Determination method of producing water for shale gas well, determination method of accumulated liquid and liquid drainage method

A technology for shale gas wells and determination methods, which is applied in the fields of earthwork drilling, wellbore/well components, and special data processing applications, etc. It can solve the problems of large errors, inability to analyze and calculate the height of liquid accumulation, and affect the decision-making of tool running positions, etc. problems, to achieve the effect of reducing bottomhole pressure, avoiding production stoppage and improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

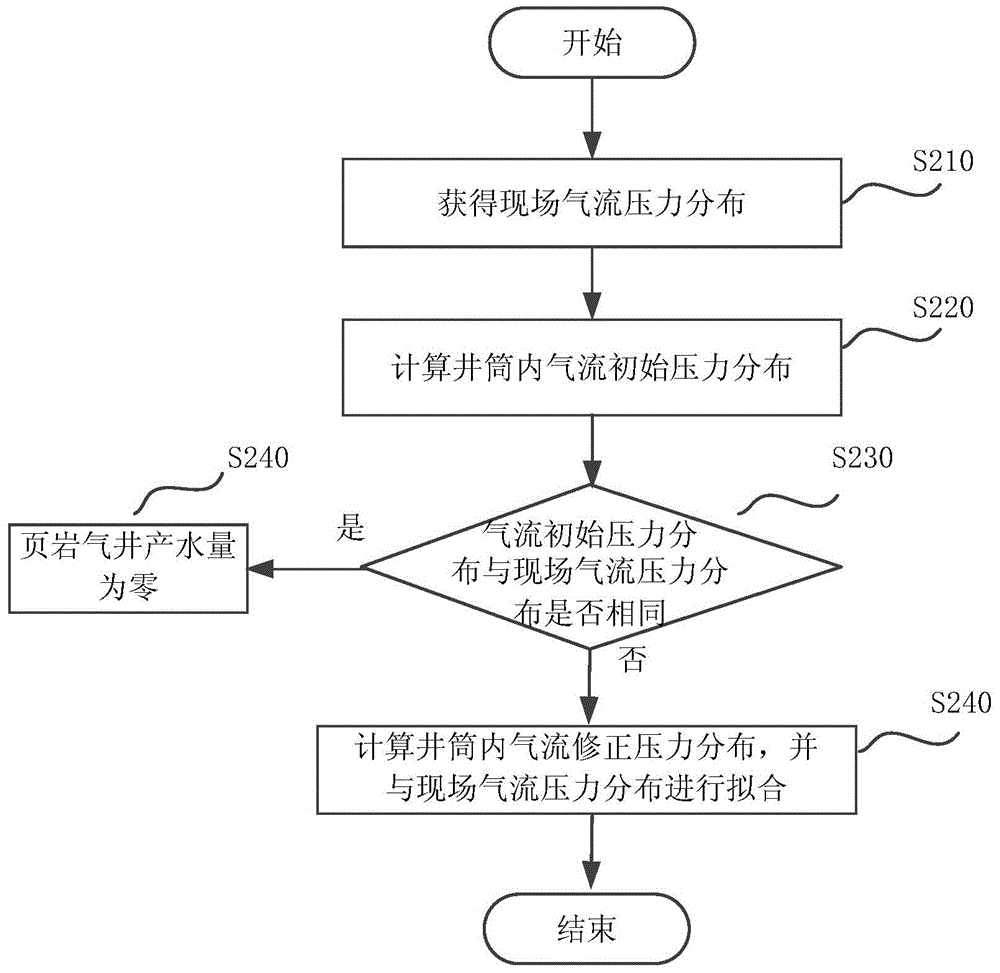

[0058] This embodiment provides a method for discriminating water production in shale gas wells and a method for predicting water production, which can be accurately calculated when the water production is extremely low.

[0059] Because the changes of fluid physical parameters in the wellbore are usually coupled, such as pressure, temperature, etc., which will affect each other, they cannot be calculated separately during the calculation process, and these parameters must be coupled and solved. The embodiment of the present invention is based on the theoretical results of expressions (1) and (2), adopts the method of calculating downwards from the wellhead, first divides the wellbore into sections, and then calculates section by section from the wellhead. The parameters of the upper outlet of each section are known, first assume a temperature value at the lower inlet, then use the pressure calculation model of the above expression (1) to calculate the lower inlet pressure, and...

Embodiment 2

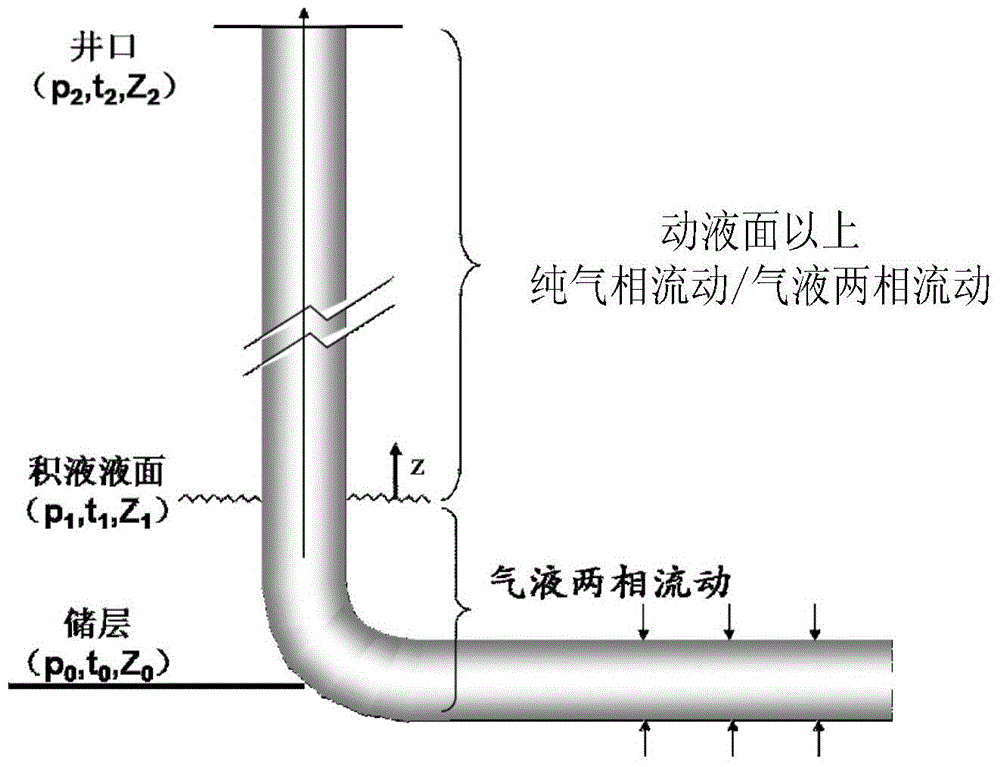

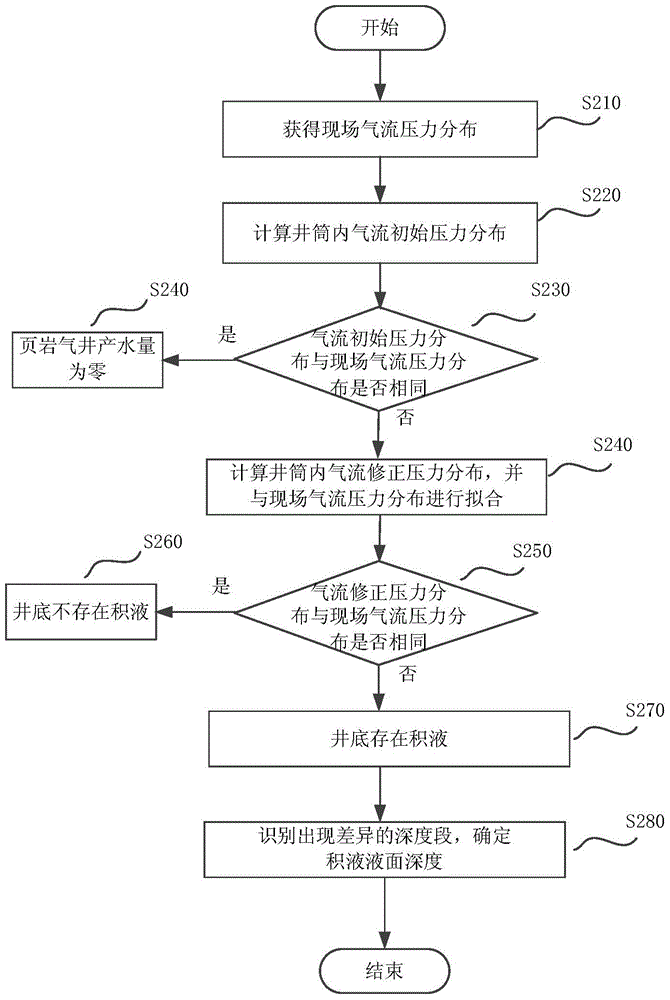

[0067] This embodiment provides a method for discriminating fluid accumulation at the bottom of a shale gas well and predicting the depth of fluid accumulation. Such as image 3 As shown, the method of this embodiment is based on the wellbore pressure fitting results of the first embodiment. exist image 3 The same steps are given the same reference numerals.

[0068] The difference from Example 1 is that in image 3 In the process, it also includes judging whether the calculated gas flow correction pressure distribution is the same as the on-site gas flow pressure distribution in the depth section near the bottom of the well (step S250), if they are the same, there is no liquid accumulation at the bottom of the well (step S260), if not If they are the same, there is fluid accumulation at the bottom of the well (step S270).

[0069] Further, if the calculated airflow correction pressure distribution is different from the on-site airflow pressure distribution in the depth s...

Embodiment 3

[0072] This embodiment provides a liquid drainage method for shale gas well bottomhole liquid accumulation, which can guide the site to take out the liquid accumulation by running oil pipes, prevent the gas well from shutting down due to excessive liquid accumulation, and improve the drainage efficiency of the shale gas well.

[0073] When it is judged that there is fluid accumulation at the bottom of the well, in order to discharge the fluid accumulation at the bottom of the well, it is necessary to run the tubing. Two parameters need to be determined when using the method of running the tubing, namely the running depth and the size of the tubing. This embodiment provides a method for determining the running depth of the oil pipe and the size of the oil pipe. The running depth of the tubing needs to be below the dynamic liquid level of the effusion, and the depth of the liquid level of the effusion can be obtained through the calculations in the examples, which is the minimum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com