Thin-film transistor LCD pixel structure and its making method

A liquid crystal display and thin film transistor technology, which is applied to the pixel structure of the thin film transistor liquid crystal display and its manufacturing field, can solve the problems of column spacer 12 sliding, white Mura, gate line dislocation, etc. The effect of great technological freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

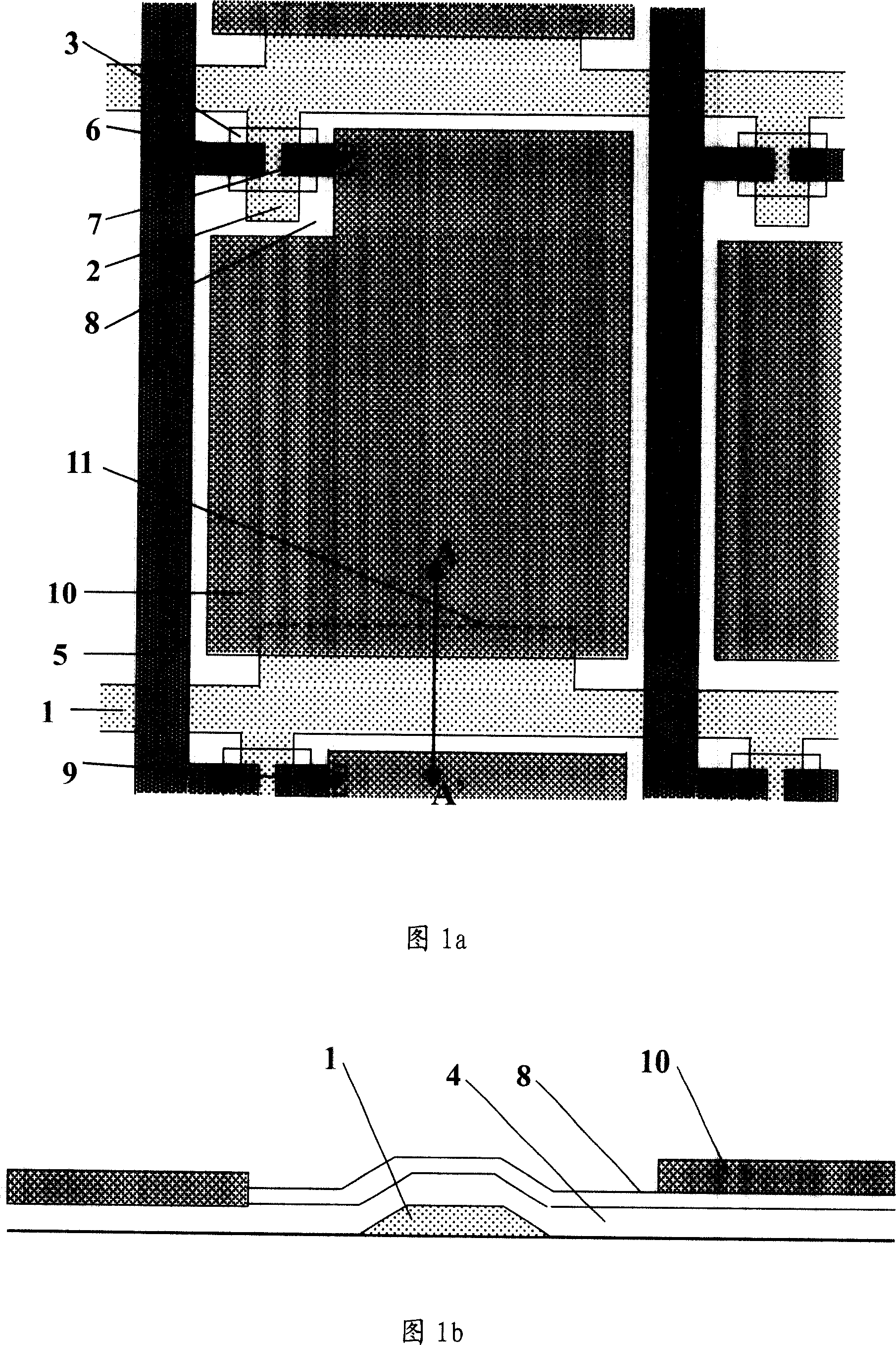

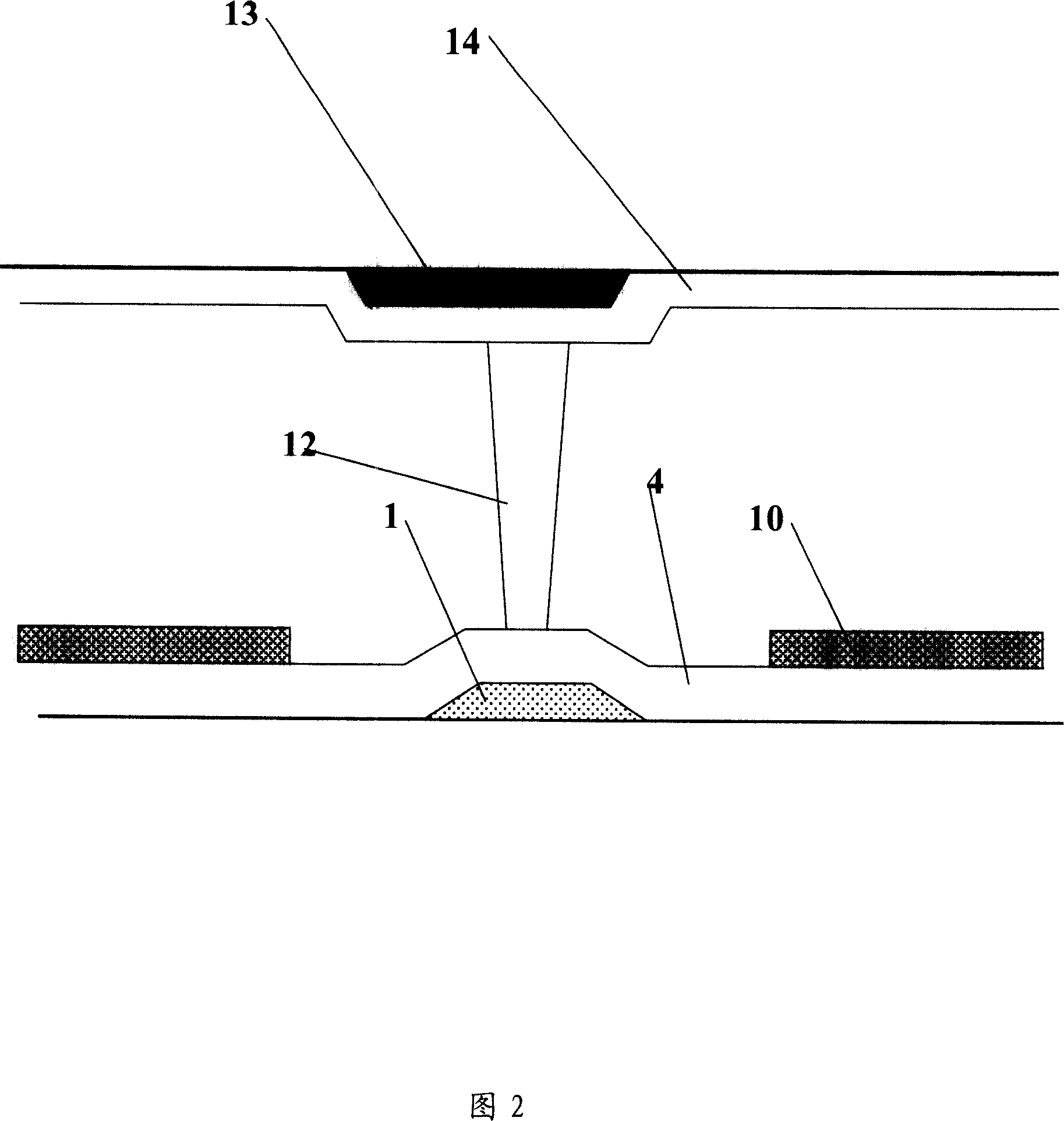

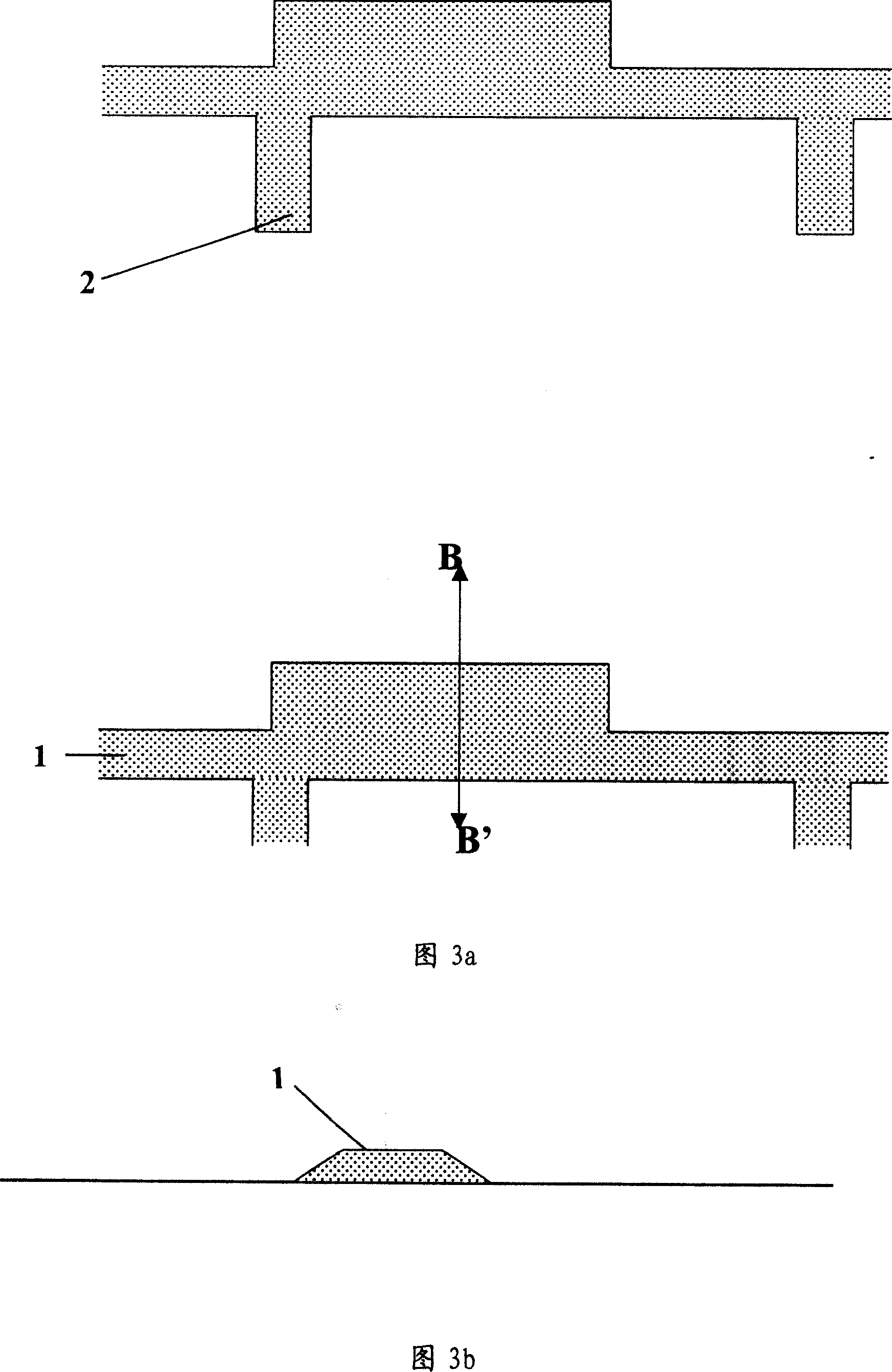

[0040] As shown in FIG. 7a, it is a planar structure diagram of a pixel in the present invention. The pixel structure includes: an insulating substrate; a gate line 1 and a gate electrode 2 formed on the insulating substrate; a gate insulating layer 4 formed on the gate electrode 2; a silicon island 3 formed on the gate insulating layer 4; The drain electrode 6 and the source electrode 7 above the island 3; the data line 5 and the drain electrode 6 of the source-drain electrode are integrated; the passivation layer 8 formed on the source-drain electrode covers the entire substrate; The passivation layer via hole 9; the pixel electrode 10 is connected to the source electrode 7 through the passivation layer via hole 9; the gate line protrusion 11 and the pixel electrode 10 together form a storage capacitor. These parts are not different from the prior art. The pixel structure is different from the prior art in that a hole 8a is formed on the gate insulating layer 4 and the passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com