Etchant composition and method of manufacturing metal wiring using the same

A composition and etchant technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as difficulty in single-layer use, poor adhesion between copper and glass substrates or silicon insulating layers, etc. The effect of saving manufacturing cost, reducing process defects, and reducing the variation of taper angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] According to an exemplary embodiment of the present invention, the nitrogen-based cyclic compound may be a 3 nitrogen-based cyclic compound. The 3 nitrogen-based cyclic compound means a compound containing 3 nitrogens (N) in the ring.

[0052] Specifically, cyclic compounds based on three nitrogens may include 1,2,4-triazole, 3-amino-1,2,4-triazole, 3-mercapto-1,2,4-triazole, 3- Amino-1,2,4-triazole-5-thiol or a mixture of at least two of them.

[0053] The content of the nitrogen-based cyclic compound may be about 0.1 wt % to 2 wt % based on the total weight of the etchant composition according to the exemplary embodiment of the present invention. According to an exemplary embodiment of the present invention, when the amount of the nitrogen-based cyclic compound is less than 0.1% by weight, the etching rate of copper cannot be controlled, the CD loss increases, and the straightness of the wiring is also deteriorated, which will cause problems in applications. A serio...

Embodiment 5

[0102] Example 5 shows the use of phosphorous acid instead of phosphoric acid and shows a good level of accumulation of etch amount at the same level as the etchant composition including phosphoric acid.

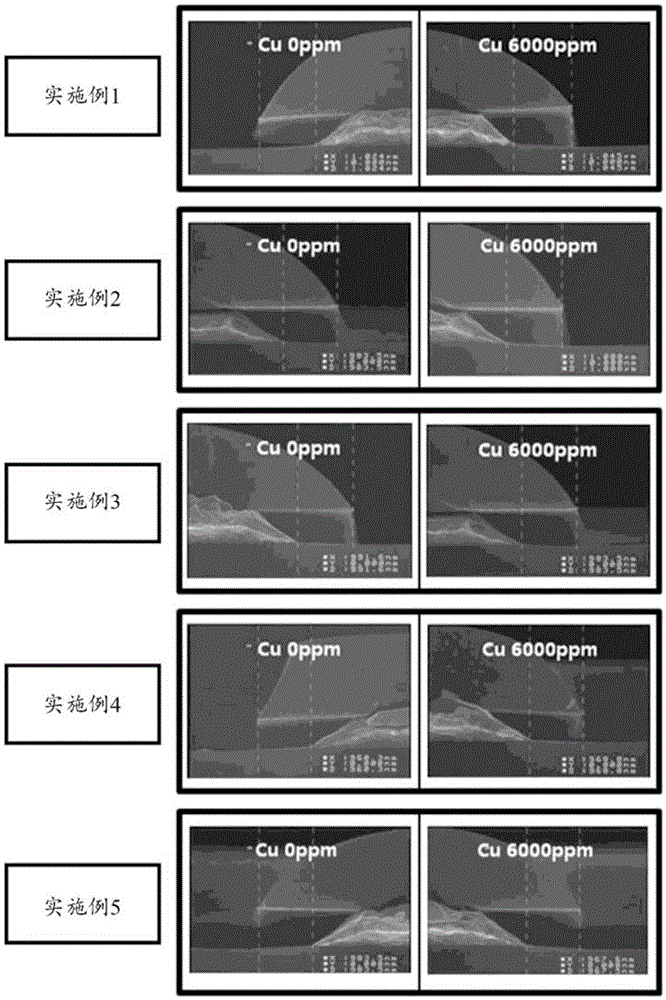

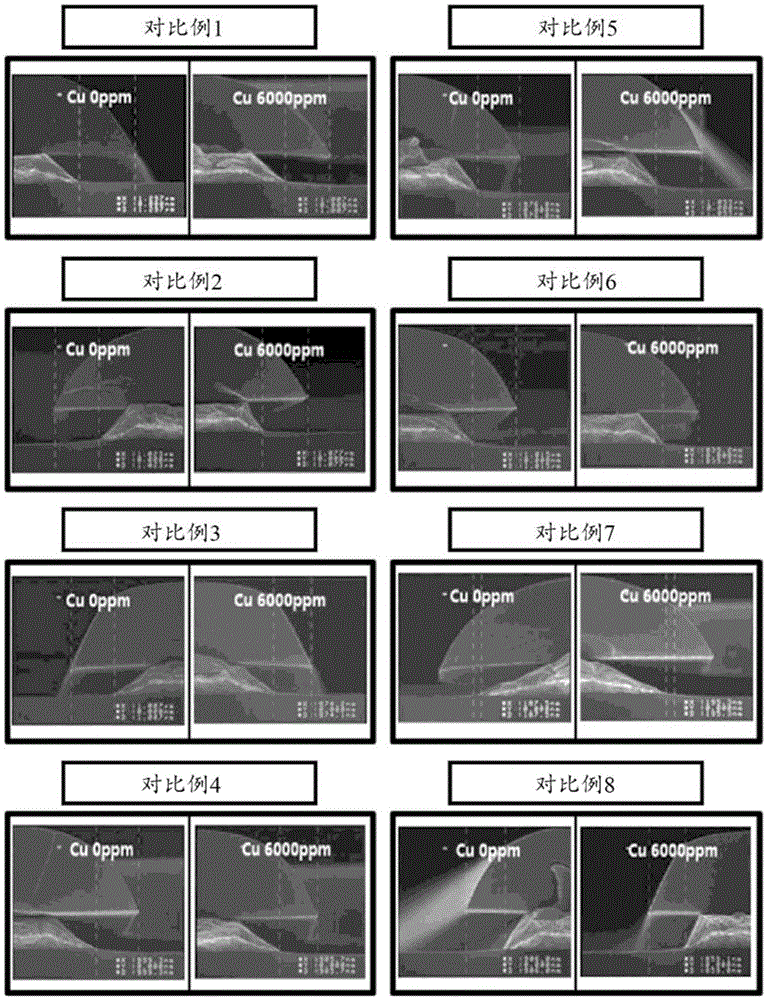

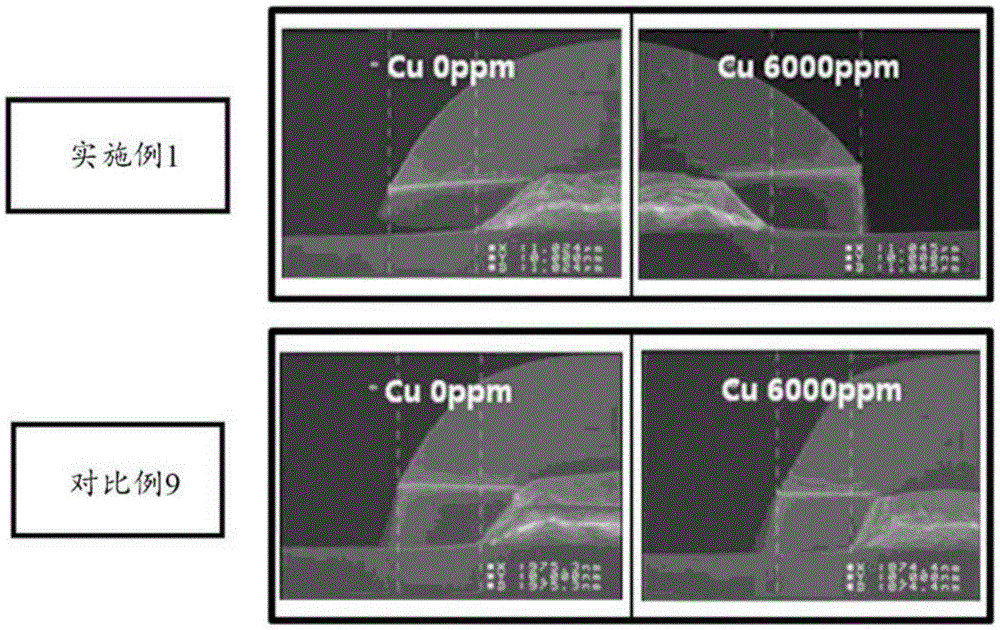

[0103] However, Comparative Example 1 not including the cyclic compound based on three nitrogens and Comparative Example 2 not including phosphoric acid or phosphorous acid did not perform the function of maintaining the etching amount and the taper angle corresponding to copper accumulation. In addition, Comparative Example 3 not including methanesulfonic acid showed that the etching amount and taper angle were not maintained corresponding to copper accumulation and titanium tail was excessively generated, so the etchant composition not including methanesulfonic acid was not appropriate. refer to figure 2 with 4 , Comparative Example 1 shows the problem of maintaining the taper angle or reducing the cut dimension deviation (CD deviation) depending on the accumulation leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com