Effective control method for vortex cavitation flowing in low-temperature liquid expander

A low-temperature liquid and control method technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of undiscovered public information, etc., and achieve the goal of suppressing induced cavitation, improving performance and operating reliability, and avoiding vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

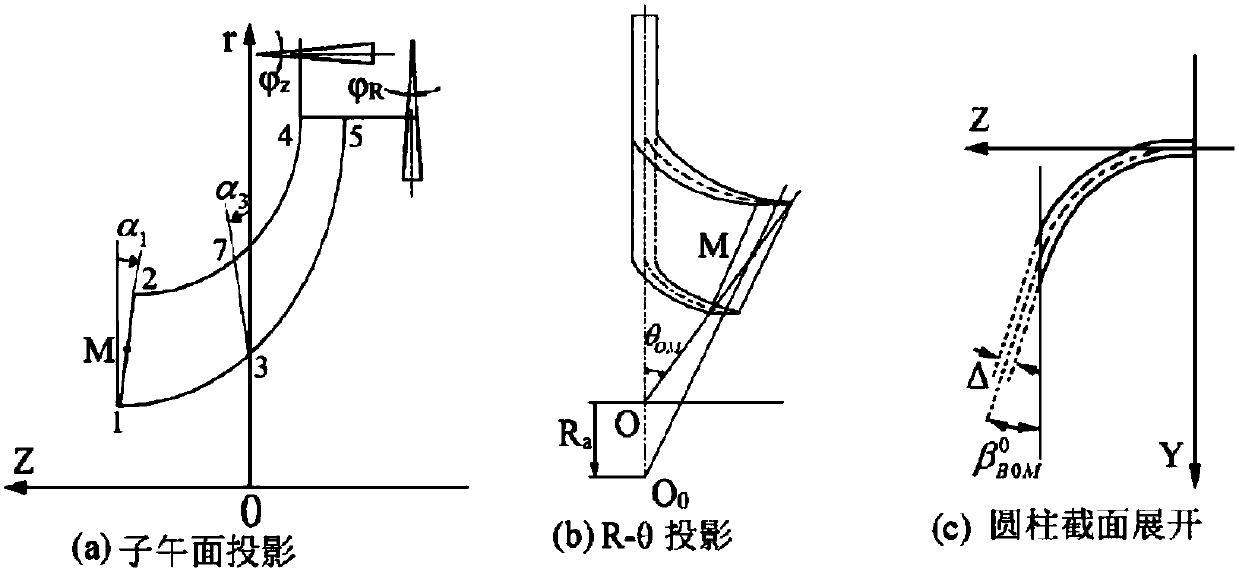

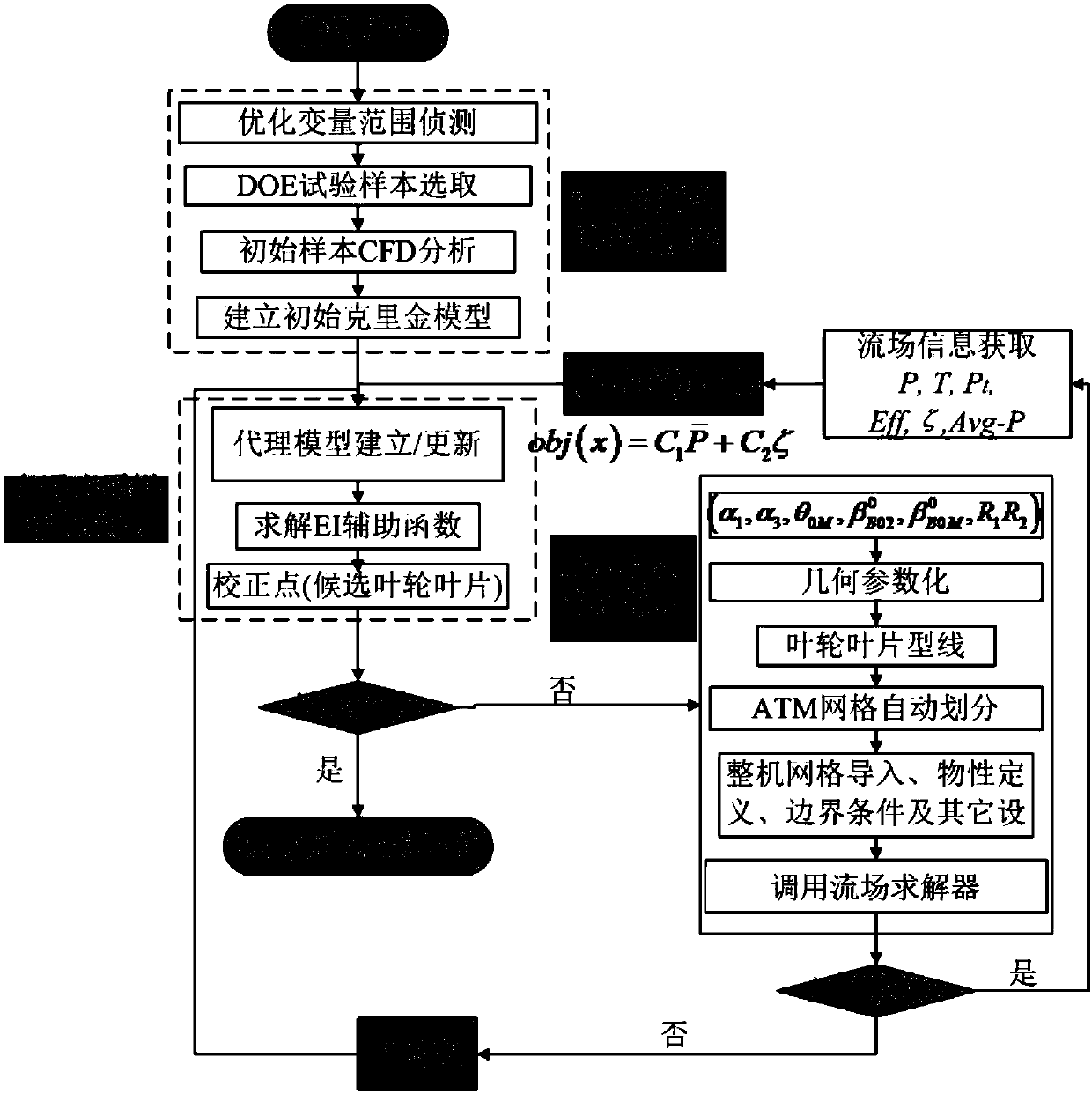

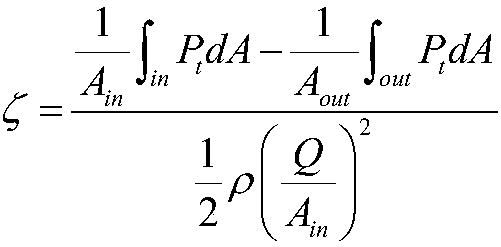

[0034] refer to figure 1 The effective control method of the vortex cavitation flow in the cryogenic liquid expander of the present invention includes the research on the vortex cavitation mechanism of the cryogenic liquid expander considering the thermodynamic effect of the cryogenic fluid, the sensitivity of the impeller geometric parameters of the vortex cavitation flow in the cryogenic liquid expander characteristic analysis, characterization of complex vortex cavitation flow in cryogenic liquid expander, construction of flow field optimization objective function and flow field optimization control variables for the purpose of controlling vortex cavitation flow, and parallel optimization control problems of vortex cavitation flow solve.

[0035] 1. The specific process of the study on the vortex cavitation mechanism of the cryogenic liquid expander considering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com