Compressor welding tool

A technology for welding tooling and compressors, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve the problem of poor dimensional consistency and stability of scraper compressor components, unguaranteed welding quality, and impact on Solve problems such as welding production speed, achieve the effect of shortening tooling adjustment time, reducing blanking and scribing work, and improving welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

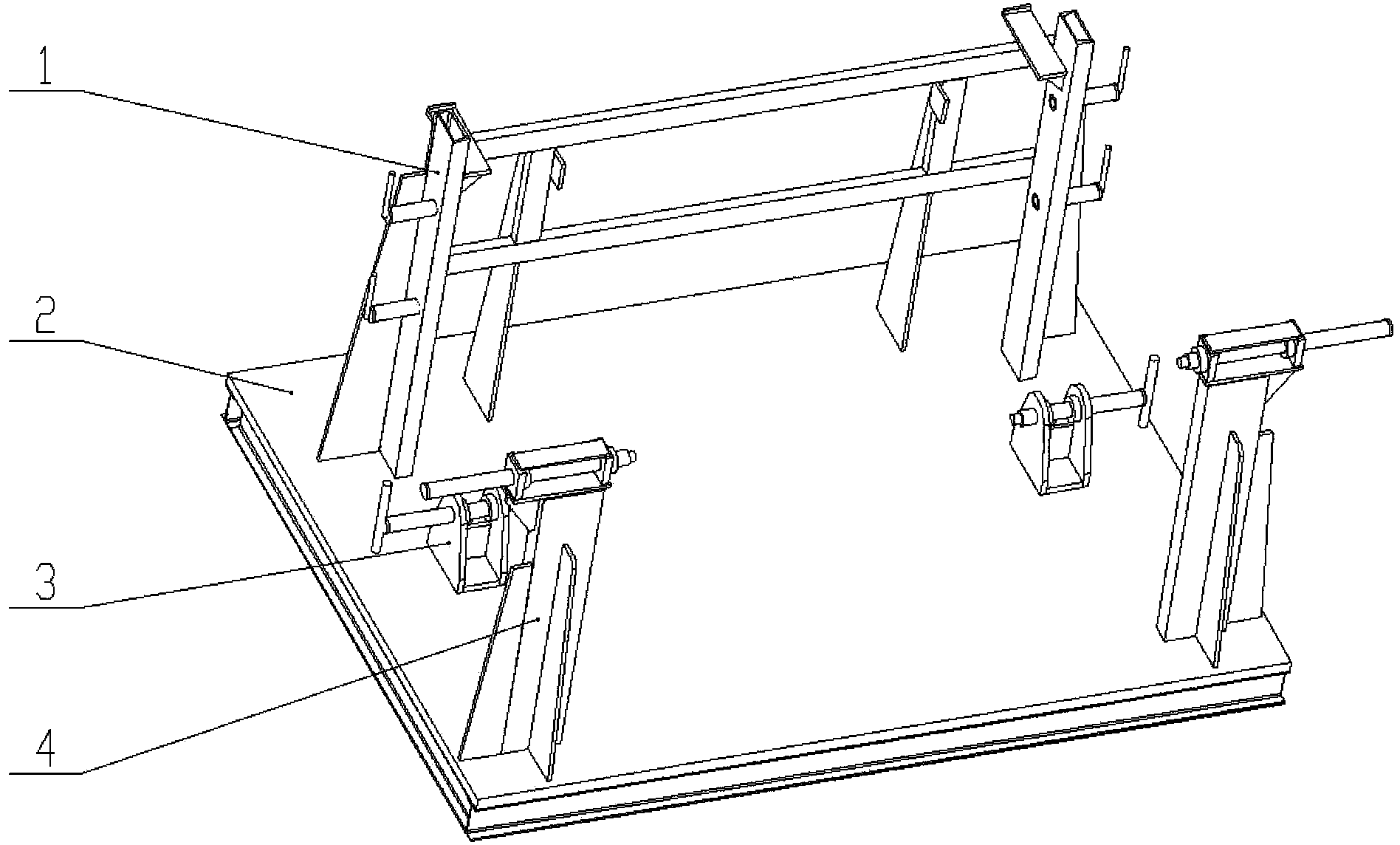

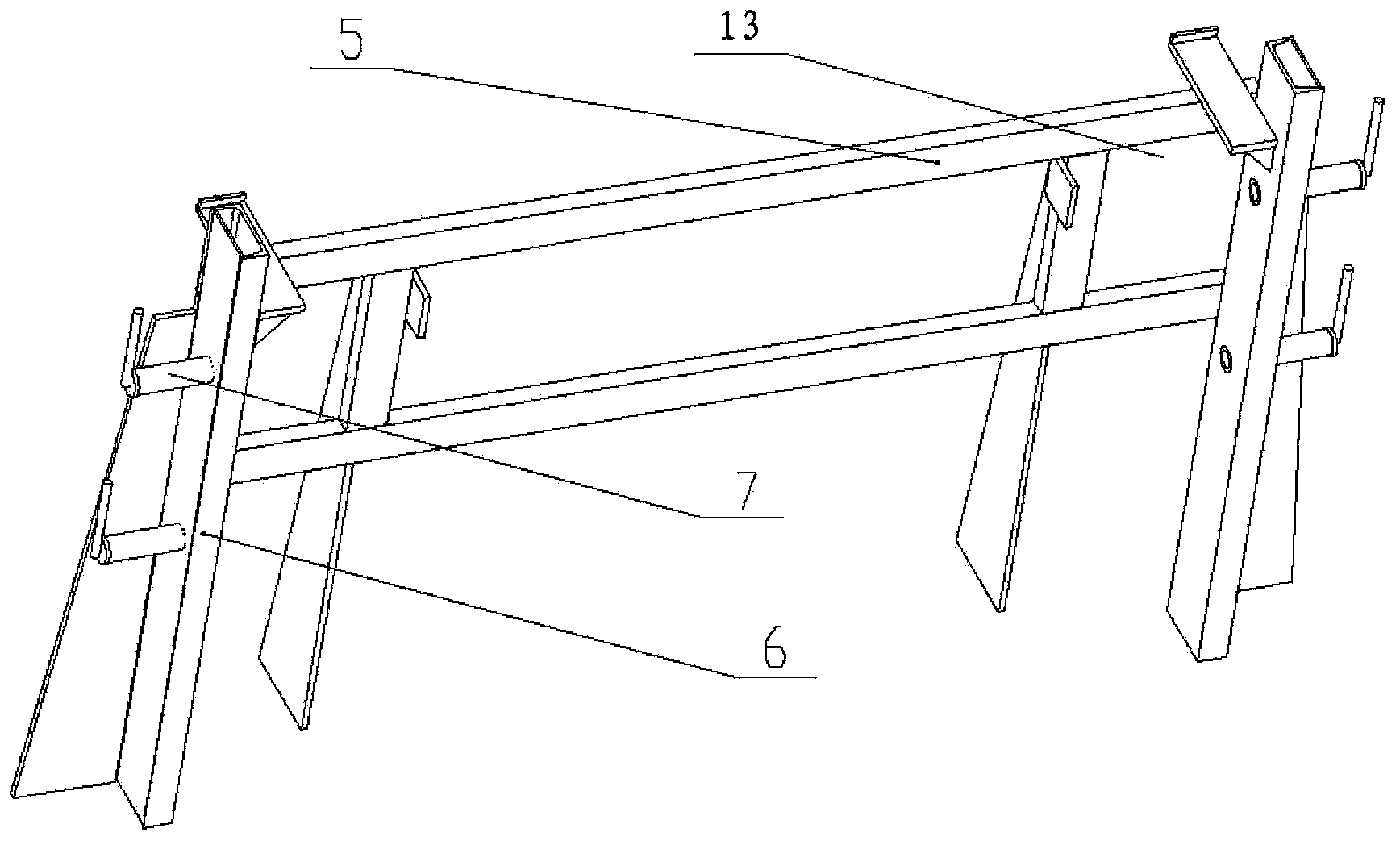

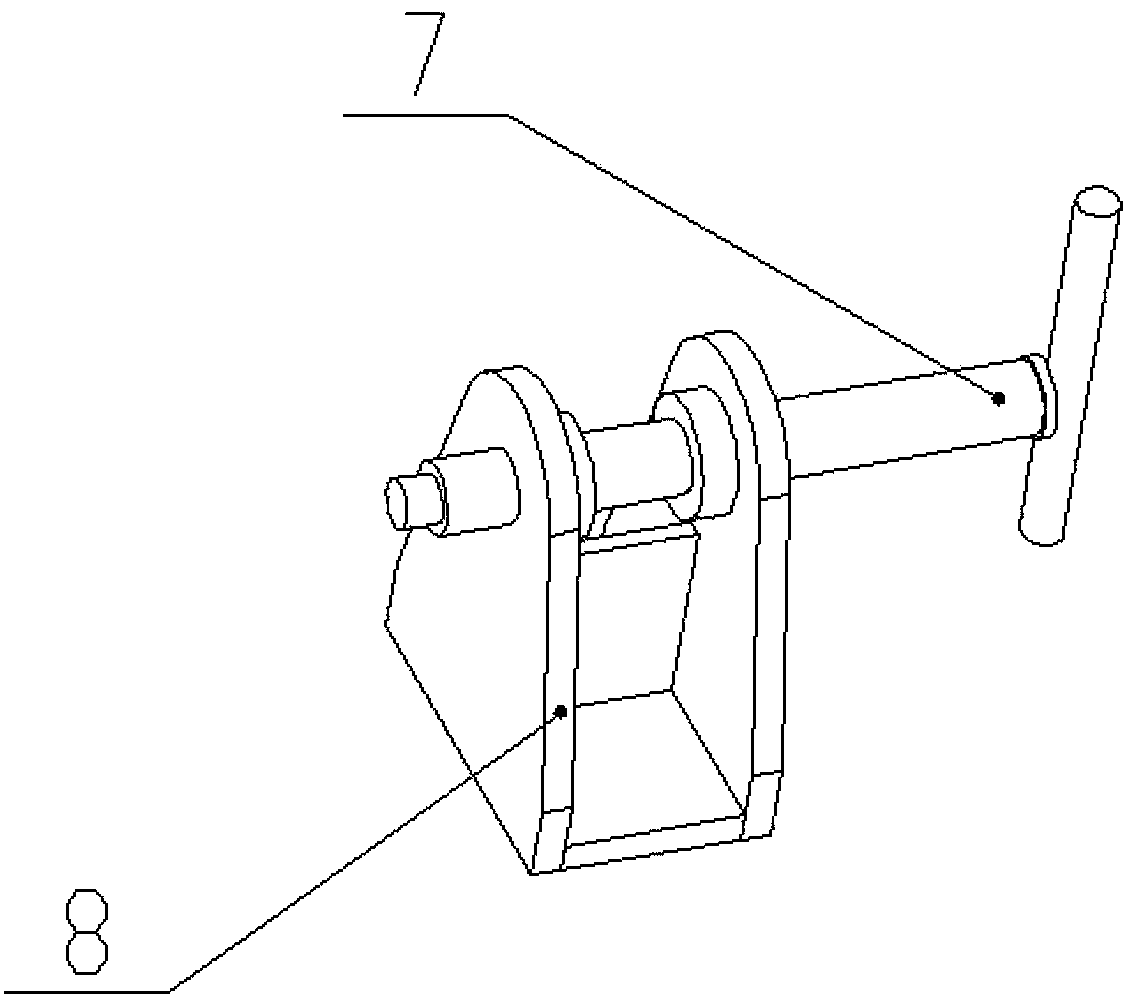

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in , a compressor welding tool, comprising: a locking support box positioning mold assembly 1 is fixed on one side of the base platform 2 close to the edge, and two adjustments are fixed on the other side of the base platform 2 close to the two corners. The connecting rod 9 is opposite to the extrusion plate shaft seat positioning die 4, and an adjusting screw 7 is fixed between the locking support box positioning die assembly 4 and the extrusion plate shaft seat positioning die 1 near the edge of the base platform 2 Direction is relative to extruding oil cylinder seat positioning mold 3.

[0028] The positioning mold assembly 1 of the locking support box includes: a support connecting frame 5, an adjusting screw column 6, and an adjusting screw 7, and the horizontal ends of the supporting connecting frame 5 are fixed on one side of the adjusting screw column 6, and the adjusting screw column 6. The device...

Embodiment 2

[0034] see Figure 5 , the actual welding of the compressor:

[0035] In the welding production of the compressor, when hoisting, use the fixing groove 13 of the locking support box positioning mold assembly 1 on the base platform 2 as a reference for positioning, and use its adjusting screw 7 to rotate and push to the compressor fixing seat for the first fulcrum Fixing and coaxiality adjustment, the second fulcrum positioning is performed by squeezing the U-shaped slot 8 of the positioning mold 3 of the cylinder seat, and the second fulcrum is fixed and coaxiality is fixed and coaxiality is carried out by setting the top adjusting screw 7 to rotate and push to the compressor fixing seat Adjustment, and then through the rotation of the adjustment connecting rod 9 of the positioning die 3 of the extrusion plate shaft seat, the third point is fixed and the coaxiality adjustment is carried out on the compressor fixed seat, and the six direction points are pressed and positioned, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com