Quartz stone anti-fouling agent and preparation method and application thereof

A technology of quartz stone and antifouling agent, used in antifouling/underwater coatings, paints containing biocides, coatings, etc., which can solve the problems of non-persistence, poor antifouling power, and affecting the gloss of quartz stone surface. , to achieve the best anti-fouling power, scrub resistance chemical stability, long-lasting anti-fouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

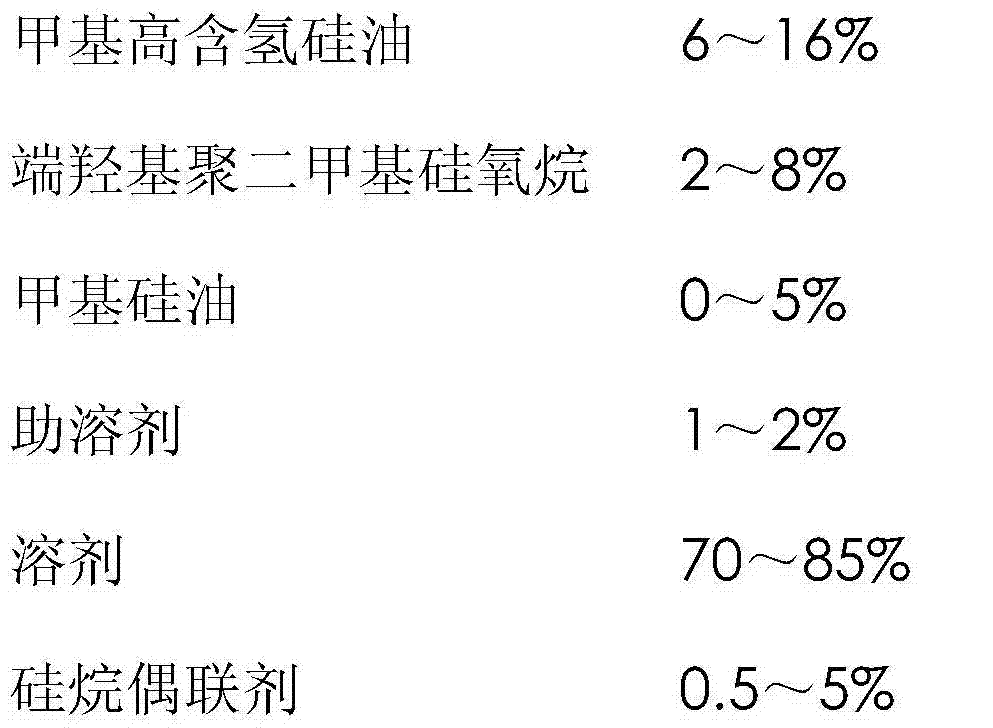

[0032] Under stirring, 12% (mass) of methyl high hydrogen-containing silicone oil with a hydrogen content of 1.5%, 3% (mass) of hydroxyl-terminated polydimethylsiloxane with a hydroxyl content of 8%, 1% (mass) The viscosity at 25°C is 100mm 2 ·s -1 Add methyl silicone oil to 82.5% (mass) n-heptane, then add 1% (mass) ethylene glycol, and finally add 0.5% (mass) KH-550 while stirring, and continue stirring for 2 minutes. Obtain the quartz stone antifouling agent of the present invention.

Embodiment 2

[0034] Add 83% (mass) of 83% (mass) of methyl high hydrogen silicone oil with 1.6% hydrogen content and 6% (mass) of hydroxyl group content of 7% under stirring. D40 solvent oil, then add 2% (mass) of ethylene glycol ether, and finally add 1% (mass) of DL-602 while stirring, and continue to stir for 2 minutes to obtain the quartz stone of the present invention antifouling agent.

Embodiment 3

[0036] Under stirring, 16% (mass) of methyl hydrogen-containing silicone oil with a hydrogen content of 1.55%, 8% (mass) of hydroxyl-terminated polydimethylsiloxane with a hydroxyl content of 6%, 1% (mass) The viscosity at 25°C is 1000mm 2 ·s -1 Add methyl silicone oil to 71% (mass) n-hexane, then add 2% (mass) ethanol, and finally add 2% (mass) Kh-560 while stirring, and continue stirring for 2 minutes to obtain the present invention. Described quartz stone antifouling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com