LED (Light Emitting Diode) chip and manufacturing method thereof

An LED chip and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large current density and light emitting angle, and achieve the effects of increasing light efficiency, reducing current accumulation, and increasing light emitting angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

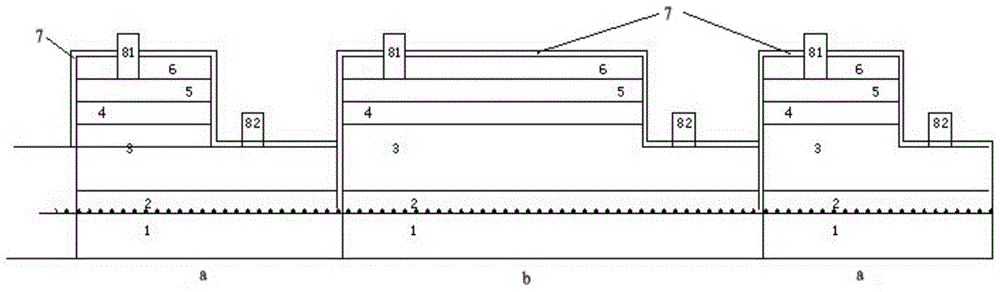

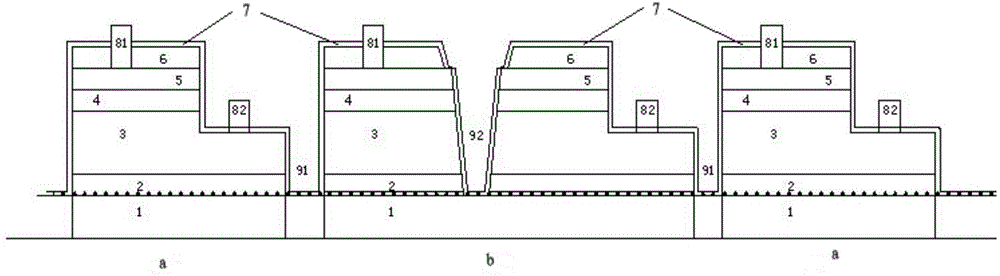

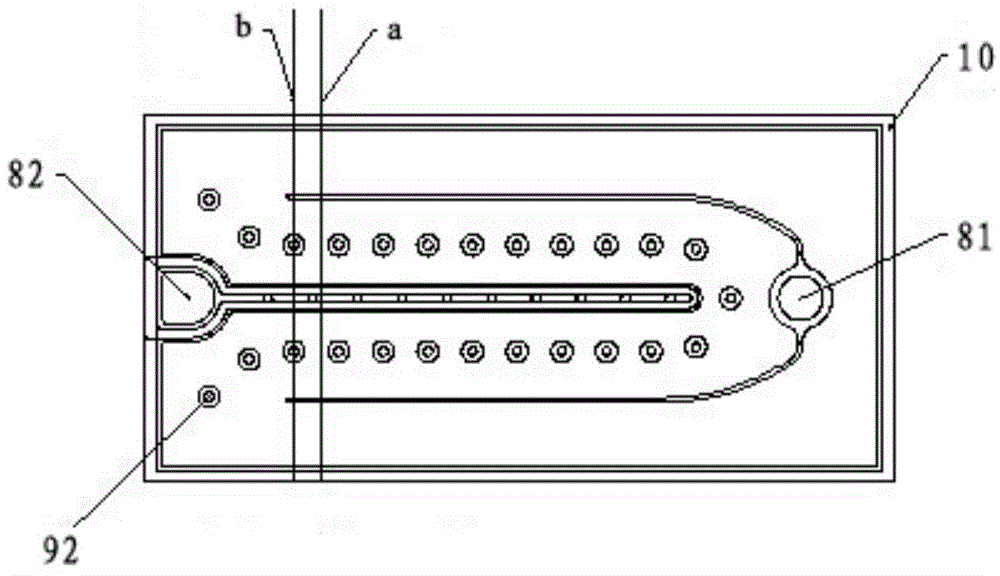

[0047] Such as figure 2 with image 3 As shown, this embodiment provides an LED chip, including: a PSS substrate 1, a buffer layer 2, an N-type semiconductor layer 3, a light-emitting layer 4, a P-type semiconductor layer 5, a transparent conductive layer 6 and Protective layer 7.

[0048] The PSS substrate 1 in the present invention is a patterned sapphire substrate. The transparent conductive layer 6 is an indium tin oxide film. The protective layer 7 is a protective layer made of silicon dioxide. Of course, the material of the protective layer is not specifically limited here.

[0049] A P electrode 81 is provided on the transparent conductive layer 6, and the P electrode 81 extends axially to penetrate the protective layer 7, and an N electrode 82 is provided on the N-type semiconductor layer 3. The P electrode 81 and the N electrode 82 are both reflective electrode structures Here, the reflective electrode structure is a nickel / aluminum structure or a nickel / silver structur...

Embodiment 2

[0070] Such as figure 2 with image 3 As shown, this embodiment provides an LED chip, including: a PSS substrate 1, a buffer layer 2, an N-type semiconductor layer 3, a light-emitting layer 4, a P-type semiconductor layer 5, a transparent conductive layer 6 and Protective layer 7.

[0071] The PSS substrate 1 in the present invention is a patterned sapphire substrate. The transparent conductive layer 6 is an indium tin oxide film. The protective layer 7 is a protective layer made of silicon dioxide. Of course, the material of the protective layer is not specifically limited here.

[0072] A P electrode 81 is provided on the transparent conductive layer 6, the P electrode 81 extends axially to penetrate the protective layer 7, and an N electrode 82 is provided on the N-type semiconductor layer 3. The P electrode 81 and the N electrode 82 are both reflective electrodes Structure, the reflective electrode structure here is a nickel / aluminum structure or a nickel / silver structure, t...

Embodiment 3

[0093] Such as figure 2 with image 3 As shown, this embodiment provides an LED chip, including: a PSS substrate 1, a buffer layer 2, an N-type semiconductor layer 3, a light-emitting layer 4, a P-type semiconductor layer 5, a transparent conductive layer 6 and Protective layer 7.

[0094] The PSS substrate 1 in the present invention is a patterned sapphire substrate. The transparent conductive layer 6 is an indium tin oxide film. The protective layer 7 is a protective layer made of silicon dioxide. Of course, the material of the protective layer is not specifically limited here.

[0095] A P electrode 81 is provided on the transparent conductive layer 6, and the P electrode 81 extends axially to penetrate the protective layer 7, and an N electrode 82 is provided on the N-type semiconductor layer 3. The P electrode 81 and the N electrode 82 are both reflective electrode structures Here, the reflective electrode structure is a nickel / aluminum structure or a nickel / silver structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com