Gradient structure polymer nano-composite material and preparation method and application thereof

A technology of nanocomposite materials and gradient structures, which is applied in the field of polymer nanocomposites with gradient structures and its preparation, and can solve problems such as high loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

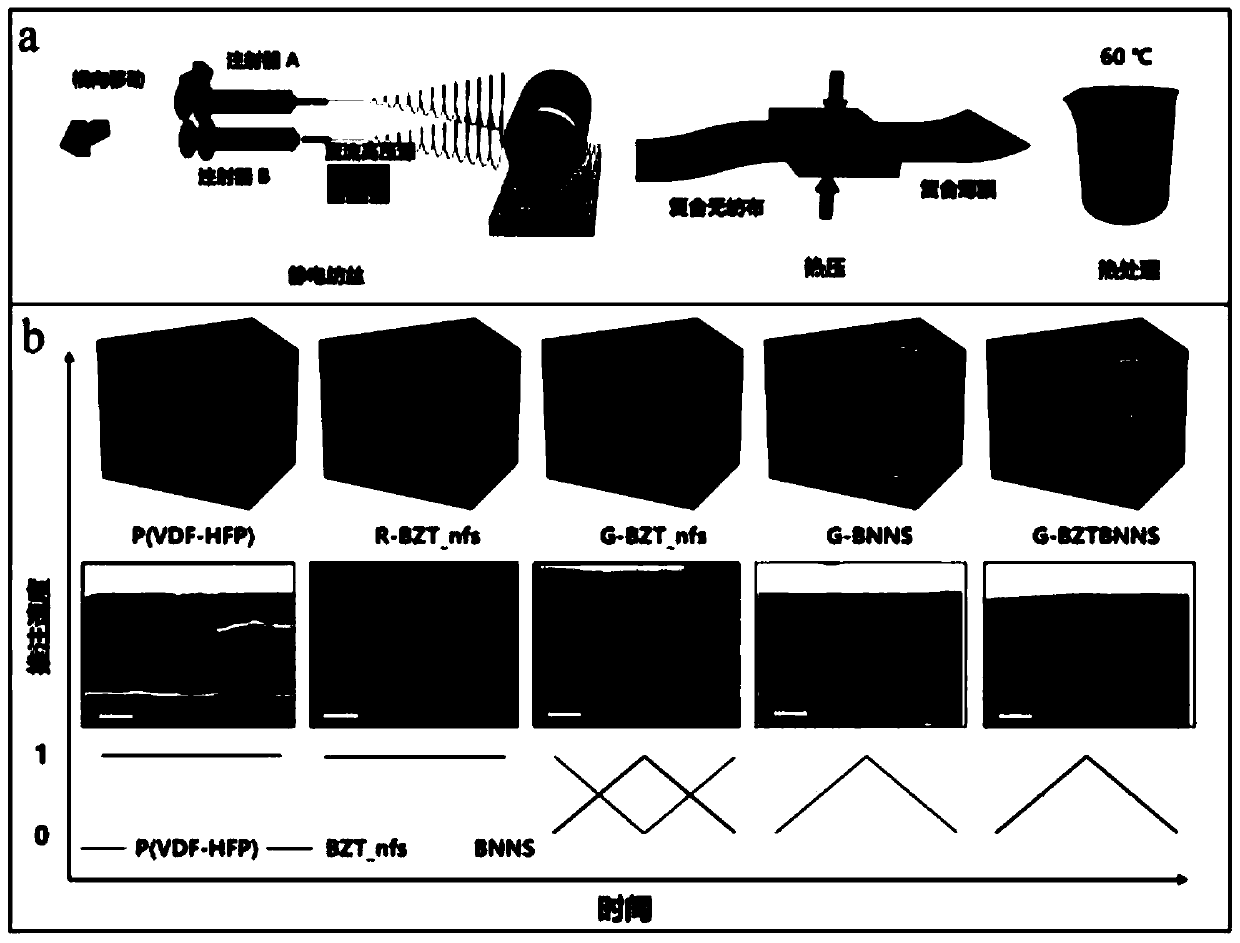

[0057] Example 1. Preparation of Nanofiber Filled Formal Gradient Structure Polymer Nanocomposite

[0058] Follow the steps below to prepare Ba(Zr 0.21 Ti 0.79 )O 3 Nanofibers:

[0059] (1) Measure 1.703g of barium acetate, 1.815g of tetrabutyl titanate, 0.5116g of tetrabutyl zirconate, and 1.34g of acetylacetone into 9ml of acetic acid and stir to dissolve for 1 hour. After completely dissolving, add 0.5 g of polyvinylpyrrolidone and continue to stir for 2 h to obtain a precursor solution.

[0060] (2) Transfer the above precursor solution into a syringe for electrospinning. The injection speed is 1.0mL / h, the high-voltage electric field is 1.3kV / cm, and the fiber is received by the roller. The roller speed is 300rpm, and the fiber is obtained after electrospinning for 10h. non-woven fabric.

[0061] (3) The above-mentioned fiber non-woven fabric is calcined, and the treatment process is as follows: the heating rate is 10°C / min, the temperature is kept at 550°C for 0.5h,...

Embodiment 2

[0068] Example 2, preparation of nano-sheet-filled polymer nanocomposites with trans gradient structure

[0069] Prepare BN nanosheets according to the following steps:

[0070] (1) Take 2g of granular BN raw material and 2g of corundum microspheres respectively and put them into a ball mill jar, and mill for 2 hours.

[0071] (2) After ball milling, remove the corundum microspheres, disperse the ball milled BN in isopropanol, and let stand for 8 hours.

[0072] (3) Centrifuge at 200 rpm, after 30 min, take out the supernatant, and continue to centrifuge at 5000 rpm for 10 min. Place the precipitate in an oven at 80°C and dry to obtain BN nanosheets.

[0073] according to figure 1 The schematic flow diagram shown in the preparation of nanosheet-filled trans-gradient structured polymer nanocomposites, the specific steps are as follows:

[0074] (1) Measure 1g of polymer P(VDF-HFP) (molecular weight: 470,000), add it to a mixed solvent of 3mL of DMF and 2ml of acetone, and sti...

Embodiment 3

[0078] Example 3, Preparation of Interpenetrating Gradient Structure Polymer Nanocomposite

[0079] according to figure 1 The schematic flow diagram shown in the preparation of interpenetrating gradient polymer nanocomposites, the specific steps are as follows:

[0080] (1) Measure 1g polymer P (VDF-HFP) (molecular weight is 470,000), join in the mixed solvent of the DMF of 3mL and 2ml acetone, stir to stable sol, obtain polymer precursor sol; Ba( Zr 0.21 Ti 0.79 )O 3 Nanofibers were added to the above P(VDF-HFP) sol to prepare Ba(Zr 0.21 Ti 0.79 )O 3 Nanofiber / P (VDF-HFP) sol, stirring is even with to steady state, obtains polymer composite precursor sol A (in the gained precursor sol, the mass concentration of polymer P (VDF-HFP) is 20%; Ba( Zr 0.21 Ti 0.79 )O 3 The amount of nanofiber added is controlled in the final composite material of Ba(Zr 0.21 Ti 0.79 )O 3 The volume fraction of nanofibers is 10%).

[0081] (2) Measure 1g of polymer P(VDF-HFP) (molecular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com