Manufacturing process for iron-silicon-aluminum alloy powder

A technology of iron-silicon aluminum alloy and manufacturing process, which is applied in the direction of metal processing equipment, transportation and packaging, etc., to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

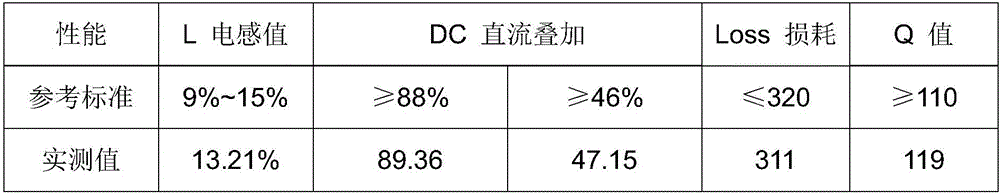

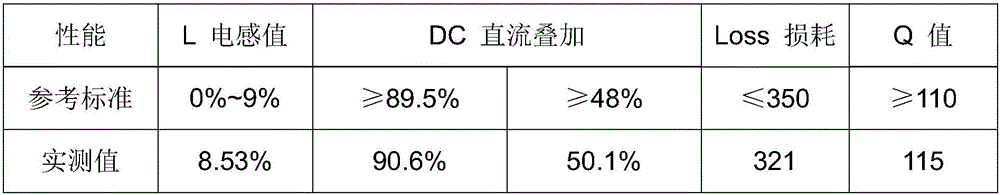

Examples

Embodiment Construction

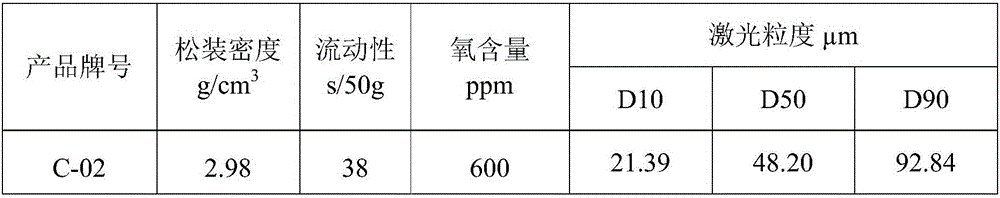

[0019] The realization steps of the manufacturing process of the sendust aluminum alloy powder that the present invention proposes are:

[0020] A, each raw material is weighed batching respectively, and the percentage by weight of each raw material is: iron 84%, silicon 9%, aluminum 6%, SiCa28 alloy 1%;

[0021] B. Use a graphite crucible as the body of a non-vacuum intermediate frequency induction furnace, put 4 iron rods with a diameter of 50mm and a length equivalent to the height of the graphite crucible in the graphite crucible, set the power of the non-vacuum intermediate frequency induction furnace to 20KW, and keep the iron The red hot state of the rod is 4 hours, and the temperature of the iron rod is used to preheat the graphite crucible for 4 hours;

[0022] C. Put in the prepared iron and silicon, and increase the power of the non-vacuum intermediate frequency induction furnace evenly from 20KW to 80KW within 20 minutes. When the iron and silicon are red, adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com