Continuous casting and rolling and boronizing method and device of conductive aluminium alloy rod

An aluminum alloy rod, continuous casting and rolling technology, applied in metal rolling and other directions, can solve the problems of uneven composition of aluminum melt, low product qualification rate, incomplete boronization, etc., to avoid cleaning and production stoppage, improve product quality quality, avoiding the effect of secondary melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

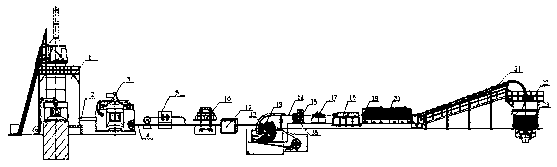

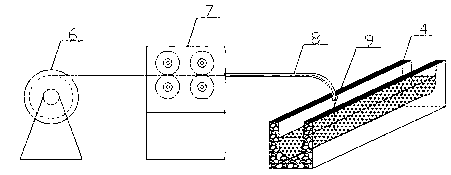

[0028] see figure 1, the process method of the present invention is mainly as follows: melt the electrical aluminum ingot in the smelting furnace 1, then transfer it to the holding furnace 3 through the diversion launder 2 for alloying, and then degas and remove impurities from the alloyed aluminum melt , slag removal, covering agent coverage, thermal insulation and other purification treatments, after the thermal insulation and static aluminum melt comes out of the thermal insulation furnace 3, it flows through the on-line boronization device 5 and on-line degassing device connected to the back through the discharge launder 4 10 and ceramic filter device 11, and then poured into the continuous casting machine 13 smoothly through the horizontal casting system 12 composed of upper ladle, tundish, lower ladle and horizontal casting launder. The molten al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com