Lithium ion battery diaphragm with high heat resistance and high adhesion and preparation method thereof

A lithium-ion battery, high heat-resistant technology, applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve problems such as prone to lithium precipitation, poor battery safety, fire or explosion , to achieve the effects of improving flatness and safety, preventing deformation and analysis of lithium, and preventing fire and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

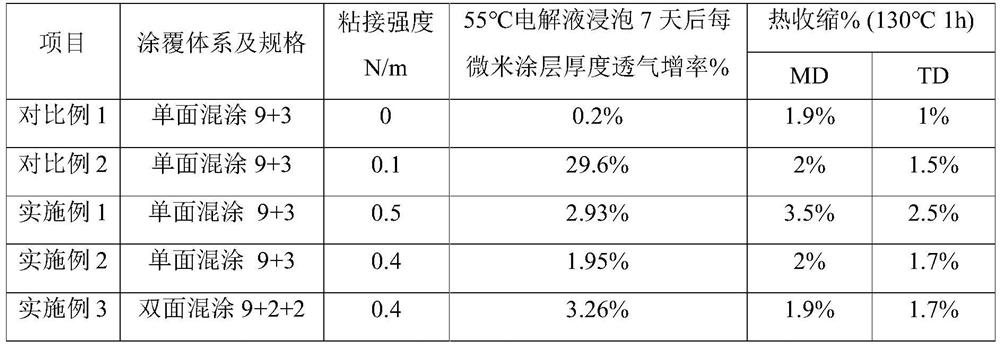

Embodiment 1

[0043] The selected polymer is polyvinylidene fluoride-hexafluoropropylene copolymer powder:

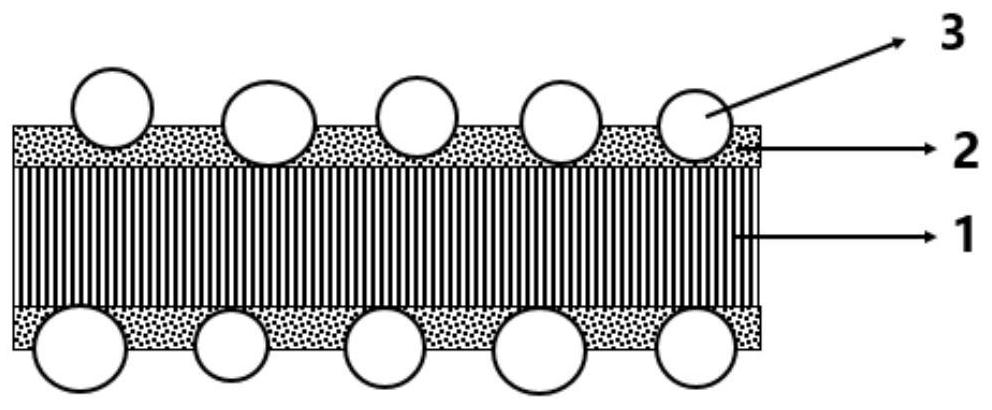

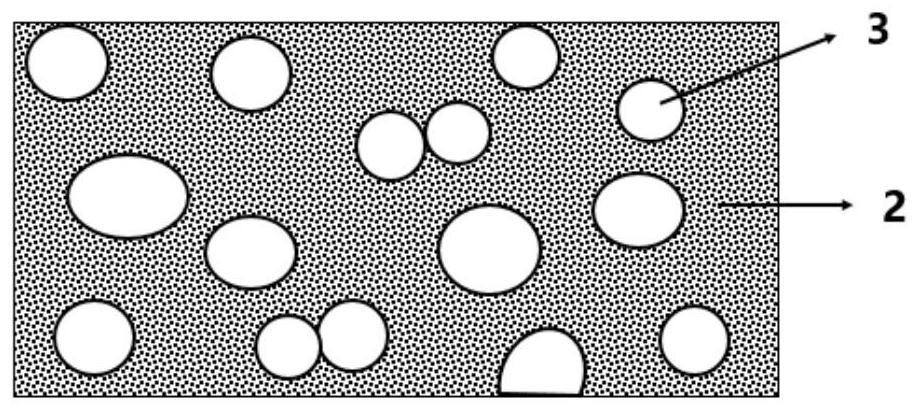

[0044]Add 0.125kg sodium carboxymethylcellulose to 12.375kg deionized water, mix and stir evenly to obtain solution A; add 0.188kg dispersant (sodium polyacrylate, solid content 45%, Shenzhen Chenyu Technology Co., Ltd., CYF-02) , 12.5kg of polyvinylidene fluoride-hexafluoropropylene copolymer powder (secondary aggregate D50 is about 8 μm, Arkema (Changshu) Fluorochemical Co., Ltd., LBG) was added to the above solution A and stirred and kneaded to form a uniform creamy mixture B; add 37.5kg of alumina (D50 is about 0.6μm, Jinyi Arteo (Suzhou) Lithium Battery Material Technology Co., Ltd.), 100kg of deionized water to the mixture B, stir evenly to prepare slurry C; Add 14.7kg of binder polyacrylate (25.5% solid content, Hunan Gaorui Power Material Co., Ltd.) and 0.14kg of wetting agent fatty alcohol polyoxyethylene ether to the material C to prepare a coating slurry. The above-mentio...

Embodiment 2

[0046] The selected polymer is polymethyl methacrylate emulsion:

[0047] Add 0.18kg sodium carboxymethyl cellulose to 4.2kg deionized water, mix and stir evenly to obtain solution A; add 0.25kg dispersant polyacrylate (sodium polyacrylate, solid content 45%, Shenzhen Chenyu Technology Co., Ltd., CYF -02), 50kg of alumina (D50 is about 0.6μm, Jinyi Arteo (Suzhou) Lithium Battery Material Technology Co., Ltd.) and 110Kg of deionized water were added to the above solution A and stirred evenly to make slurry B; 21.28kg of poly Methyl methacrylate emulsion (D50 is 5 μm, solid content 15%, swelling rate about 200%, Japan Zeon Co., Ltd.) is added to slurry B, stirred evenly to prepare slurry C; A binder polyacrylate (25.5% solid content, Hunan Gaorui Power Supply Material Co., Ltd.), and 0.1 kg of a wetting agent fatty alcohol polyoxyethylene ether were prepared into a coating slurry. The above-mentioned slurry will be coated on one side of the 9 μm base film using microgravure coa...

Embodiment 3

[0049] The selected polymer is polymethyl methacrylate emulsion:

[0050] Add 0.18kg sodium carboxymethyl cellulose to 4.2kg deionized water, mix and stir evenly to obtain solution A; add 0.25kg dispersant polyacrylate (sodium polyacrylate, solid content 45%, Shenzhen Chenyu Technology Co., Ltd., CYF -02), 50kg of alumina (D50 is about 0.6μm, Jinyi Arteo (Suzhou) Lithium Battery Material Technology Co., Ltd.) and 110Kg of deionized water were added to the above solution A and stirred evenly to make slurry B; 21.28kg of poly Methyl methacrylate emulsion (D50 is 5 μm, solid content 15%, swelling rate about 200%, Japan Zeon Co., Ltd.) is added to slurry B, stirred evenly to prepare slurry C; A binder polyacrylate (25.5% solid content, Hunan Gaorui Power Supply Material Co., Ltd.), and 0.1 kg of a wetting agent fatty alcohol polyoxyethylene ether were prepared into a coating slurry. Use micro-gravure coating to coat the above slurry on both sides of the 9 μm base film, and dry to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com