Thin-layer asphalt pavement bonding layer capable of absorbing stress and construction method of thin-layer asphalt pavement bonding layer

A technology of asphalt pavement and bonding layer, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, and can solve the problems of thin-layer asphalt pavement damage, high mixing temperature, and high requirements on the production process of asphalt mixture. , to achieve the effect of preventing congestion and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

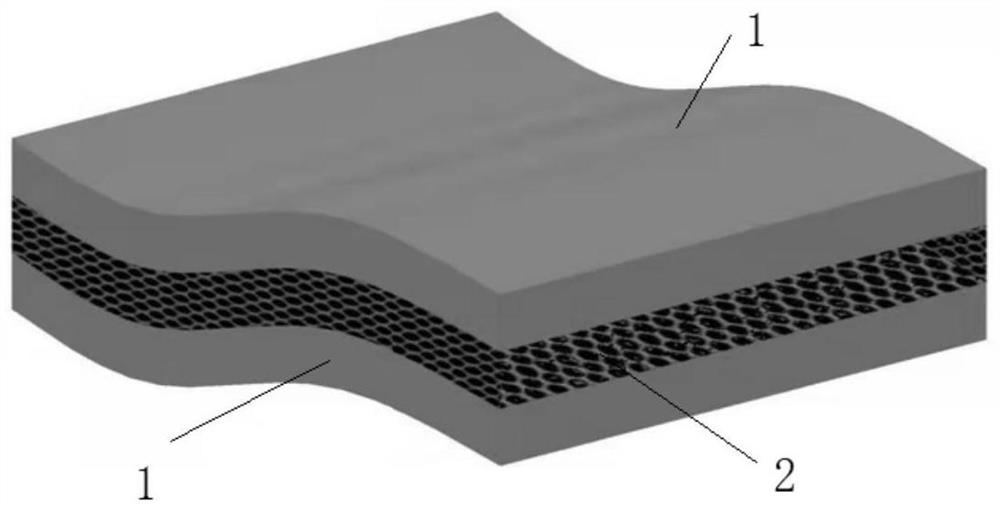

Image

Examples

Embodiment 1

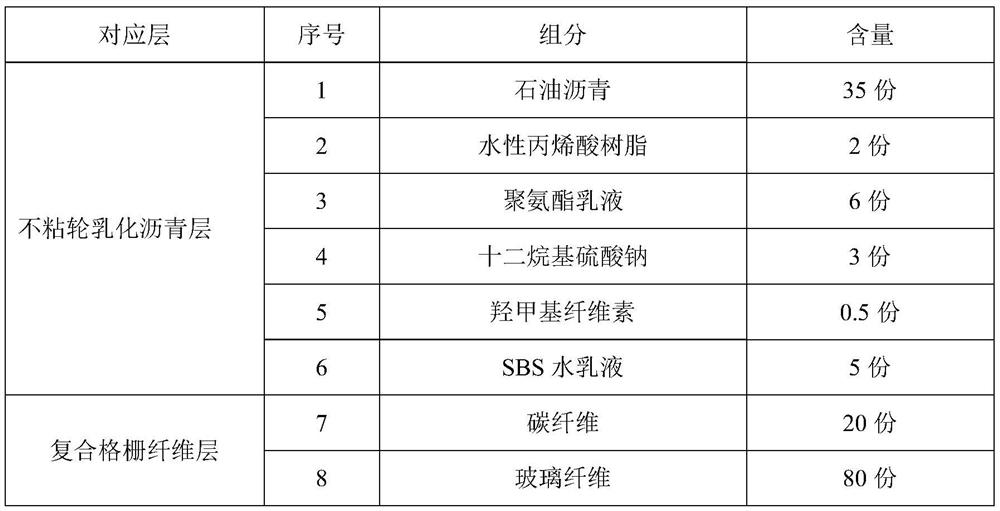

[0026] The components and contents of the thin asphalt pavement adhesive layer in this embodiment are shown in Table 1 below. Wherein, the SBS aqueous emulsion is formed by mixing linear SBS, sodium lauryl sulfate and water in a ratio of parts by weight of 10:1:89.

[0027] Table 1 Component content of thin asphalt pavement adhesive layer

[0028]

[0029] The construction process steps of the thin-bed asphalt pavement bonding course of the present embodiment are as follows:

[0030] (1) Preparation of non-stick wheel emulsified asphalt: first, heat base asphalt to 170°C, add asphalt blending agent and emulsified asphalt stabilizer in turn, and stir to obtain modified asphalt; mix asphalt emulsifier, SBS water emulsion and water-based resin with 48 Dilute with water, add hydrochloric acid, adjust the pH value to 2, and make a soap solution; adjust the temperature of the modified asphalt to 165°C, adjust the temperature of the soap solution to 50°C, and mix the two to obtai...

Embodiment 2

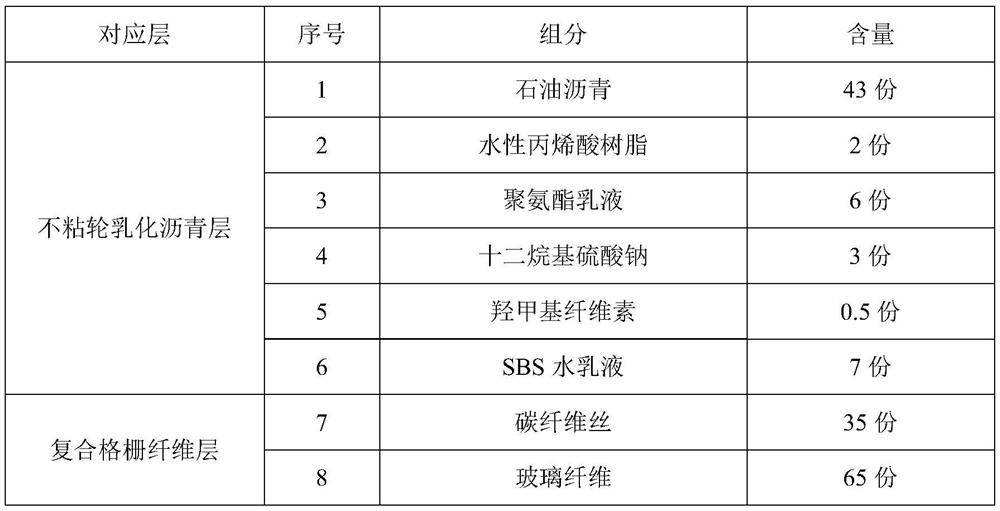

[0033] The components and contents of the thin asphalt pavement adhesive layer in this embodiment are shown in Table 2 below. Among them, the SBS aqueous emulsion is formed by mixing linear SBS, sodium lauryl sulfate and water with a weight fraction ratio of 10:1:89.

[0034] Table 2 Component content of thin asphalt pavement adhesive layer

[0035]

[0036] The construction process steps of the thin-bed asphalt pavement bonding course of the present embodiment are as follows:

[0037] (1) Preparation of non-stick wheel emulsified asphalt: first, heat base asphalt to 170°C, add asphalt blending agent and emulsified asphalt stabilizer in turn, and stir to obtain modified asphalt; mix asphalt emulsifier, SBS water emulsion and water-based resin with 48 Dilute with water, add hydrochloric acid, adjust the PH value to 2, and make a soap solution; adjust the temperature of the modified asphalt to 165°C, adjust the temperature of the soap solution to 50°C, and mix the two to obt...

Embodiment 3

[0040] The components and contents of the thin asphalt pavement adhesive layer in this embodiment are shown in Table 3 below. Among them, the SBS aqueous emulsion is formed by mixing linear SBS, sodium lauryl sulfate and water with a weight fraction ratio of 10:1:89.

[0041] Table 3 Component content of thin asphalt pavement adhesive layer

[0042]

[0043] The construction steps of the thin-bed asphalt pavement bonding course of the present embodiment are as follows:

[0044] (1) Preparation of non-stick wheel emulsified asphalt: first, heat base asphalt to 170°C, add asphalt blending agent and emulsified asphalt stabilizer in turn, and stir to obtain modified asphalt; mix asphalt emulsifier, SBS water emulsion and water-based resin with 48 Dilute with water, add hydrochloric acid, adjust the pH value to 2, and make a soap solution; adjust the temperature of the modified asphalt to 165°C, adjust the temperature of the soap solution to 50°C, and mix the two to obtain a no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com