A kind of single crystal nickel cobalt lithium manganate cathode material and preparation method and application thereof

A technology of nickel cobalt lithium manganate and positive electrode material, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve problems such as damage, cycle life deterioration, increase battery polarization and internal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

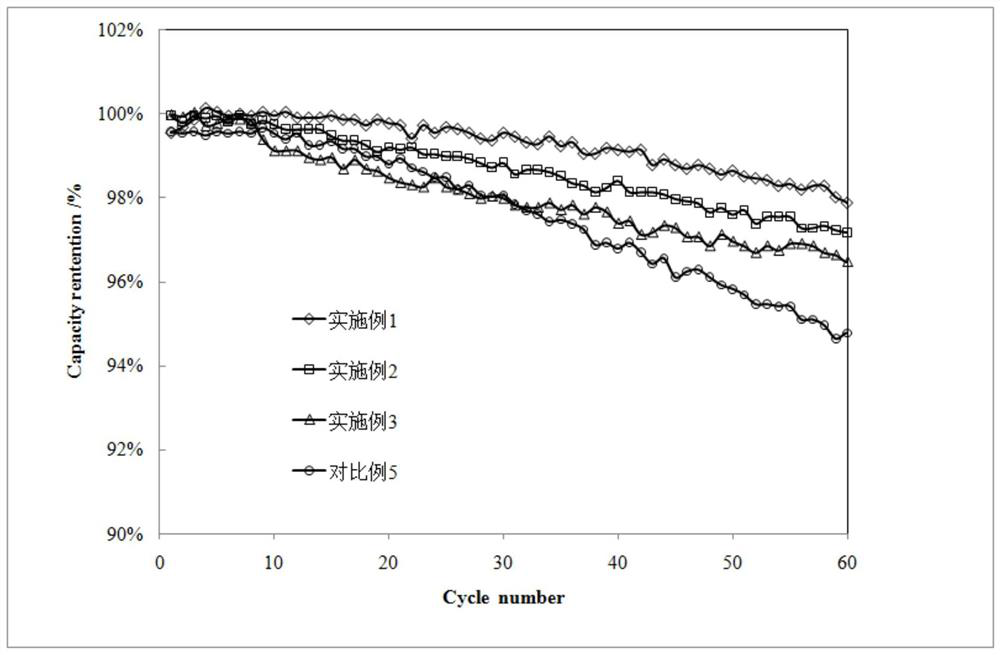

Embodiment 1

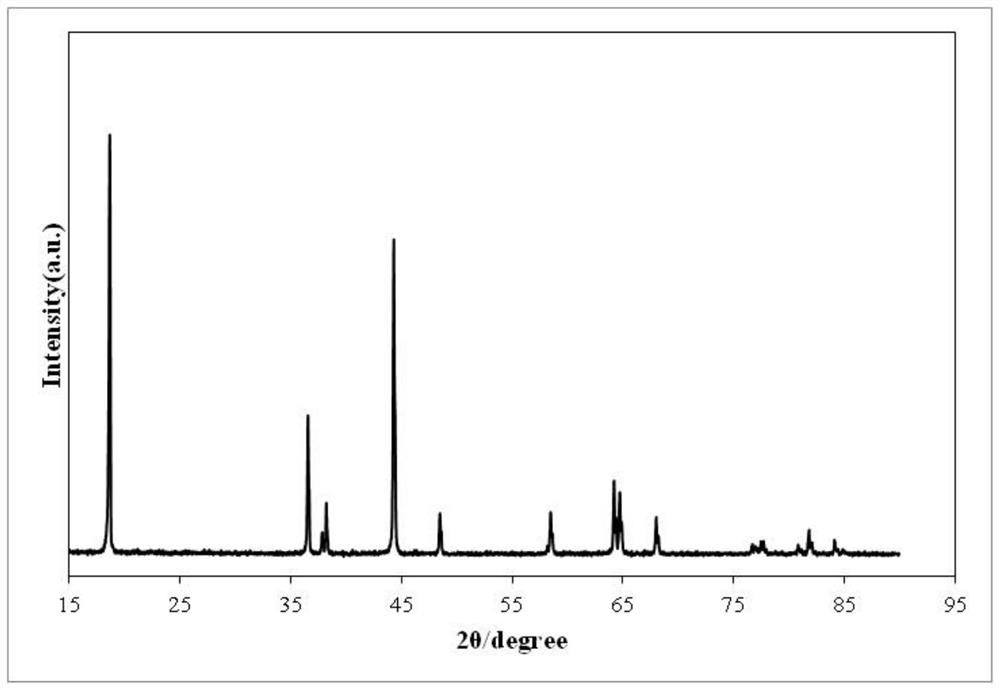

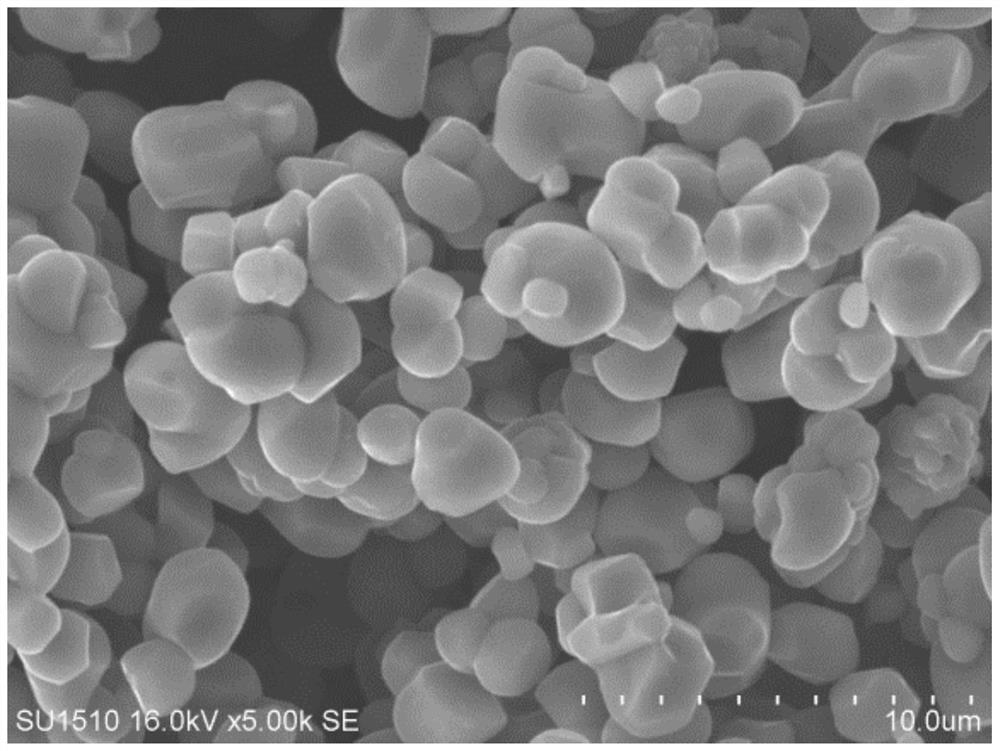

[0038] This example provides a method for preparing a single crystal nickel cobalt lithium manganate cathode material and the prepared single crystal nickel cobalt lithium manganate cathode material.

[0039] The preparation method includes: (1) adding the solid mixture of the alumina to the aluminum metaphosphate in a ratio of 1:2 by mass to ultrapure water to form a slurry A, so that the proportion of solid matter in the slurry is 30% , the slurry was stirred at 600rpm for 2h. Then, the obtained slurry A was mixed with single crystal Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 The precursor was added to the grinding machine at a mass ratio of 5:6, and the dispersed slurry was ground by using a grinding sphere with a particle size of 0.1 mm and maintaining the rotating speed at 3000 rpm in the sand mill. The slurry was stirred using a dispersing disc at 600 rpm for 2 h. The dispersed slurry was drawn into a spray dryer and spray-dried at 300 rpm. The obtained spray-dried material was s...

Embodiment 2

[0044] This example provides a method for preparing a single crystal nickel cobalt lithium manganate cathode material and the prepared single crystal nickel cobalt lithium manganate cathode material.

[0045] The preparation method includes: (1) the same method as step (1) in Example 1, to obtain the composite material B.

[0046] (2) In the same manner as in step (2) of Example 1, shell material C is obtained.

[0047] (3) Preparation of core layer: Weigh the lithium source and the ternary single crystal material precursor Ni according to the molar ratio of Li: ternary material precursor = 1.05:1 0.7 Co 0.1 Mn 0.2 (OH) 2 , After mixing the above materials in a high-speed mixer of 600r / min for 45min, put them into an atmosphere furnace, sintering temperature 930±10℃, sintering time 12h, sintering atmosphere is oxygen atmosphere, and obtain core layer material E.

[0048] (4) The shell material C is used as the cladding layer, and the core material E is added in a high-spee...

Embodiment 3

[0050] This example provides a method for preparing a single crystal nickel cobalt lithium manganate cathode material and the prepared single crystal nickel cobalt lithium manganate cathode material.

[0051] The preparation method includes: (1) the same method as step (1) in Example 1, to obtain the composite material B.

[0052] (2) In the same manner as in step (2) of Example 1, shell material C is obtained.

[0053] (3) Preparation of core layer: Weigh the lithium source and the ternary single crystal material precursor Ni according to the molar ratio of Li: ternary material precursor = 1.05:1 0.83 Co 0.11 Mn 0.06 (OH) 2 , After mixing the above materials in a high-speed mixer of 600r / min for 45min, put them into an atmosphere furnace, the sintering temperature is 890±10℃, the sintering time is 12h, the sintering atmosphere is an oxygen atmosphere, and the core layer material F is obtained.

[0054] (4) The shell layer material C is used as the cladding layer, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com