Electrode sheet and electrochemical device

An electrode sheet and non-electrode technology, which is applied in the field of electrochemical energy storage devices, can solve problems such as weak adhesion between the active material layer and the current collector, affecting the cycle performance of the electrochemical device, and limited improvement in the safety of the electrochemical device. Achieve the effects of improving conductivity and energy density, preventing fire and explosion, and preventing coating peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

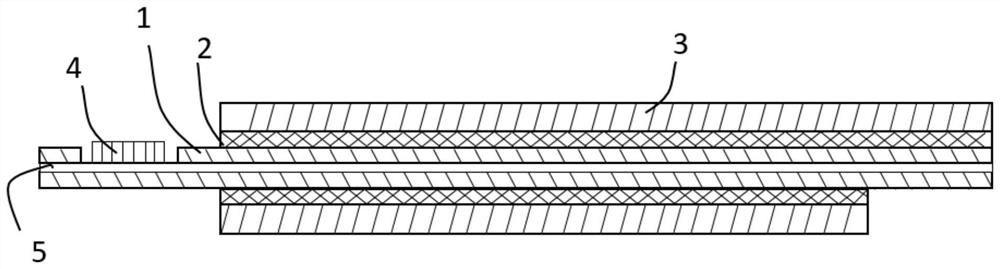

Image

Examples

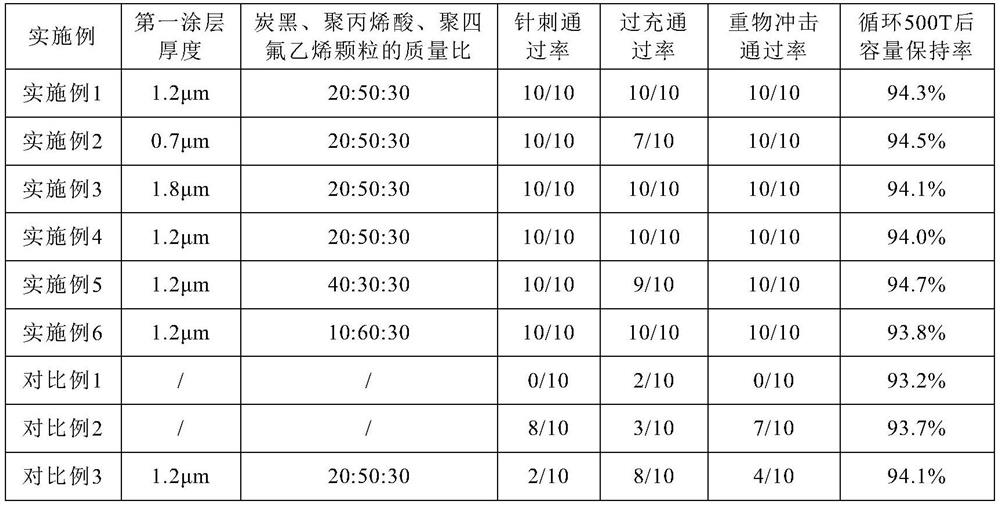

Embodiment 1

[0051] 1. Preparation of positive electrode sheet

[0052] Add carbon black, polyacrylic acid, and polytetrafluoroethylene particles into the planetary mixer in sequence, and add water as a solvent to it, and disperse evenly to make the first slurry; among them, carbon black, polyacrylic acid, polytetrafluoroethylene The mass ratio of ethylene particles is 20:50:30;

[0053] Then use a 150-mesh gravure coater to coat the first slurry on the front and back surfaces of the aluminum foil at a coating speed of 50m / min. After the coating is completed, place it in an oven and dry at 95°C to form a first coat;

[0054] Add lithium iron phosphate, barium sulfate, carbon black, carbon tubes, and PVDF into the planetary mixer in sequence, and add N-methylpyrrolidone (NMP) therein as a solvent, and after dispersing evenly, make a second slurry; , the mass ratio of lithium iron phosphate, barium sulfate, carbon black, carbon tube and PVDF is 70:22:2:1:5;

[0055]Then use a 110-mesh gra...

Embodiment 2~ Embodiment 6

[0063] The difference between embodiment 2 and embodiment 1 is that the thickness of the first coating is 0.7 μm, and all the other conditions are basically the same as embodiment 1;

[0064] The difference between embodiment 3 and embodiment 1 is that the thickness of the first coating is 1.8 μm, and all the other conditions are basically the same as embodiment 1;

[0065] The difference between embodiment 4 and embodiment 1 is that aluminum oxide is used to replace barium sulfate, and all the other conditions are basically the same as embodiment 1;

[0066] The difference between embodiment 5 and embodiment 1 is that the mass ratio of carbon black, polyacrylic acid, and polytetrafluoroethylene particles is 40:30:30, and all the other conditions are substantially the same as embodiment 1;

[0067] The difference between Example 6 and Example 1 is that the mass ratio of carbon black, polyacrylic acid, and polytetrafluoroethylene particles is 10:60:30, and the rest of the condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com