stirring, and stir at room temperature for 10 hours to obtain a nano-silica dispersion;

[0075] 2) Slowly add 6 g of γ-methacryloxypropyltrimethoxysilane dropwise into the nano-silica dispersion, stir at room temperature for 30 h, centrifuge at high speed, wash the centrifuged solid product with ethanol and distilled water several times, and then Dry at 110°C for 30 hours to obtain vinyl silica nanoparticles;

[0076] 3) Add 0.8mL of 1-vinylimidazole, 0.8m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com