Hafnium silicate environment barrier coating for ceramic-based composite material matrix and preparation method thereof

A composite material and ceramic-based technology, applied in the field of ceramics, can solve problems such as poor matching of thermal expansion coefficient, instability of thermal expansion coefficient of coating, poor crystallinity of coating, etc., achieve good high temperature stability, improve service life, Effect of increasing coating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of HfSiO used in ceramic matrix composite matrix 4 A method for preparing an environmental barrier coating, comprising the following steps:

[0033] (1) HfO 2 and SiO 2 Mixing, wet mixing and ball milling on a ball mill, drying, grinding, sieving, and then sintering for high-temperature solid-state reaction;

[0034] (2) After the high-temperature solid-state reaction is over, add deionized water for slurry preparation, then ball mill, and then spray granulate to obtain HfSiO 4 powder material;

[0035] (3) Spray a layer of Si layer on the surface of the ceramic matrix composite material as the base layer, and then apply HfSiO 4 The powder material is sprayed on the surface of the base layer as a surface layer to form a multi-layer coating;

[0036] (4) The environmental barrier coating is obtained by heat-treating the multi-layer coating.

[0037] Further, HfO 2 and SiO 2 The ratio is 1:1~2:1.

[0038] Further, the ball milling time in the step (1) is 2...

Embodiment 1

[0046] Coating preparation:

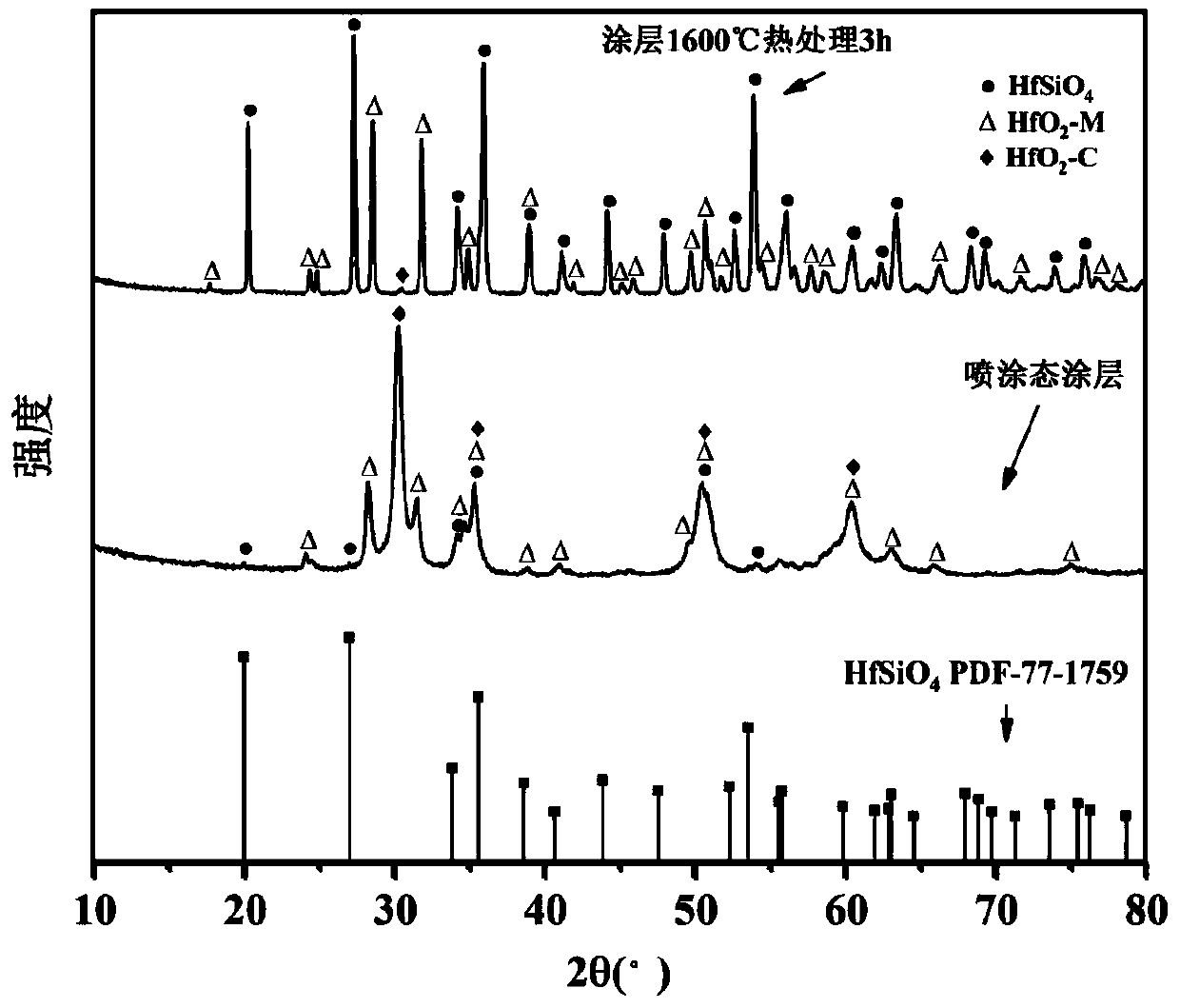

[0047] (1) SiO 2 and HfO 2 The powders are mixed at a ratio of 1:1, wet-mixed and ball-milled on a ball mill for 24 hours, dried, ground, passed through a 250-mesh sieve, and then sintered in a high-temperature furnace at 1600°C for high-temperature solid-state reaction;

[0048] (2) After the high-temperature solid-state reaction is completed, add deionized water for slurry preparation, ball milling for 24 hours, and spray granulation to obtain HfSiO 4 Powder material (particle size 35~125μm);

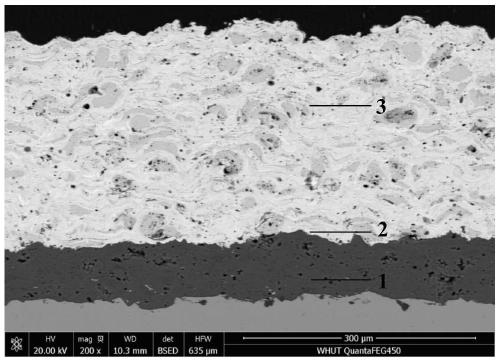

[0049] (3) Use plasma spraying technology to spray a Si layer on the ceramic matrix composite material as the bottom layer, the thickness is 100 μm, the spraying power is 40kW, and the spraying distance is 110mm; use the plasma spraying technology to spray the surface layer on the bottom layer, and the surface layer material is HfSiO 4 , the thickness of the surface layer is 250μm, the spraying power is 40kW, and the spraying distance is 110mm; a multi...

Embodiment 2

[0057] Coating preparation:

[0058] (1) SiO 2 and HfO 2 The powder is mixed according to 1.5:1, wet-mixed and ball-milled on a ball mill for 24 hours, dried, ground, passed through a 250-mesh sieve, and then sintered in a high-temperature furnace at 1500°C for high-temperature solid-state reaction;

[0059] (2) After the high-temperature solid-state reaction is completed, add deionized water for slurry preparation, ball milling for 24 hours, and spray granulation to obtain HfSiO 4 Powder material (particle size 35~125μm);

[0060] (3) Use plasma spraying technology to spray a Si layer on the ceramic matrix composite material as the bottom layer, the thickness is 90 μm, the spraying power is 35kW, and the spraying distance is 100mm; use the plasma spraying technology to spray the surface layer on the bottom layer, and the surface layer material is HfSiO 4 , the thickness of the surface layer is 300μm, the spraying power is 35kW, and the spraying distance is 100mm; a multi-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com