Patents

Literature

68results about How to "Process defect reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

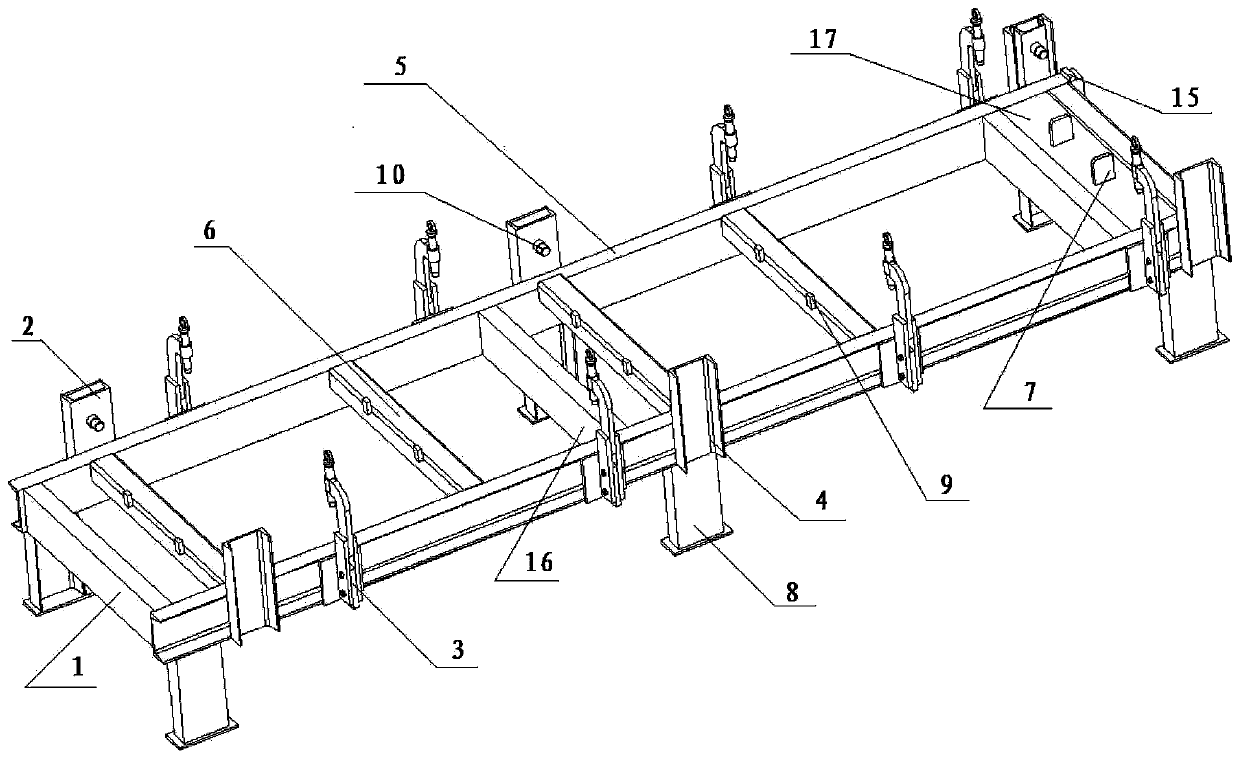

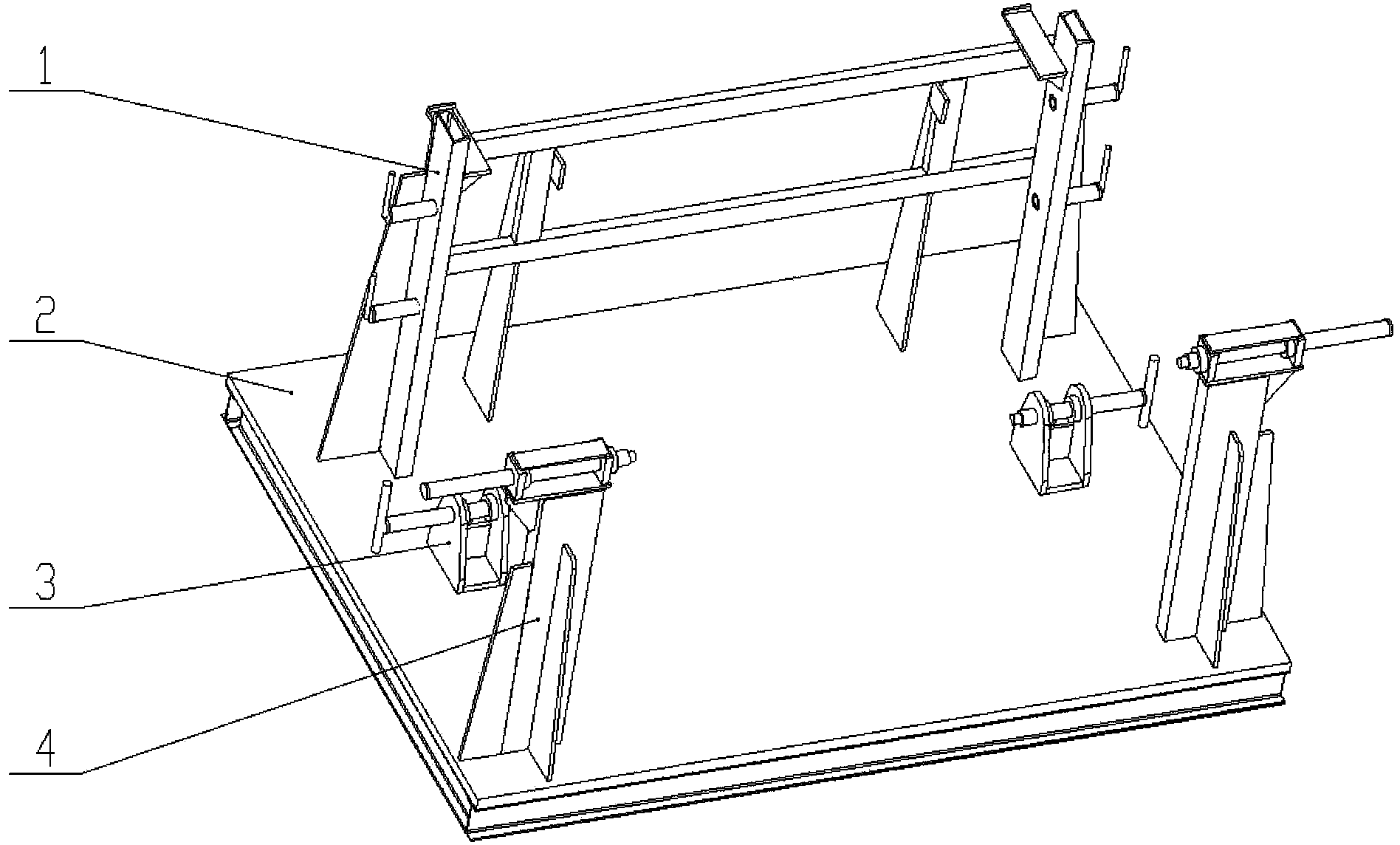

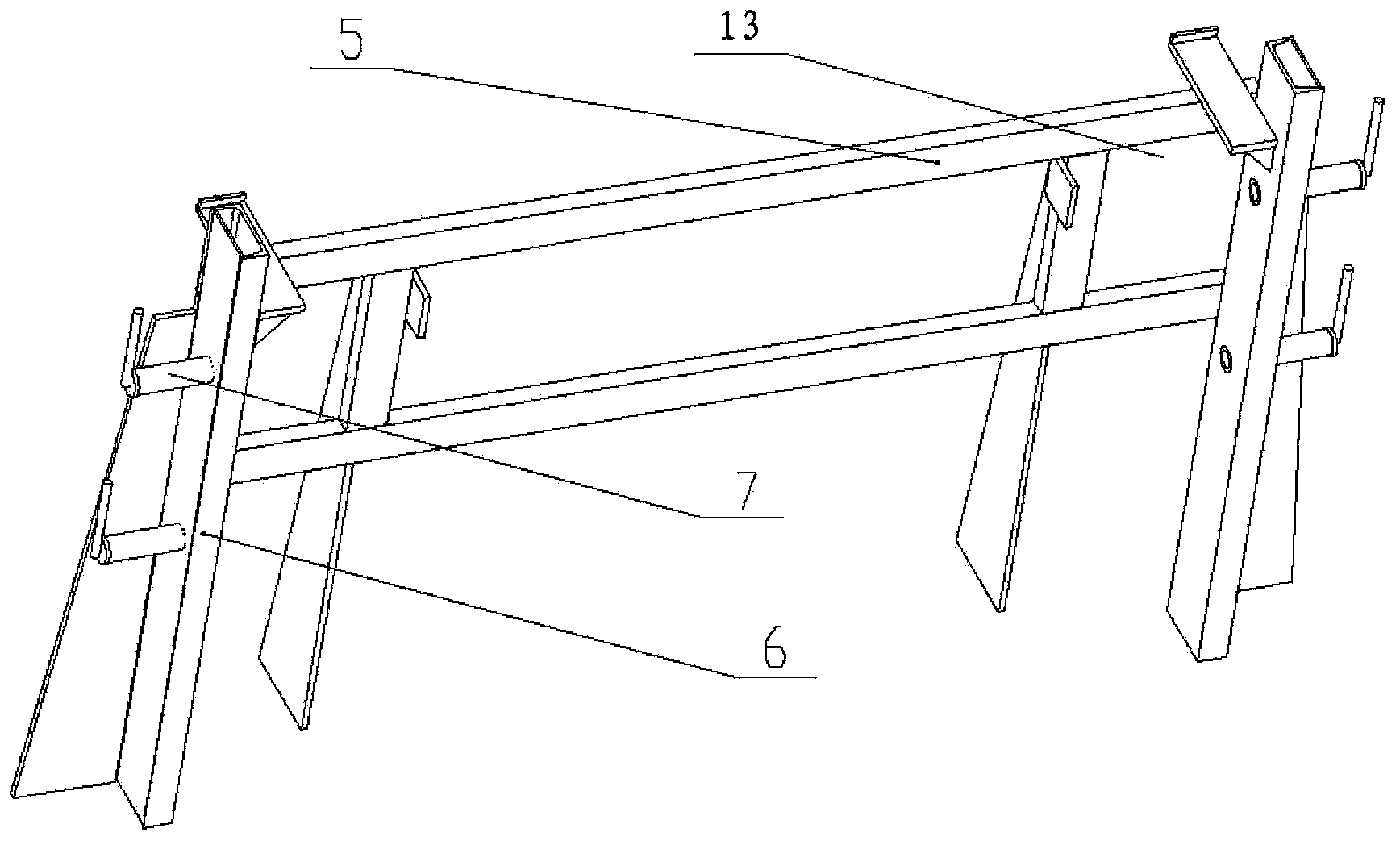

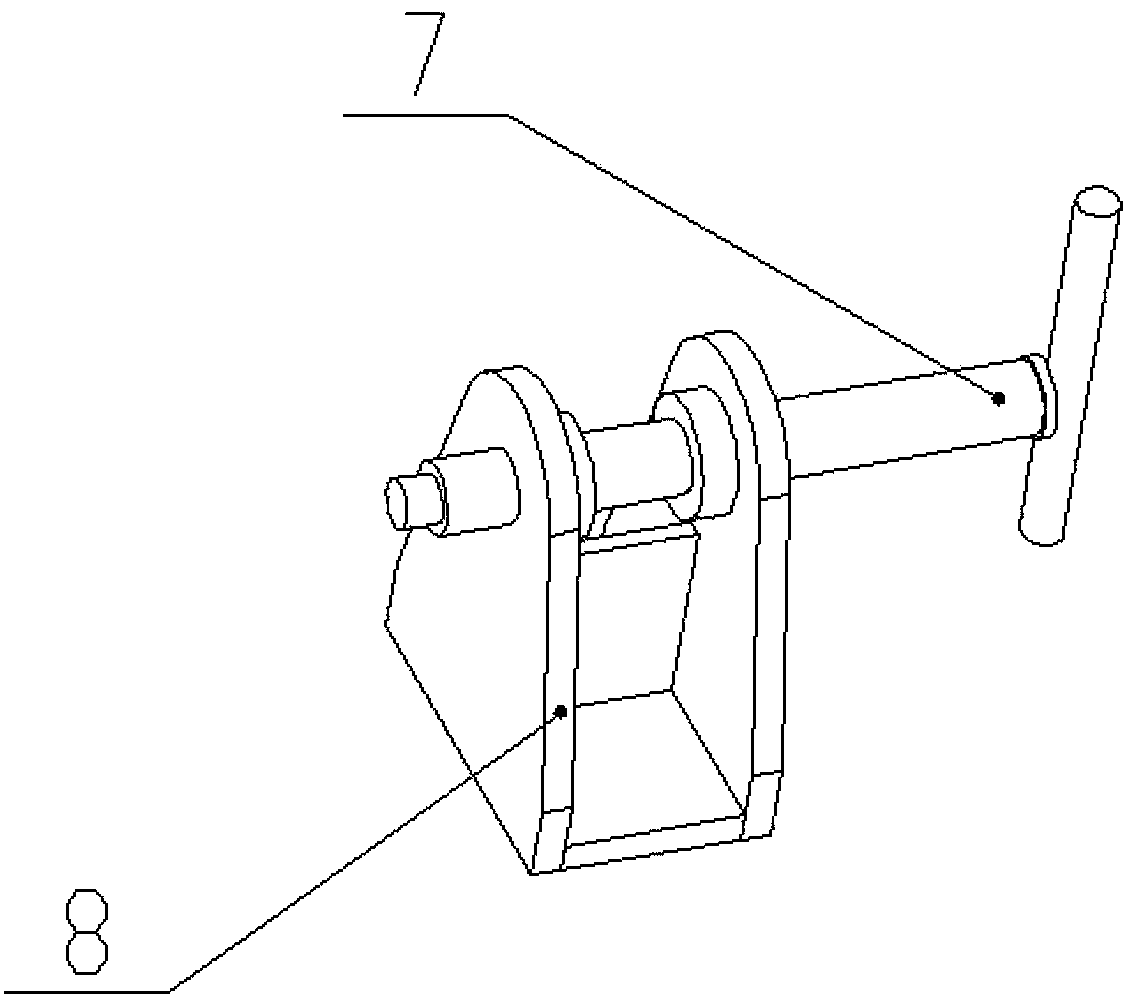

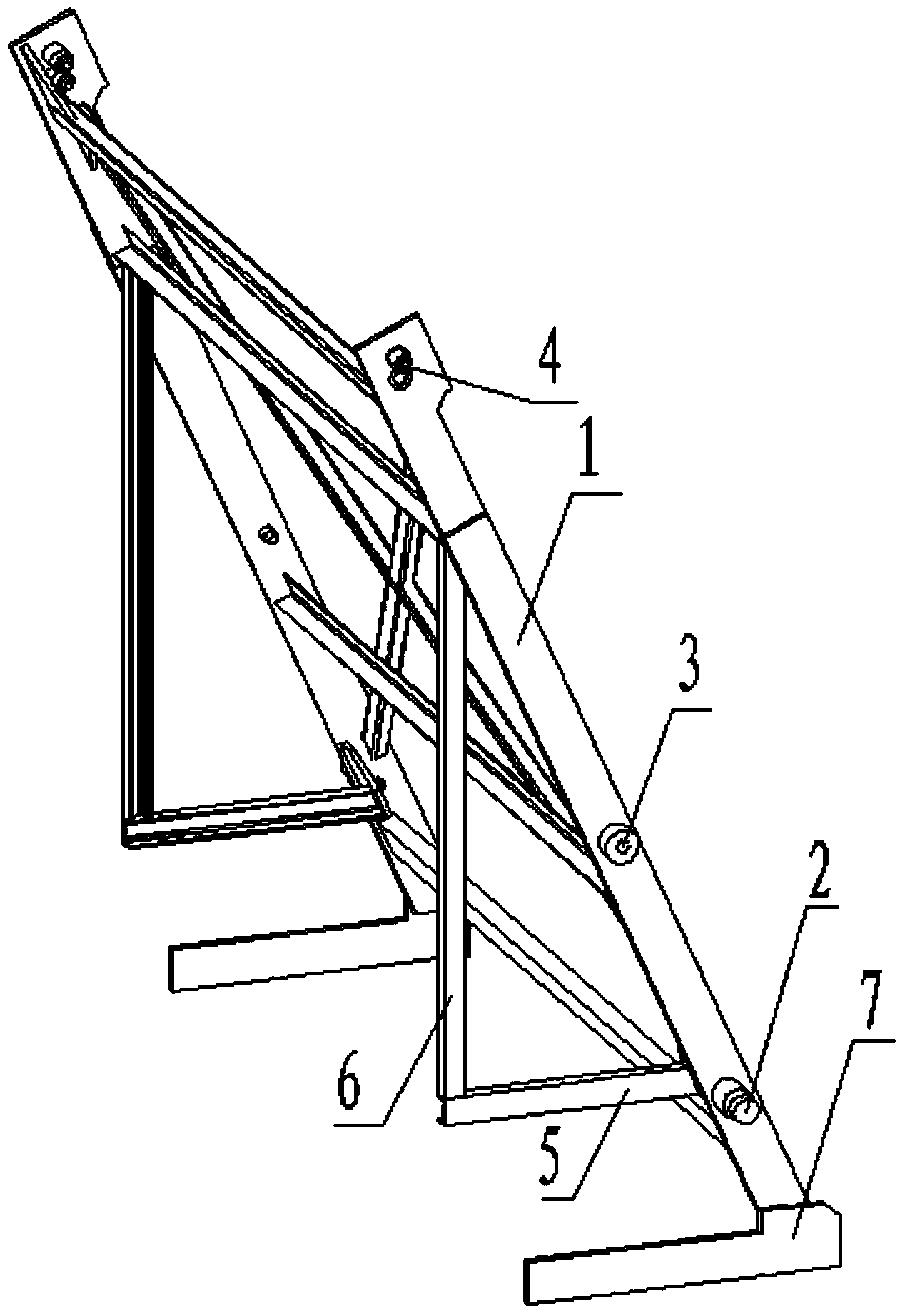

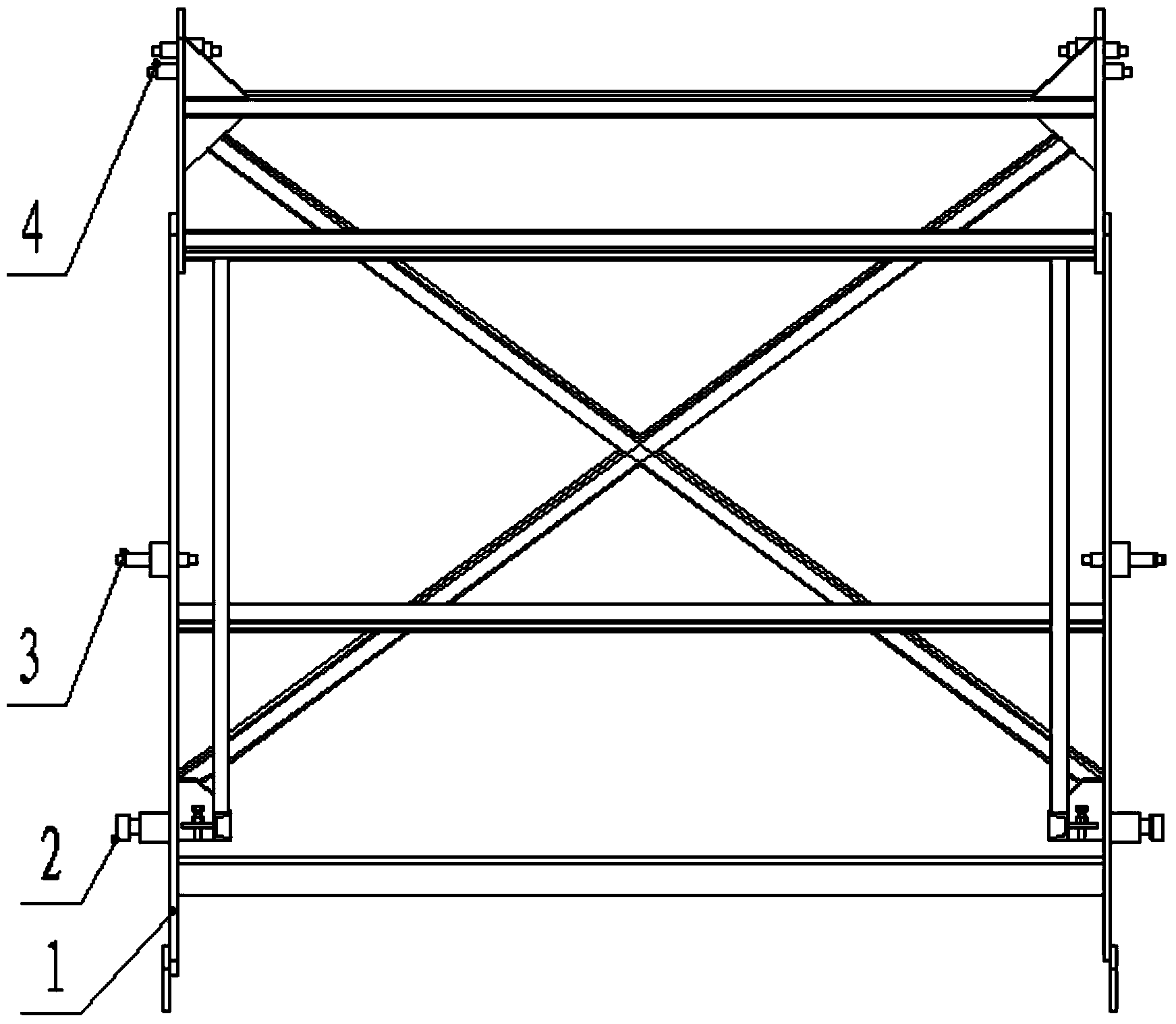

Carriage longitudinal beam tailor welding tool

ActiveCN103418965ASave adjustment timeHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention relates to a carriage longitudinal beam tailor welding tool. The carriage longitudinal beam tailor welding tool comprises a fixing frame and a first stand column which is fixed on the edge of one side of the fixing frame, wherein the edge of the other side of the fixing frame is fixedly connected with the lower portion of a second stand column, a regulating rod is fixed on the edge of the position, between the first stand column and the second stand column, of the fixing frame, and a base plate is fixedly connected with the surface of one end of the fixing frame. The carriage longitudinal beam tailor welding tool has the advantages that a part to be welded is accurately located and reliably clamped, so that the part to be welded is conveniently assembled and welded, and structural accuracy of the part to be welded is improved.

Owner:广西玉柴专用汽车有限公司

Casting method of ZL101 thin-wall aluminium alloy part

The invention discloses a casting method of a ZL101 thin-wall aluminium alloy part. The method includes steps of: 1) preparing moulding sand raw materials; 2) preparing binder slurry, wherein the binder slurry comprises 36-40% by weight of starch, 6-8% by weight of furan resin, 14-16% by weight of calcium bentonite, 3-5% by weight of bagasse cellulose powder having a size of -100 meshes, 1-2% by weight of zinc stearate and 2-3% by weight of sodium tripolyphosphate, with the balance being water; 3) preparing moulding sand; 4) manufacturing a casting and gating system; 5) smelting a ZL101 alloy, wherein 0.035% of Sr is added for modification, argon is fed after slag removal, gas removal is performed by rotation, smelting is performed when the temperature is 735-745 DEG C, and the alloy is allowed to stand for 10-12 min after smelting; 6) casting, wherein the aluminum alloy casting temperature is controlled to e 720-730 DEG C, and the casting speed is controlled in a manner that the former two fifth of the total casting amount adopts a speed of 6-8 kg / s, the middle two fifth adopts a speed of 4-5 kg / s, and the last one fifth adopts a speed of 6-8 kg / s; and 7) cooling with the mould, opening the mould, cleaning and performing thermal processing.

Owner:DAYE HONGTAI ALUMINUM IND CO LTD

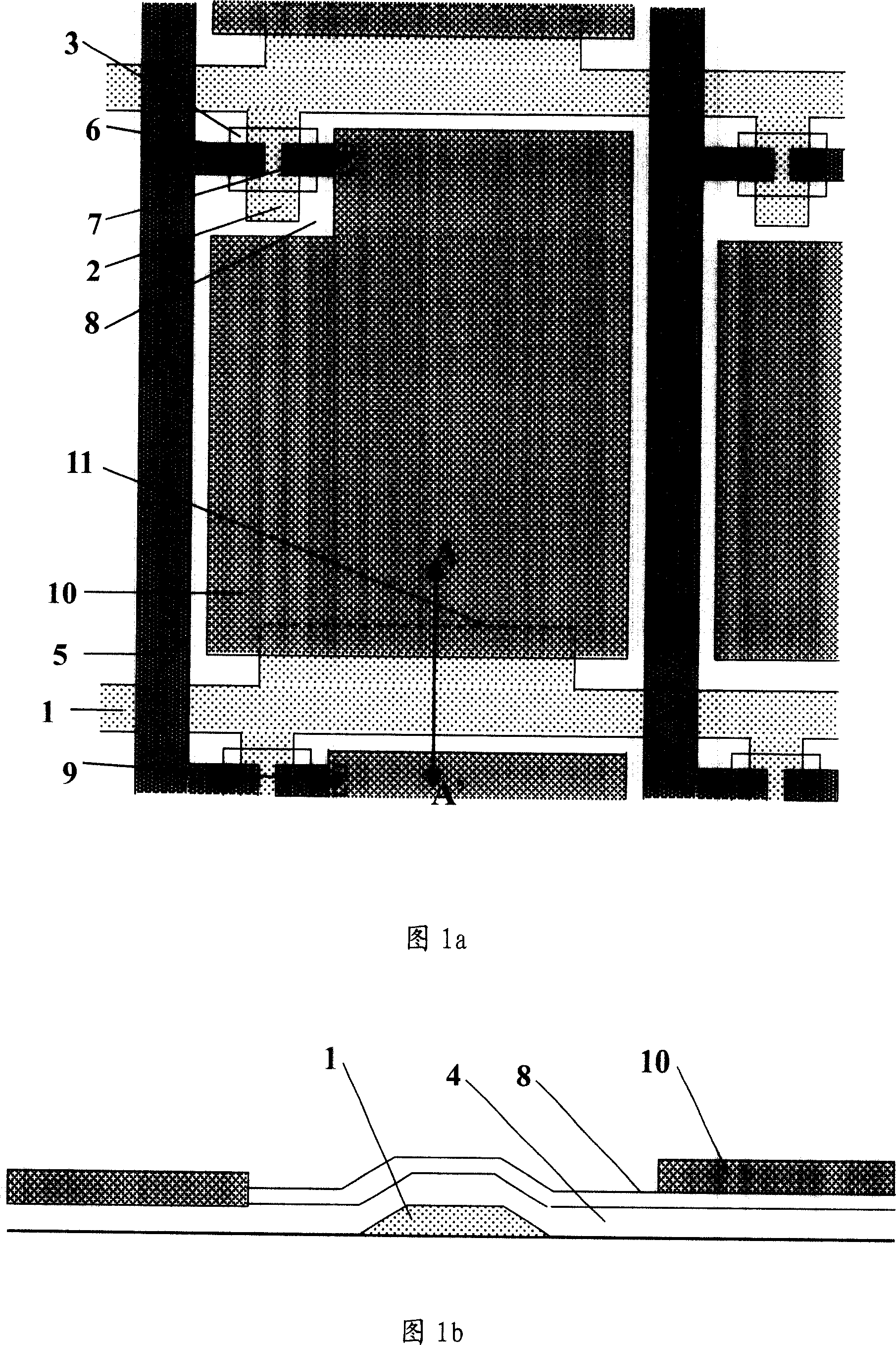

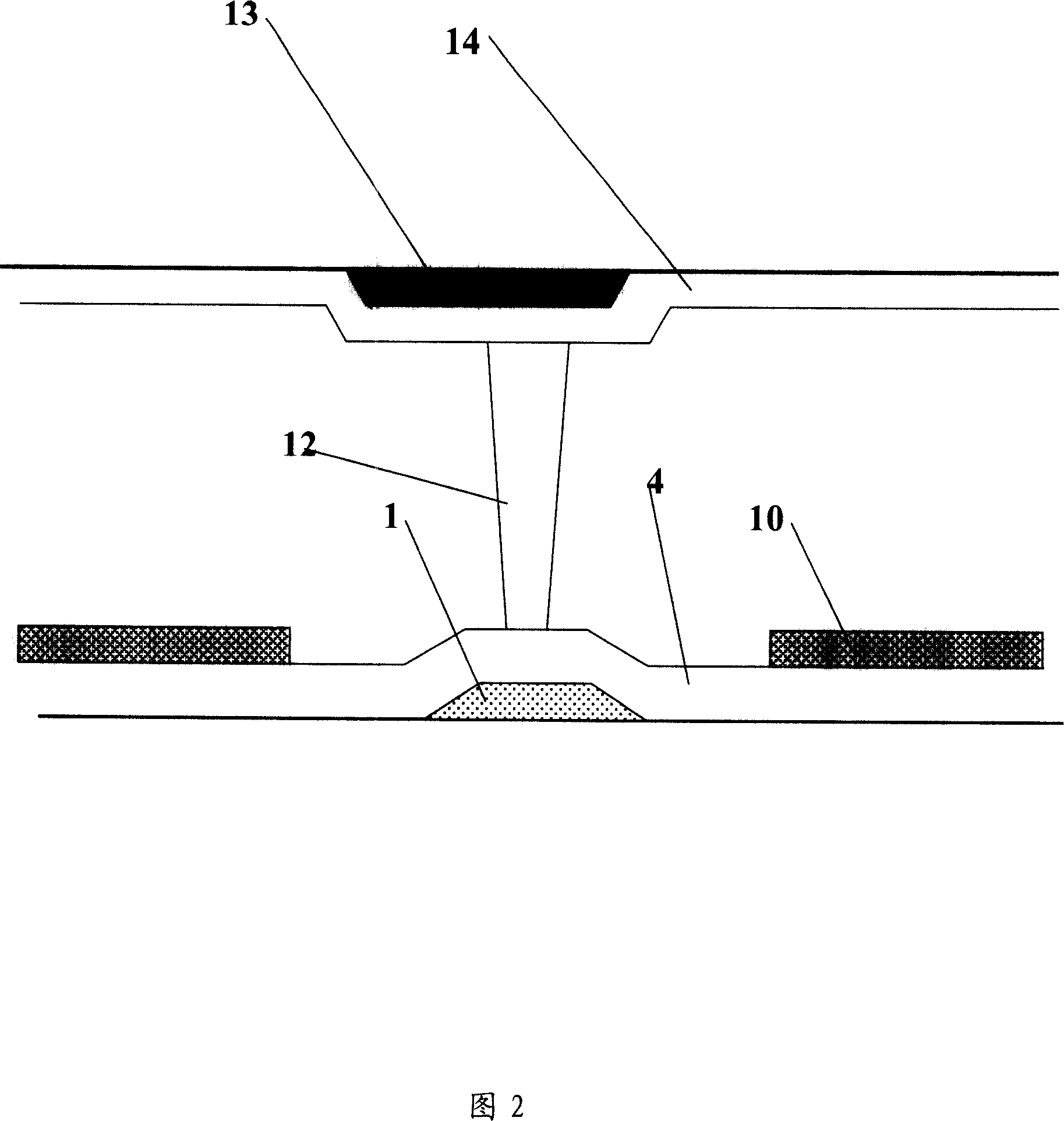

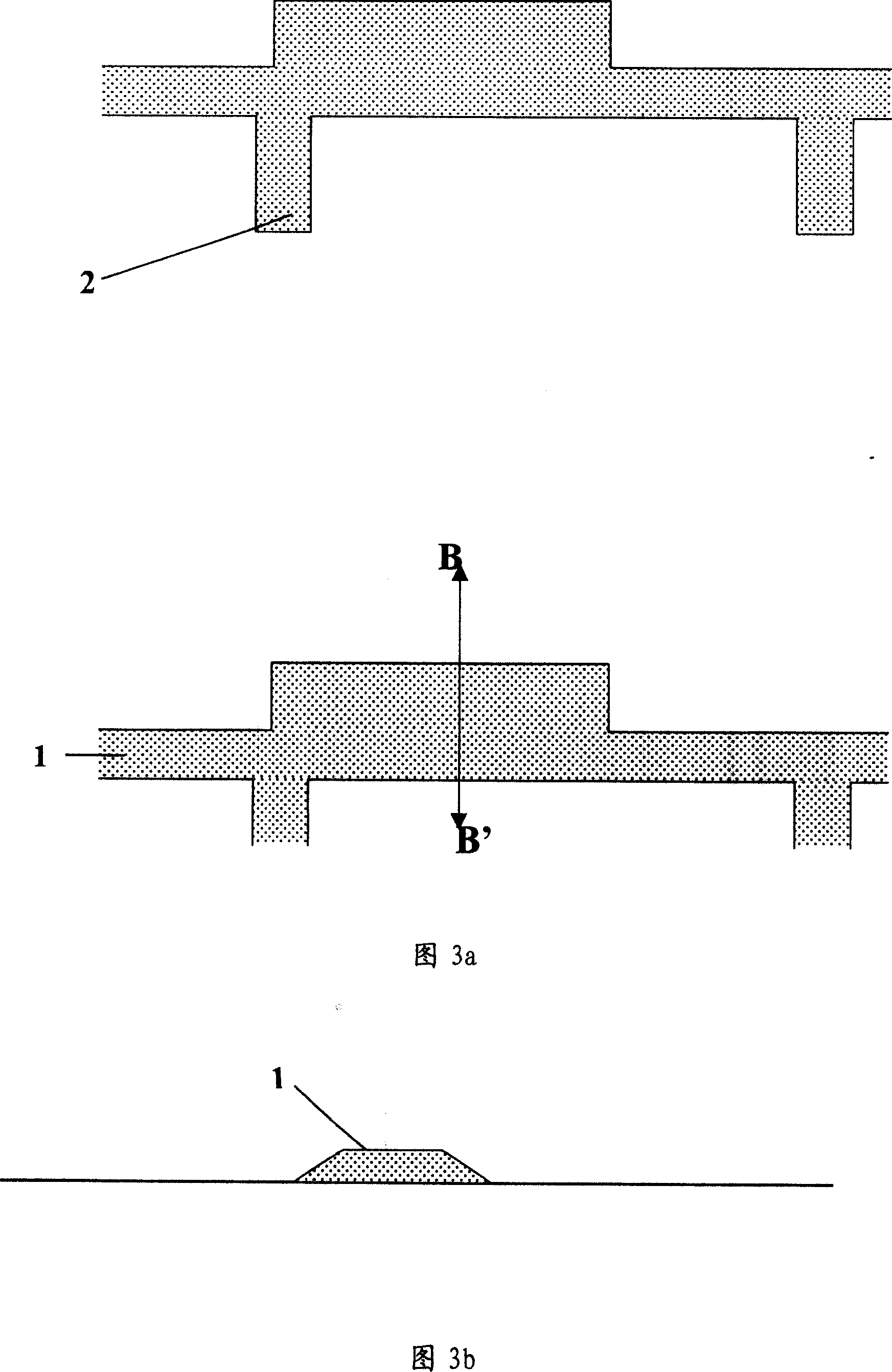

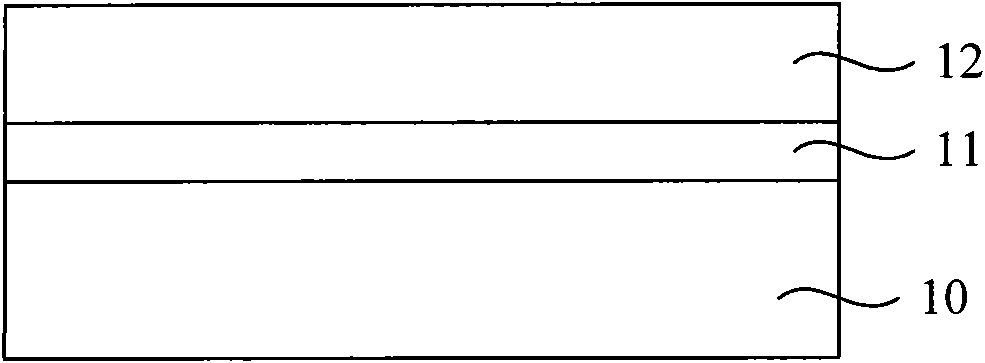

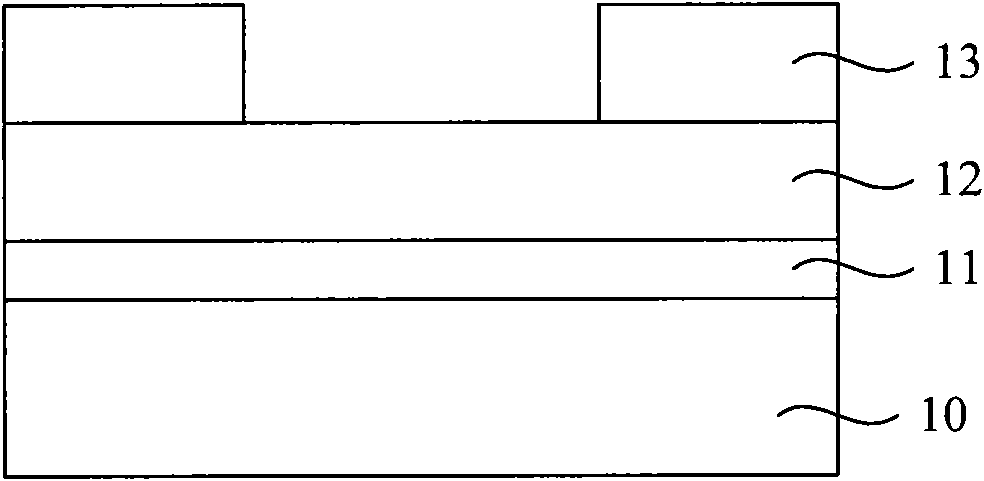

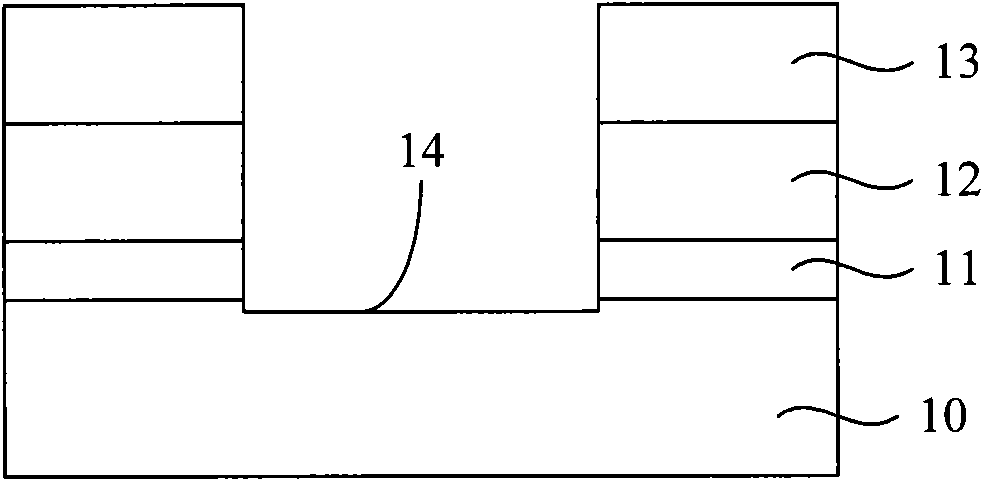

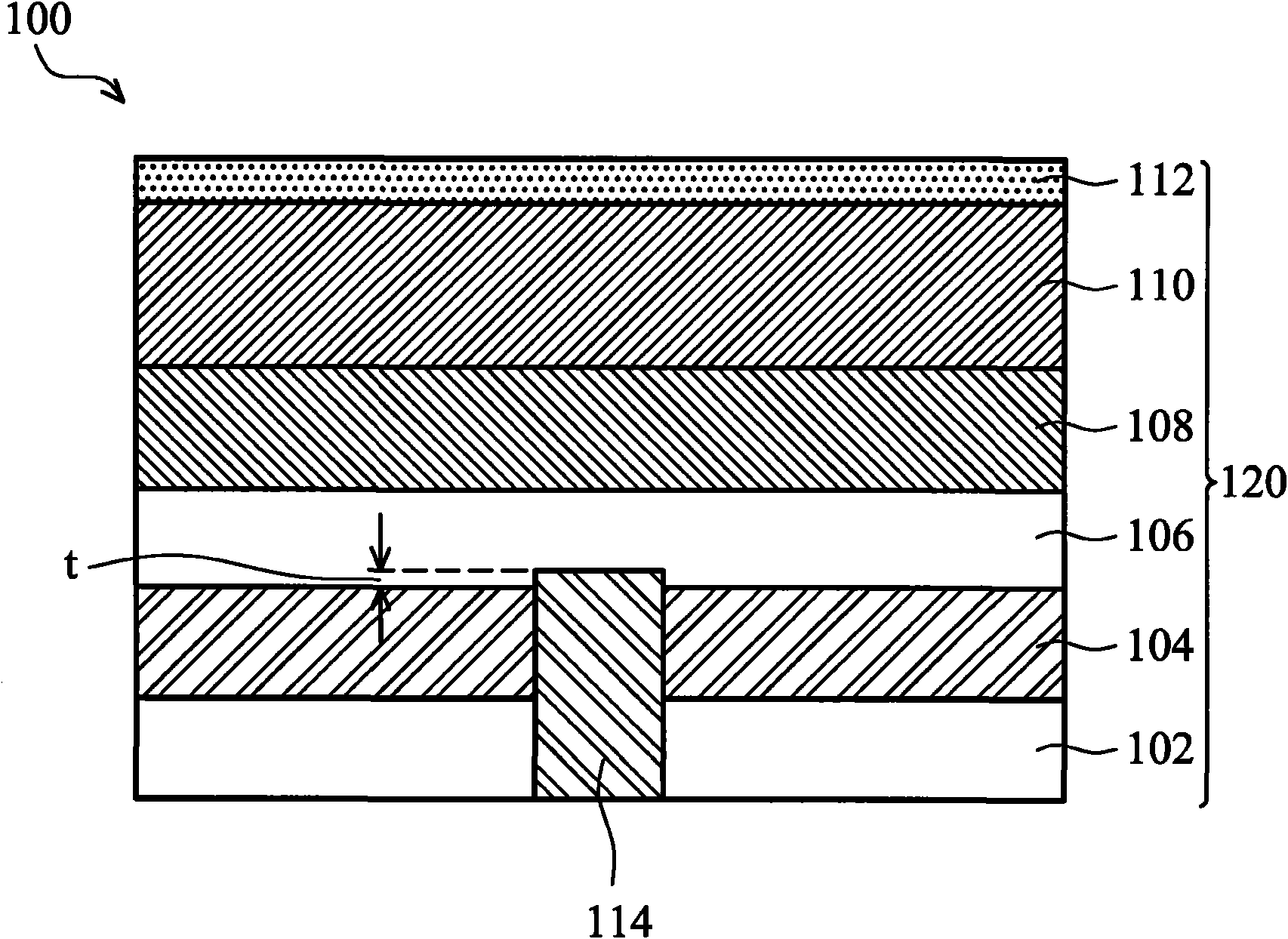

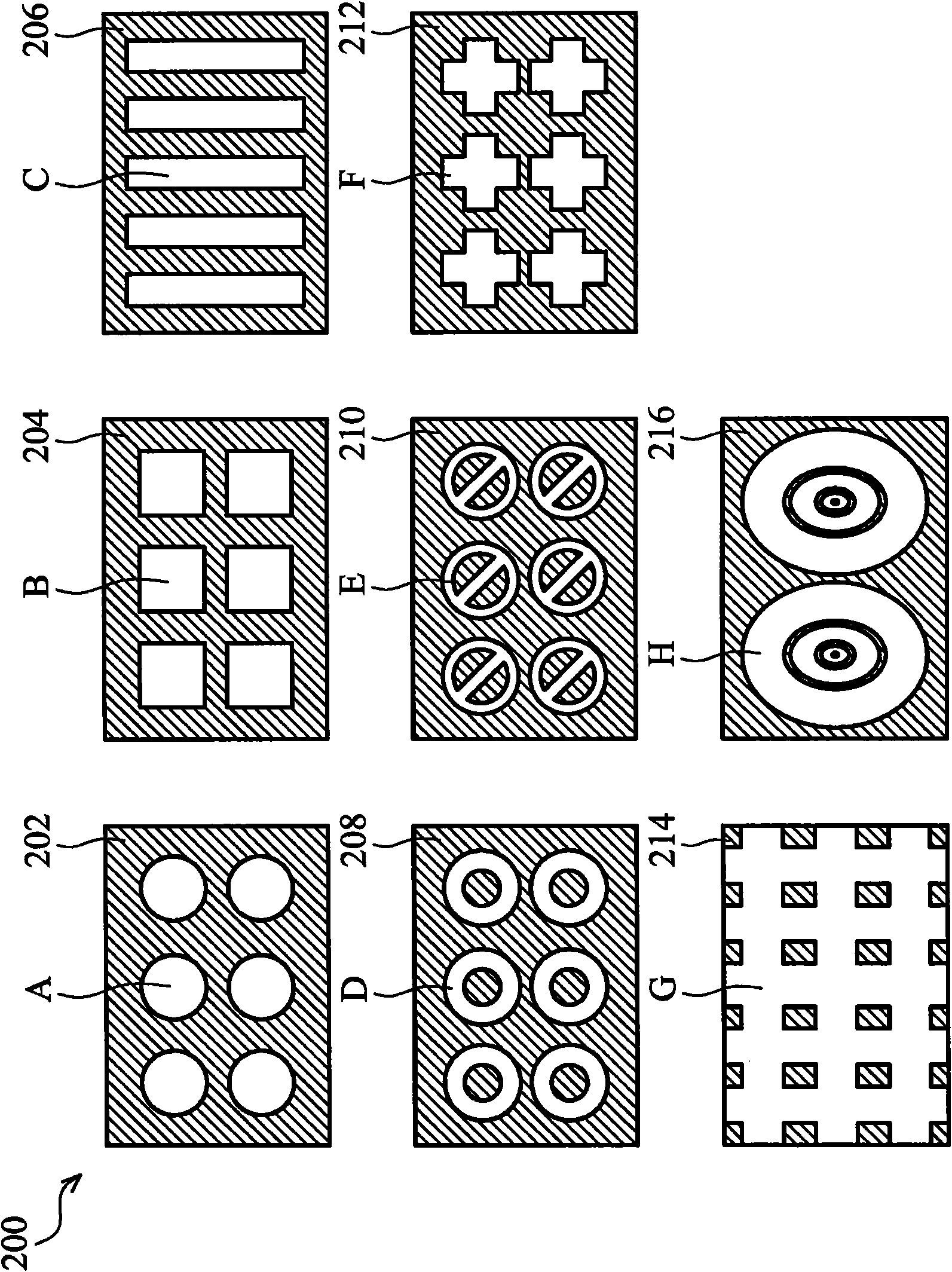

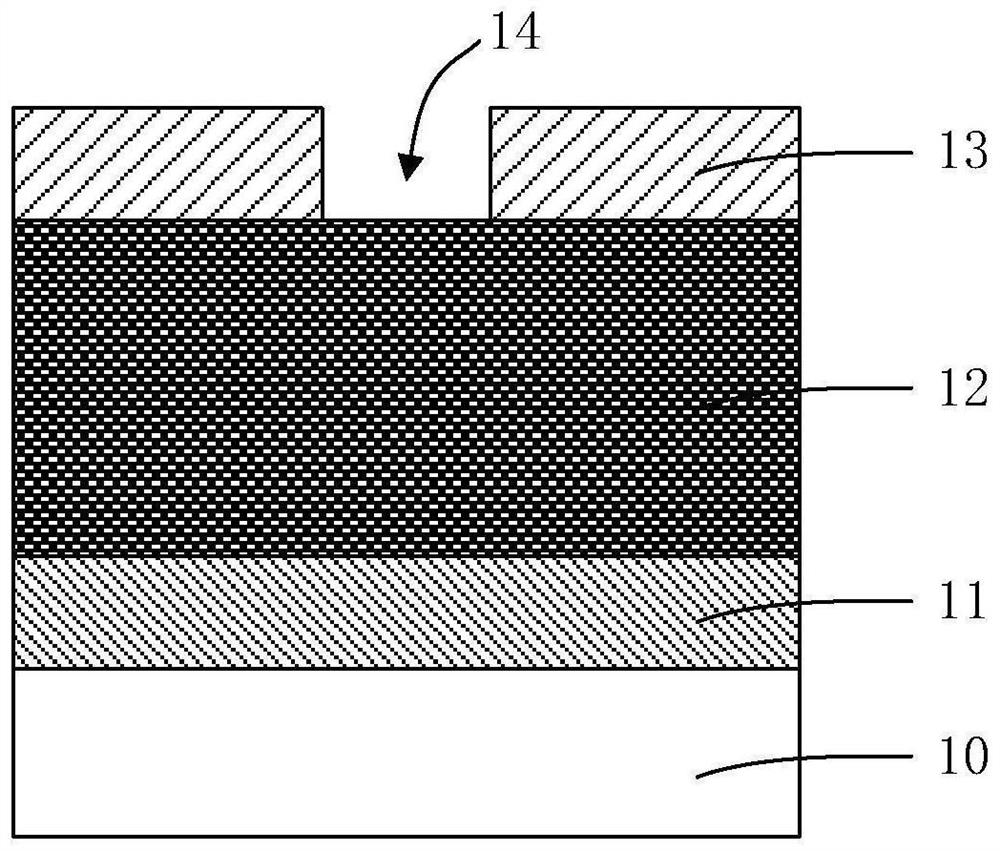

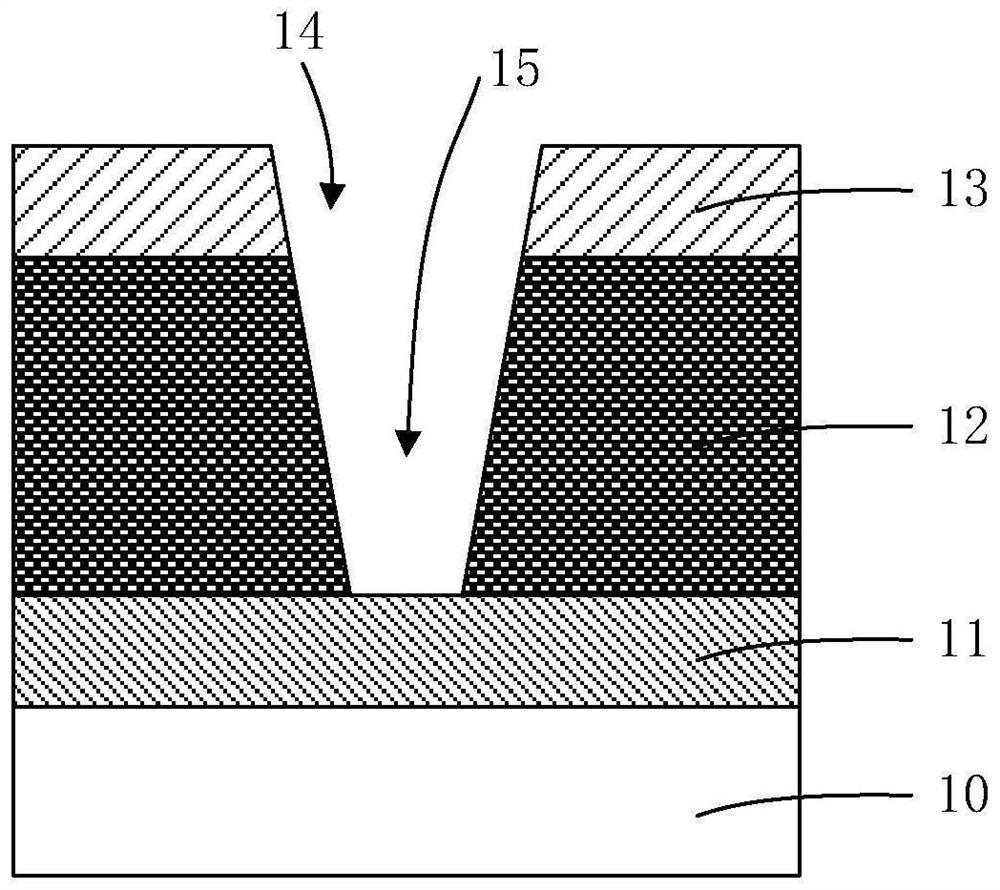

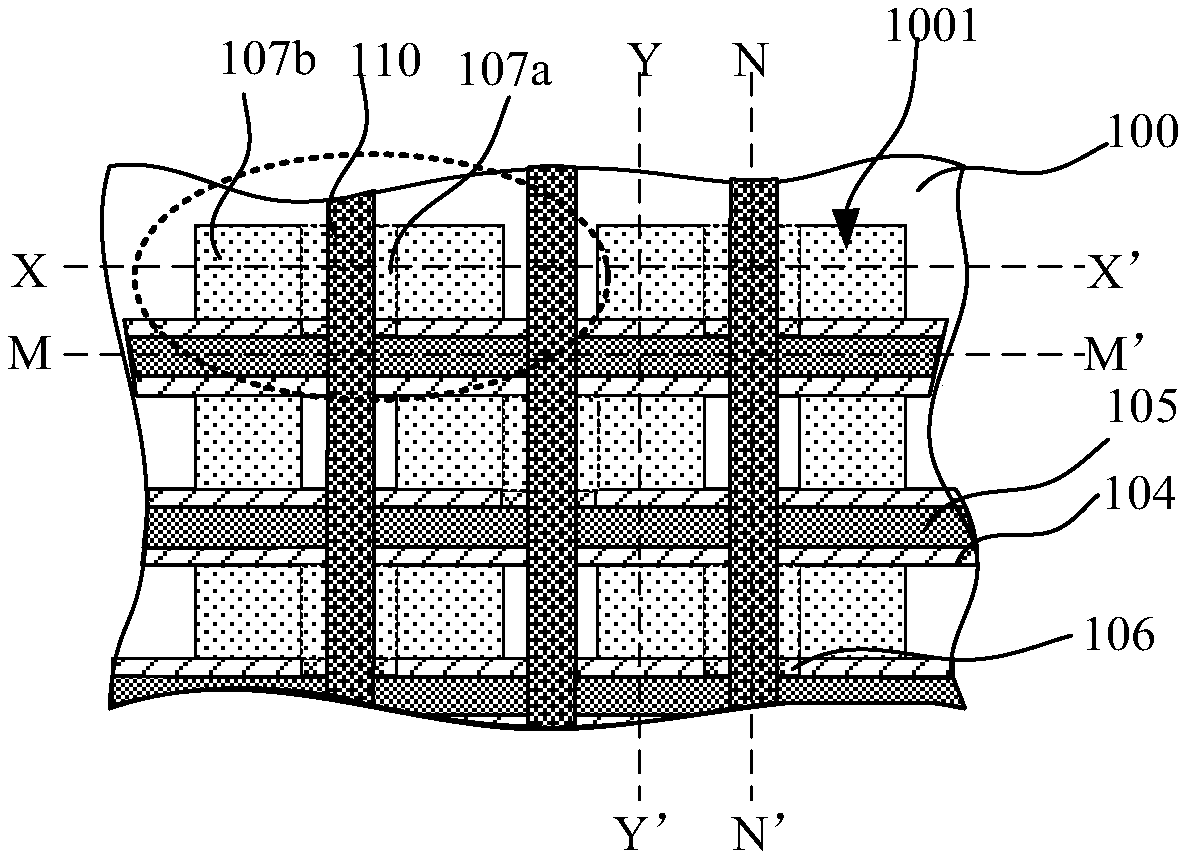

Thin-film transistor LCD pixel structure and its making method

ActiveCN101126876AImprove qualityImprove white mura phenomenonPhotomechanical exposure apparatusMicrolithography exposure apparatusLiquid-crystal displayThin-film-transistor liquid-crystal display

The utility model discloses an LCD pixel structure of a thin film transistor (TFT), which comprises a glass substrate, a plurality of grid lines, a grid electrode, a grid insulating layer, a silicon island, a source electrode, a leakage electrode, a plurality of data lines, a passivation layer and a pixel electrode. A hole is formed in the grid insulating layer and the passivation layer at the upper end of the grid lines, and a pixel electrode material layer is formed at the lower end of the hole. The utility model also discloses a manufacturing method of the thin film transistor (TFT) LCD pixel architecture, with the through hole forming in the pixel electrode, and also forming a matched hole with the columnar pad in shape and size at the upper end of the grid lines corresponding to the position of the columnar pad. The utility model has the advantages of effectively improving the phenomenon of white Mura comparing with the prior art, increasing the craft degree of freedom, reducing process defects, and improving the picture quality.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

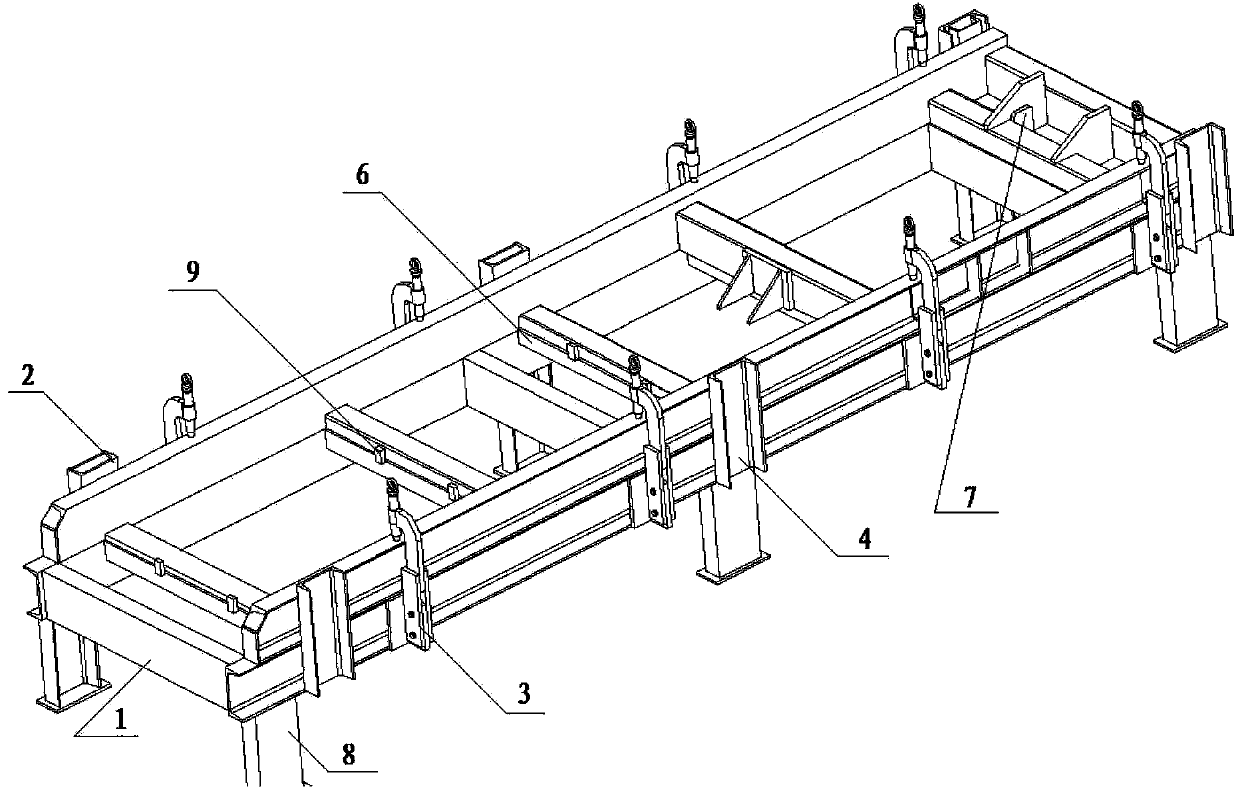

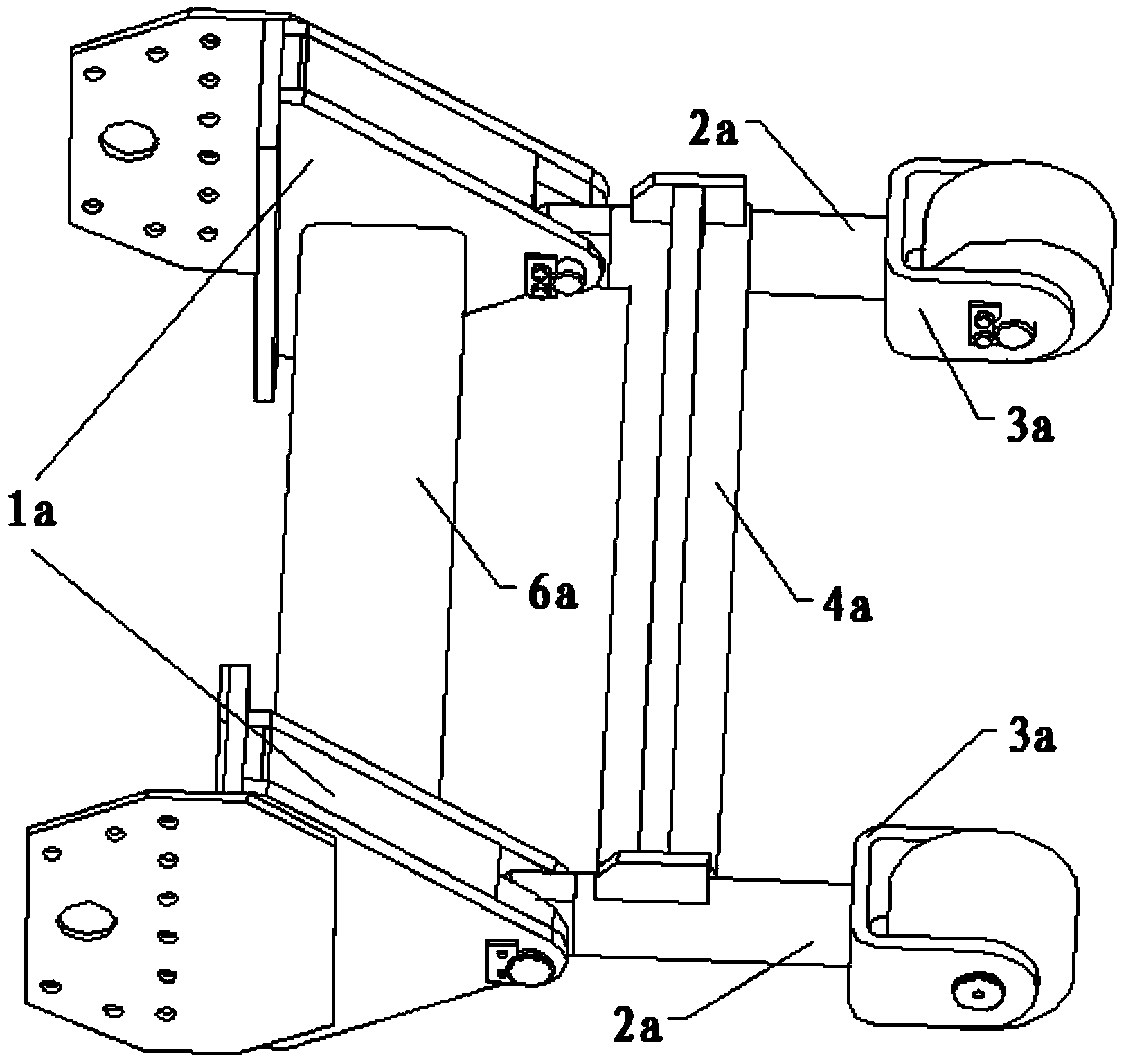

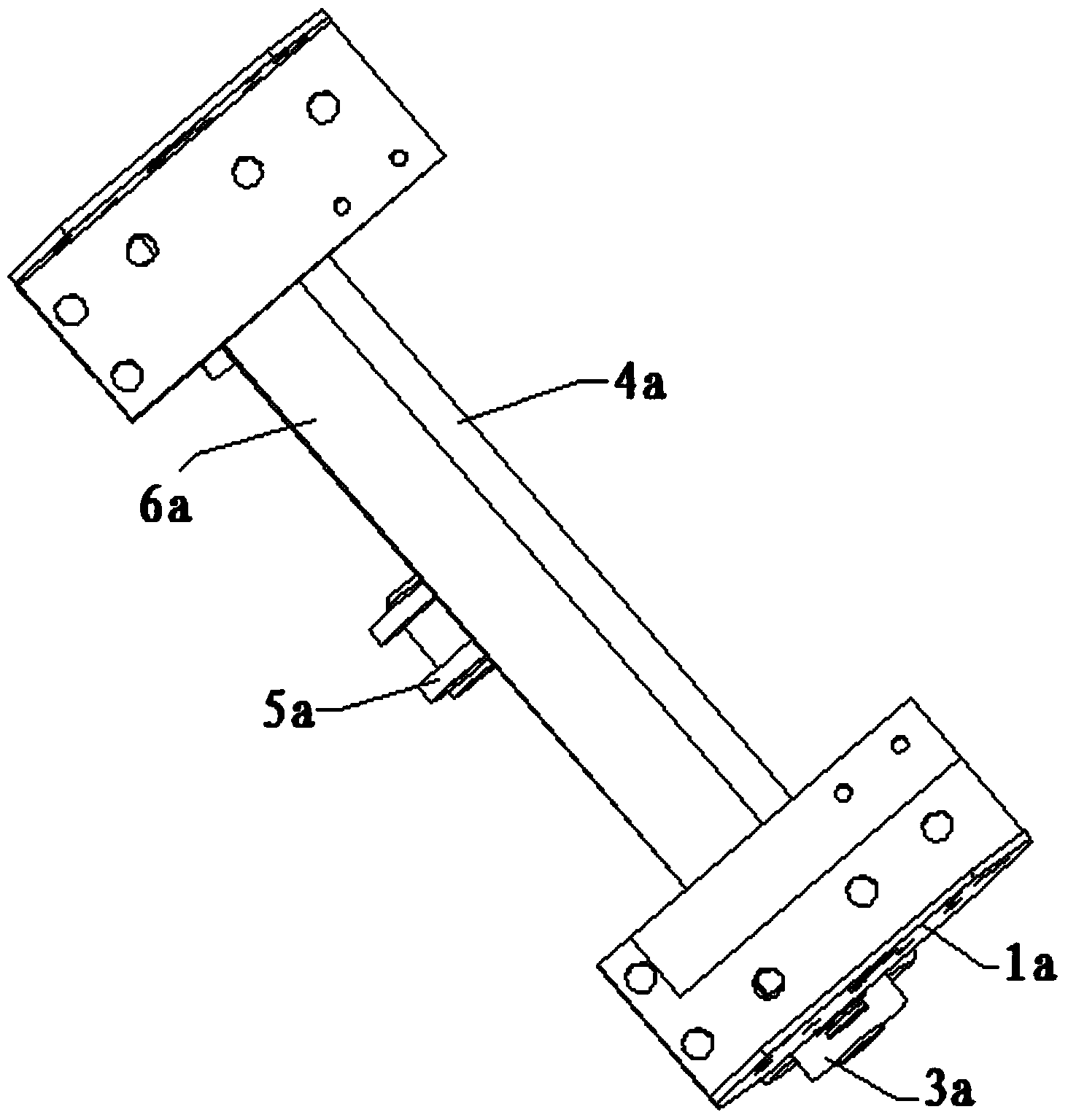

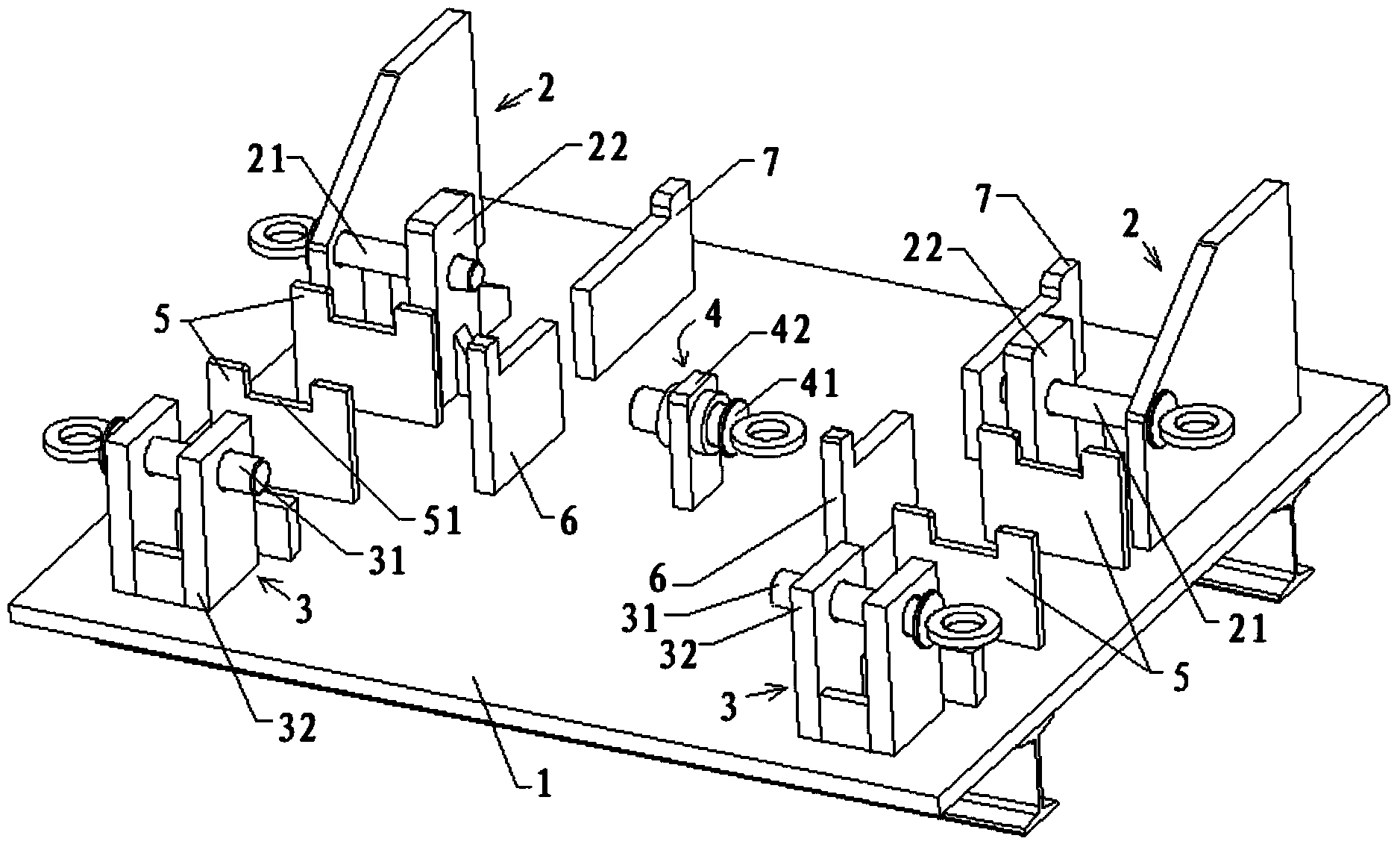

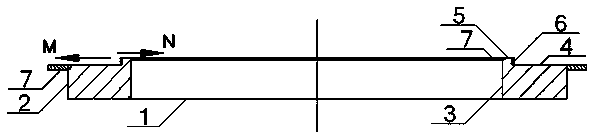

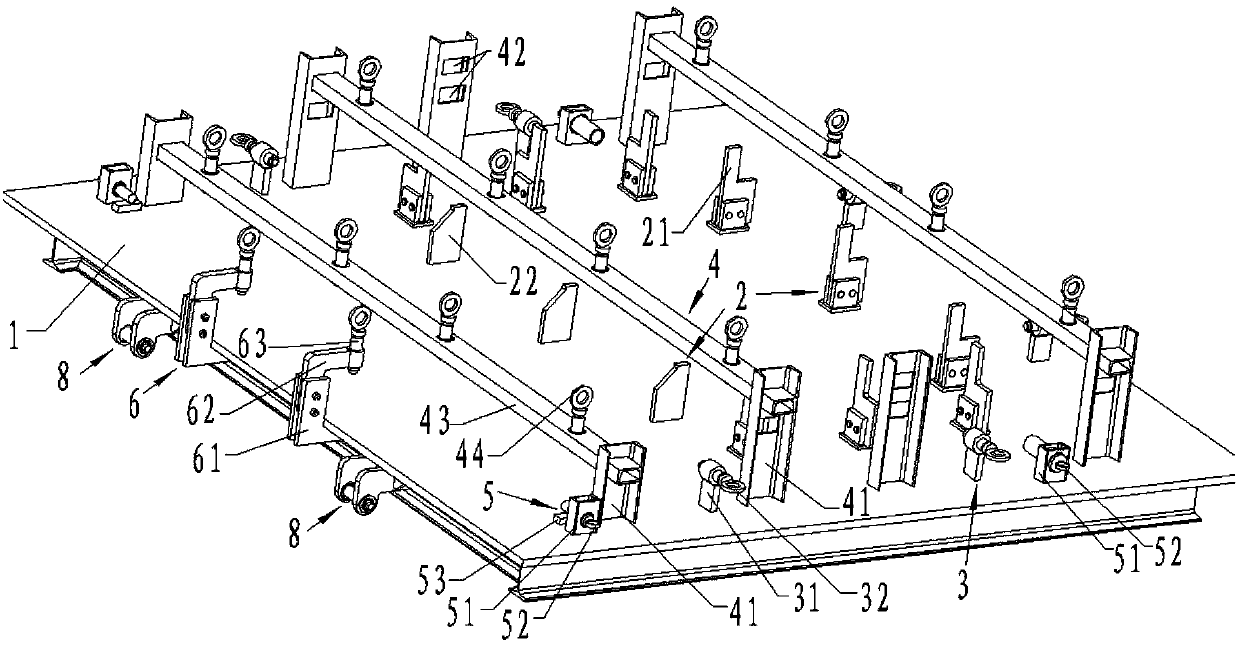

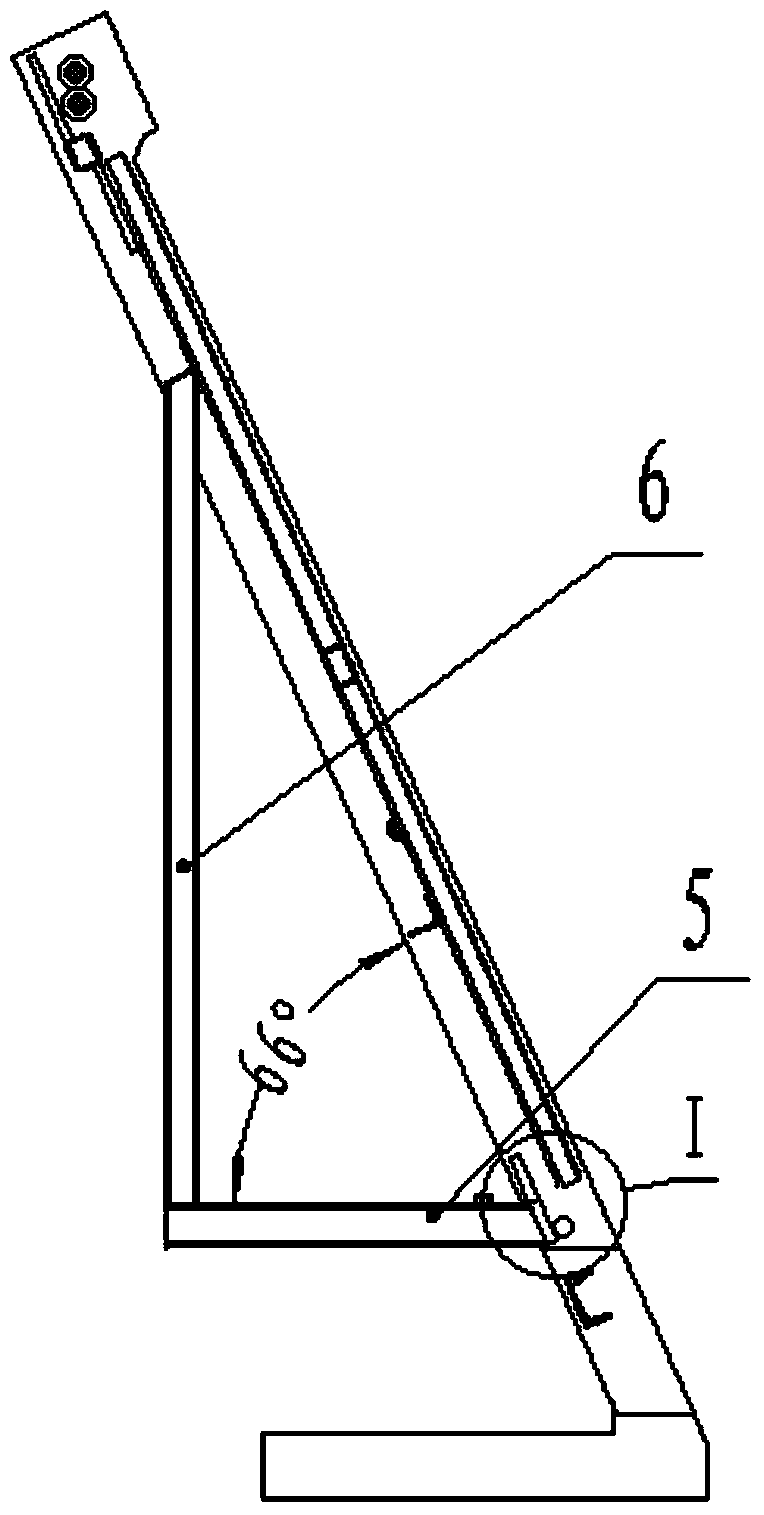

Tailored welding tool for landing leg supports of hooklifts

ActiveCN104259720AReduce failureHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesWelding

The invention discloses a tailored welding tool for landing leg supports of hooklifts. The tailored welding tool comprises a supporting base board and a first positioning base, a second positioning base, a plurality of landing leg base plates, a plurality of drawing arm base plates and a third positioning base which are fixed on the supporting base board. The tailored welding tool can overcome the defects of the landing leg supports of having deviation easily and being difficult to adjust and poor in stability during tailored welding.

Owner:广西玉柴专用汽车有限公司

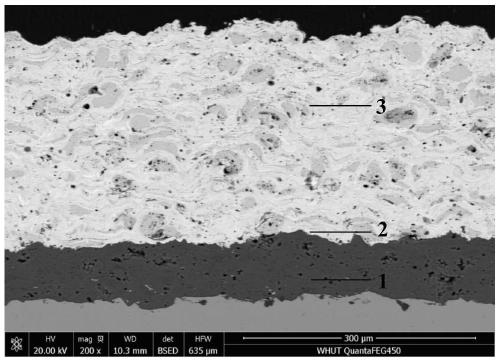

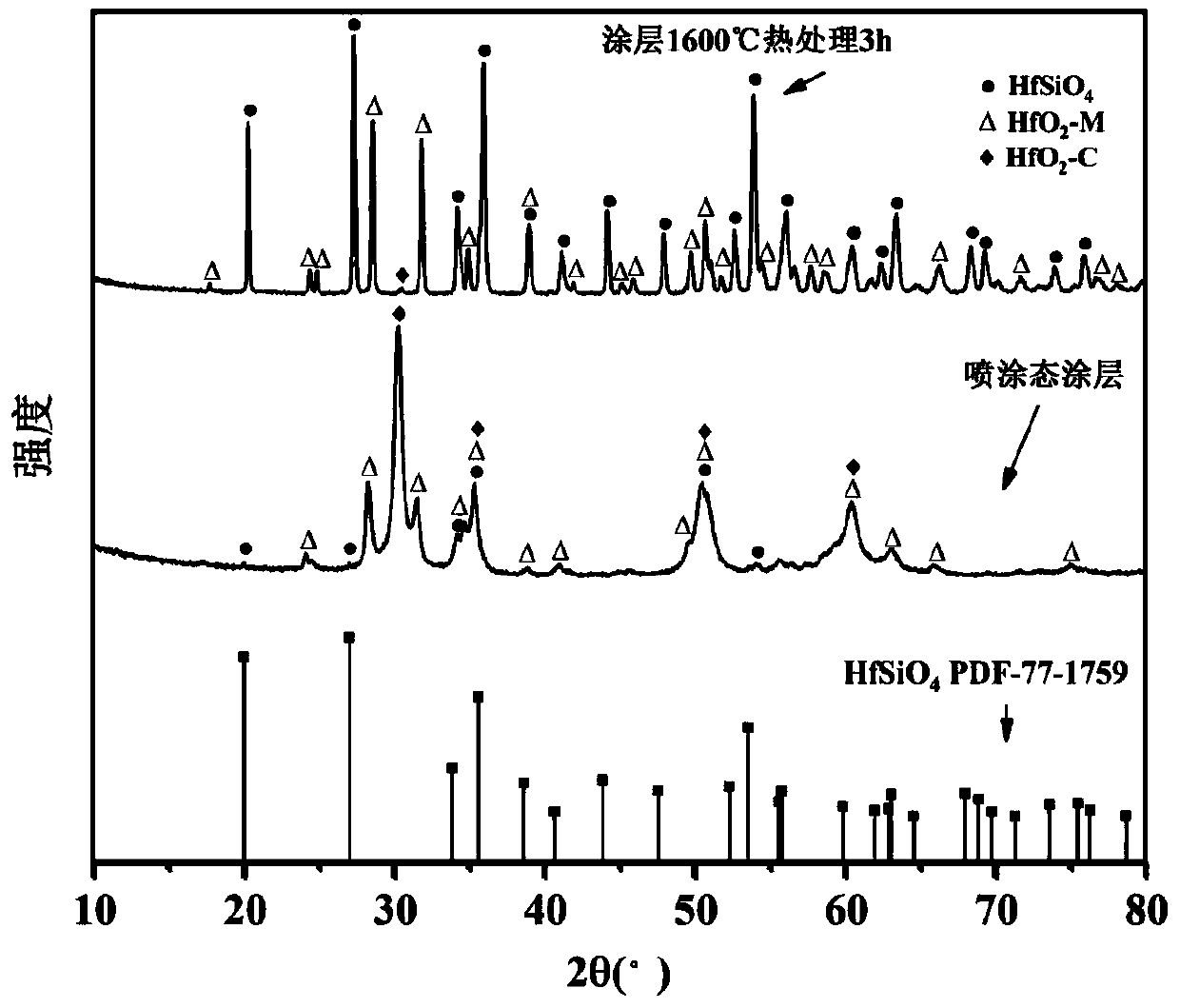

Hafnium silicate environment barrier coating for ceramic-based composite material matrix and preparation method thereof

The invention provides a hafnium silicate environment barrier coating for a ceramic-based composite material matrix and a preparation method thereof. The preparation method comprises the following steps: (1) mixing HfO2 and SiO2, carrying out wet mixing and ball milling on a ball mill, drying, grinding, sieving, sintering, and carrying out a high-temperature solid-phase reaction; (2) after the high-temperature solid-phase reaction is finished, adding deionized water for slurry preparation, then performing ball milling, and performing spray granulation to obtain an HfSiO4 powder material; (3) firstly spraying a Si layer on the surface of a ceramic-based composite matrix as a priming coat, and then spraying the HfSiO4 powder material on the surface of the priming coat as a surface layer to form a multi-layer coating; and (4) carrying out a heat treatment on the multi-layer coating to obtain the environmental barrier coating. Due to the added heat treatment, the crystallinity of the HfSiO4 surface layer is improved, the binding force of each layer of the coating is better, the stability is higher, and the water and oxygen resistance of the environment barrier coating is greatly improved. The provided preparation method is simple and easy to control, and is easy for industrial production and application.

Owner:WUHAN UNIV OF TECH

Method for manufacturing shallow groove isolation structure

InactiveCN102087989AReduce etchingSmooth chamferSemiconductor/solid-state device manufacturingEngineeringDry etching

The invention discloses a method for manufacturing a shallow groove isolation structure, which comprises: forming a hard mask of which an opening exposes from a substrate, and oxidizing the substrate in an oxygen atmosphere; and forming a shallow groove on the substrate at the position of the opening by a dry etching method after the oxidation treatment. The method for manufacturing the shallow groove isolation structure can form a relatively round shallow groove top chamber and reduce the probability of process defects.

Owner:CSMC TECH FAB1 +1

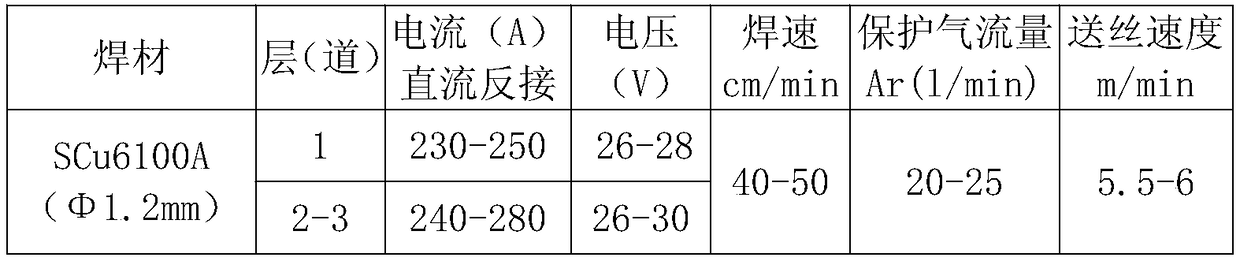

Process method for carrying out bead welding on steel with aluminum bronze

InactiveCN109128436AImprove production efficiencyGood surfacing qualityArc welding apparatusAir coolingAluminium bronze

The invention discloses a process method for carrying out bead welding on steel with aluminum bronze. The process method comprises the following steps that firstly, a stainless steel wire wheel is used for removing an oxidation film on a face to be subjected to bead welding of a bead welding workpiece; then, overall preheating is carried out on the bead welding workpiece, the preheating temperature is 150 DEG C-200 DEG C, and the temperature is kept for 0.5-1 hour after preheating; and next, arc blowout plates are additionally arranged on the two sides of the face to be subjected to bead welding, continuous welding is carried out on the bead welding workpiece through consumable electrode inert gas shielded welding, the bead welding interlayer-temperature is larger than or equal to 150 DEGC, reasonable welding materials and welding process parameters are selected, after welding is completed, annealing heat treatment is carried out on the bead welding workpiece, the initial temperatureis 100 DEG C-150 DEG C, the temperature is kept for 2-2.5 hours after the temperature is gradually raised to 300 DEG C-400 DEG C, the temperature is kept for 1-1.5 hours after the temperature is raised to 500 DEG C-560 DEG C, and after the bead welding workpiece is cooled to 200 DEG C along with a furnace, the bead welding workpiece is output out of the furnace to be subjected to air cooling to the room temperature. By means of the design, the bead welding quality is good, and the bead welding quality is high.

Owner:WUHAN MARINE MACHINERY PLANT

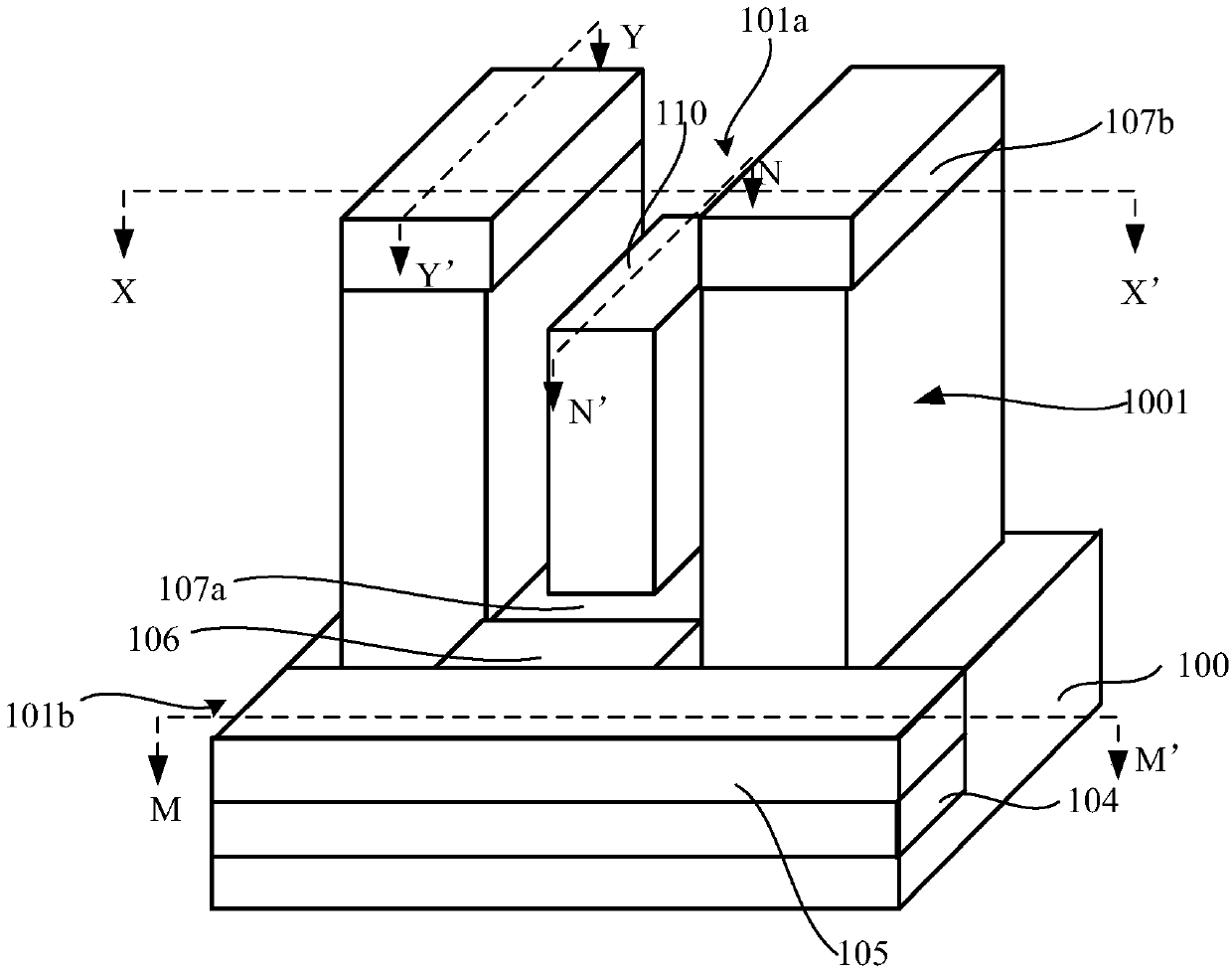

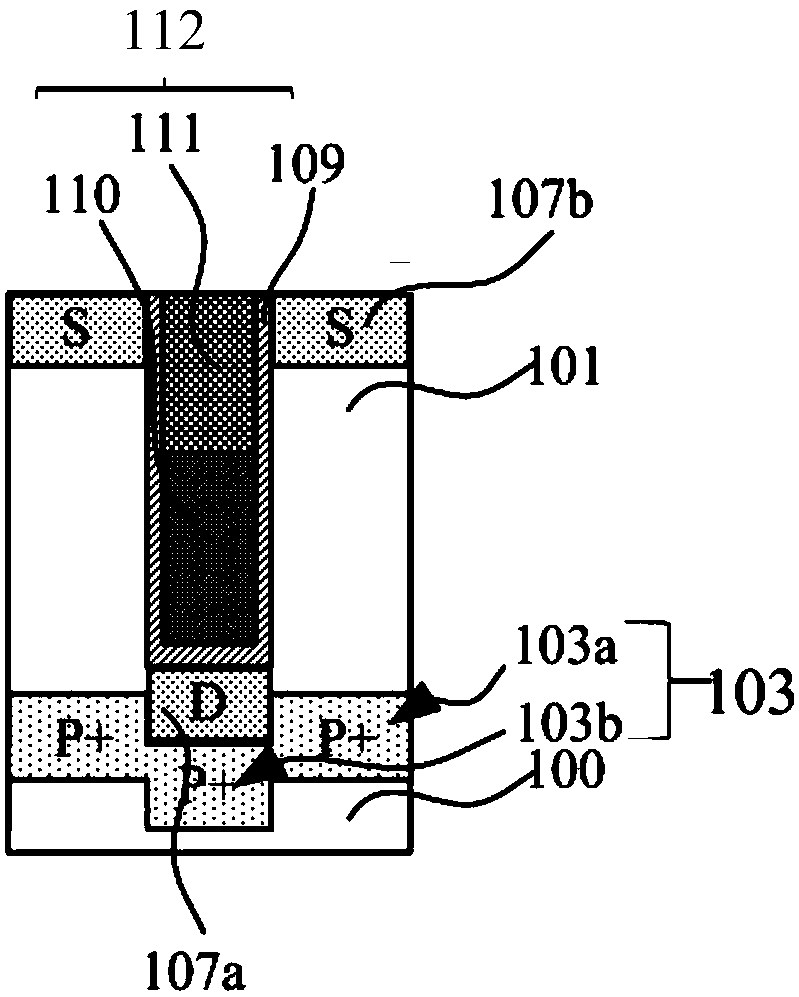

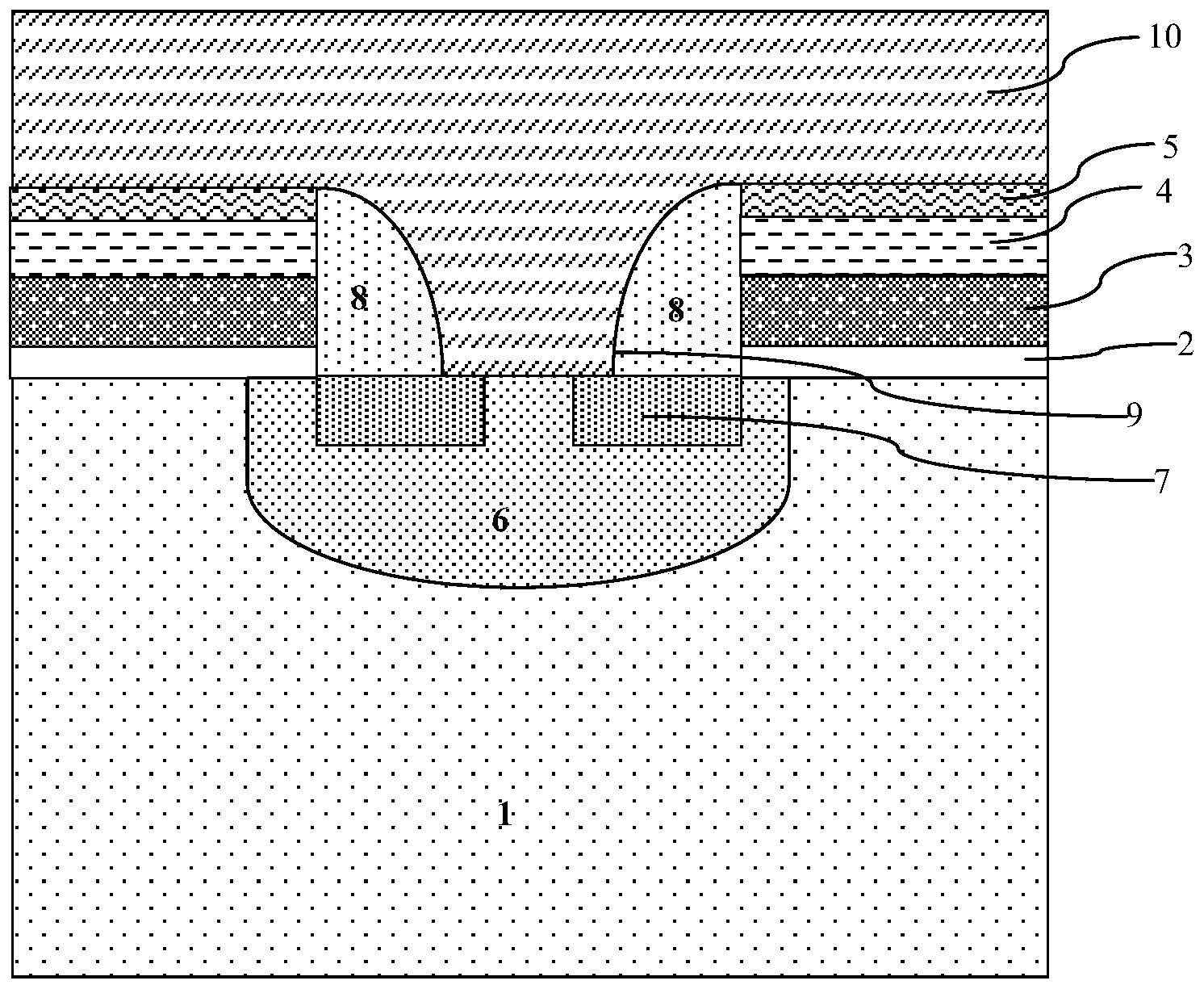

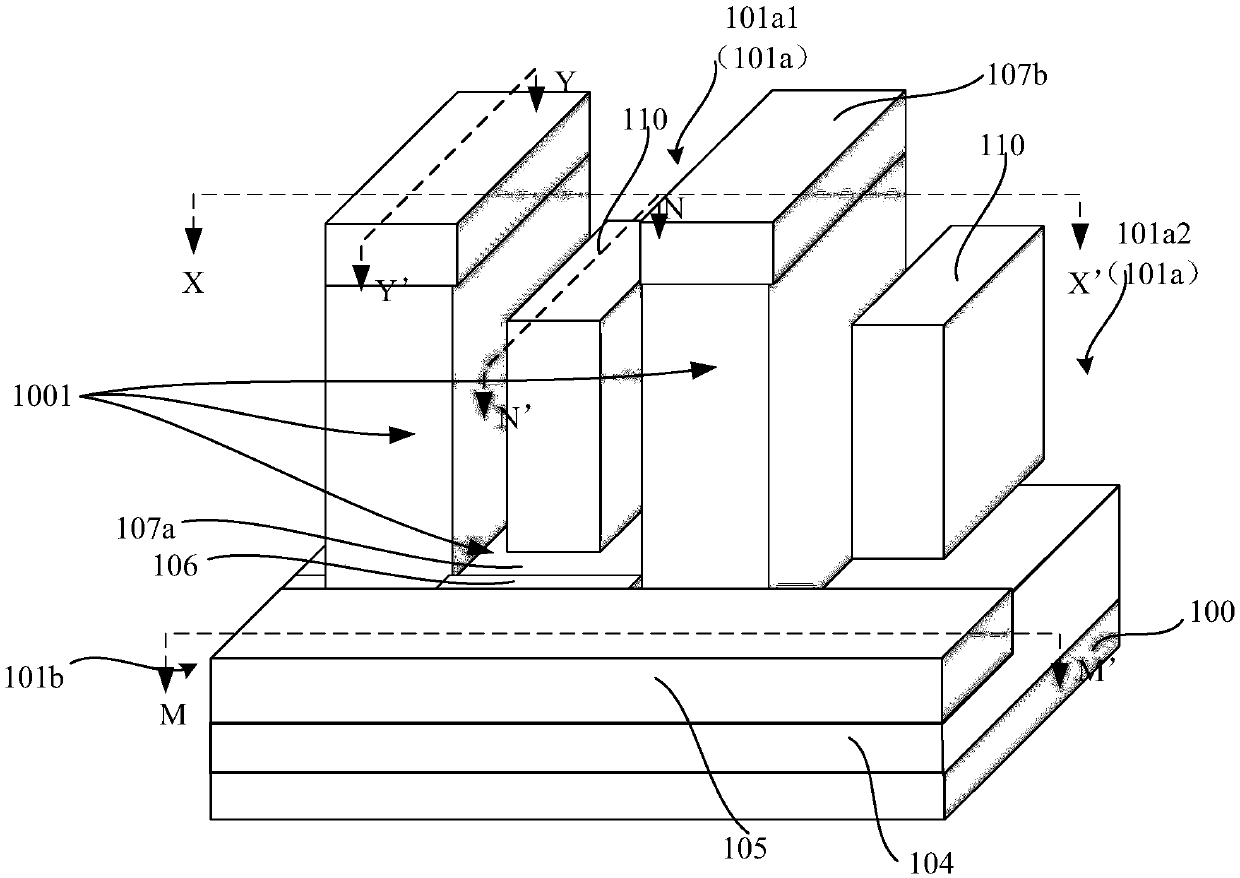

Double-vertical-channel transistor, integrated circuit memory and preparation method thereof

PendingCN110931558AHighly integratedIncrease the effective channel lengthTransistorSemiconductor/solid-state device manufacturingElectrical connectionStructural engineering

The invention provides a double-vertical-channel transistor, an integrated circuit memory and a preparation method thereof. A first trench extending along a first direction is formed in the vertical fin; first source / drain regions are formed in the fins at the tops of the two sides of the first trench; a second source / drain region is formed in the fin at the bottom of the first trench; a first gate structure is filled in the first trench and extends along the first direction; the embedded wires are filled in the second trench in the side wall, extending along the second direction, of the vertical fins, so that the first source / drain regions on the two sides of the first trench and the second source / drain region at the bottoms of the first trench respectively form double vertical L-shaped channels, the effective channel length is increased, and the short channel effect is overcome; and the second source / drain region and the electric connection embedded wire thereof are positioned at thebottom of the transistor and do not need to be directly led out from the upper surface, so that isolation at the periphery of the transistor is easier to form, the device area is reduced, the processis simplified and the performance is improved.

Owner:CHANGXIN MEMORY TECH INC

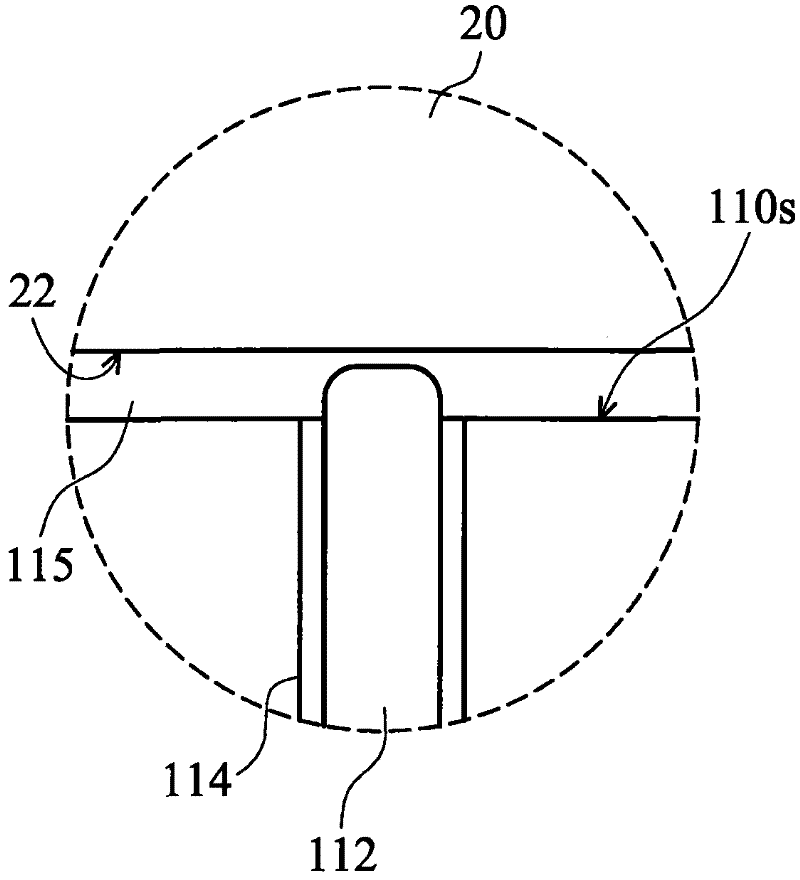

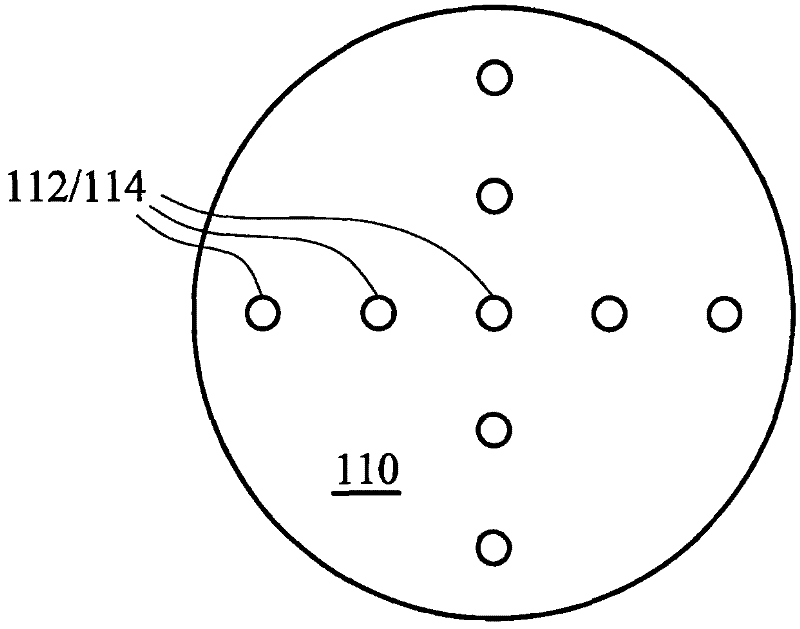

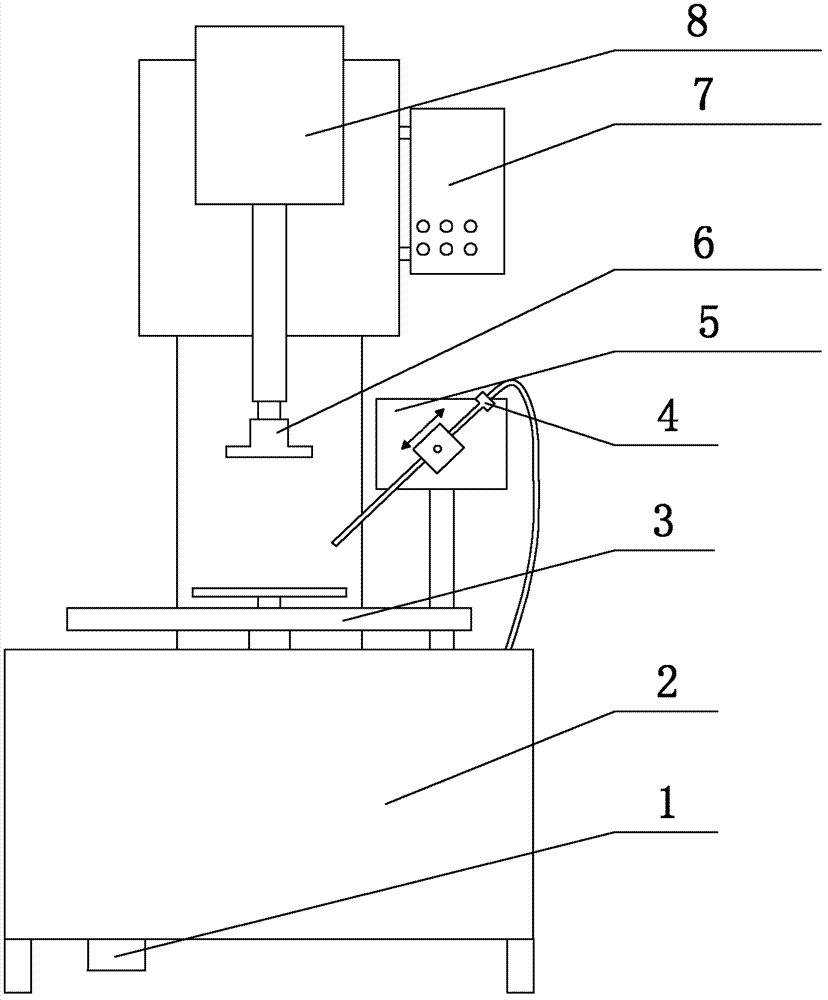

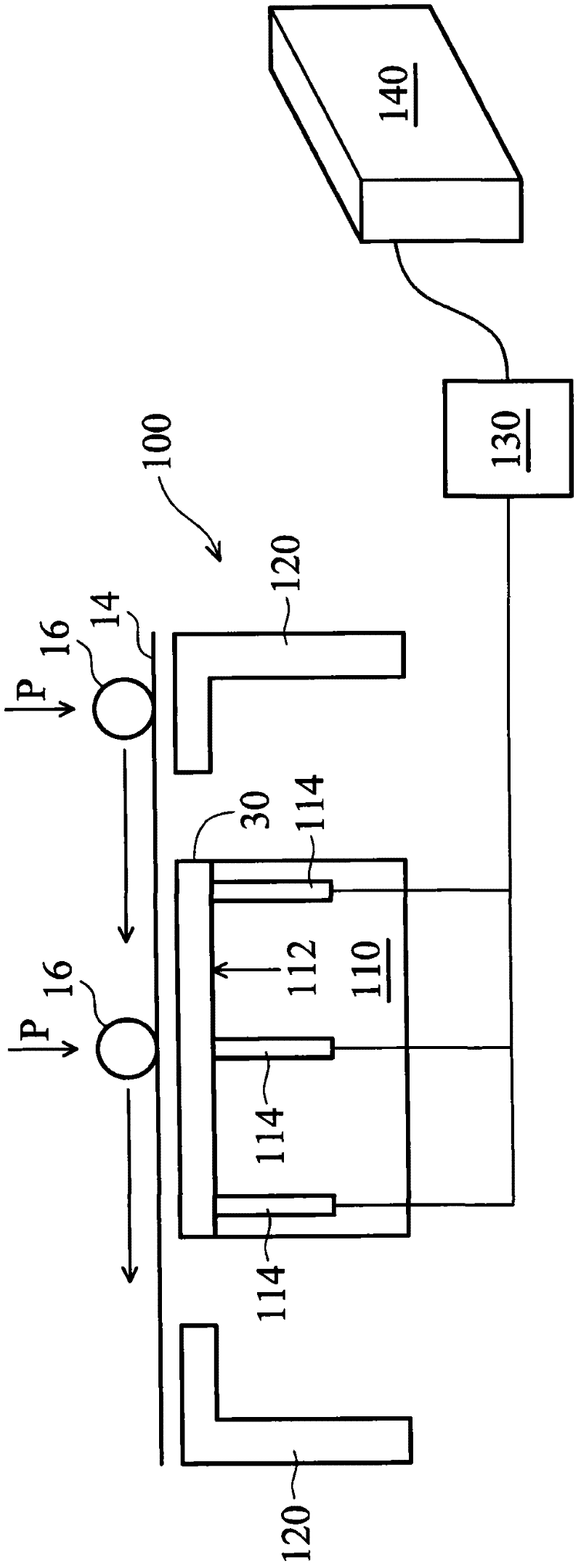

System and method for wafer back-grinding control

ActiveCN102441840AProcess defect reductionConsistent thicknessSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringWafer backgrinding

In a system or method for controlling wafer back-grinding, a chuck table has a surface for supporting a semiconductor wafer during a back-grinding process, one or more holes in the surface, and one or more sensors disposed in the one or more holes for monitoring a parameter during back-grinding. A computer-implemented process control tool is coupled to receive one or mote outputs from the one or more sensors and control the back-grinding process based on the received one or more outputs. The system and method for wafer back-grinding control can effectively reduce process defects and enable the thickness of the semiconductor wafer to be consistent in the process of back-grinding.

Owner:TAIWAN SEMICON MFG CO LTD

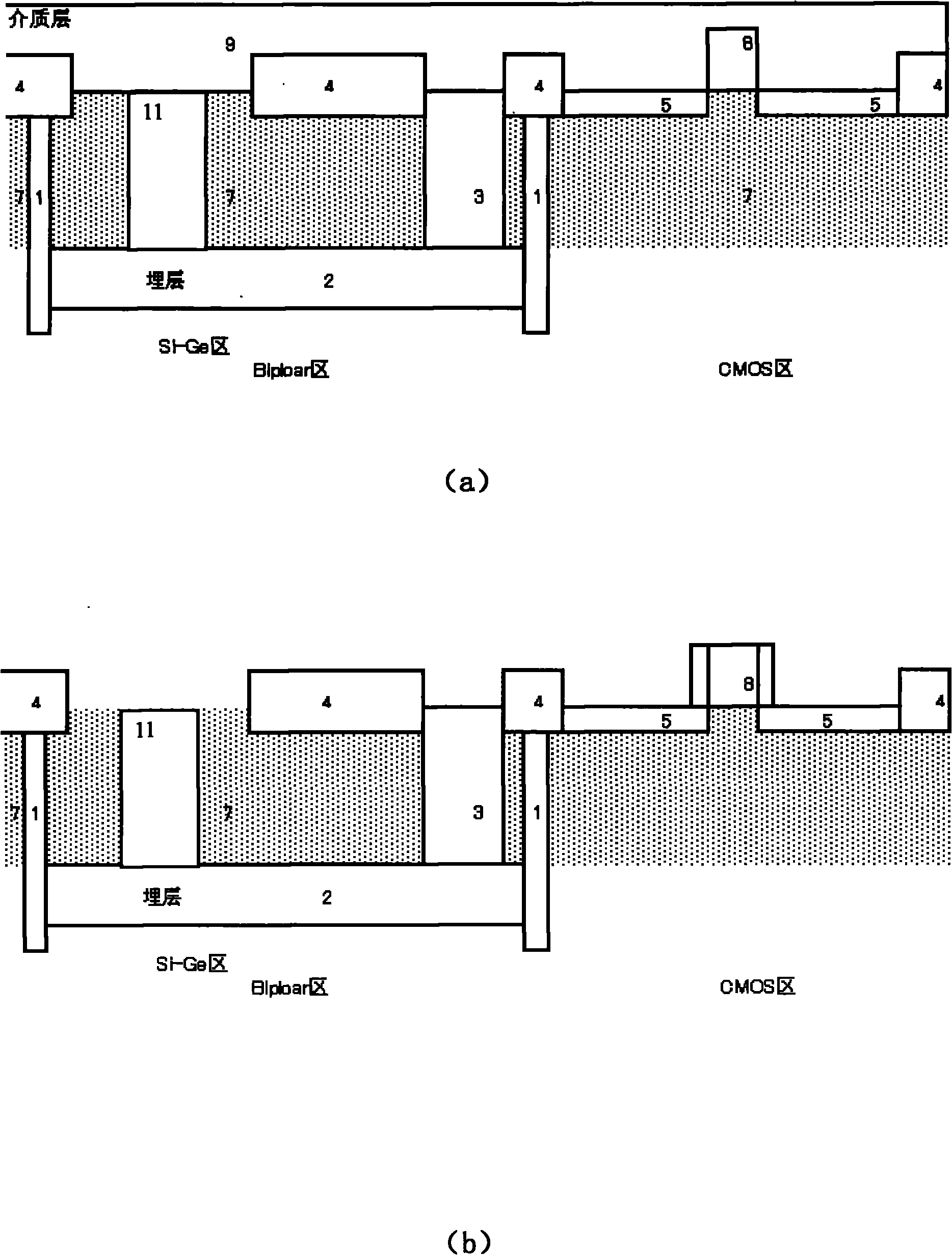

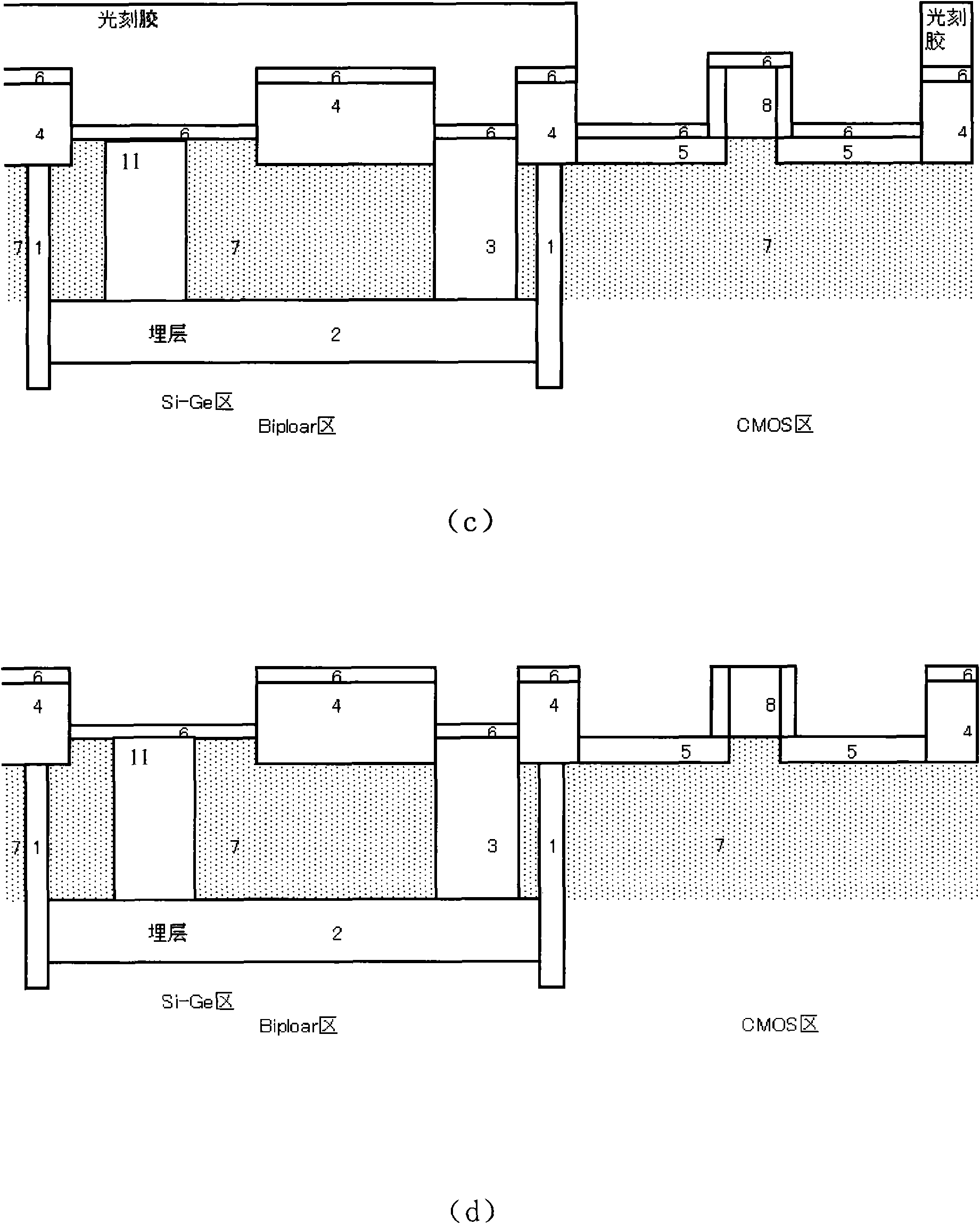

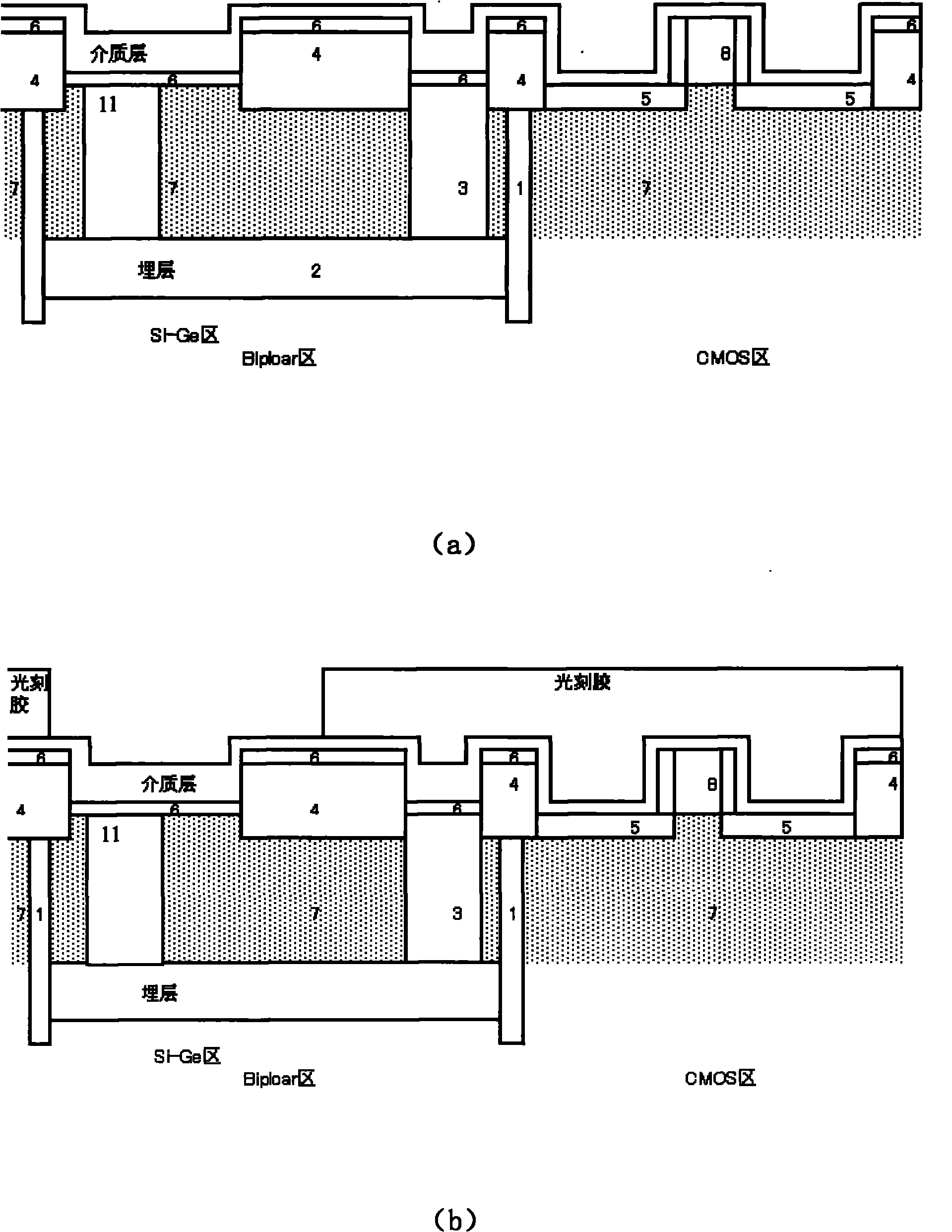

Preparation technique of SiGe Bi-CMOS appliance

ActiveCN101937879AImprove yieldImprove reliabilityPhotomechanical apparatusSemiconductor/solid-state device manufacturingCMOSSalicide

The invention discloses a preparation technique of a SiGe Bi-CMOS appliance. The step of forming a side wall and a metallic silicide barrier layer of the SiGe Bi-CMOS appliance comprises the following steps of: 1, depositing a dielectric film layer; 2, spin-coating a negative photoresist; 3, exposing with a photomask of the metallic silicide barrier layer to form a metallic silicide barrier layer pattern; 4, etching to form the side wall and removing the dielectric film layer on the non-metallic silicide barrier layer at the same time; 5, growing the dielectric film layer protecting the CMOS appliance; 6, photoetching and etching to open a Si / Ge growth zone; and 7, performing the subsequent Si / Ge appliance forming process. In the invention, the side wall and the metallic silicide barrier layer are formed through photolithography at one time by photoetching the metallic silicide barrier layer with the negative photoresist, so that the process flow is simplified and the yield and reliability of the appliance are improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

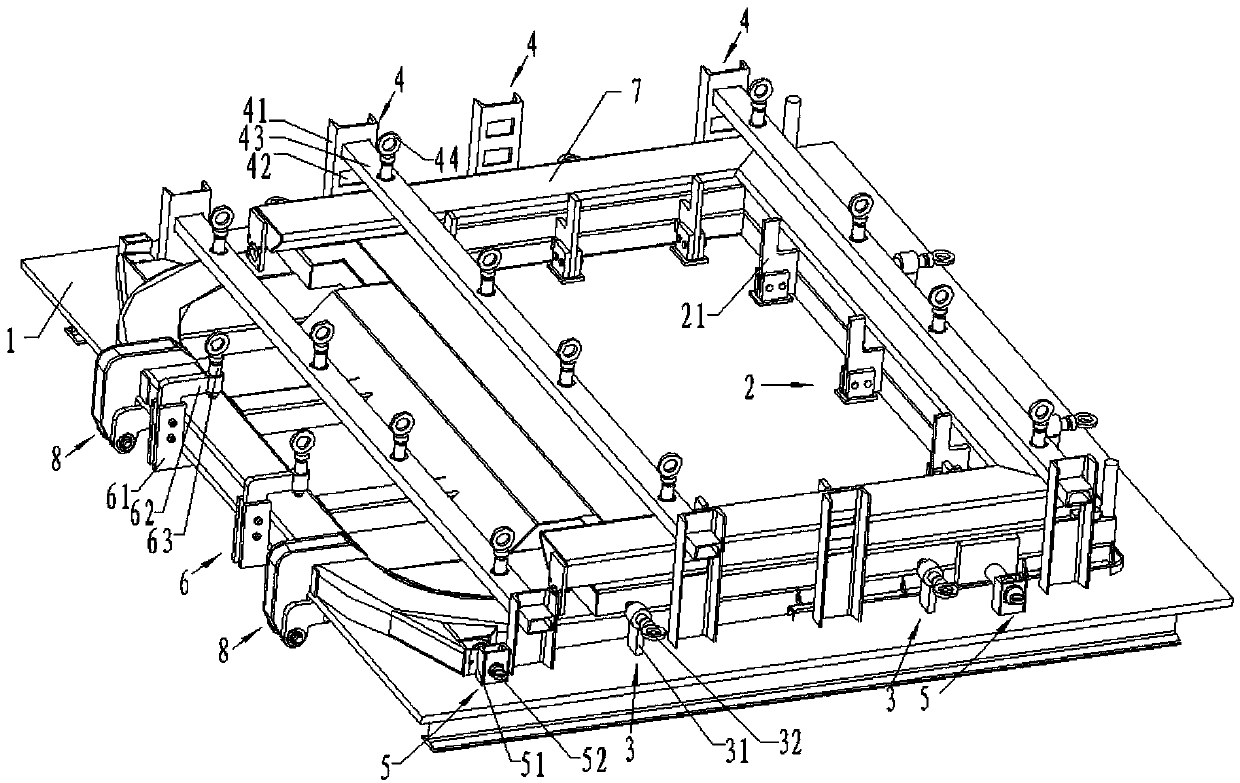

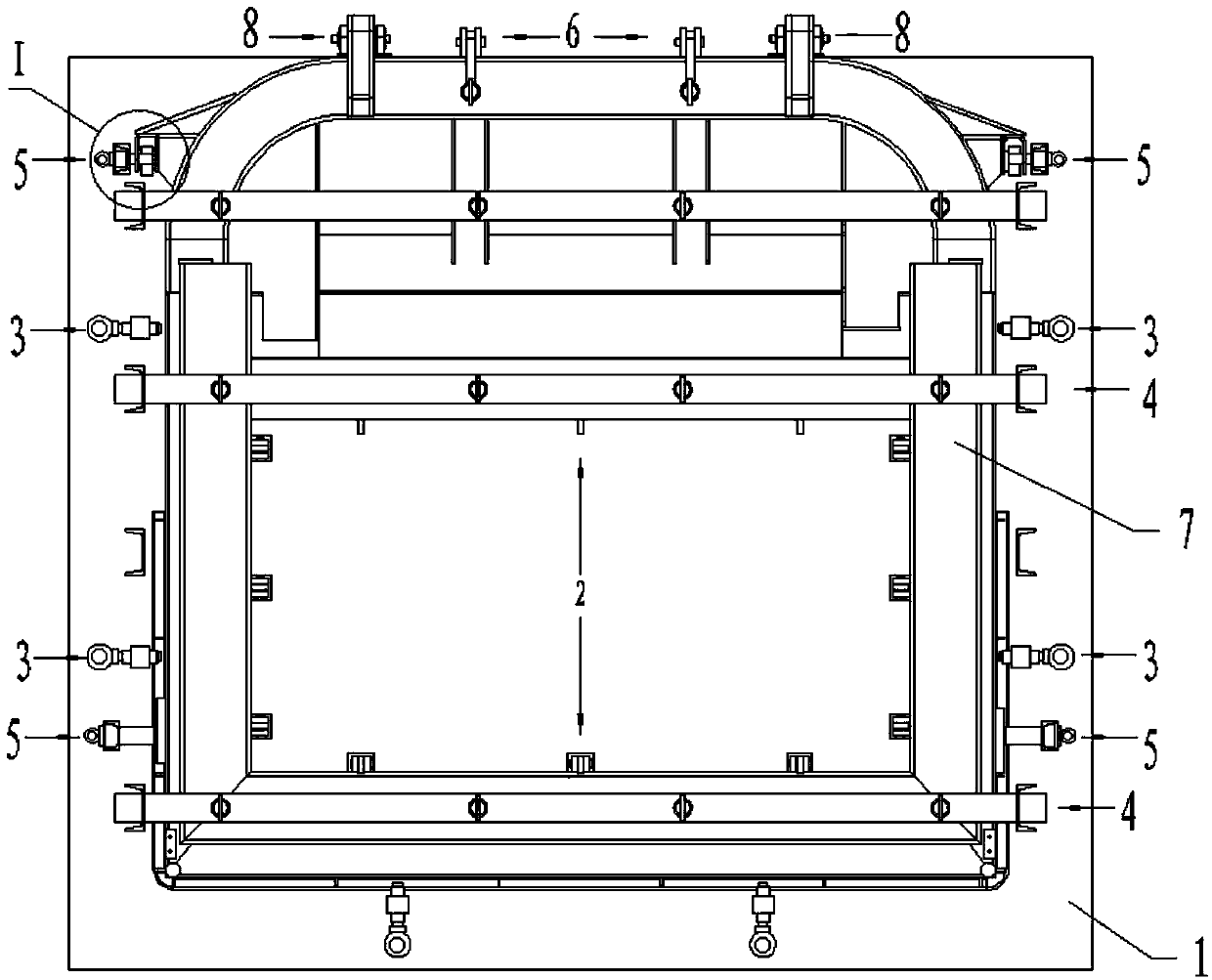

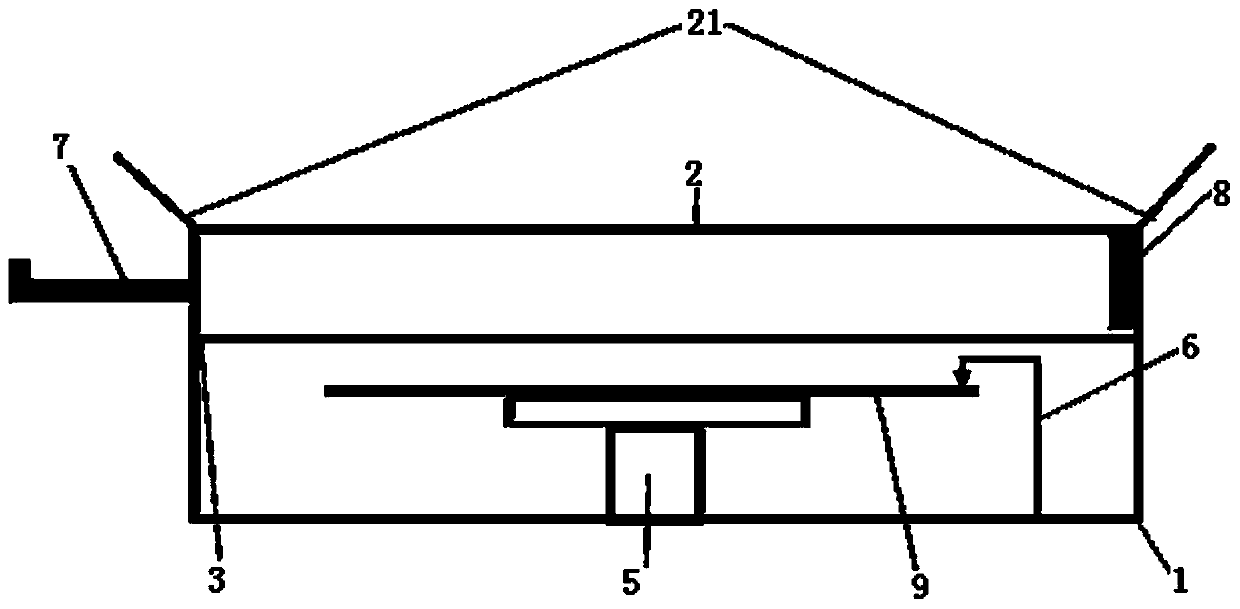

Rear compartment door tailor welding tool

ActiveCN104191132AHigh precisionBest welding positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBack door

The invention discloses a rear compartment door tailor welding tool which comprises a compartment tailor welding base plate, a fixing compression mechanism, clamping mechanisms and a hanging lug mold. The fixing compression mechanism comprises a compartment positioning assembly, a plurality of compartment compression assemblies and a plurality of compartment adjusting assemblies, wherein the compartment positioning assembly is fixed to the upper surface of the compartment tailor welding base plate so as to position a rear compartment door, the compartment compression assemblies are fixed to the two sides of the compartment tailor welding base plate so as to compress the rear compartment door, and the compartment adjusting assemblies are fixed to the surface of the periphery of the compartment tailor welding base plate. The clamping mechanisms are fixed to the front end and the rear end of the upper surface of the compartment tailor welding base plate and matched with clamping portions of the rear compartment door. The hanging lug mold is fixed to the front end of the compartment tailor welding base plate and matched with a hanging lug at the front end of the rear compartment door. According to the rear compartment door tailor welding tool, the problems that deviation is prone to occurrence, adjustment is difficult and stability is poor when manual tailor welding is adopted can be solved, and therefore welding quality can be improved.

Owner:广西玉柴专用汽车有限公司

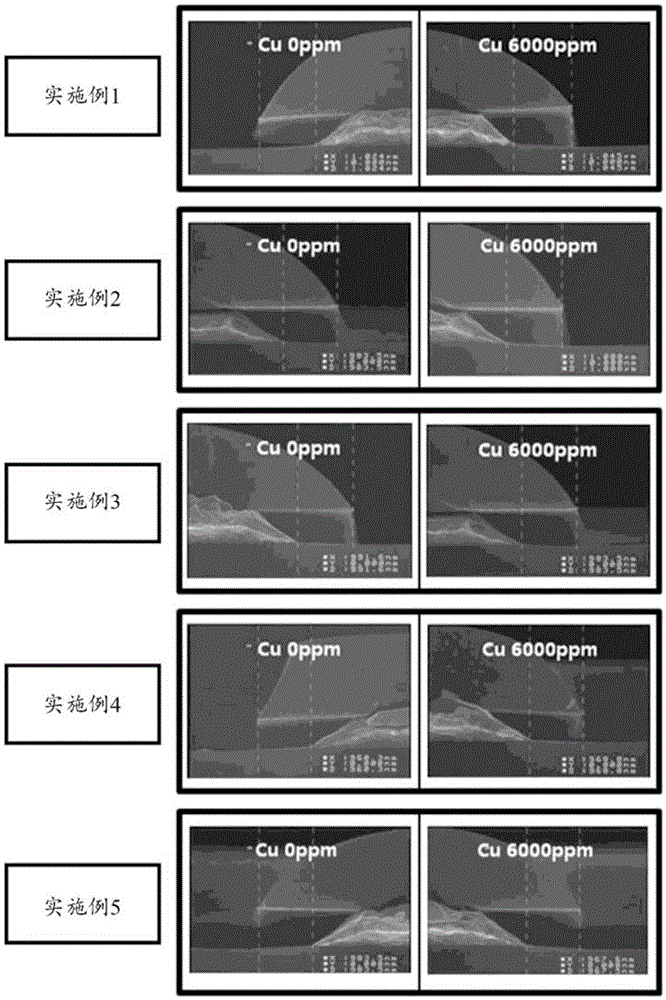

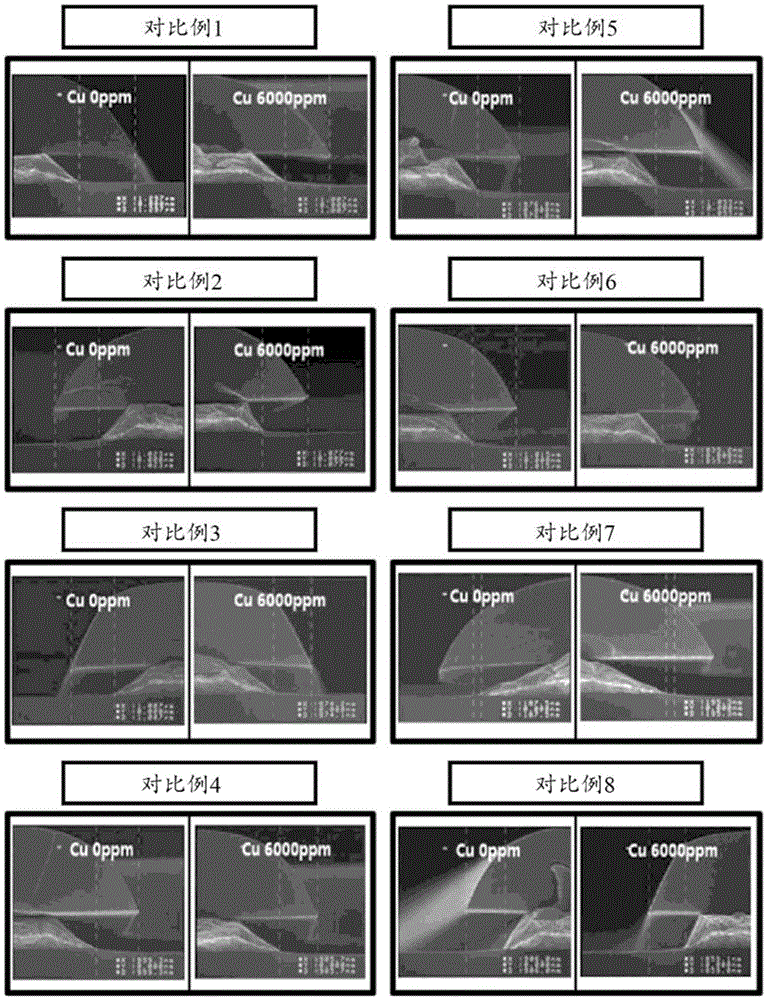

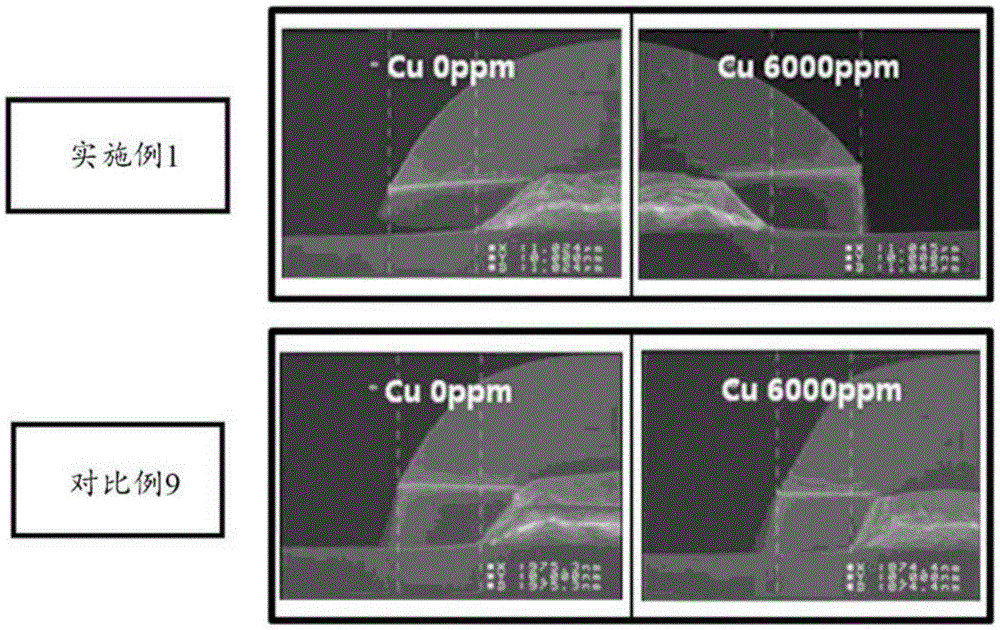

Etchant composition and method of manufacturing metal wiring using the same

ActiveCN105734570AReduced taper angle variationProcess defect reductionSolid-state devicesSemiconductor/solid-state device manufacturingPhosphoric acidChemistry

The invention discloses an etchant composition which includes: 10-20 weight % of persulfate; 0.1-10 weight % of phosphoric acid (H3PO4) or phosphorous acid (H3PO3); 0.1-2 weight % of nitrogen-based ring compounds; 0.1-5 weight % of sulfoacid compounds; 0.1-2 weight % of copper corrosion-inhibitive agents; 0.1-2 weight % of fluorine compound; and residual water which together with the other components constitute a total weight of 100 weight %. The invention also discloses a method of manufacturing metal wiring using the etchant composition.

Owner:SAMSUNG DISPLAY CO LTD +1

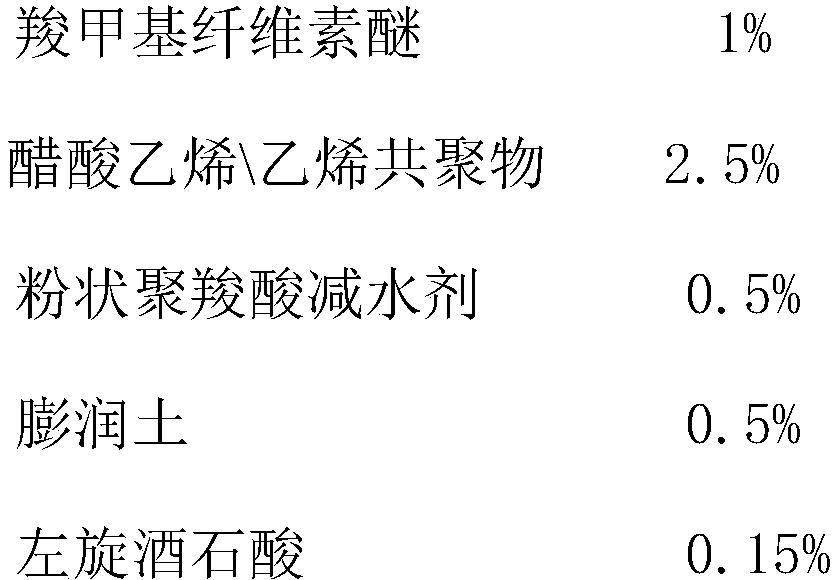

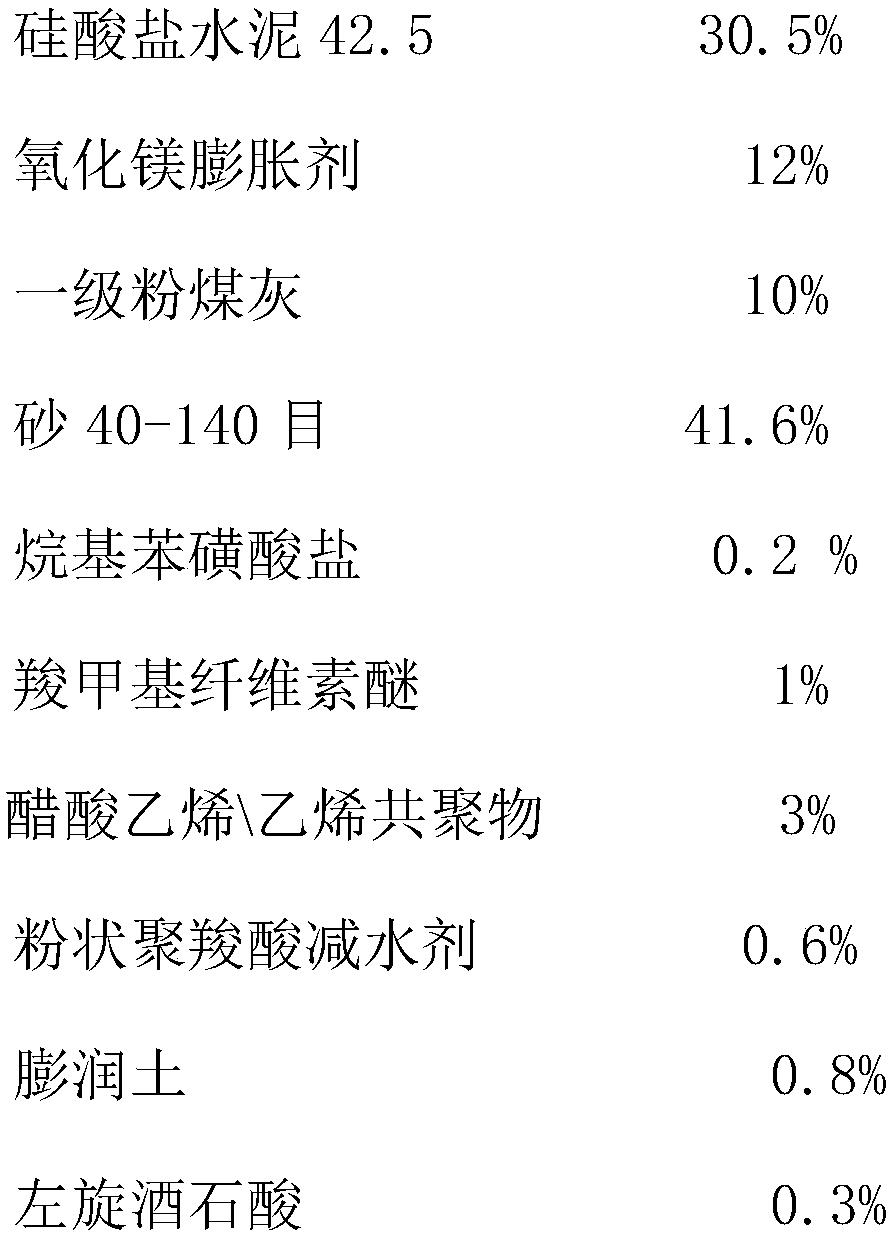

Mortar for packing and pouring

Mortar for packing and pouring is composed of 20%-50% of Portland cement, 2%-30% of a volume stabilizer, 2%-30% of a mixing material, 16%-65% of sand, 1.5%-3% of cellulose ether, 0.01%-2% of an air entraining agent, 0.2%-5% of a thixotropic lubricant, 1%-6.0% of redispersible latex powder, 0.2%-0.25% of a water reducer, and 0.15%-0.25% of a retarder. The mortar has good adhesion power, high strength and high impermeability, and has the 14 d bonding strength of more than or equal to 0.6 MPa, the 28 d flexural strength of more than or equal to 3.5 MPa, the 28 d compressive strength of more thanor equal to 21 MPa, the shrinkage rate of less than -0.04%, and the impermeability of more than or equal to 2.1 MPa. The mortar can solve the technical problems of cracking and leakage from the material, is simple and feasible in operation method, and convenient and simple in use process, has tools matched for use, is more dense in filling, can greatly reduce process defects from the process, reduces leakage risks, and is suitable for industrialized production and market promotion use.

Owner:重庆绿恒环保科技有限公司

Martensitic stainless steel pump case product for manufacturing spray pump of containment for nuclear power plant

ActiveCN104588591ANo sticky sandHigh dimensional accuracyFoundry mouldsFoundry coresFuranFurnace temperature

The invention relates to a martensitic stainless steel pump case product for manufacturing a spray pump of a containment for a nuclear power plant. High purity molten steel with low gas content and uniform components is obtained by intermediate frequency furnace and VOD duplexing smelting; process parameters are obtained by system design of industrial analysis, chromite sands are used in a pump case runner, and the outer layer of the chromite sands is cast by furan resin sands to ensure that the runner is smooth and level; the accuracy of a core assembly and a lower core is ensured by using a snap-gauge, so that the dimensional tolerance of the runner satisfies the requirement; thermal treatment process parameters are adjusted through a process test, in-furnace temperature, temperature raising rate, insulating temperature, quenching temperature and quenching transfer time are controlled, and the problems of low impact performance and high hardness are solved through tempering twice. The problem that previous cast product is more in porosity defect, severe in surface sand burning, poor in dimensional precision of the runner and relatively poor in mechanical property is solved, and the corrosion-resistant martensitic stainless steel pump case cast which is high in dimensional precision, few in technical defect, compact in internal tissue and free of sand burning in the cavity of the runner is obtained.

Owner:遵义拓特铸锻有限公司

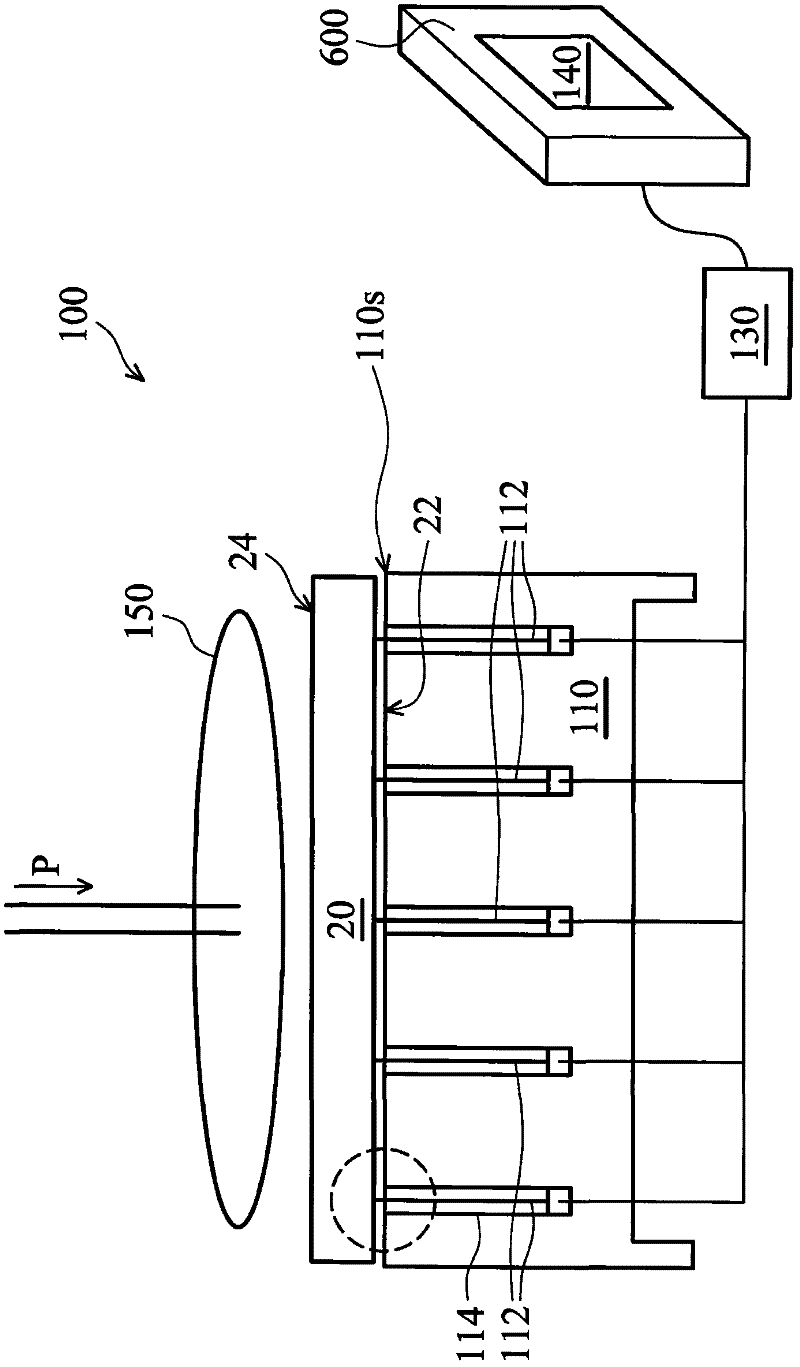

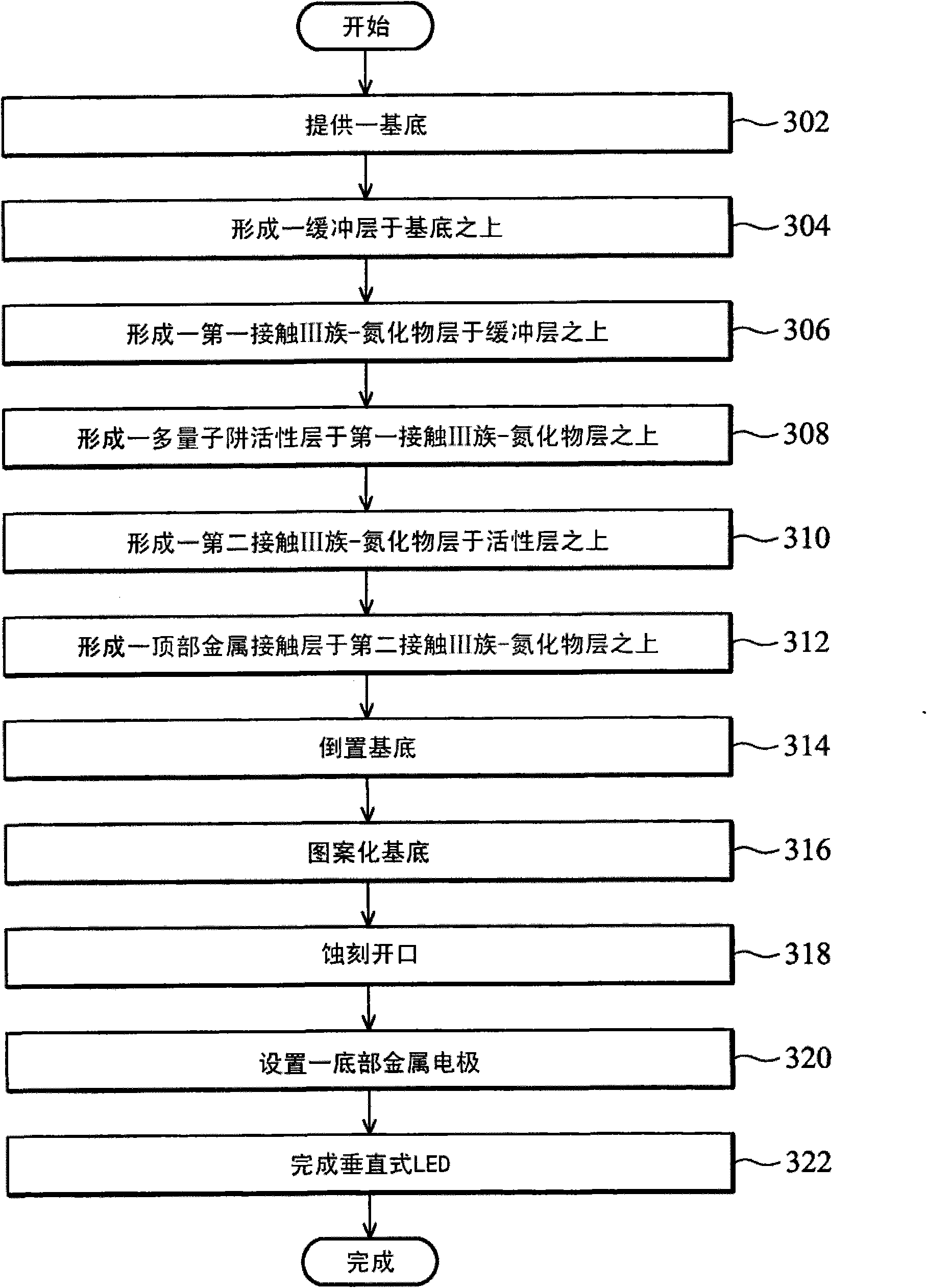

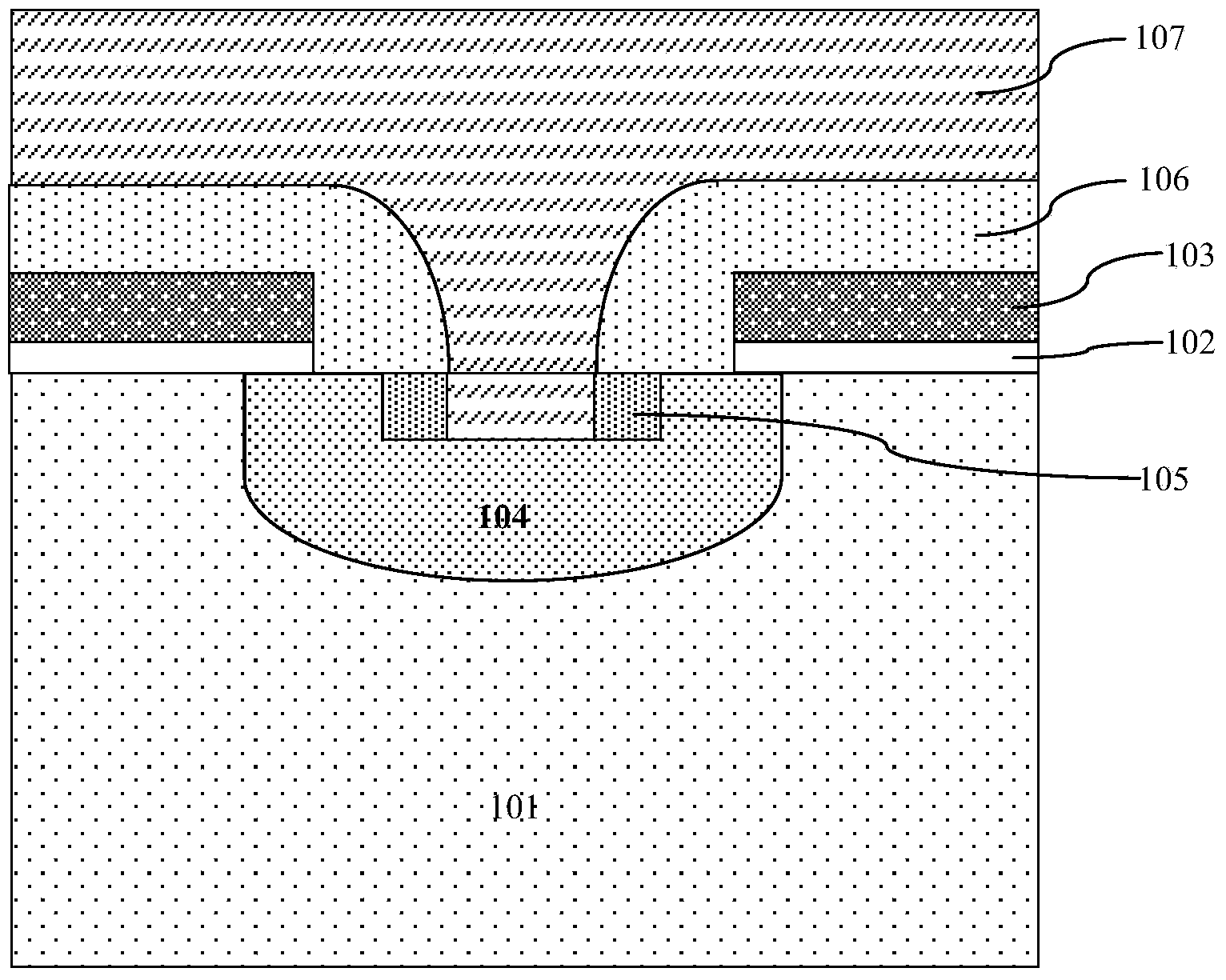

Vertical iii-nitride light emitting diodes on patterned substrates with embedded bottom electrodes

InactiveCN101635328AReduce processProcess defect reductionSemiconductor devicesNucleationActive layer

A light emitting diode (LED) device is presented. The LED device includes a substrate, a layered LED structure, and an embedded bottom electrode. The layered LED structure includes a buffer / nucleation layer disposed on the substrate, an active layer, and a top-side contact. A first-contact III-nitride layer is interposed between the buffer / nucleation layer and the active layer. A second-contact III-nitride layer is interposed between the active well layer and the top-side contact. A bottom electrode extends through the substrate, through the buffer / nucleation layer and terminates within the first-contact III-nitride layer.

Owner:TAIWAN SEMICON MFG CO LTD

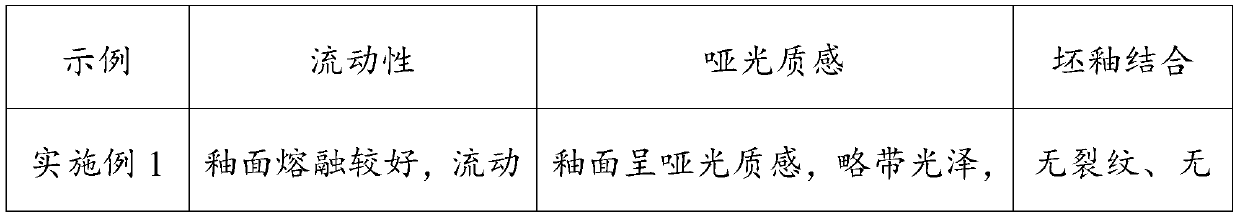

Composition for preparing matte white glaze, and firing method of matte white glaze

The invention belongs to the technical field of ceramic glaze preparation, and particularly relates to a composition for preparing matte white glaze, and a firing method of the matte white glaze. According to the matte white glaze provided by the invention, slag powder, calcined kaolin and talc are matched for use, so that the problem that bubbles are generated on the glaze due to the fact that alarge amount of gas is released in the slag powder firing process can be avoided, the texture of the glaze is improved, the roughness of the glaze is improved, the thermal expansion coefficient of theglaze is adjusted, and the problem that the glaze cracks due to the fact that a large amount of slag powder is added into the glaze is reduced; the slag powder has high fluidity under a high-temperature firing condition, and the calcined kaolin and the talc are matched for use, so that bubbles generated on the glaze surface can be inhibited while the problem of high fluidity of the slag powder ata high temperature is controlled, the glaze surface is smooth, and the glaze surface texture is improved; and a large amount of slag powder can be utilized to realize recycling of the slag powder, and environmental pollution and resource waste can be effectively reduced.

Owner:JINGDEZHEN CERAMIC INSTITUTE

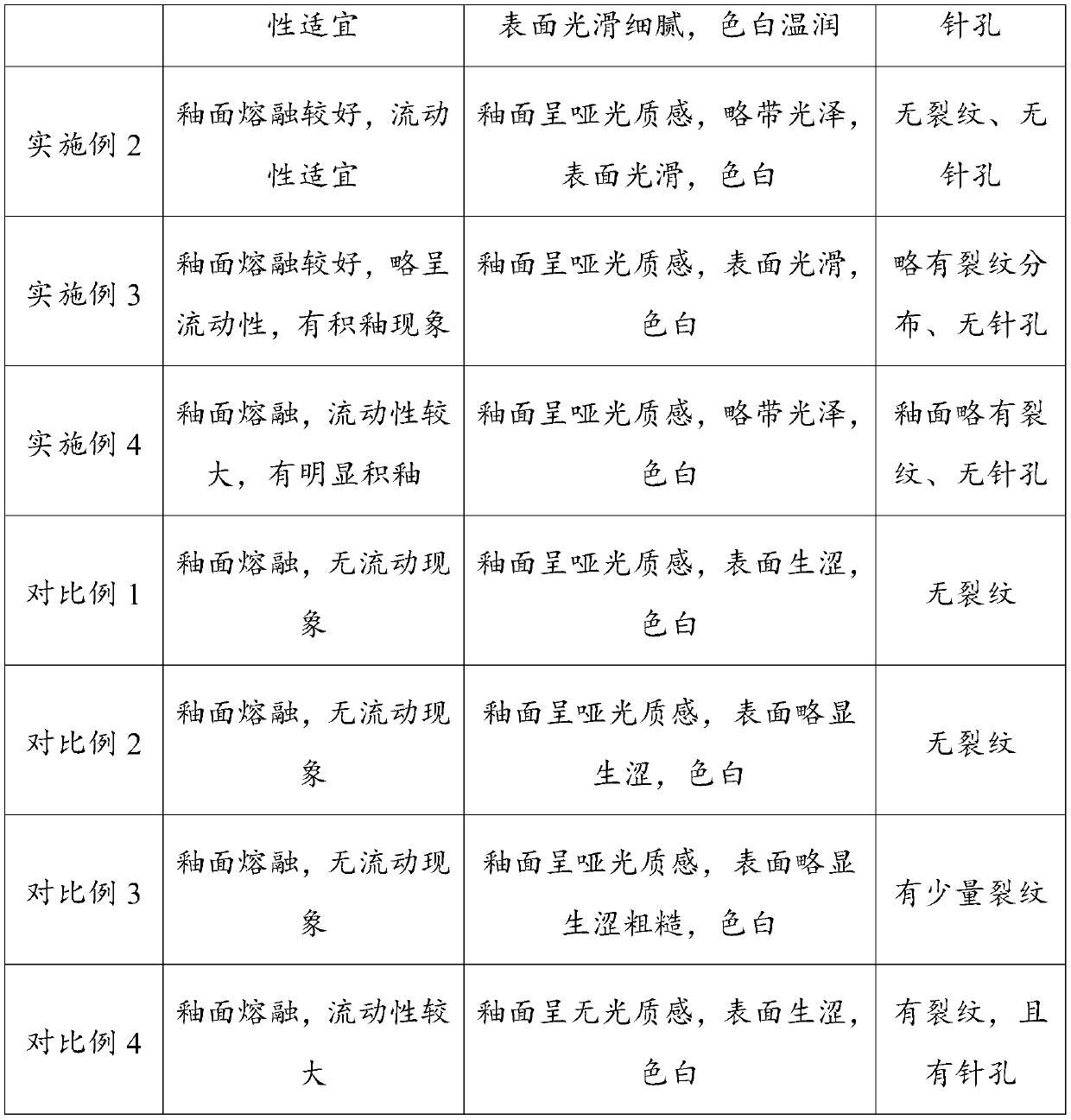

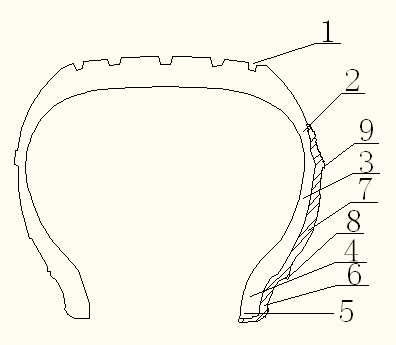

Knockover-proof safety tyre

InactiveCN102632773ATo prevent the situation of decouplingImprove rigidityTyre sidewallsEngineeringMechanical engineering

The invention relates to a tyre with a novel structure which is applicable to an electric vehicle and a lightweight motorcycle and particularly relates to a knockover-proof safety tyre. The knockover-proof safety tyre comprises a tyre crown, a tyre shoulder, a tyre side, seam allowance and tyre tiptoe, and is characterized in that gummed industrial cloth is reinforced between the tyre tiptoe and the tyre side, a sizing material is reinforced on the tyre side and the tyre shoulder, a circumferential arc bump is arranged at the joint of the seam allowance and the tyre side, and a circumferential bump is arranged at the joint of the tyre shoulder and the tyre side. The knockover-proof safety tyre has the beneficial effects of being capable of effectively preventing the occurrence of knockover of the tyre, the rigidity of the tyre is enhanced so that people feel more comfortable in riding, the process defects of hungry joint on the tyre side and the tyre shoulder is greatly reduced in the manufacturing process of the tyre, and the knockover-proof safety tyre meets the requirements for prolonging the service life of the tyre and improving the production qualification rate.

Owner:SHANDONG RUIXIANG TIRE MFG

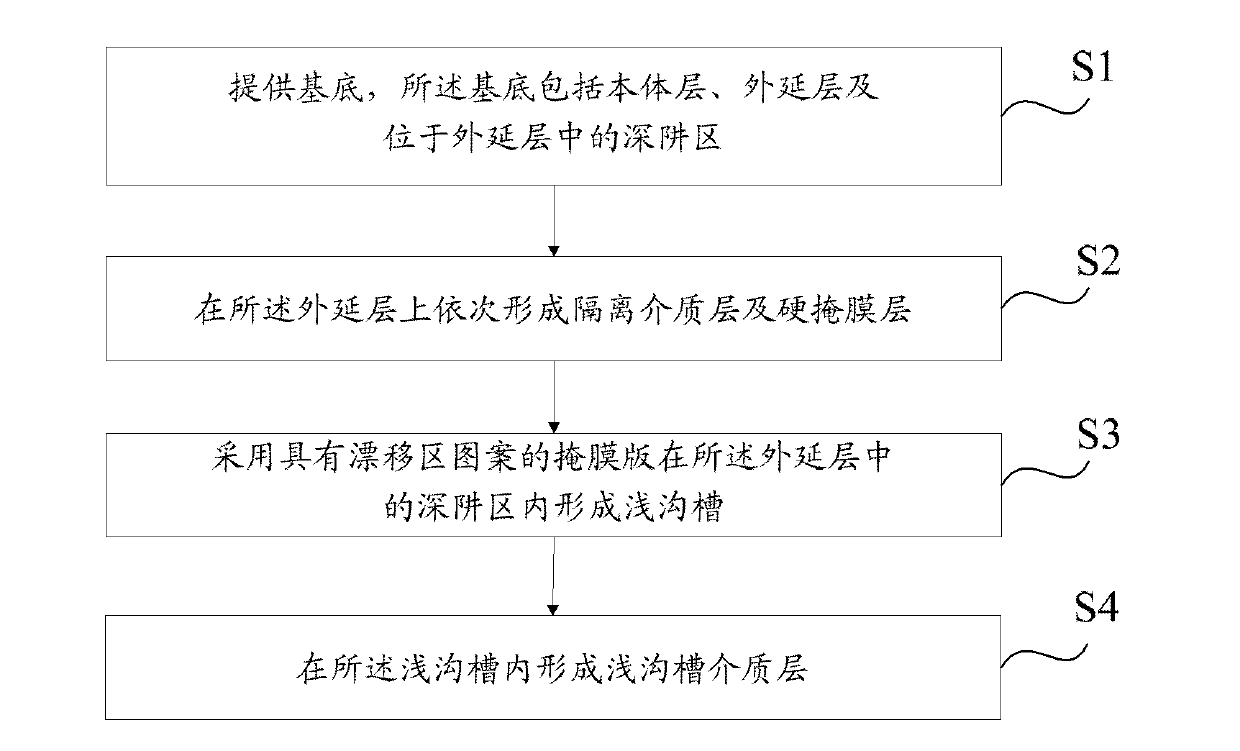

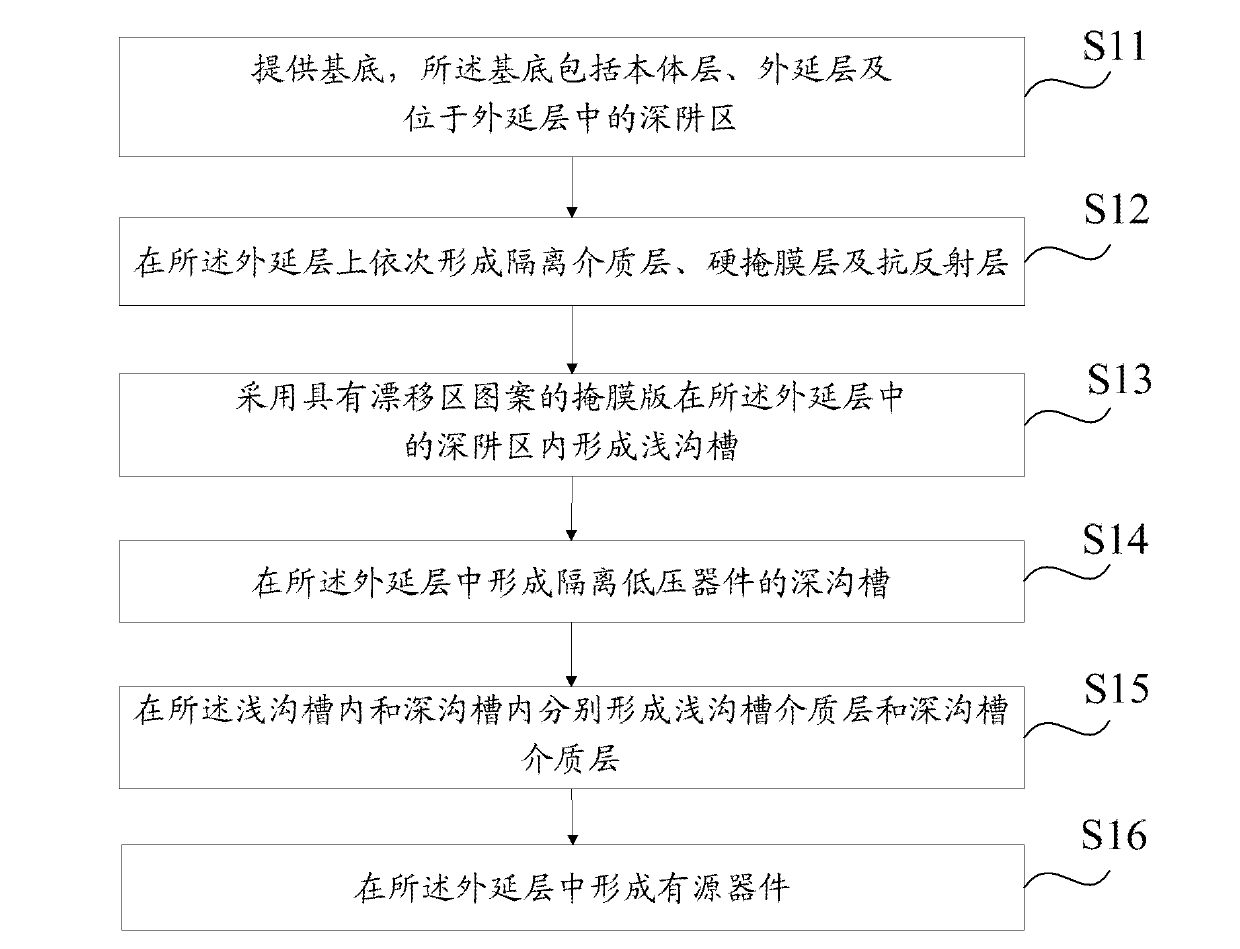

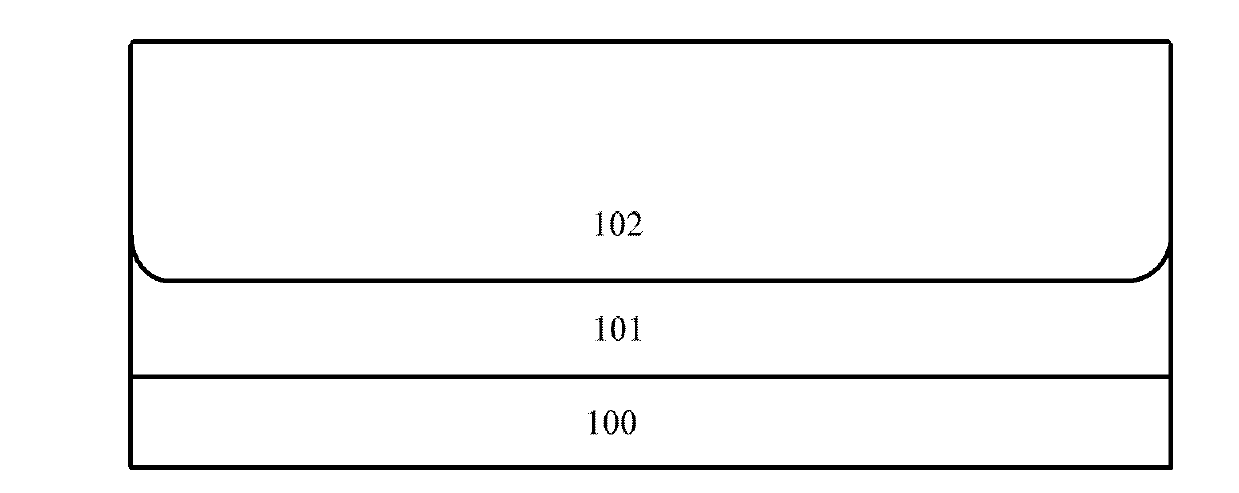

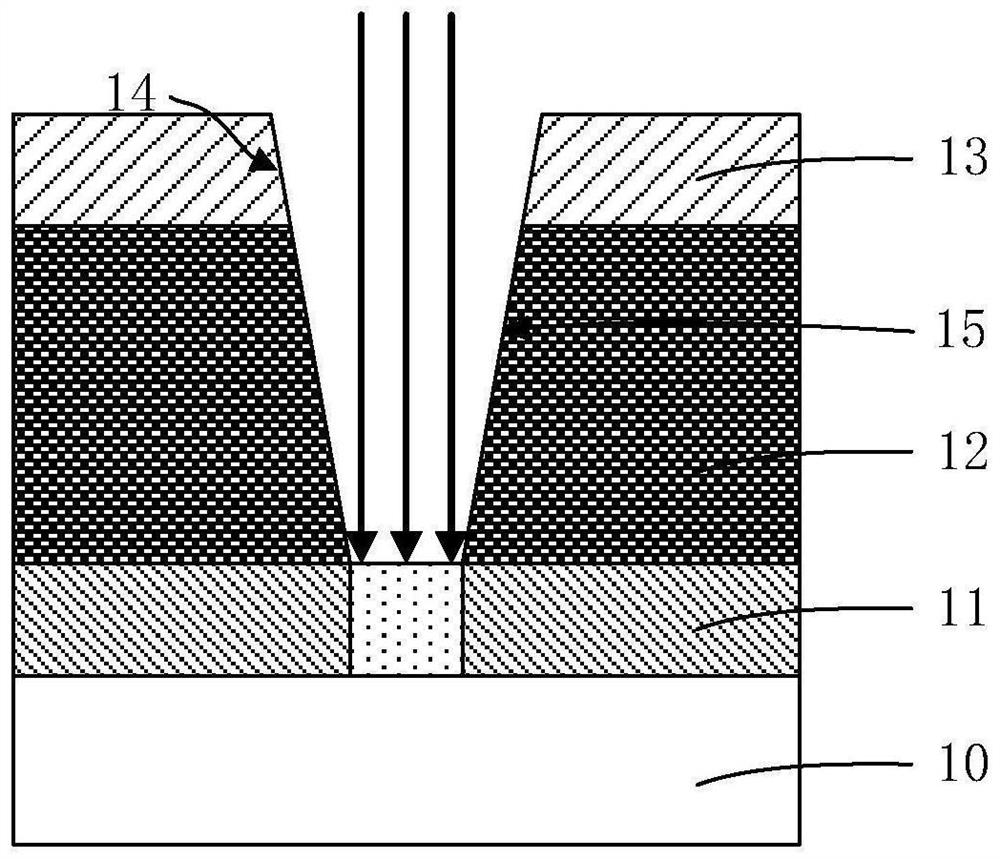

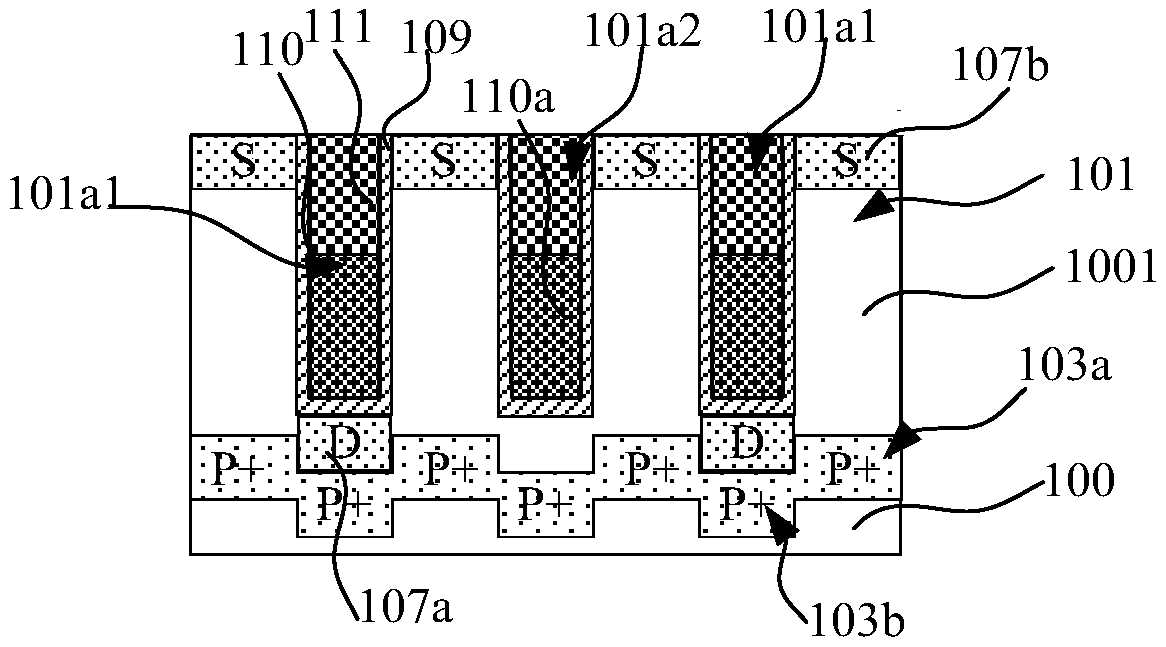

LDMOS (laterally diffused metal oxide semiconductor) device and manufacture method thereof

ActiveCN102569075AProcess defect reductionAchieve global flatteningSemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorCompound (substance)

The embodiment of the invention discloses an LDMOS device and a manufacture method of the device. The method comprises providing a substrate including a body layer, an epitaxial layer and a deep well region located in the epitaxial layer; sequentially forming an isolation medium layer and a hard mask layer on the epitaxial layer; forming a shallow trench in the deep well region in the epitaxial layer by using a mask with a drift region pattern; and forming a shallow trench medium layer in the shallow trench. The LDMOS device manufacture method provided by the invention can manufacture devices with a key dimension of 0.18 mum or below, and can realize global planarization of the substrate surface when carrying out subsequent CMP (chemical mechanical polishing) process, thereby reducing the occurrence of process defects.

Owner:CSMC TECH FAB2 CO LTD

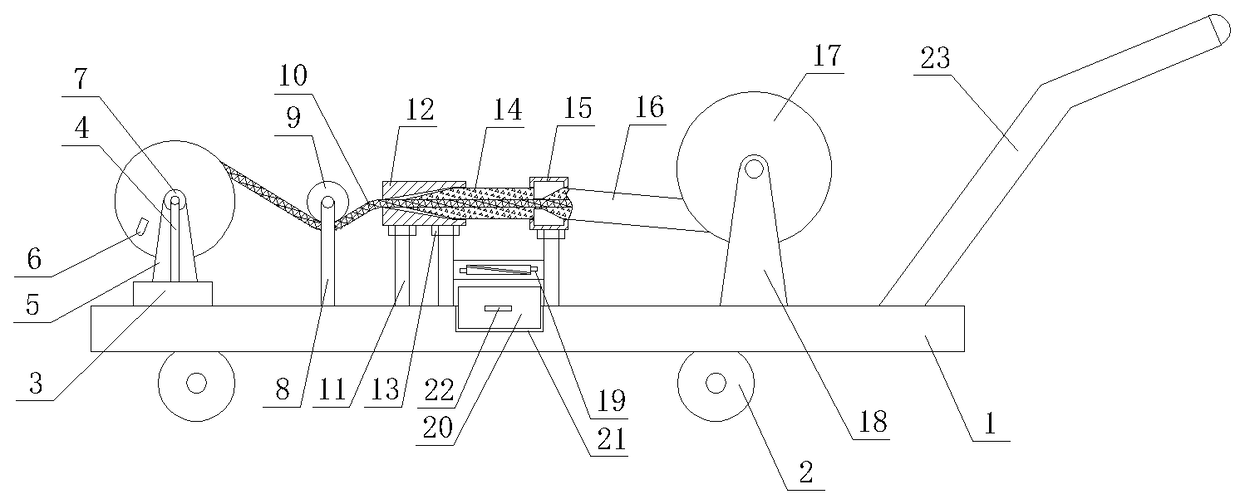

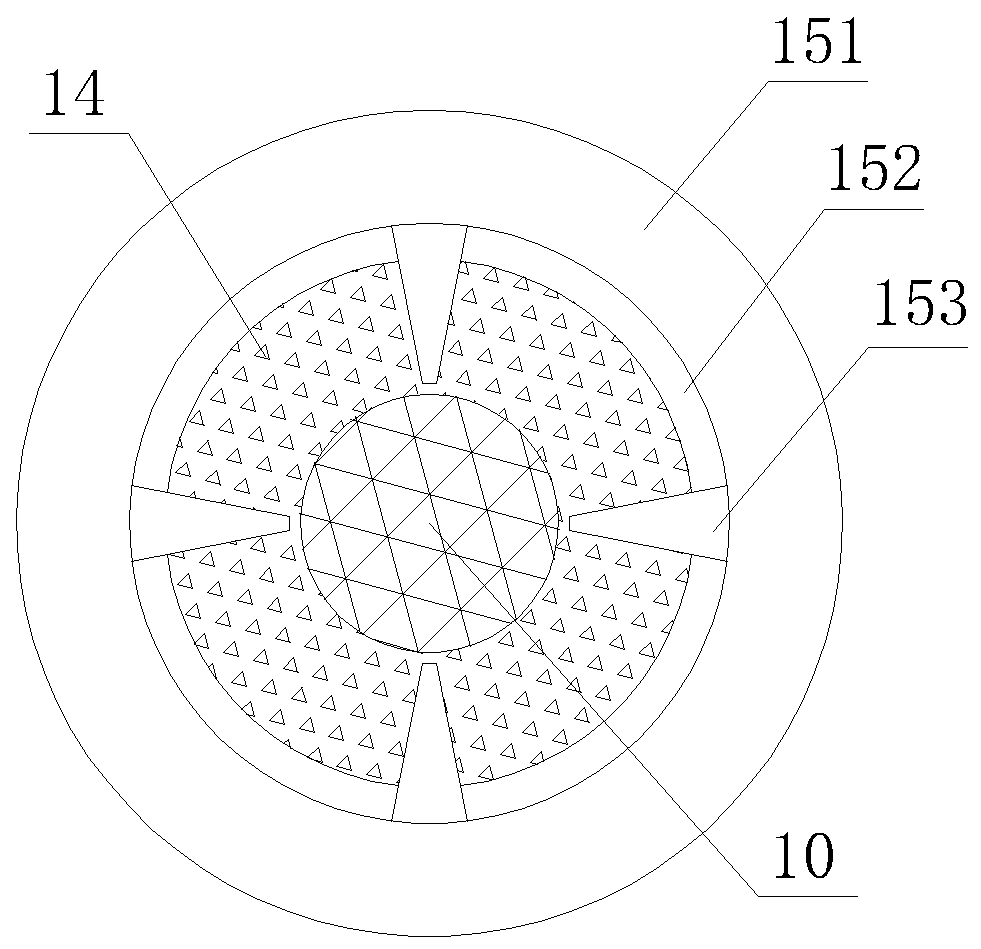

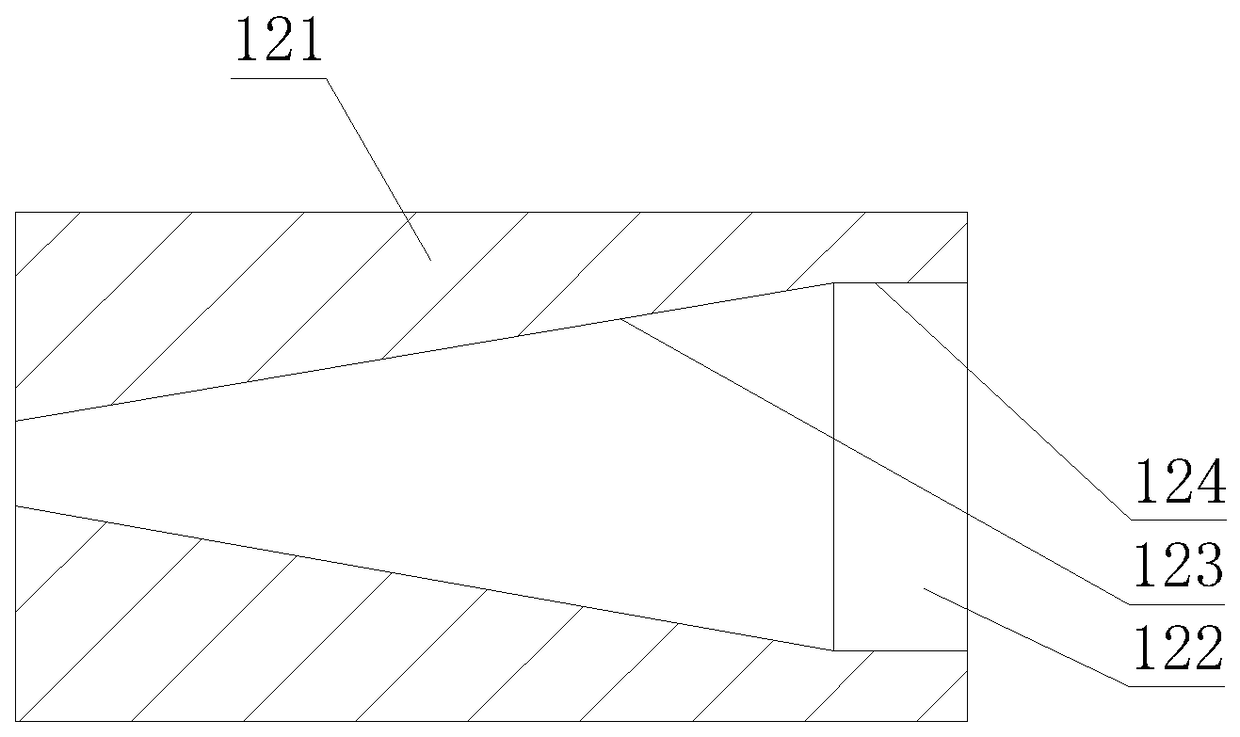

Rapid stripping device of insulating layer of cable head

InactiveCN108539669ASimple structureEasy to operateApparatus for removing/armouring cablesEngineeringFully automatic

The invention discloses a rapid stripping device of an insulating layer of a cable head. The device comprises a rack, a first support, a second support, a third support, a fourth support, a fifth support, a spool rotationally mounted on the first support, a tensioning wheel rotationally mounted on the second support, a stripping assembly fixedly mounted on the third support, a cutter assembly fixedly mounted on the fourth support and a cable reel rotationally mounted on the fifth support, wherein the first support, the second support, the third support, the fourth support and the fifth supportare fixedly arranged on the rack sequentially. The device has the characteristics of being simple in structure and convenient and reliable to operate; flexible movement can be facilitated by means ofuniversal wheels, labor is saved, the insulating layer and a cable core are automatically collected after being separated, and the device is fully automatic in the whole process and high in strippingefficiency.

Owner:STATE GRID CORP OF CHINA +1

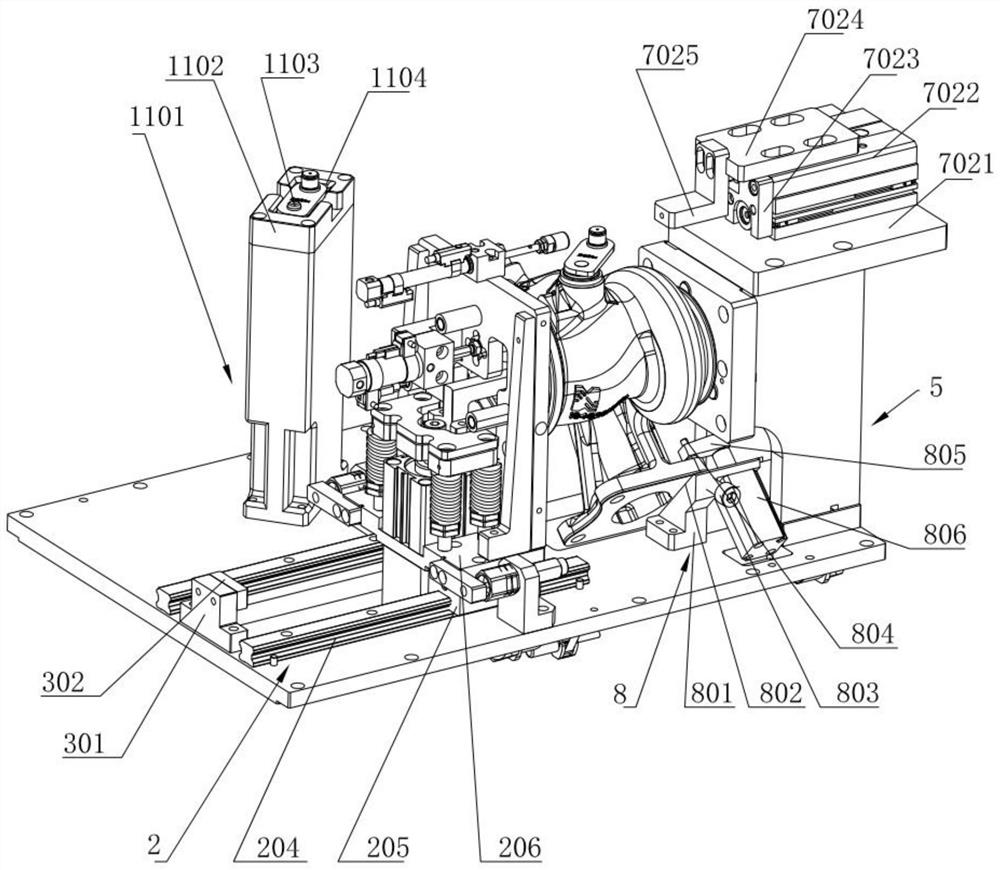

Compressor welding tool

ActiveCN103406696AHigh precisionSolve difficultyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a compressor welding tool which comprises a locking and supporting box positioning die component, extruding plate rotating shaft seat positioning dies and extruding oil cylinder seat positioning dies. The locking and supporting box positioning die component is fixed on one side of a base platform, the extruding plate rotating shaft seat positioning dies are oppositely fixed on the other side of the base platform, and the extruding oil cylinder seat positioning dies opposite in direction are fixed on the base platform between the locking and supporting box positioning die component and the extruding plate rotating shaft seat positioning dies. The compressor welding tool has the advantages that to-be-welded components are enabled to be accurately positioned and reliably clamped, assembling and welding of a to-be-welded piece are facilitated, structural accuracy of the to-be-welded piece is improved, and the like.

Owner:广西玉柴专用汽车有限公司

Semiconductor structure and manufacturing method thereof

PendingCN114420629AThe process steps are simpleShorten production timeSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallographySemiconductor structure

The invention provides a semiconductor structure and a manufacturing method thereof, and the method comprises the steps: providing a substrate, and sequentially forming a pattern definition layer, a pattern transfer layer and a pattern mask layer on the substrate; etching the pattern mask layer to form a first groove exposing the pattern transfer layer; the pattern transfer layer at the bottom of the first groove is etched, a second groove exposing the pattern definition layer is formed, and the side wall of the second groove is perpendicular to the upper surface of the pattern definition layer; and carrying out ion doping on the exposed pattern definition layer through the first groove and the second groove, wherein the pattern definition layer doped with ions is used as a metal blocking layer. Compared with the prior art, the metal blocking layer with the same size can be finally formed by forming the first groove with the small opening size, so that the adjacent metal blocking layers can be formed in the same process step, the process steps are simplified, the manufacturing time is saved, the occurrence rate of process defects is reduced, and the cost is reduced.

Owner:SHANGHAI INTEGRATED CIRCUIT EQUIP & MATERIALS IND INNOVATION CENT CO +1

Method for manufacturing MOS grid device

InactiveCN103855034AGuaranteed uniformityEnsure consistencySemiconductor/solid-state device manufacturingSemiconductor devicesEtchingMedia layer

The invention discloses a method for manufacturing an MOS grid device. The method includes the following steps that a grid medium layer, a grid layer, a grid heightening layer and an etching retaining layer are sequentially formed on the surface of a semiconductor substrate; the photoetching technology is used for forming a grid graph structure; a body zone is formed; a source zone is formed by photoetching through the filling technology; a side wall layer is deposited; comprehensive etching is carried out on the side wall layer and a relative-width side wall is formed; the etching technology is adopted and autoregistration etching is carried out on the relative-width side wall to form a grid hole forming zone and a source zone hole forming zone; a front face metal layer is deposited; a front face electrode leading-out terminal is formed through photoetching in an etching mode. Compared with a traditional photomask registration technology, the requirement for photoetching precision is lowered. Meanwhile, the evenness and uniformity of the relative-width side wall are ensured, and therefore defects caused by the mask technology and the limitation on the current density are reduced, device density can be improved, and therefore the integration degree is improved. In addition, the additional etching barrier layer can also lower the precision requirement for the etching technology and the difficulty of the etching technology is lowered.

Owner:宁波达新半导体有限公司 +1

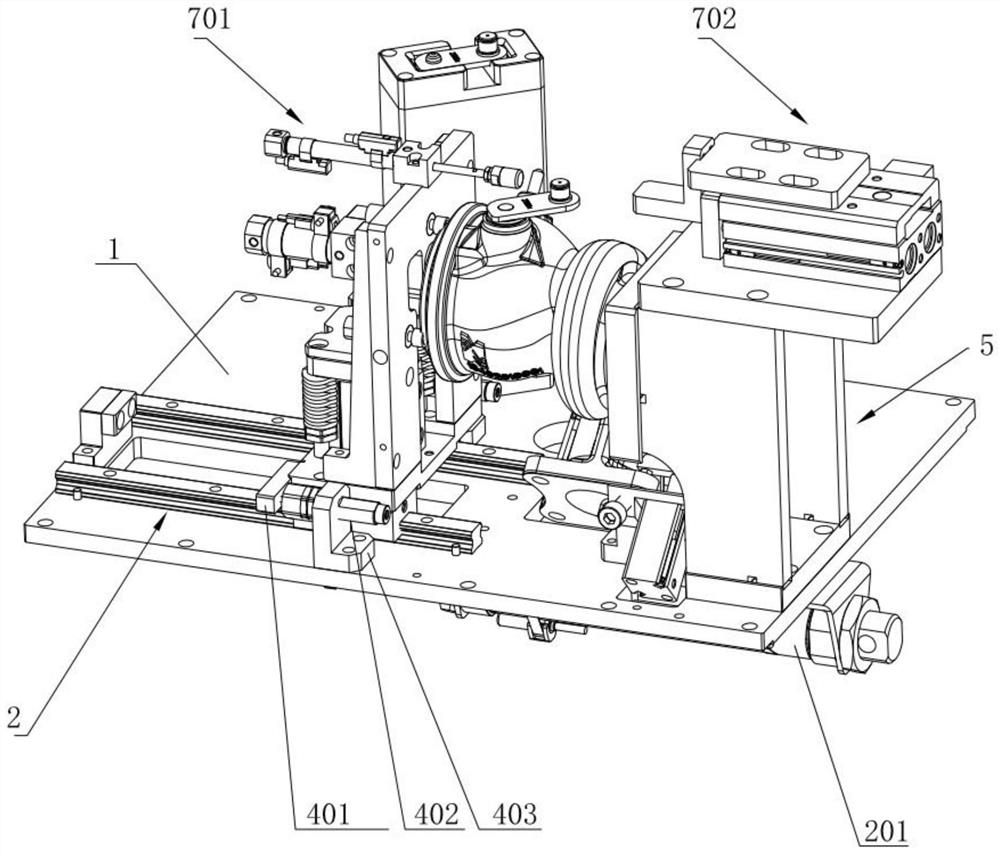

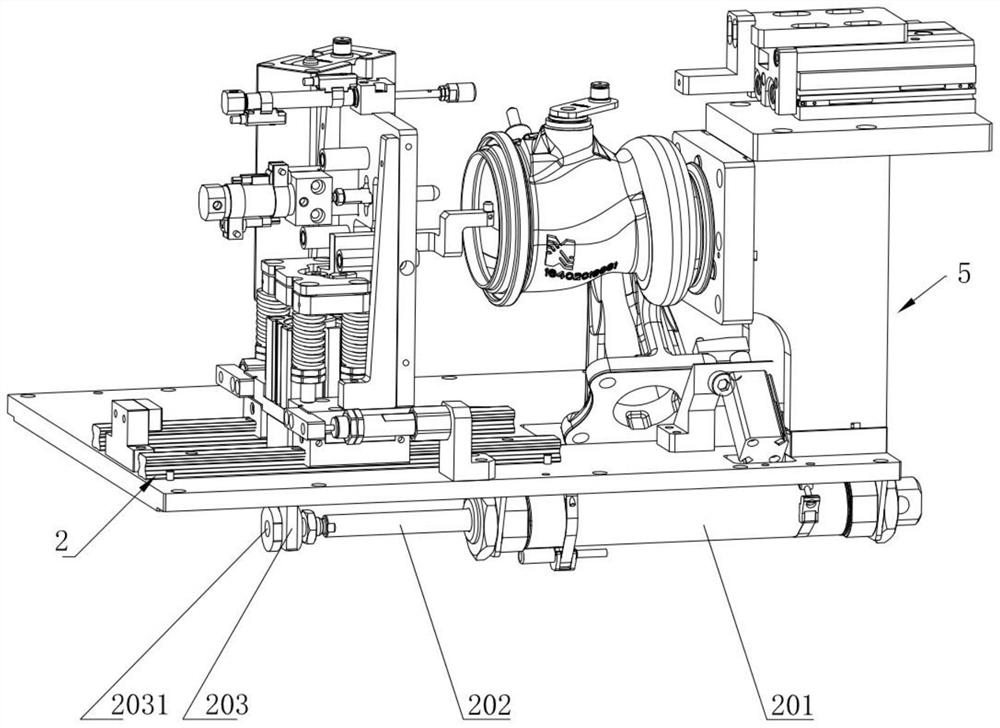

Volute welding tool

PendingCN112276436ANot easy to damageStrong interactionWelding/cutting auxillary devicesAuxillary welding devicesBypass valvePhysics

The invention relates to a volute welding tool. The volute welding tool comprises a bottom plate, and a transferring device used for doing linear displacement, a positioning device used for installingand positioning a volute, a clamping and limiting device used for fixing the volute and a bypass valve in the volute and an angle clamping and adjusting device used for adjusting the inclination angle of the volute are arranged on the bottom plate. By means of the volute welding tool, the volute can be accurately and reliably positioned and clamped, the part precision and replaceability are improved, welding and positioning to the volute can be achieved after the volute welding tool is used, the situation that the volute welding quality is not high is avoided, the volute is located at the optimal welding position after being installed, process defects are effectively reduced, and the welding speed is increased. By means of the volute welding tool, positioning, clamping and overturning actions during manual part assembling are replaced, the labor intensity of workers is reduced, the automation degree is high, and the production efficiency is greatly improved.

Owner:江苏高铭科飞自动化设备有限公司

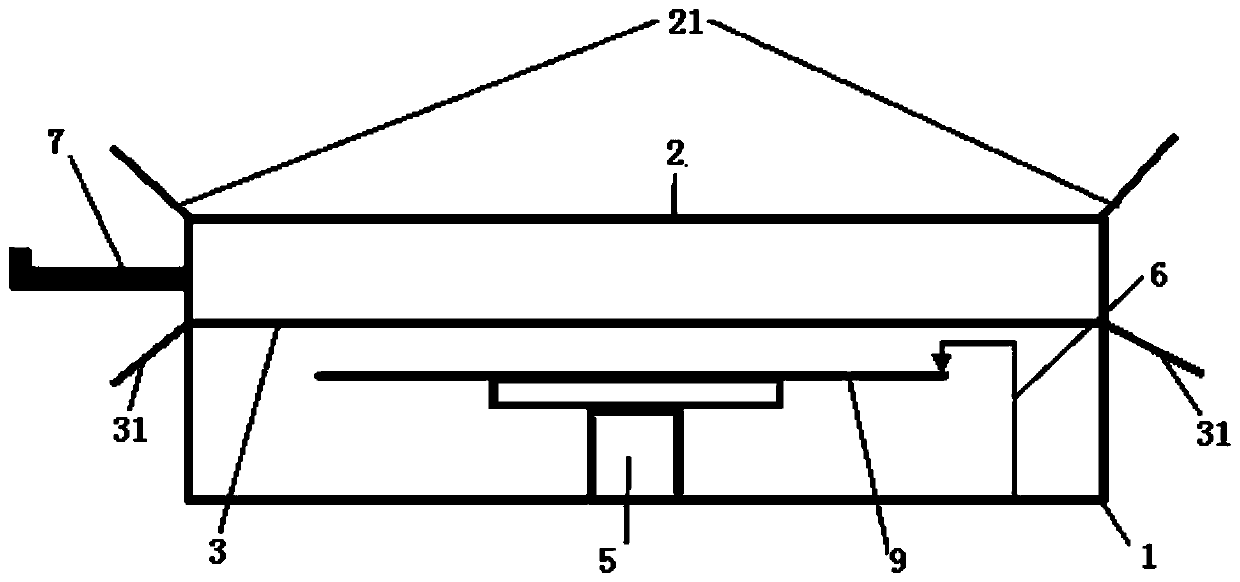

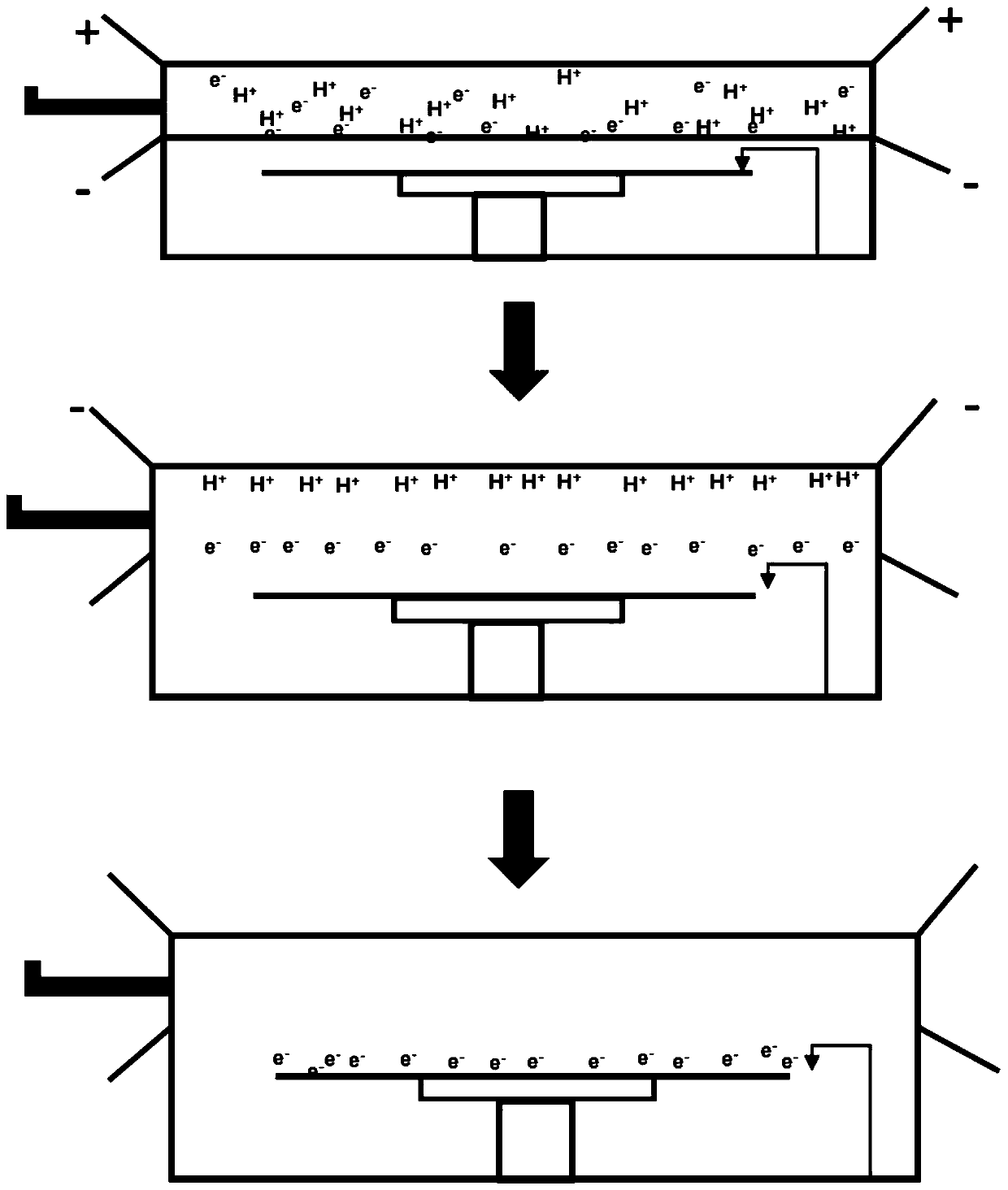

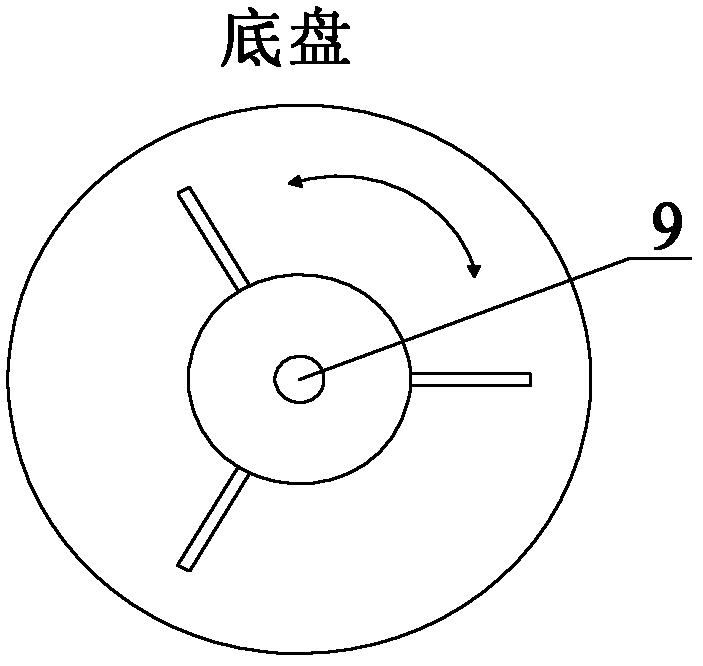

Wafer surface charge eliminating device and method

ActiveCN110505742AEliminate distractionsProcess defect reductionFinal product manufactureElectrostatic chargesDevice formEngineering

The invention discloses a wafer surface charge eliminating device. A shell of the wafer surface charge eliminating device forms a closed cavity; a partition plate is fixed in the middle of the shell,and isolates the closed cavity formed by the shell into a closed upper chamber and a closed lower chamber when the partition plate is unfolded; the side wall of the shell at the lower chamber is provided with a wafer placement door that can be opened and closed; an upper pole plate is disposed in the upper chamber and parallel to the partition plate; the shell is an insulating material; the upperpole plate and the partition plate are both conductive materials; the upper pole plate is connected to an upper electrode; the partition plate is connected to a lower electrode; a charge measuring device and a worktable capable of lifting and rotating are placed in the lower chamber; and the side wall of the upper chamber is provided with a ventilation interface. The invention also discloses a wafer surface charge eliminating method of the wafer surface charge eliminating device. The invention can eliminate the interference of wafer surface charges on manufacturing and measurement processes, reduce process defects, and improve the measurement pattern accuracy.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Buffer cylinder welding tool

ActiveCN102950405AEasy to assembleCompact structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering gun

The invention relates to a buffer cylinder welding tool comprising a switch, a base, a bottom plate, a welding gun, a transmission mechanism, a pressing mechanism, a controller, a support and a buffer cylinder. The switch is arranged below the base, the bottom plate, the support and the transmission mechanism are arranged on the base, the pressing mechanism and the controller are connected on the support, the pressing mechanism is arranged above the bottom plate, the welding gun is movably connected with the transmission mechanism, the switch is connected with the controller, and the controller is in control connection with the bottom plate. Compared with the prior art, the buffer cylinder welding tool has the advantages of simple and compact structure, high welding speed and the like.

Owner:SHANGHAI LONGYU ELEVATOR ACCESSORIES

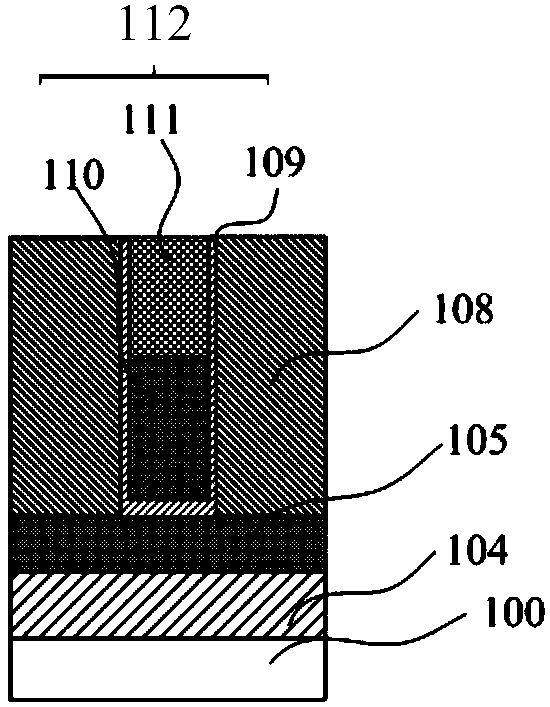

Semiconductor device and preparation method thereof

PendingCN110931557AReduce areaHighly integratedSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

The invention provides a semiconductor device and a preparation method thereof. A second trench extending along a second direction is formed in a semiconductor substrate. U-shaped fins are arranged onthe two sides of the second trench in a staggered mode. The U-shaped fin is provided with a first trench extending along a first direction. The first source / drain regions are formed in the fins at the tops of the two sides of the first trench; a second source / drain region is formed in the fin at the bottom of the first trench; a gate line is filled in the first trench and extends along the firstdirection; the embedded wire is filled in the second trench extending along the second direction, so that the two first source / drain regions in the U-shaped fin respectively form double vertical L-shaped channels with the second source / drain region, the effective channel length is favorably increased, the short channel effect is overcome, and the smaller feature size and the higher integration degree are further favorably realized; and the U-shaped fins on the two sides of the second trench are arranged in a staggered manner, so that the coupling effect between adjacent active regions can be improved, and the device performance can be improved.

Owner:CHANGXIN MEMORY TECH INC

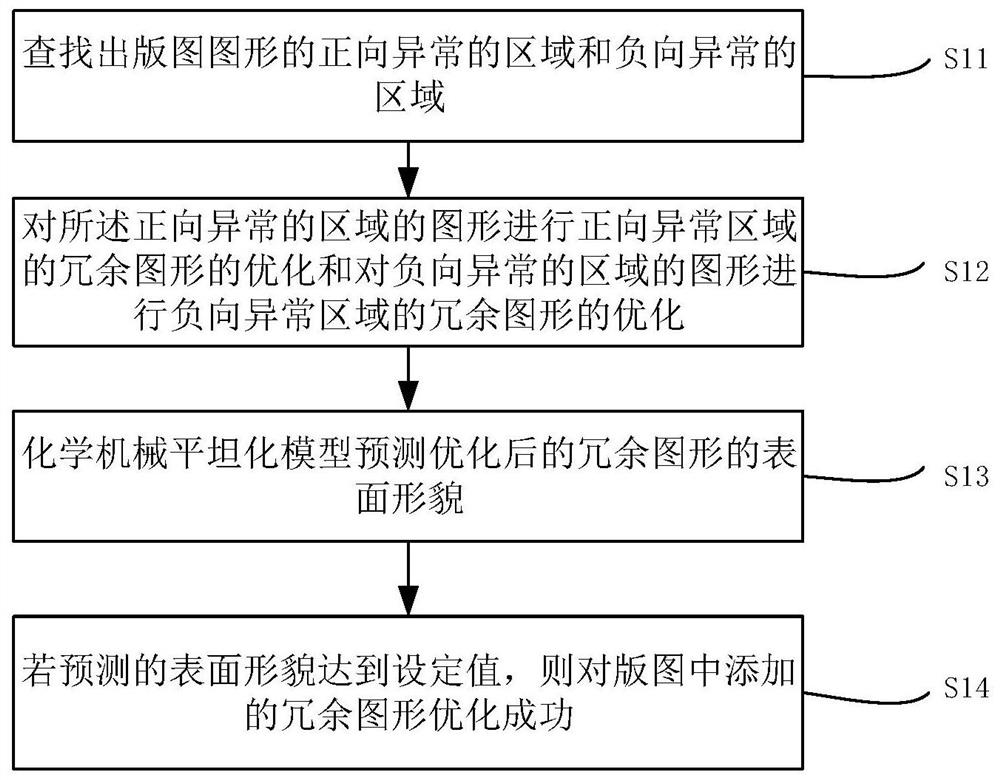

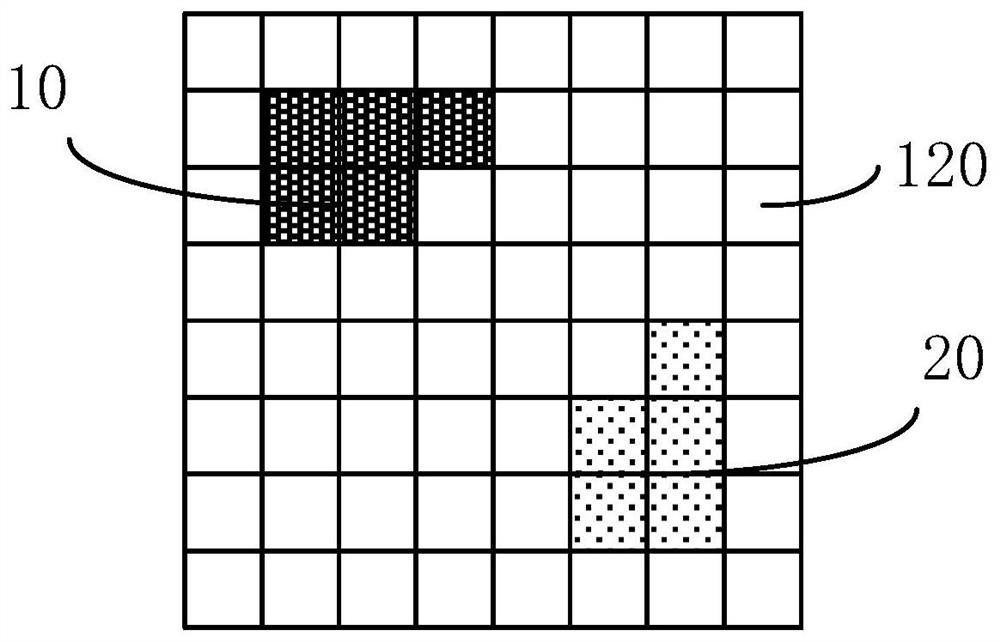

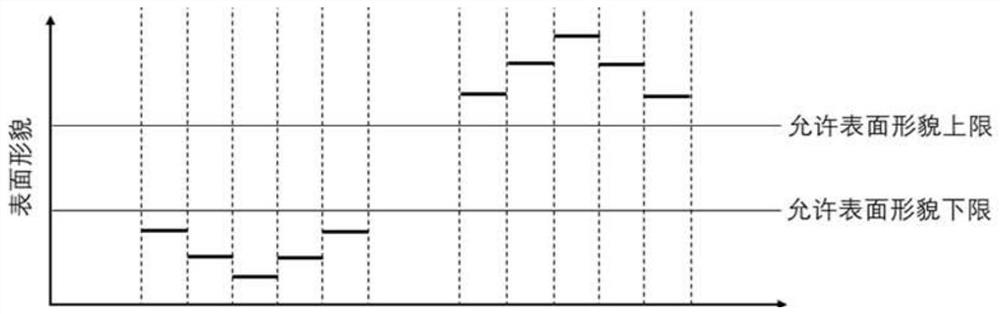

Method for optimizing redundant graphics

PendingCN112036114AImprove optimization effectImprove uniformityComputer aided designSpecial data processing applicationsGraphicsManufacturing technology

The invention provides an algorithm for adding and optimizing a redundant graph. The algorithm comprises the following steps of: searching a positive abnormal region and a negative abnormal region ofa version graph; optimizing the redundant graph of the positive abnormal area and optimizing the redundant graph of the negative abnormal area for the graph of the positive abnormal area; enabling thechemical mechanical planarization model to predict the surface topography of the optimized redundant graph; and if the predicted surface topography reaches a set value, successfully optimizing the redundant graph added in the layout. According to the method, the existing redundant graph is optimized, and the surface appearance of the redundant graph predicted and optimized by the chemical mechanical planarization model is used as a feedback means of the added redundant graph, so that the uniformity of local graph distribution of layouts of different layers among different products can be optimized, and the optimization effect of redundant graph addition is further improved; and the uniformity of the surface morphology of each layer after process machining is improved, and the process defects of the subsequent manufacturing process are reduced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

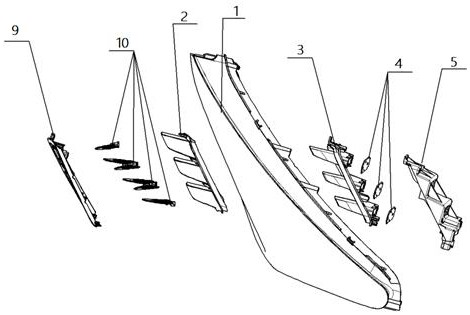

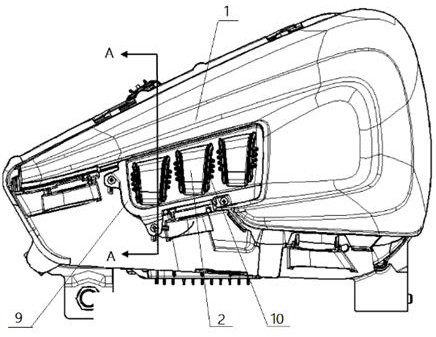

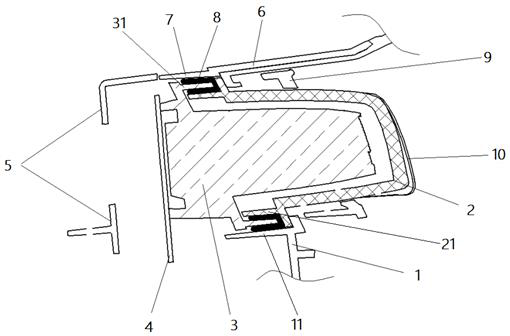

Automobile front combination lamp sealing structure

ActiveCN113701122AReduce difficultyReduce processing difficultyInternal combustion piston enginesSignalling/lighting devicesLight guideEngineering

The invention relates to an automobile front combination lamp sealing structure which comprises a headlamp mask, a plurality of lamplet masks arranged in the headlamp mask and connected with the headlamp mask, light guide plates arranged in the lamplet masks and circuit boards arranged at the rear ends of the light guide plates, and is characterized in that inner clamping parts are arranged on the inner side of the headlamp mask; outer clamping parts are arranged at the rear parts of the lamplet masks; the outer clamping parts of the lamplet masks and the inner clamping parts of the headlamp mask are correspondingly clamped to form U-shaped glue grooves; sealant is coated in the rubber grooves; a rubber rib is arranged at the rear end of the light guide plate, and the rubber rib at the rear end of the light guide plate is inserted into the rubber groove coated with the sealant to form a complete local sealing structure. A complete local sealing structure can be formed, the problem that fogging on the local area of the surface of the lamp mask cannot be eliminated is solved, the appearance quality of the automobile lamp is improved, and the product percent of pass is increased; and the processing procedure can be simplified, and the processing cost is reduced.

Owner:深蓝汽车科技有限公司

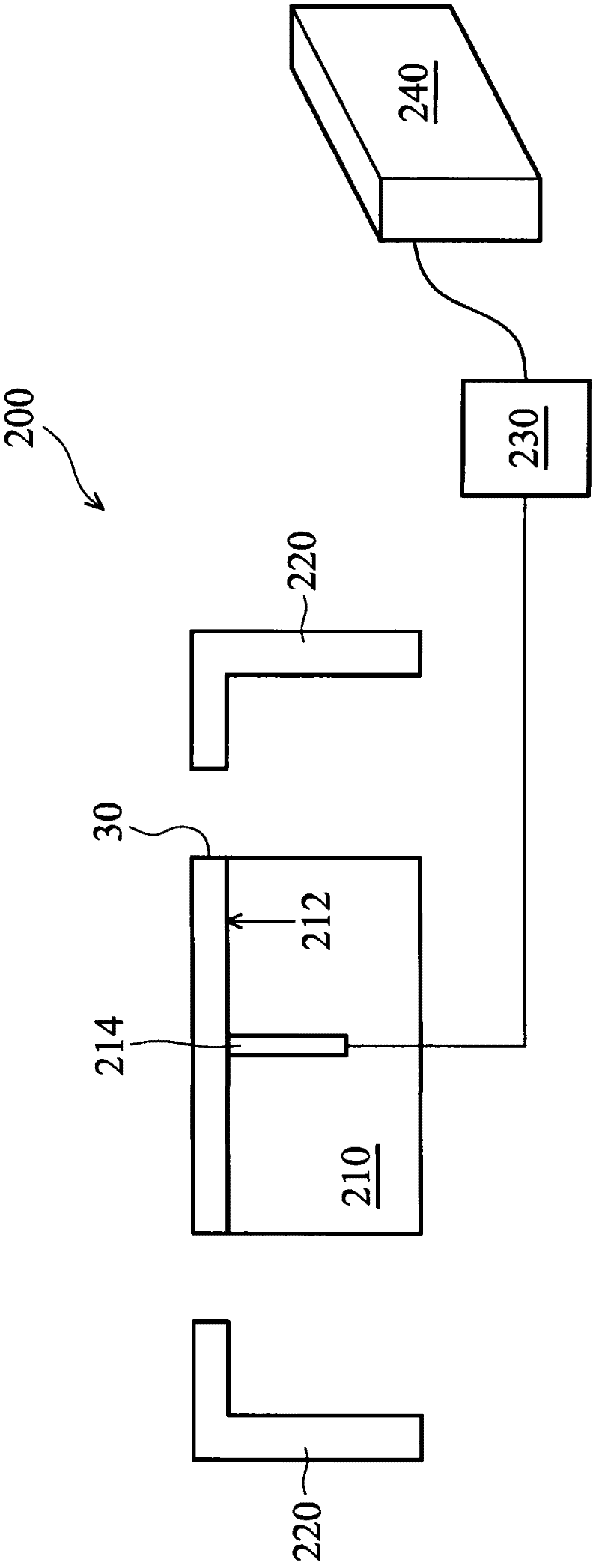

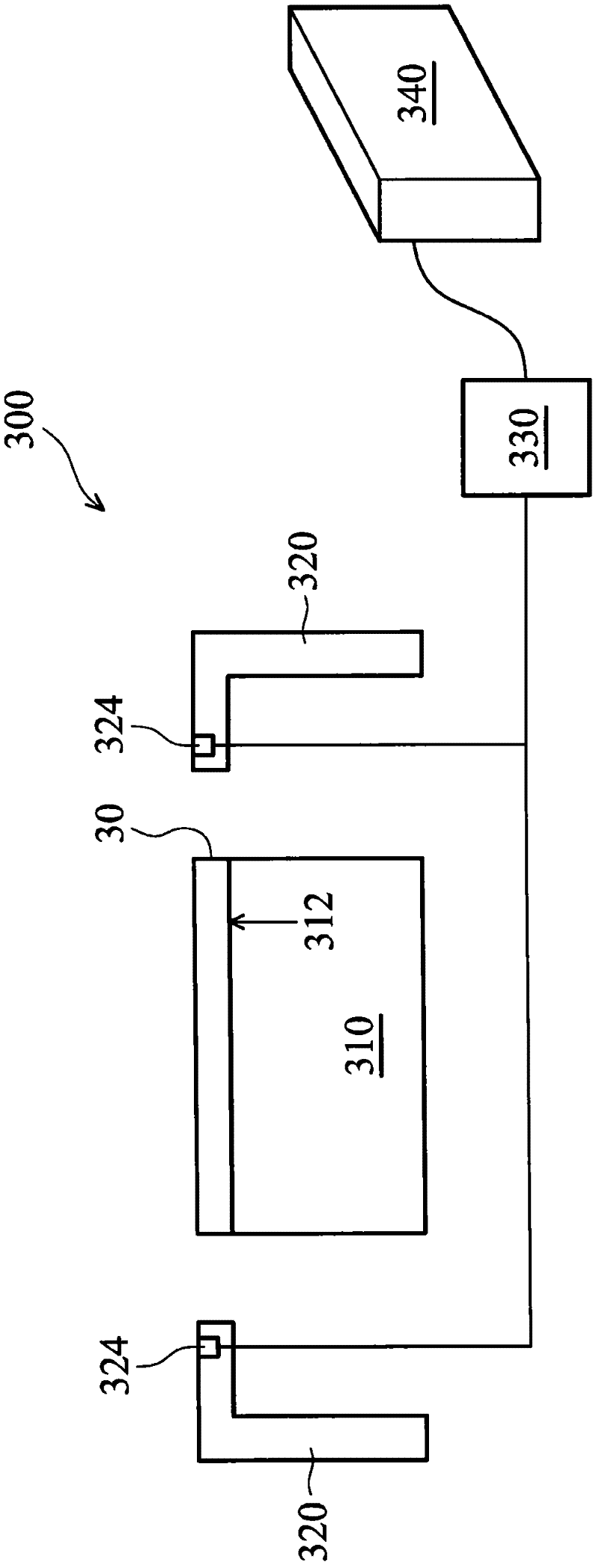

Semiconductor process processing system and method

ActiveCN102398208AProcess defect reductionProgramme controlLapping machinesEngineeringElectrical conductor

The present invention provides a semiconductor process processing system and a method, wherein processing defects arising during processing of a semiconductor wafer prior to back-grinding are reduced with systems and methods of sensor placement. The system comprises one or more holes bored into a chuck table for receiving semiconductor wafers; or a support table next to the chuck table; one or more sensors disposed in the holes for monitoring parameters during a pre-back-grinding (PBG) process; a control box converting a set of signals received from the sensors; a computer-implemented process control tool receiving the converted set of signals from the control box and determining whether the PBG process will continue.

Owner:TAIWAN SEMICON MFG CO LTD

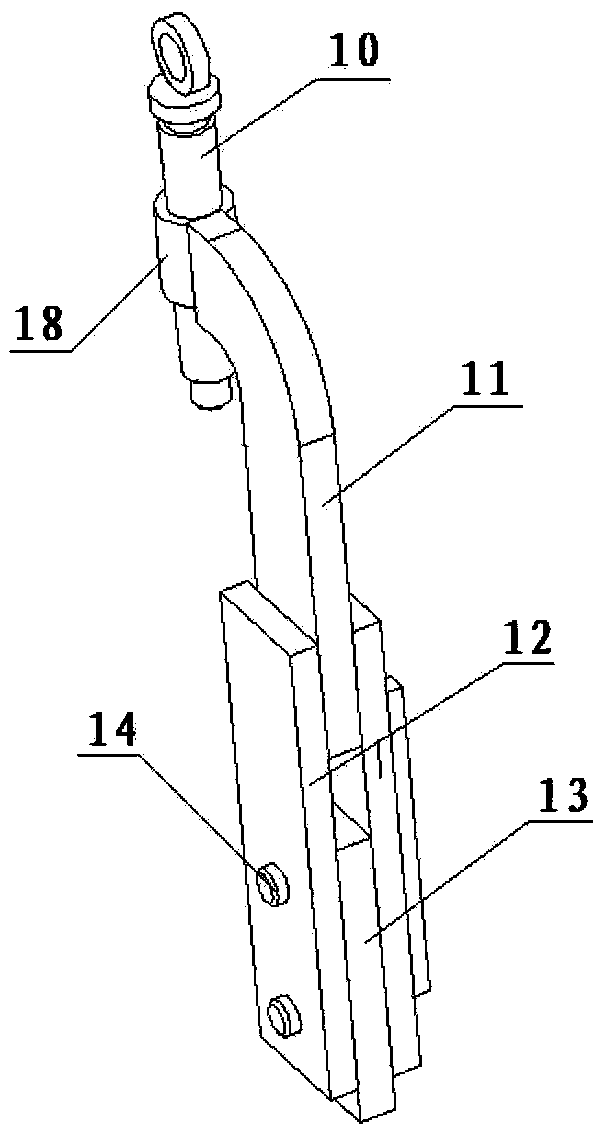

Compartment suspension loop mold

InactiveCN104227298ASave adjustment timeHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesBiochemical engineering

Owner:广西玉柴专用汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com