Nanofiber membrane and preparation method and application thereof

A nanofiber film and fiber technology, which can be used in fiber processing, pharmaceutical formulations, textiles and papermaking, etc., and can solve the problem that the degradation rate is difficult to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] In this example, the electrospun membrane of the shell part is prepared by the following method, which specifically includes the following steps:

[0074] 1) Dissolve 7.5g of gelatin and 0.75g of genipin in a mixed solvent of 50mL of acetic acid and water (volume ratio 9:1), stir magnetically at room temperature for 12h, and obtain a shell solution with a mass volume fraction of 16.5%

[0075] 2) Electrospinning the solution, using a stainless steel drum as the receiving device, the voltage is 20KV, the receiving distance is 15cm, the spinning liquid feeding rate is 1mL / h, and the spinning is 5h. A drug-loaded film with a thickness of about 250 μm was obtained.

[0076] 3) Soak the obtained fiber membrane in a fume hood at room temperature and dry for 72 hours to ensure that the residual solvent is fully volatilized.

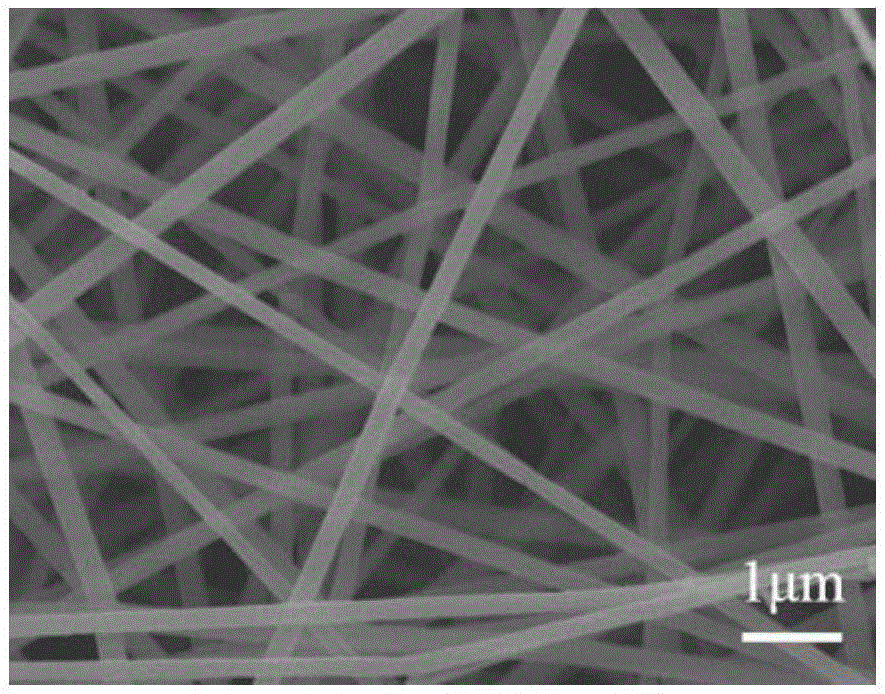

[0077]The spinning film prepared by embodiment 1 is carried out scanning electron microscope observation, the result is as follows Figure 1A As shown, ...

Embodiment 2

[0079] In this embodiment, the electrospun membrane of the core part is prepared by the following method, which specifically includes the following steps:

[0080] 1) Dissolve 3 g of polylactic acid-glycolic acid and 3 g of polycaprolactone in 20 mL of hexafluoroisopropanol, then add 0.0625 g of DOX, and stir magnetically at room temperature for 12 hours to obtain an inner core solution with a mass volume fraction of 30 w / v%.

[0081] 2) The solution was electrospun, with a stainless steel flat table as the receiving device, the voltage was 20KV, the receiving distance was 15cm, the spinning liquid inflow rate was 0.17mL / h, and the spinning was 5h. A drug-loaded film with a thickness of about 250 μm was obtained.

[0082] 3) Soak the obtained fiber membrane in a fume hood at room temperature and dry for 72 hours to ensure that the residual solvent is fully volatilized.

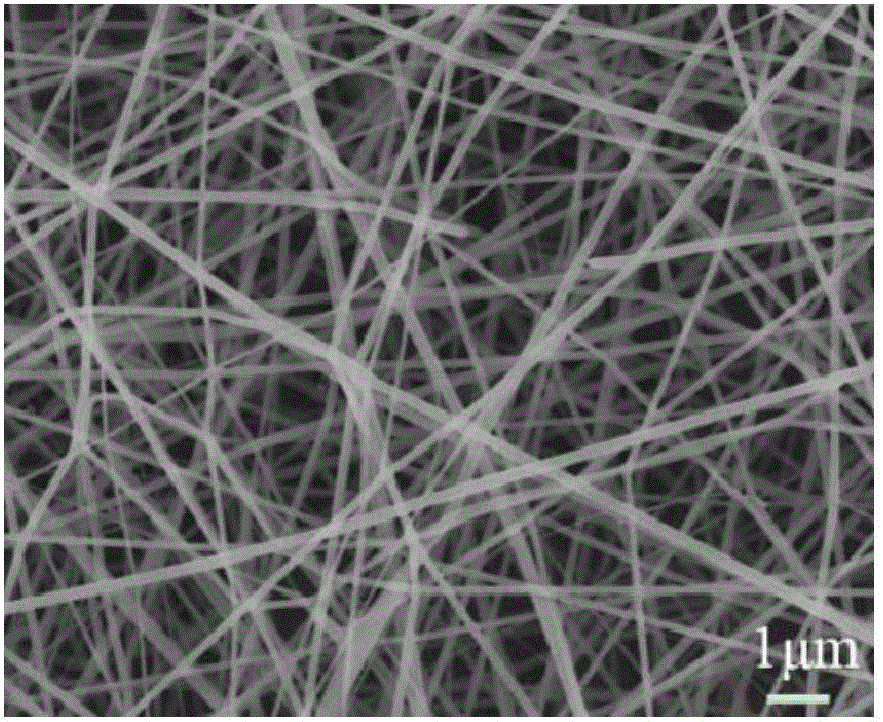

[0083] The spinning membrane prepared by embodiment 2 is carried out scanning electron microscope observat...

Embodiment 3

[0085] In this embodiment, the nanofibrous membrane with core-shell structure is prepared by the following method, which specifically includes the following steps:

[0086] 1) Dissolve 3g of polylactic acid-glycolic acid (weight average molecular weight of 80,000) and 3g of polycaprolactone (weight average molecular weight of 60,000) in 20mL of hexafluoroisopropanol, then add 0.0625g of DOX, and stir magnetically at room temperature After 12 hours, an inner core solution A with a mass volume fraction of 30w / v% was obtained.

[0087] 2) Dissolve 7.5g of gelatin and 0.75g of genipin in a mixed solvent of 50mL of acetic acid and water (volume ratio 9:1), and magnetically stir at room temperature for 12h to obtain a shell solution B with a mass volume fraction of 16.5%;

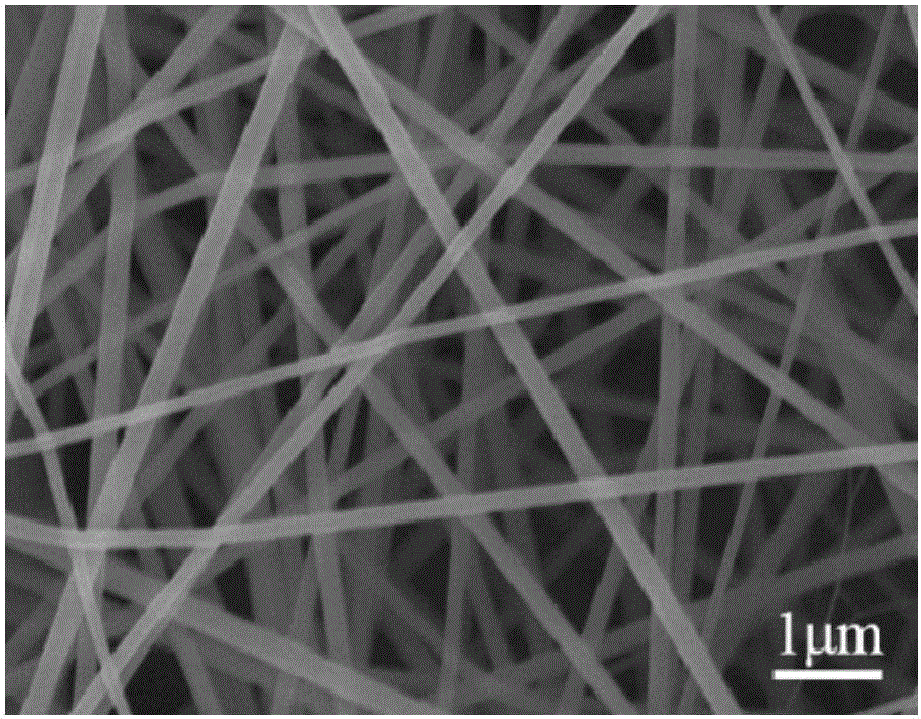

[0088] 3) The solution was electrospun, and solution A and solution B were placed in two syringes, which were pushed by propellers respectively. The propulsion speeds of solution A and solution B were 0.17mL / h an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com