Method for controlling coking coal dampness

A technology of coking coal and humidity, applied in coke oven, petroleum industry and other directions, can solve the problems of many operation links, huge equipment, large steam consumption, etc., and achieve the effect of reducing the oxygen content of the system, preventing fire and explosion, and preventing moisture condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

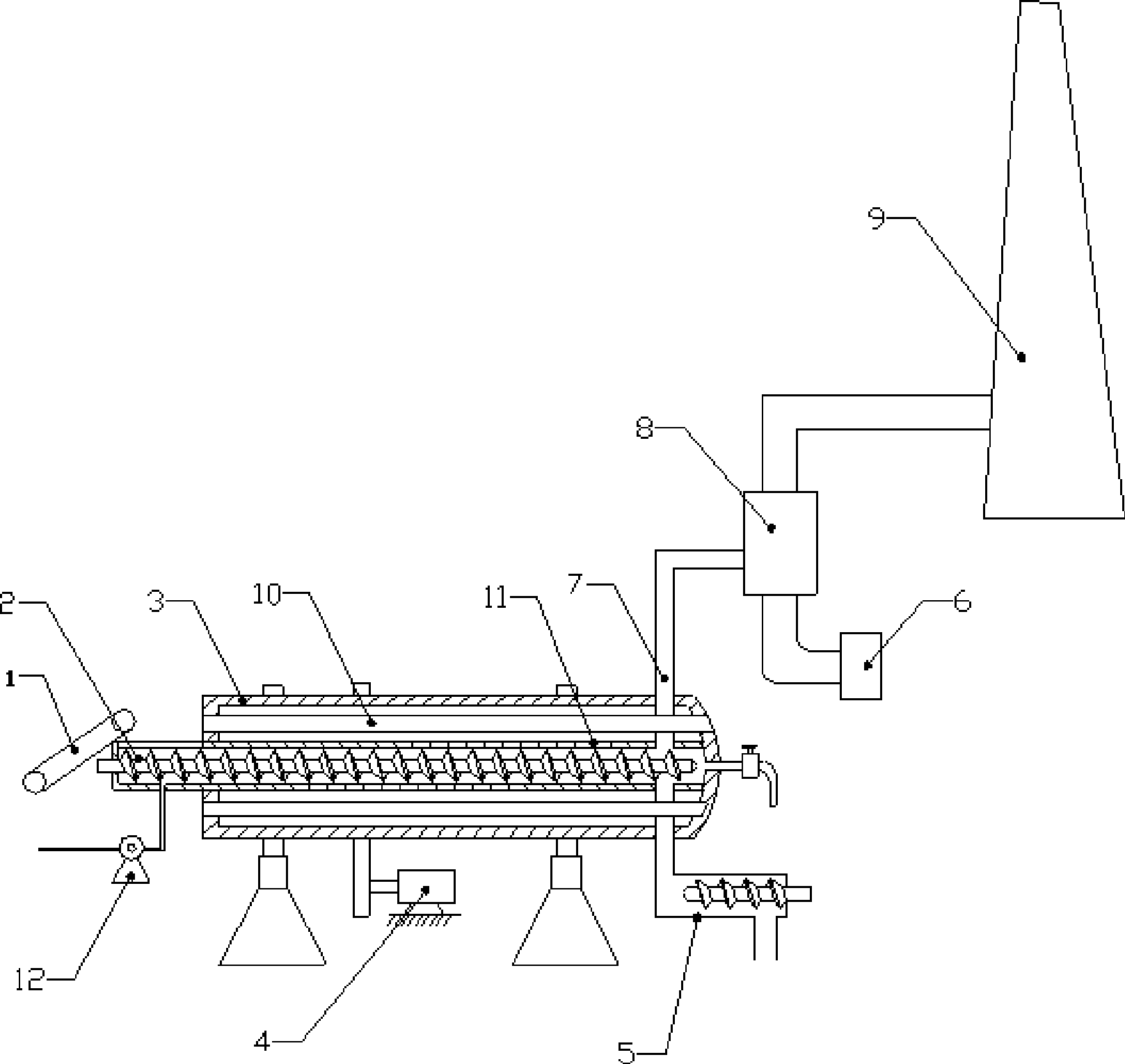

Image

Examples

Embodiment 1

[0021] The wet coal processing capacity of this embodiment is 330t / h. After the coal material passes through the drying system, the water content is adjusted from 11.6% to 9%, so as to meet the production needs of the stamped coke oven.

[0022] The specific method is as follows:

[0023] Set coal density to 1400kg / m 3 , bulk density 820kg / m 3 , the processing capacity is 330t / h, the coal inlet temperature is consistent with the atmospheric temperature at 30°C, the specific heat of coal is 1.05kJ / kg.°C, the coal outlet temperature is 80°C, the moisture content of coal is reduced by 3% on average, and the indirect drying medium is superheated steam , the steam pressure is 1.2MPaG, the steam temperature is 300°C, and all the steam becomes saturated water at 300°C after passing through the system. The direct drying carrier gas is coke oven exhaust gas (composed of: CO 2 : 22%, H 2 O: 5%, O 2 : 2%, N 2 : 71%), the carrier gas inlet temperature is 190°C, the carrier gas outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com