System and method for wafer back-grinding control

A technology of back grinding and control system, which is applied in semiconductor/solid-state device manufacturing, grinding automatic control device, semiconductor/solid-state device testing/measurement, etc. It can solve the problem of reducing the size of semiconductors and achieve the effect of reducing process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following description, "an embodiment" in different paragraphs does not necessarily refer to a single embodiment, and the structure can be implemented in at least one embodiment. In general, the same reference numerals are used to designate similar structures, but this does not mean that elements with the same reference numerals in each embodiment have the same structure. In addition, the structures in the illustrations are not completely drawn to scale, so the dimensions in the illustrations are not intended to limit the system described below.

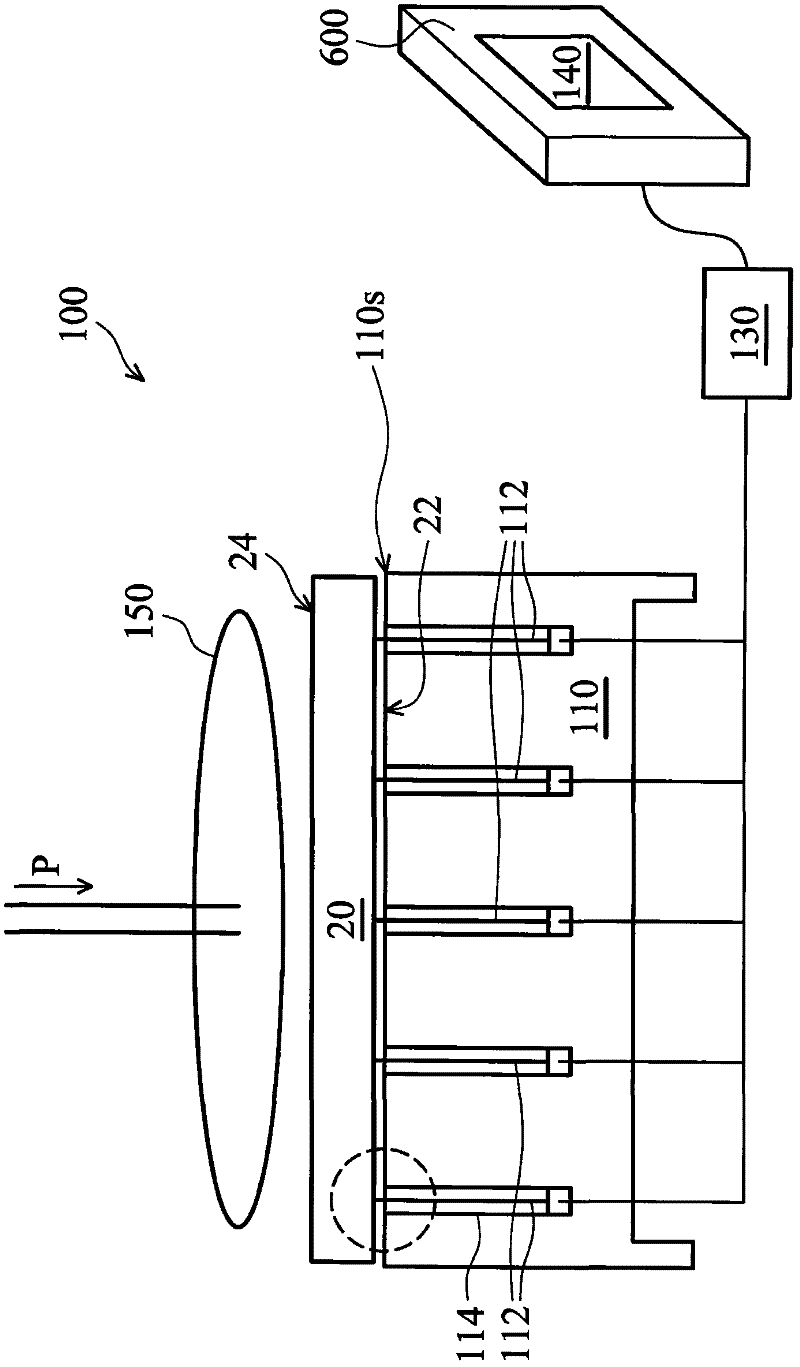

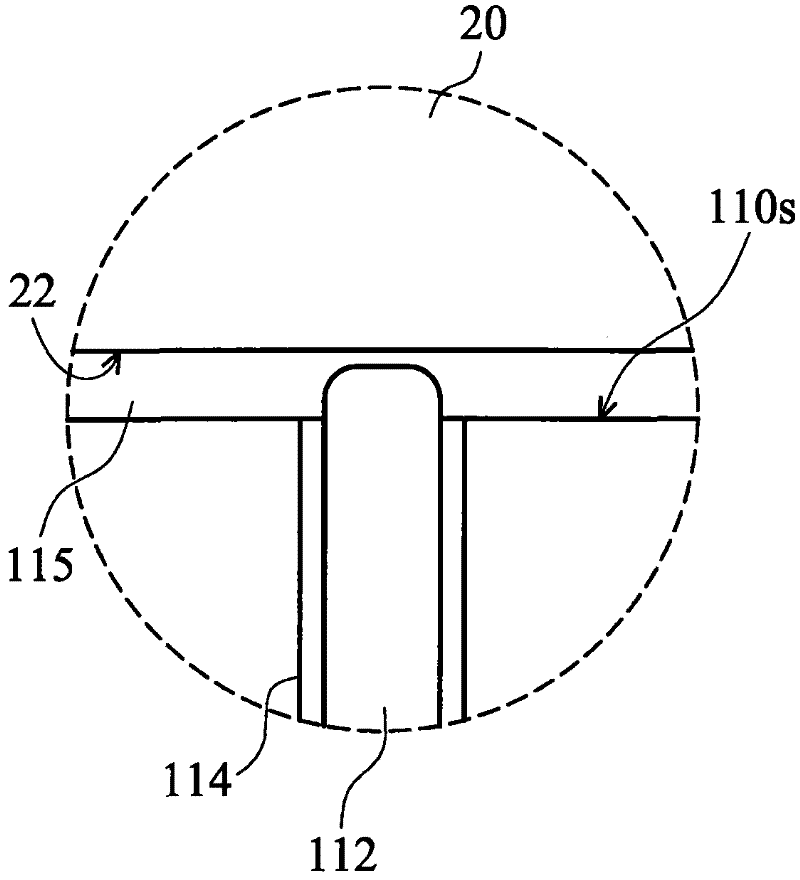

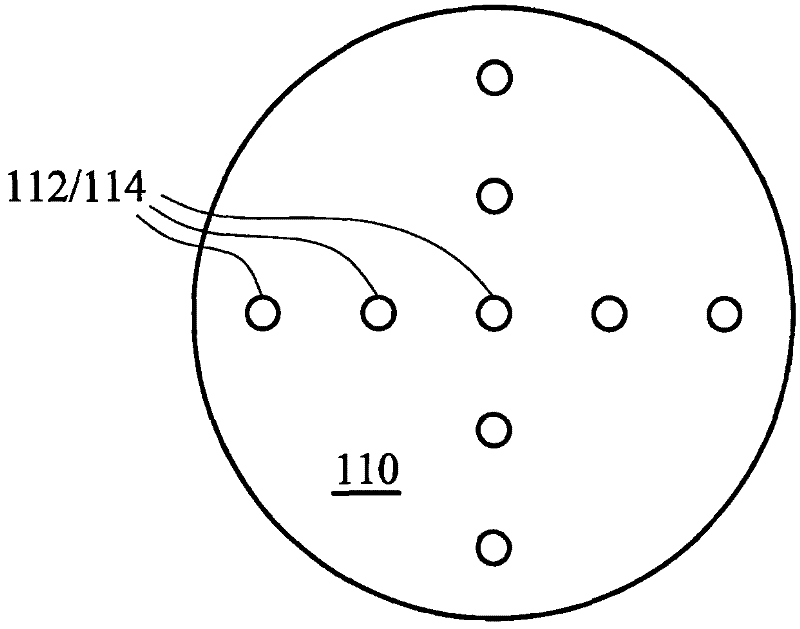

[0018] In the following description and accompanying drawings, at least one semiconductor wafer 20 (see Figure 1A ) are ground to remove excess substrate. Before the semiconductor wafer 20 is placed on the back grinding device, a grinding tape (not shown) is attached to the front side 22 of the semiconductor wafer by a device (not shown or labeled). The abrasive tape on the front side 22 of the semiconductor wafer pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com