Compact feeding skid steel receiving device

A compact and material table technology, which is applied in the direction of furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems that the space in the heating furnace area cannot be effectively used and the space is large, so as to solve the problem of difficult feeding, less equipment, and energy saving The effect of land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

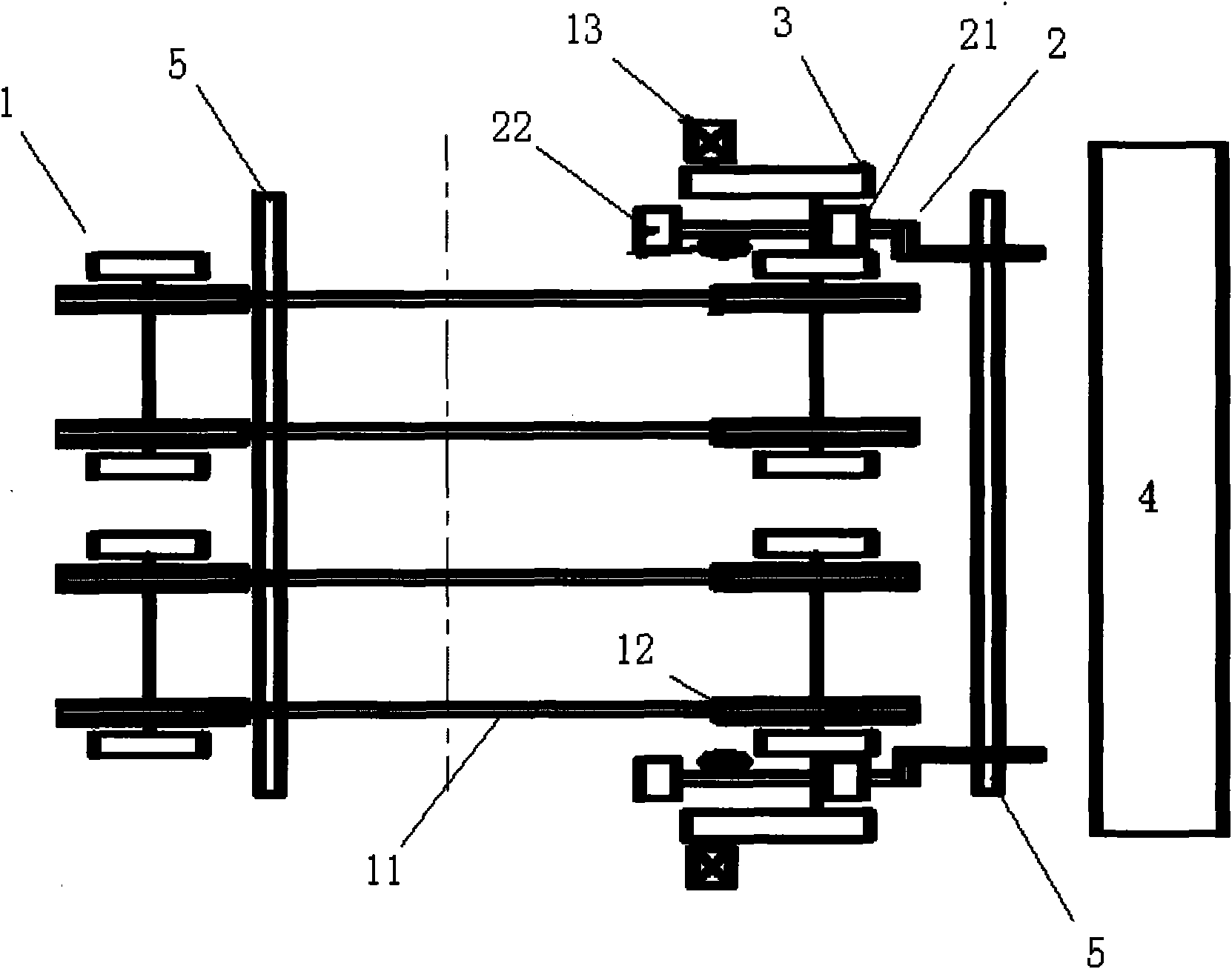

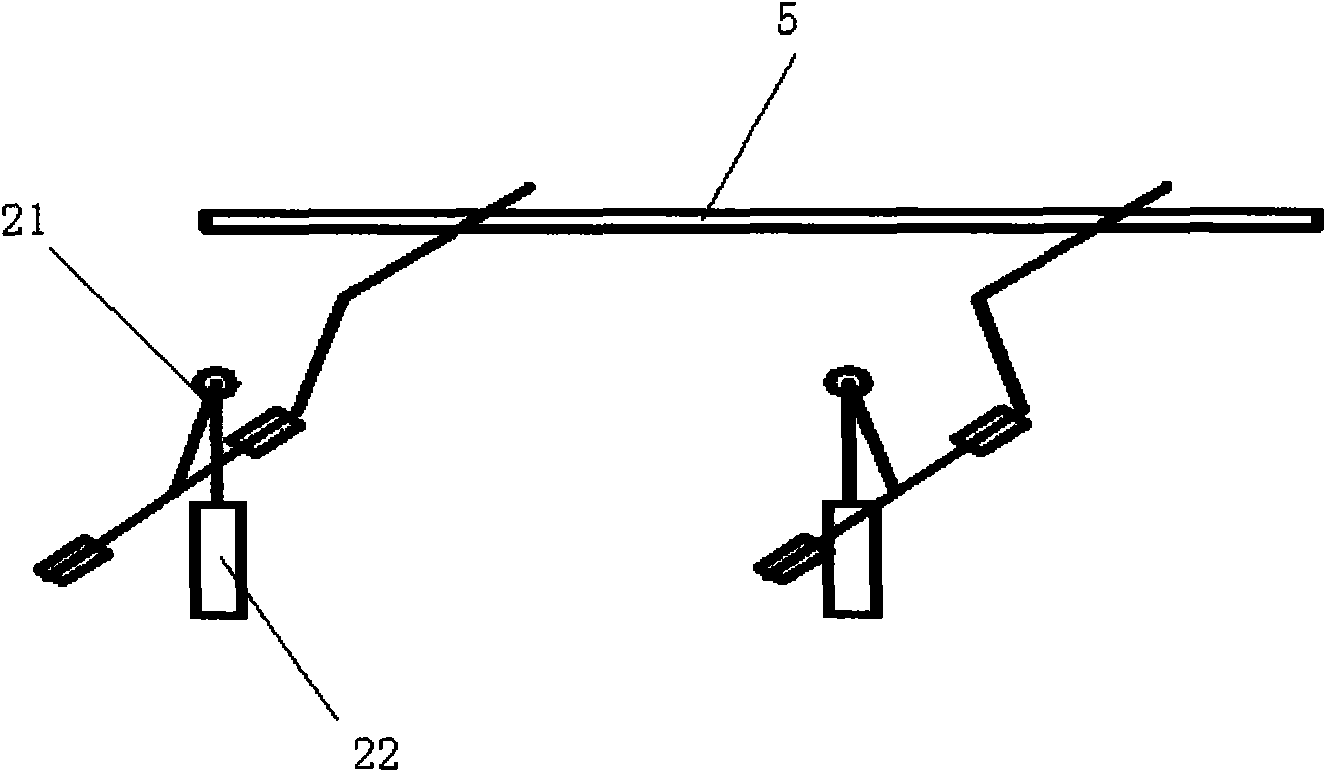

[0012] A compact feeding platform steel receiving device according to the present invention, the device includes a steel moving machine 1 and a steel feeding machine 2 . The steel moving machine 1 includes a chain 11 , a sprocket 12 and a motor 13 , and the chain 11 is wound around the sprocket 12 . The motors are two sets of 22Kw. The sprocket 12 is connected with the motor 13 through the reducer 3, and the steel billet 5 is pulled from the raw material span to the heating span by the chain driven by two groups of 22Kw motors. The steel feeding machine 2 includes a steel feeding frame 21 and a cylinder 22, the cylinders are two groups, and the rotating shaft of the steel feeding frame 21 is connected with the cylinder; the steel feeding frame 21 driven by the two groups of cylinders rises to catch the 10m long steel billet 5 , and slowly put it on the furnace mouth 4. One end of the chain 11 is arranged at the billet loading place, and the other end matches with the receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com