Composition for preparing matte white glaze, and firing method of matte white glaze

A composition and technology of white glaze, applied in the field of ceramic glaze preparation, can solve the problems of high fluidity of glaze, many bubbles on the glaze surface, easy cracking texture and the like, and achieve the effects of reducing dosage, fine texture and improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

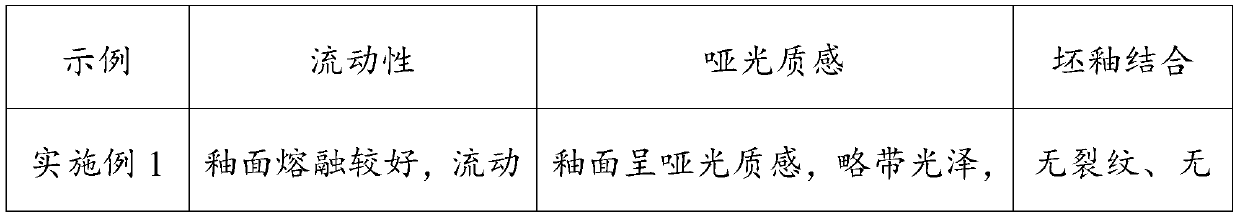

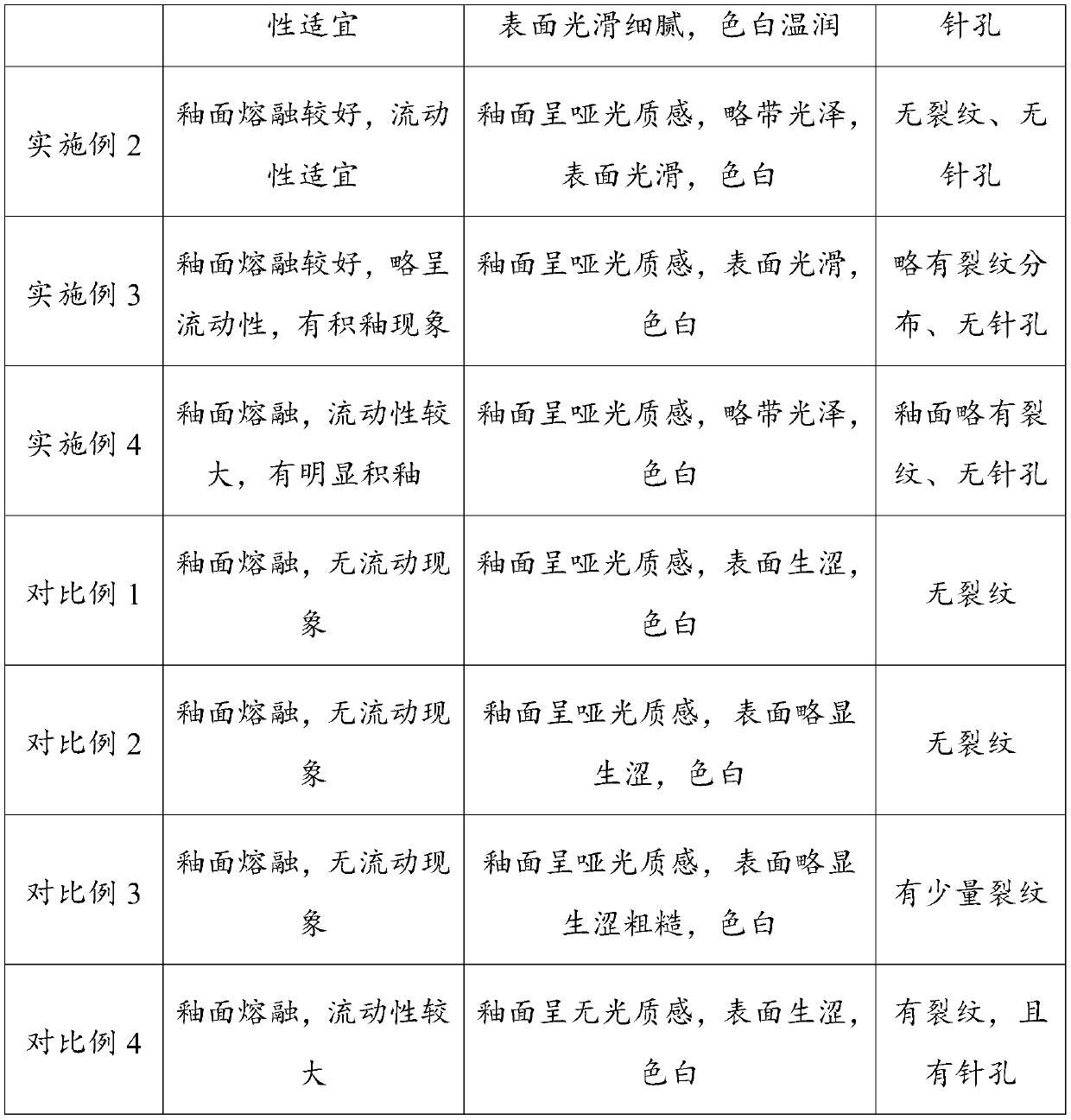

Examples

Embodiment 1

[0033] This embodiment provides a composition for preparing matte white glaze and a firing method for matte white glaze. The composition includes 4kg slag powder, 1kg kaolin, 1kg calcined kaolin, 0.5kg talc, 2.7kg potassium feldspar, 1kg of quartz and 0.3kg of zirconium silicate; the mesh number of calcined kaolin is 1250 mesh, and the mesh number of slag powder is 200 mesh.

[0034] The firing method of the matte white glaze includes the following steps:

[0035] 2kg of kaolin was heated from 25°C to 1000°C at a heating rate of 3.33°C / min, then kept at this temperature for 30 minutes, cooled to room temperature naturally, and crushed to 1250 mesh fine particle powder to obtain 1kg of calcined kaolin for future use;

[0036] Mix slag powder, kaolin, calcined kaolin, talc, potassium feldspar, quartz, zirconium silicate and water, the mass ratio of the composition to water is 1:1.2, and then put all the raw materials into a ball mill jar for rapid ball milling, ball milling 8h,...

Embodiment 2

[0040] This example provides a composition for preparing matte white glaze and a firing method for matte white glaze. The composition includes 4.2kg of slag powder, 1.0kg of kaolin, 1.0kg of calcined kaolin, 0.5kg of talc, 2.5kg of potassium Stone, 1.0kg of quartz and 0.3kg of zirconium silicate; the mesh number of calcined kaolin is 800 mesh, and the mesh number of slag powder is 200 mesh.

[0041] The firing method of matte white glaze includes the following steps:

[0042] 2kg of kaolin was heated from 26°C to 1000°C at a heating rate of 3.33°C / min, then kept at this temperature for 30 minutes, cooled to room temperature naturally, and crushed to 800-mesh fine particle powder to obtain 1kg of calcined kaolin;

[0043] Mix slag powder, kaolin, calcined kaolin, talc, potassium feldspar, quartz, zirconium silicate and water, the mass ratio of the composition to water is 1:1.2, and then put all the raw materials into a ball mill jar for rapid ball milling, ball milling 10h, th...

Embodiment 3

[0047] This embodiment provides a composition for preparing matte white glaze and a firing method for matte white glaze. The composition includes 4.5kg of slag powder, 1.0kg of kaolin, 1.0kg of calcined kaolin, 0.5kg of talc, 2.5kg of potassium Stone, 1.0kg of quartz and 0.3kg of zirconium silicate; the mesh number of calcined kaolin is 1000 mesh, and the mesh number of slag powder is 300 mesh.

[0048] The firing method of matte white glaze includes the following steps:

[0049] 2kg of kaolin is heated from normal temperature to 1000°C at a heating rate of 3.33°C / min, then kept at this temperature for 30 minutes, cooled to room temperature naturally, and crushed to 800 mesh fine particle powder to obtain 1kg of calcined kaolin for future use;

[0050] Mix slag powder, kaolin, calcined kaolin, talc, potassium feldspar, quartz, zirconium silicate and water, the mass ratio of the composition to water is 1:1.2, and then put all the raw materials into a ball mill jar for rapid bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com