Waste lithium ion battery charged crushing and waste heat recovery integrated system and method

A lithium-ion battery, waste heat recovery technology, applied in battery recycling, waste collector recycling, secondary batteries, etc., can solve problems such as unutilized surplus energy, threat to operator safety, fire and explosion, etc., to avoid excessive temperature. High runaway, simplified recovery process, prevention of fire and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific content of the present invention will be further explained in detail below in conjunction with the examples.

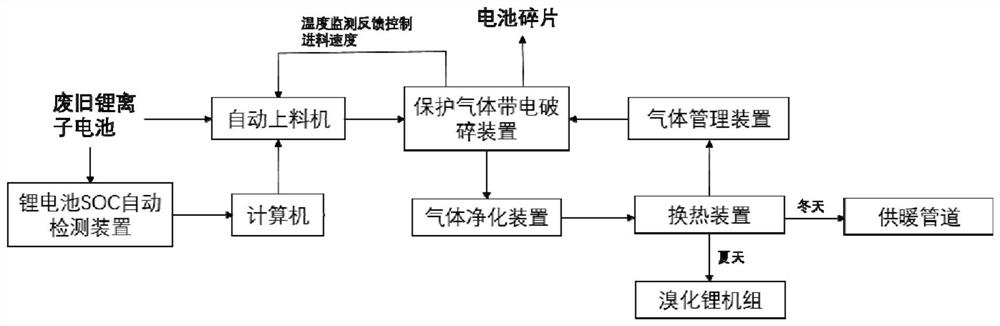

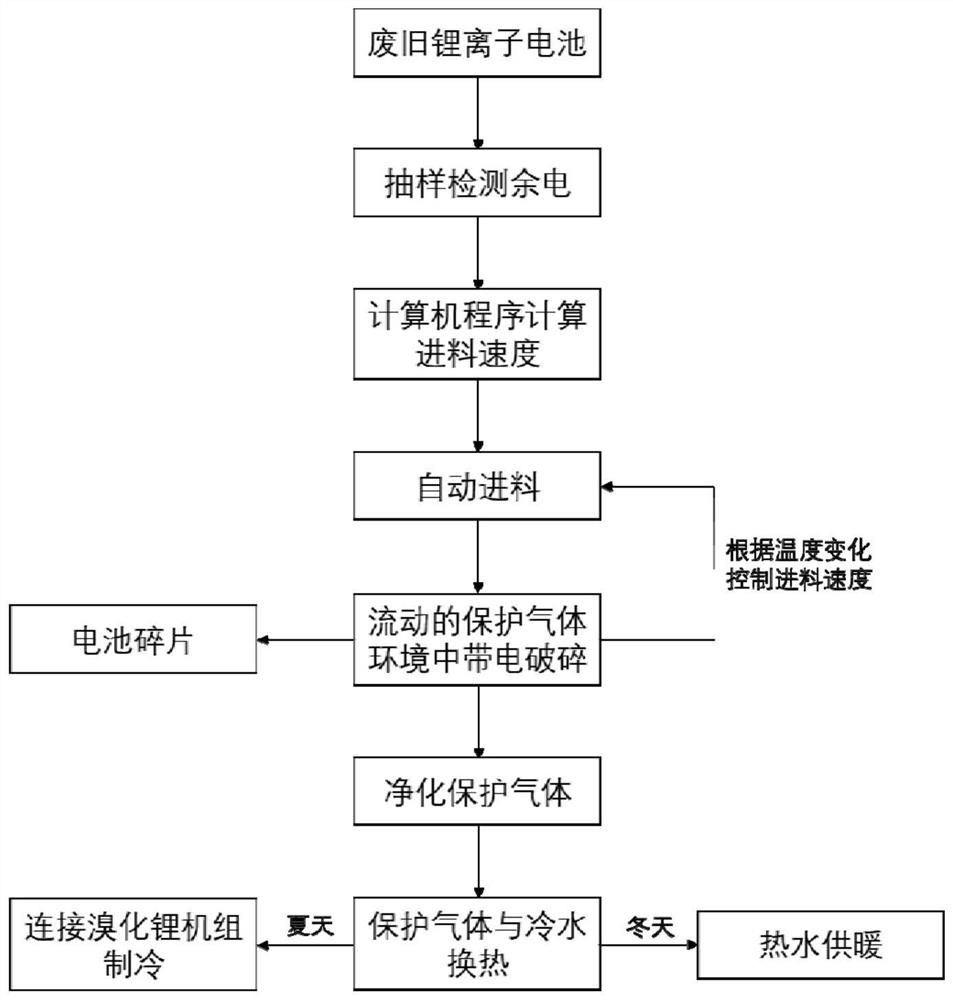

[0032] Such as figure 1 As shown, the waste lithium-ion battery charging crushing and waste heat recovery integrated system of the present invention includes an automatic feeding machine, a lithium battery SOC automatic detection device, a computer, a protective gas charging crushing device, a gas management device, a gas purification device and a heat exchange device .

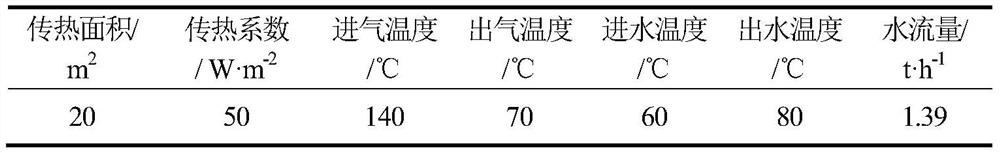

[0033] The automatic feeding machine is used to feed the protective gas charged crushing device. The lithium battery SOC automatic detection device is connected to the computer, and the detected remaining power data of the waste lithium-ion battery is sent to the computer for calculation. The computer controls the automatic feeding according to the calculation result. machine work. The lithium battery SOC automatic detection device includes a lithium battery storage box and a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com