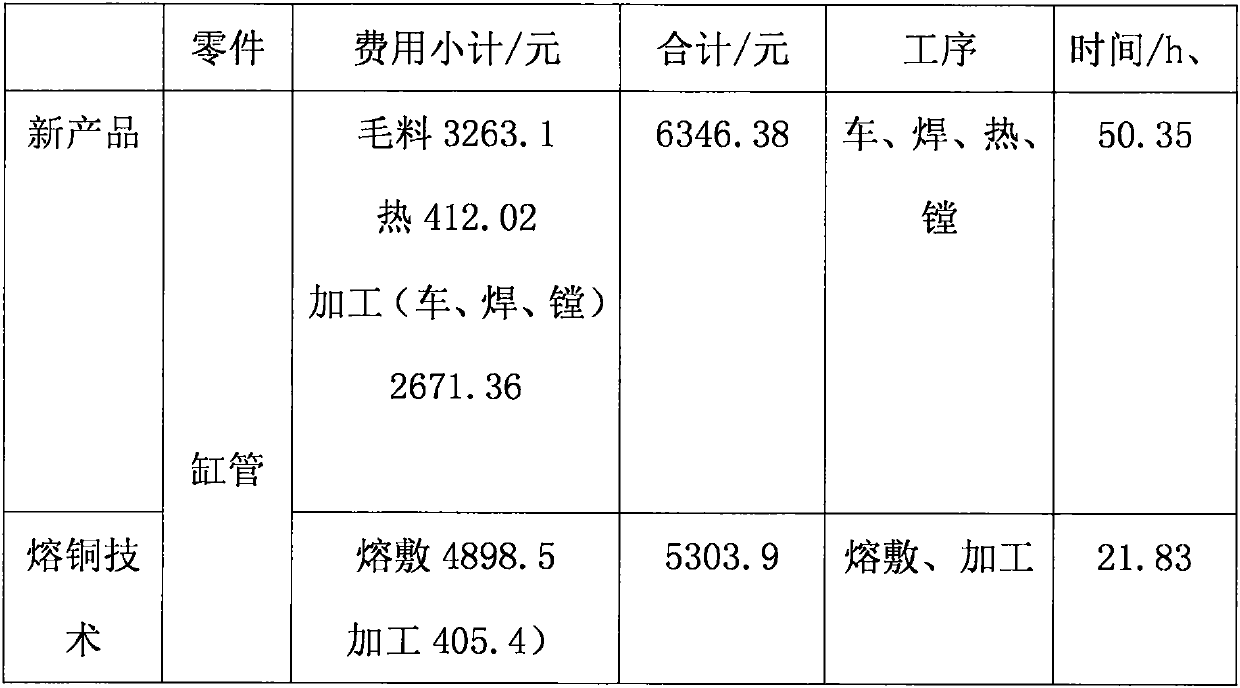

Patents

Literature

205 results about "Aluminium bronze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium bronze is a type of bronze in which aluminium is the main alloying metal added to copper, in contrast to standard bronze (copper and tin) or brass (copper and zinc). A variety of aluminium bronzes of differing compositions have found industrial use, with most ranging from 5% to 11% aluminium by weight, the remaining mass being copper; other alloying agents such as iron, nickel, manganese, and silicon are also sometimes added to aluminium bronzes.

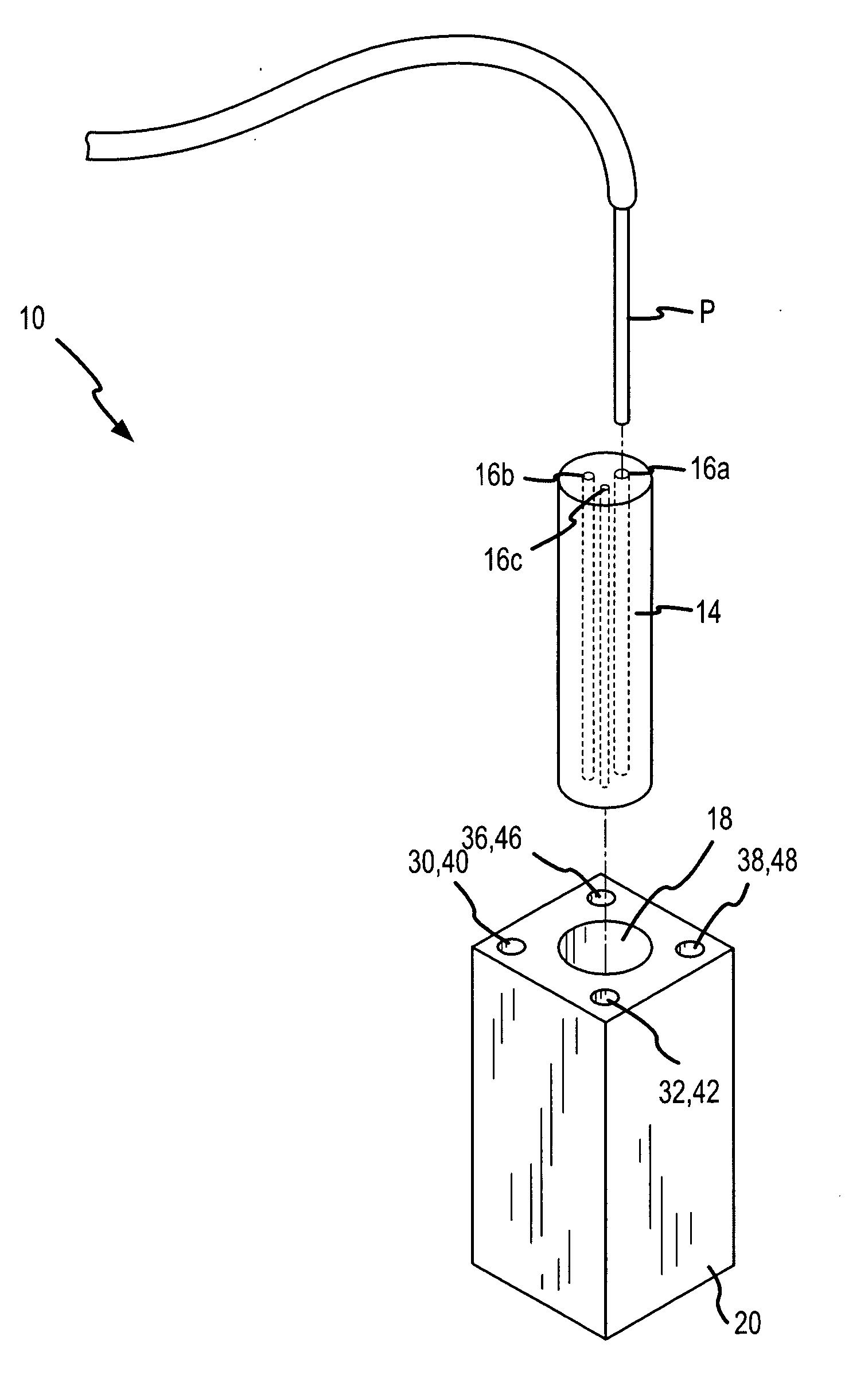

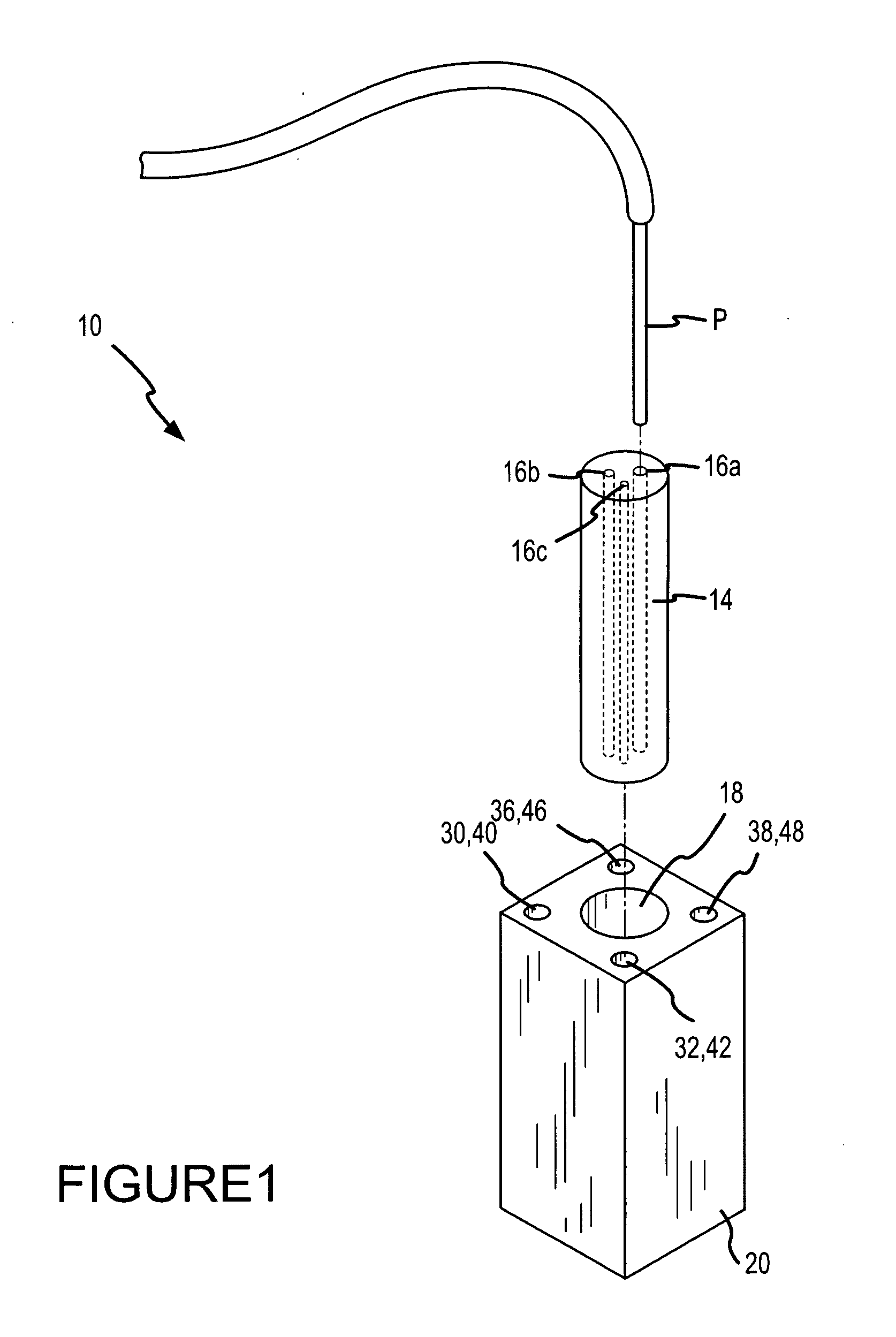

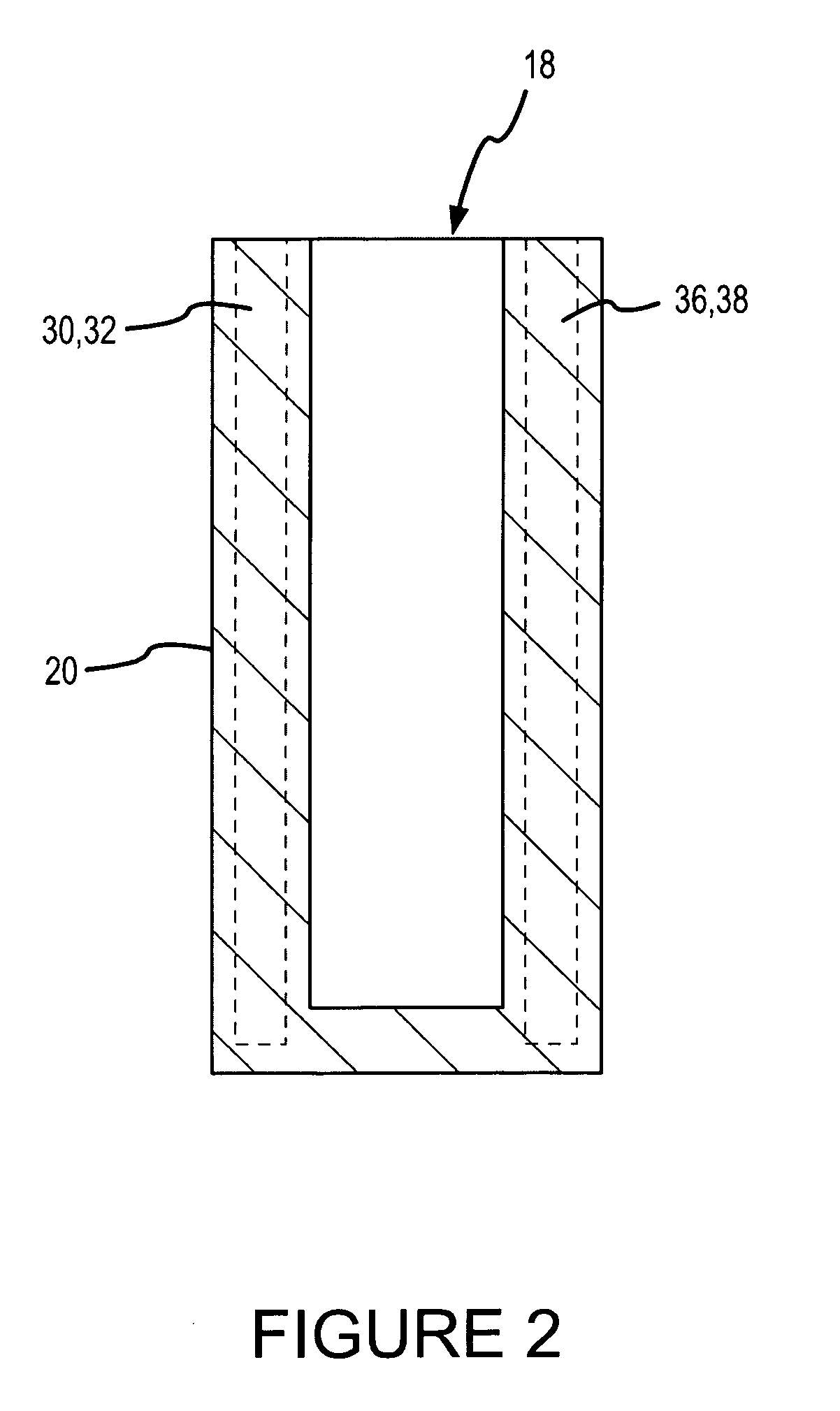

Insert and/or calibrator block formed of aluminum-bronze alloy, temperature calibration device using same, and methods of use

InactiveUS20070291814A1Reduce environmental degradationThermometer testing/calibrationCalorimeterAlloyBronze

Inserts and / or calibrator blocks formed of aluminum-bronze alloys resistant to environmental degradation, temperature calibration devices employing such inserts and calibrator blocks, and methods of using such devices and structures are disclosed. An insert and / or calibrator block for use with a temperature calibration device may be formed of an aluminum-bronze alloy having a composition selected to reduce environmental degradation thereof during use.

Owner:JOHN FLUKE MFG CO INC

Aluminum bronze and preparation method thereof

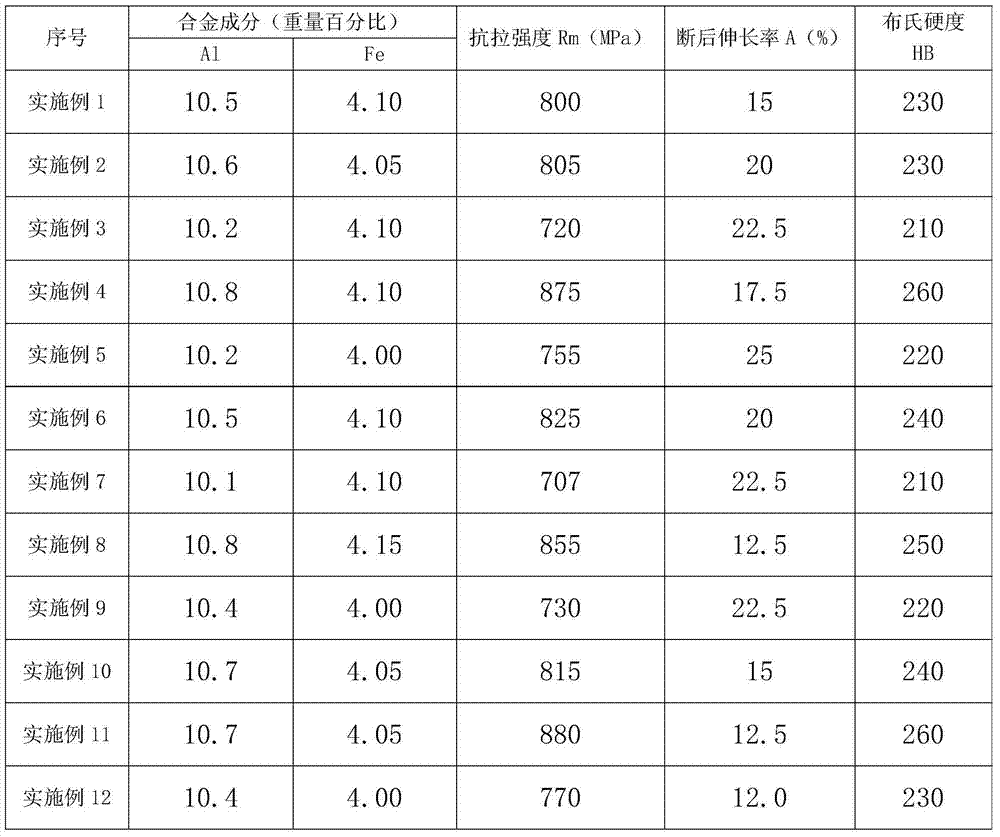

The invention discloses an aluminum bronze. The aluminum bronze comprises the following components in percentage by weight: 9.0-18.0% of aluminum, 2.0-7.0% of iron, 1-5% of manganese, 0.01-1% of zinc and the balance of copper and inevitable impurities. The aluminum bronze has the following advantages that through utilizing specific element ratio, specific processing mode and composition, the tensile strength of the aluminum bronze can reach above 700 MPa, the Brinell hardness (HB) of the aluminum bronze is 300-400, and the compressive strength of the aluminum bronze is above 1000MPa; the aluminum bronze has high wear resistance; the friction coefficient of the aluminum bronze is less than 0.15, so that scratched products and adhered products cannot be caused; the alloy has good hot working character; the alloy has high anti-softening temperature; and the aluminum bronze is not added with noble elements such as Ag and Ni, does not need to be thermally treated, and the raw material and production costs are lowered.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Wear resistant polytetrafluoroethylene material and preparation method thereof

The application discloses a wear resistant polytetrafluoroethylene material and a preparation method thereof. The method comprises steps of: preparing polytetrafluoroethylene, aluminum oxide, bronze powder, silica, glass fiber, LCP, a coupling agent, graphite, molybdenum disulfide, GF, a flame retardant, UHMWPA, POM, PC and nano-titanium dioxide in parts by weight; mixing the substances; and extruding the mixture. For a product, the tensile strength is 27-32 MPa, and the breaking elongation is 300-320%; the Shore hardness is 60-80, and the abrasion amount is 0.001-0.005 mg; and the relative density is 2.6-2.8, and the wear width is 3.4-3.5 mm / h.

Owner:苏州市德莱尔建材科技有限公司

Nickel-aluminum bronze alloy and preparation method thereof

The invention discloses a nickel-aluminum bronze alloy. The nickel-aluminum bronze alloy comprises the following chemical elements in percentage by mass: 9.5-11.5% of Al, 3.0-4.5% of Fe, 3.5-4.5% of Ni, 3-4% of Mn and the balance of Cu. The invention further provides a preparation process of the nickel-aluminum bronze alloy. The preparation process comprises the following steps: according to the mass percent of all chemical elements and by taking burning loss quantity into consideration, preparing raw materials; putting the raw materials into a furnace for melting and cooling molten raw materials into an ingot; heating the ingot to 950-980 DEG C from room temperature at the speed of 8-10 DEG C / min; keeping heat for 2 h above; taking out a sample and putting the sample into water for quenching; heating to 300-450 DEG C at the speed of 8-10 DEG C / min; keeping heat for 1-3 h; and putting the sample in air for cooling, so as to obtain the nickel-aluminum bronze alloy. The nickel-aluminum bronze alloy provided by the invention is high in hardness and wear resistance, the dry friction coefficient of the nickel-aluminum bronze alloy is about 0.25, microhardness can reach 460 HV and the nickel-aluminum bronze alloy has a wide application prospect in the fields of marine propellers, large-sized pump blades, fasteners, seawater pipe fittings, welding, explosion-proof equipment and sea water desalination.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

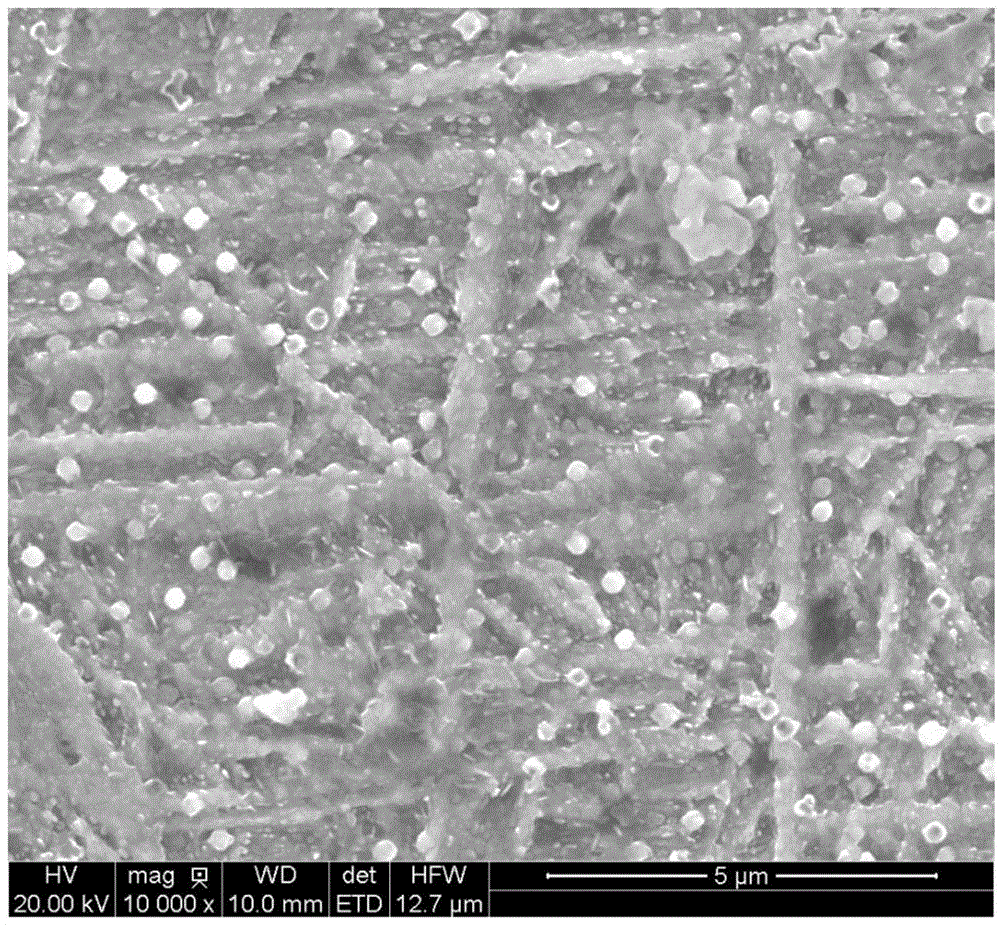

Electron beam welding method for dissimilar materials of nickel-aluminum bronze alloy and TC4 titanium alloy

InactiveCN101920391AHigh tensile strengthGood metallurgical bondElectron beam welding apparatusWelding defectTitanium alloy

The invention discloses an electron beam welding method for dissimilar materials of a nickel-aluminum bronze alloy and a TC4 titanium alloy, belongs to the field of dissimilar material fusion welding, and aims to solve the problem that an intermetallic compound layered structure is easily produced in the electron beam welding of the dissimilar materials of the nickel-aluminum bronze alloy and the TC4 titanium alloy. Different from the conventional welding method, the electron beam welding method is performed on the abutting surfaces of the TC4 titanium alloy and the nickel-aluminum bronze alloy respectively by deviating a certain distance to a nickel-aluminum bronze alloy side by using a superposition welding method. On the one hand, excellent metallurgical bonding can be formed on the welding line of the TC4 titanium alloy and the nickel-aluminum bronze alloy, and a joint does not have any welding defects, such as pores, cracks and the like; and on the other hand, the intermetallic compound layered structure formed by the welding line and the nickel-aluminum bronze alloy side can be weakened or eliminated, and continuously distributed weld microstructures can be obtained, so that the tensile strength of the joint can be improved to over 70 percent of that of the mother metal of the nickel-aluminum bronze alloy. The welding method in the invention is suitable for welding the conventional plate-like and tubular mother metals.

Owner:HARBIN INST OF TECH

Corrosion resistant multi-aluminum bronze material for pipe

The invention provides a pipe corrosion-resistant multielement aluminium bronze alloy material and the ingredients are as follows: 4.0 to 10.0wt percent of Al, 1.0 to 4.5wt percent of Fe, 1.0 to 4.5wt percent of Mn, 0.8 to 4.0wt percent of Ni, 0.05 to 0.5wt percent of Cr and the balance of Cu and unavoidable impurities; in casting state, the tensile strength is more than 385MPa, the yield strength is more than 180MPa, the yield ratio is more than 0.48, and the specific elongation is more than 27 percent; in annealing state, the tensile strength is more than 525MPa, the yield strength is more than 285MPa, the yield ratio is more than 0.55, the specific elongation is more than 42 percent and the complete immersion uniform corrosion rate is 0.01 to 0.035mm / a; the copper alloy has excellent performance, is particularly suitable for the environment with high flow rate of seawater and is an ideal material for manufacturing sea water desalinating condenser equipment, shipping sea water condenser equipment and seashore power plant condensers.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Aluminium and bronze alloy and process for preparing same

The invention discloses an aluminium bronze alloy and its preparing process with the constituents (by weight percentage) of, Cu75-82%, Al 13-16%, Mn 0.8-2.5%, Fe2.5-5.0%, Co 0.2-2.0%, Ni 0.4-2.0%, Zn 0.4-1.2%, Re 0.2-2.5%, impurity <=1.0%. The preparation comprises dispensing, melting, pre-refining in inert gas, thermal insulating, deoxidizing, charging covering agent, heat preserving and casting.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

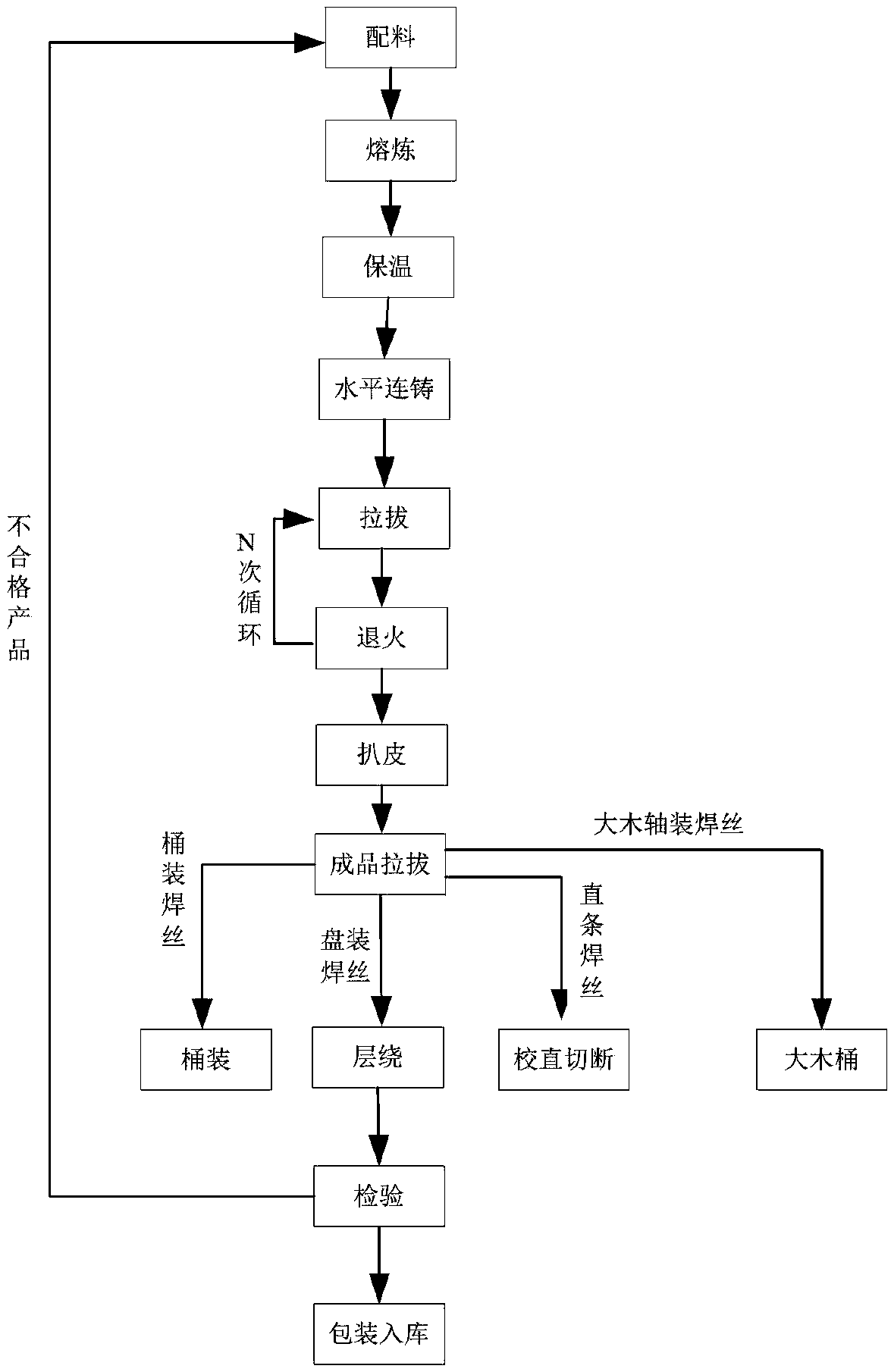

Formula and production technology of complex manganese aluminum bronze welding wire

ActiveCN109514128AEasy to operateMany stepsWelding/cutting media/materialsSoldering mediaMaterials preparationHydraulic cylinder

The invention discloses a formula and a production technology of a complex manganese aluminum bronze welding wire. The formula of the complex manganese aluminum bronze welding wire is that the complexmanganese aluminum bronze welding wire comprises the following components: 8% to 10% of Mn, 6.5% to 8.5% of Al, 1.2% to 3.0% of Fe, 1.5% to 3.0% of Ni and 0.03% to 0.1% of Si, and the balance being Cu. The production technology of the complex manganese aluminum bronze welding wire comprises the steps of material preparation; smelting; heat preservation; horizontal continuous casting; drawing andannealing; peeling and product drawing; winding (or barreling, straightening cutting, large wood shaft winding); inspection; and packaging storage. According to the formula and the production technology, Mn, Al, Fe, Ni and Si are added, impact resistance, strength, hardness, thermal stability and corrosion resistance are improved, and roundness and flatness of weld seams are improved; and operation steps of the production technology are simple and convenient, the steps are complete, and quality of the produced welding wire is high; and the welding wire is used for a hydraulic cylinder of a hydraulic bracket in mining machinery, and the service life is 4 times or above longer than the original service life.

Owner:新利得(天津)焊接材料有限公司

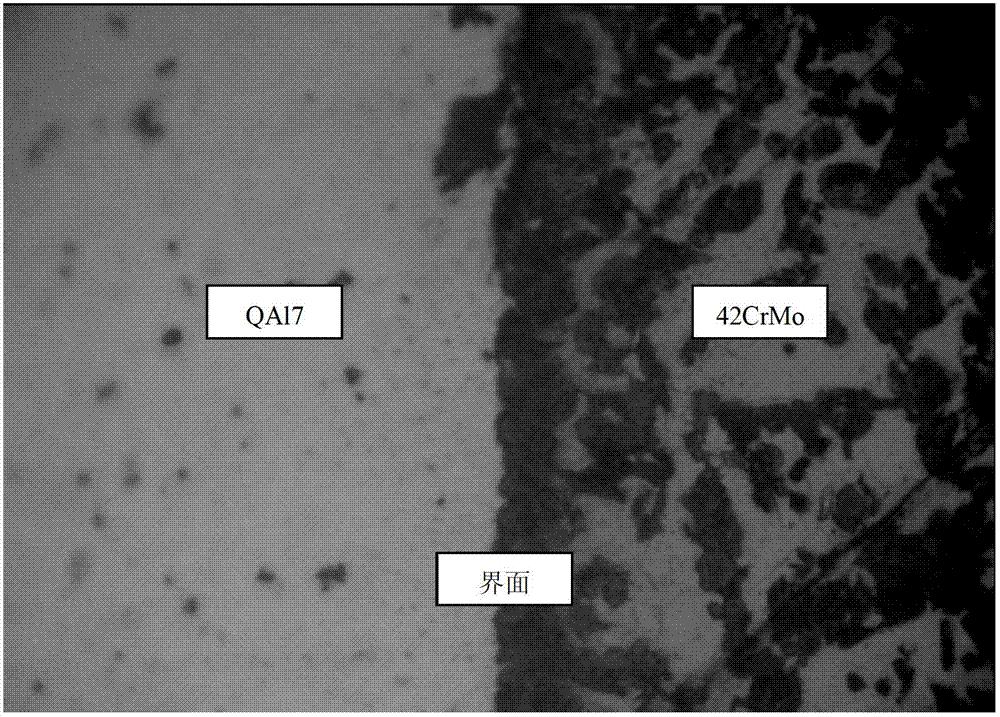

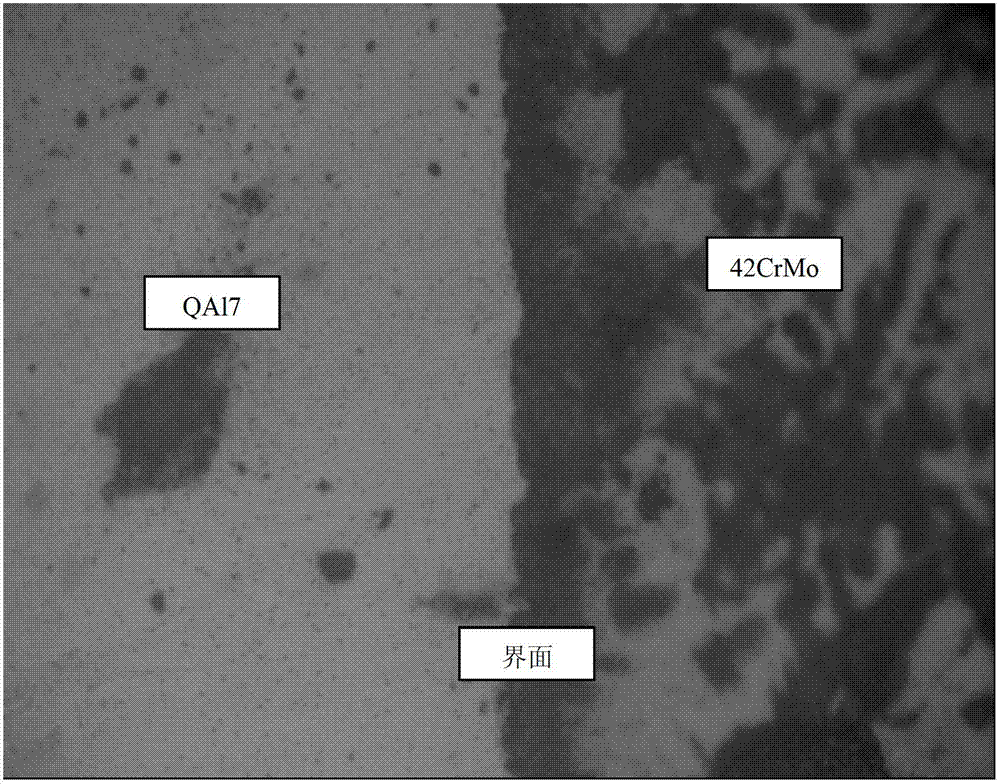

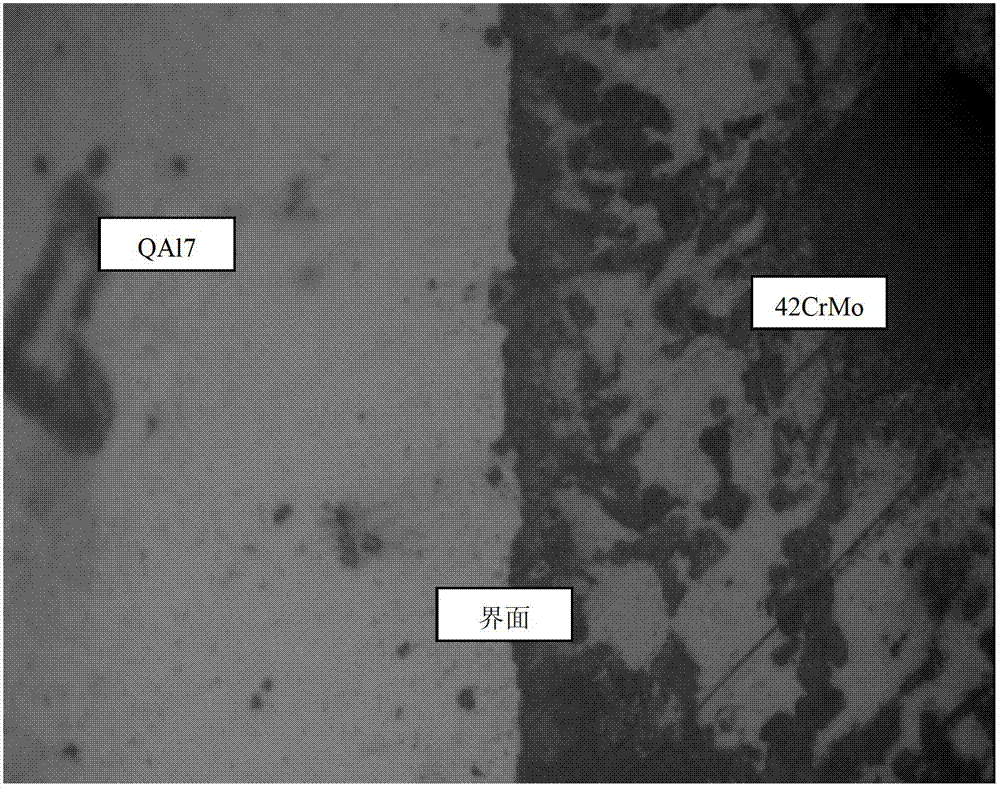

Steel-aluminum bronze bimetal material compounding method

InactiveCN102773253AAvoid interface binding performance impactImprove the bonding strength of the interfaceHot-dipping/immersion processesMetal rolling arrangementsMetallic materialsStress relief

The invention provides a compounding method of a steel-aluminum bronze bimetal plate. The method comprises the following steps of: annealing for lowering the strength of steel and aluminum bronze respectively to increase the plastic deformation capability; thermally dipping a layer of pure aluminum on a steel surface at a temperature which does not surpass a eutectoid transformation temperature; compounding aluminum-plated steel with aluminum bronze by performing cold rolling at one time at a large deformation amount; performing liquid phase diffusion annealing in a temperature range which is higher than the melting point of aluminum and lower than steel eutectoid transformation temperature; performing warm rolling immediately after diffusion annealing; finely rolling to a required size of a finished product, and flattening a plate surface; and performing stress relief annealing at last. Due to the adoption of the compounding method, the adverse effect of residual of a pure aluminum layer on an interface can be avoided, and the interface bonding performance of a steel-aluminum bronze bimetal material is improved greatly.

Owner:CHANGZHOU UNIV +1

Material for aluminumbronze surface laser cladding and laser cladding method

InactiveCN101255522AImprove performanceImprove mechanical propertiesMetallic material coating processesSquare MillimeterAlloy

The invention relates to a material for laser cladding of an albronze surface and a laser cladding method. The material is composed of 25% to 35% by weight of Cu, 11.5% to 14.5% by weight of Cr, 2.0% to 3.0% by weight of Zr, 2.5% to 3.5% by weight of B, 2.5% to 3.0% by weight of Si, 5.5% to 6.5% by weight of Fe, and the balance Ni, the above materials are 100 to 300 mesh powder; the method comprises the following steps: preparing the materials in the above proportions, uniformly mixing the prepared materials, weighting the alloy powder in 0.02g to 0.08g per square millimeter according to the area of the laser cladding, presetting the alloy powder on the albronze surface by acrylics, compacting after vacuum drying (40 DEG C to 70 DEG C), scanning the preset layer by gradually reducing laser power with a speed of 6 to 8 millimeters per second and a spot diameter of 4 millimeters.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Aluminium bronze continuously-cast tube with both high strength and high ductility, and production method thereof

The invention discloses an aluminium bronze continuously-cast tube with both high strength and high ductility, and a production method thereof. The product is composed of the following constituents in percentage by weight: 10-11.5% of aluminium, 3-5% of iron, not less than 1.5% of nickel, not less than 0.5% of manganese and the balance of copper; a rough horizontal contact casting procedure is used. The product disclosed by the invention has the characteristics of being excellent in comprehensive performance and low in machining cost. By virtue of adopting the continuous production mode, the production method is capable of producing the continuously-cast tube with any length, and suitable for the application field of modern numerical-control equipment high-speed work with high requirements on the straightness and lengths of tubes.

Owner:海门市江滨永久铜管有限公司

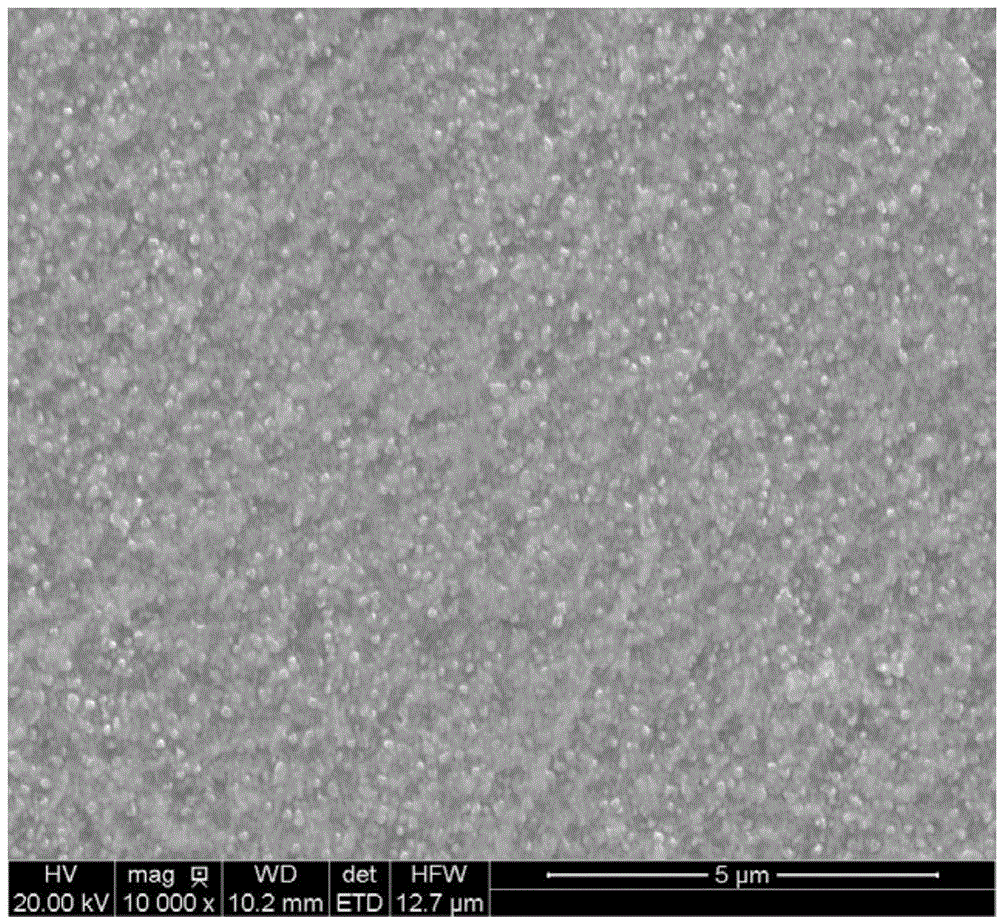

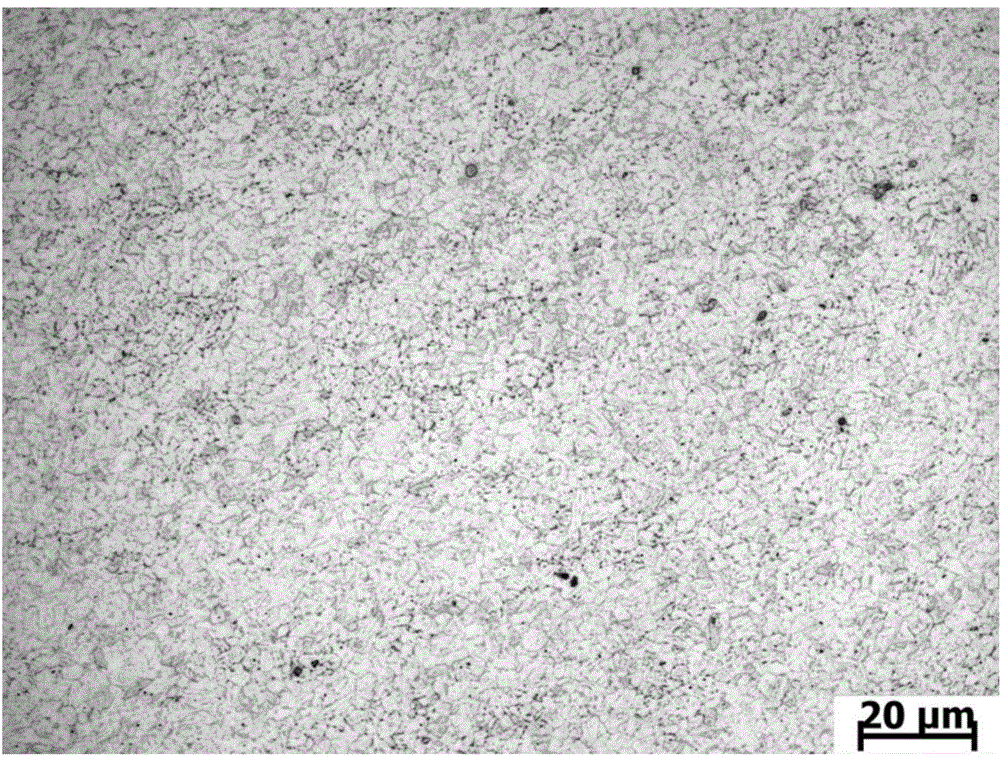

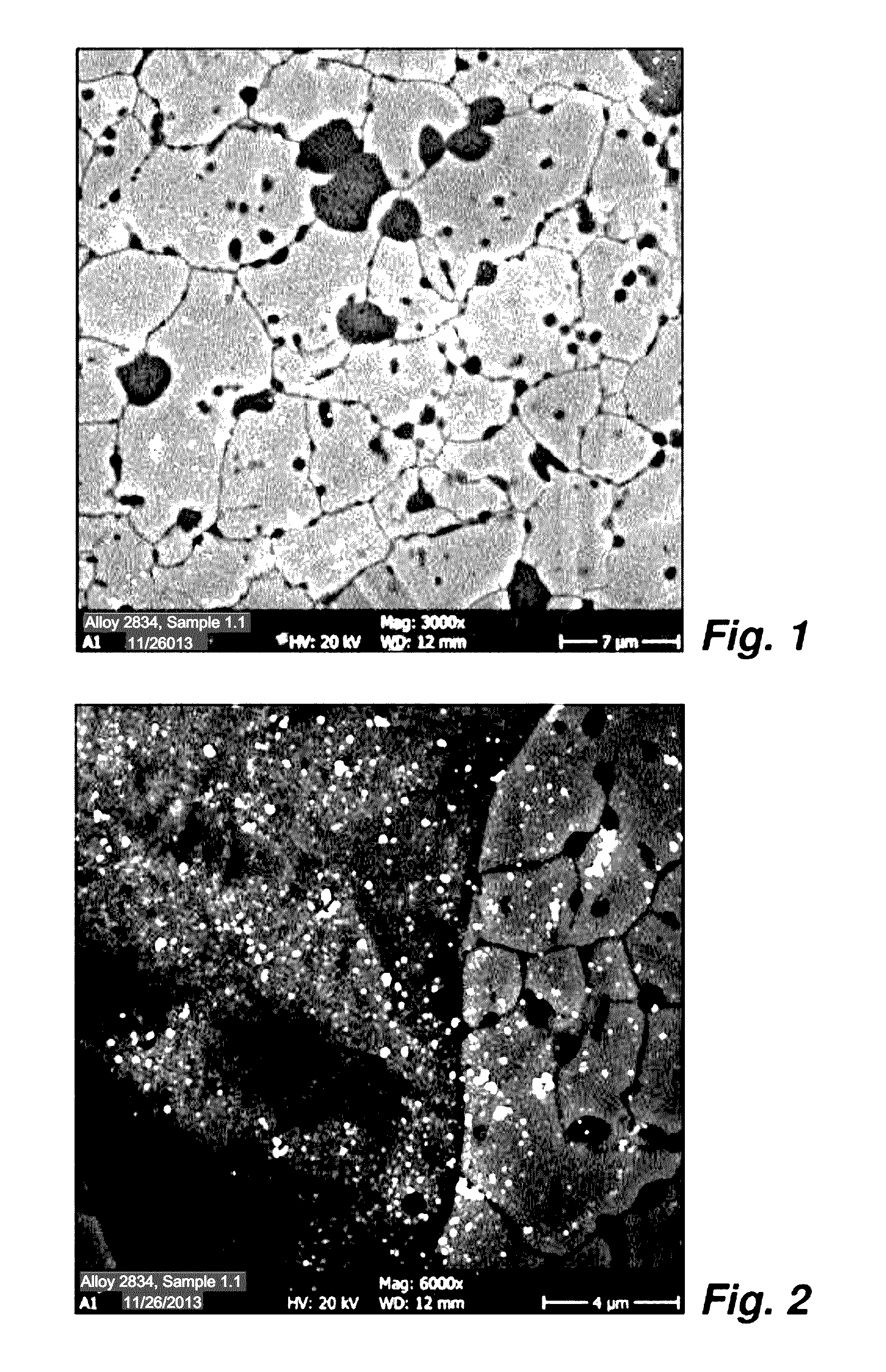

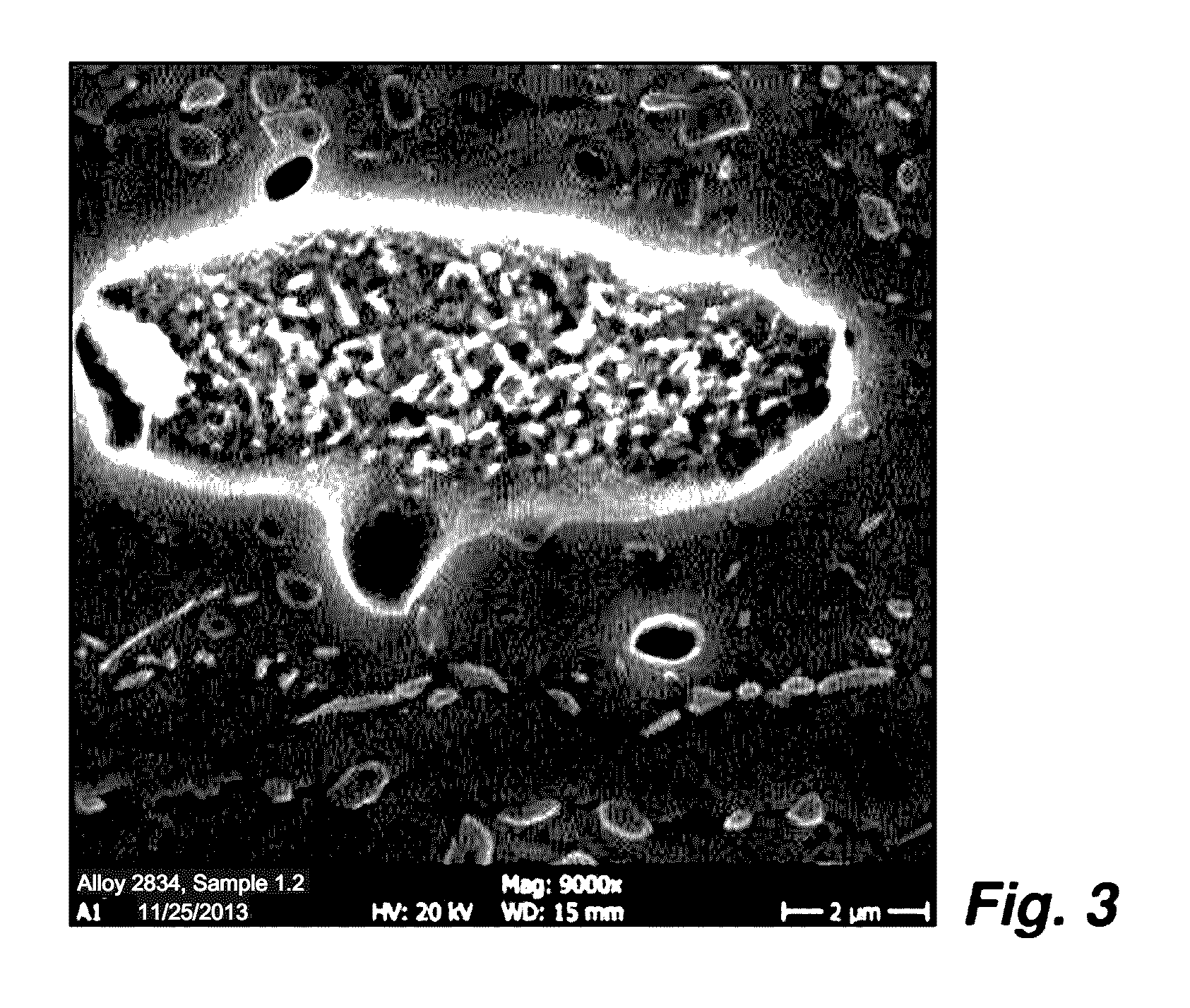

Preparation method of nickel-aluminum bronze

The invention discloses a preparation method of nickel-aluminum bronze. The preparation method comprises the following steps: smelting a pure copper plate, a copper aluminum alloy, a nickel plate, an iron plate and manganese powder in vacuum for 30-60 minutes at 1200-1300 DEG C, performing anti-vacuum casting to obtain cast ingot, and removing the oxides on the surface of the cast ingot; stirring and rubbing the surface of the surface oxide-removed cast ingot; and annealing for 2-6 hours at 500-675 DEG C and then performing air cooling. Compared with the prior art, the comprehensive performance of the nickel-aluminum bronze prepared by a process of combining vacuum smelting anti-vacuum casting, stirring and rubbing processing and thermal treatment is obviously improved; compared with the nickel-aluminum bronze prepared in an anti-vacuum mode, the nickel-aluminum bronze disclosed by the invention is relatively fine and uniform in tissue and obviously improved in strength and corrosion resistance.

Owner:SHANGHAI JIAO TONG UNIV

Layer-by-layer analysis method for surface layer of copper alloy material

ActiveCN102539517ARealize Layer-by-Layer AnalysisLayer-to-layer resolution improvementMaterial analysis by electric/magnetic meansMass spectrometrySpectrometer

The invention provides a layer-by-layer analysis method for a surface layer of a copper alloy material, comprising the steps of: selecting a glow discharge ion source and a mass spectrum analysis condition to carry out sample treatment and sample analysis; peeling an analyzed sample by utilizing the glow discharge ion source under the action of cathode sputtering; recording a continuous change signal of analyzed sample mass spectrum peak strength along with the time in a high-sensitivity mass spectrometer system in real time; and converting the continuous change signal into change of the chemical composition of the sample along with the depth by using a composition and depth double-calibration method so as to finish the layer-by-layer quantified analysis of the surface layer of an aluminum bronze membrane sample on a brass base material. In the invention, proper analysis parameters such as argon pressure, discharge voltage, sample sputtering spot surface diameter, sample measurement time and the like are selected to improve interlayer resolution to be thousands of nanometers, so that the ultrathin layer-by-layer analysis of the surface layer of bronze on the brass base material is realized.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

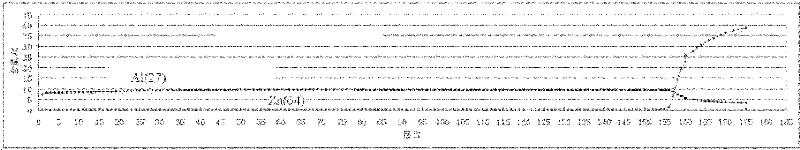

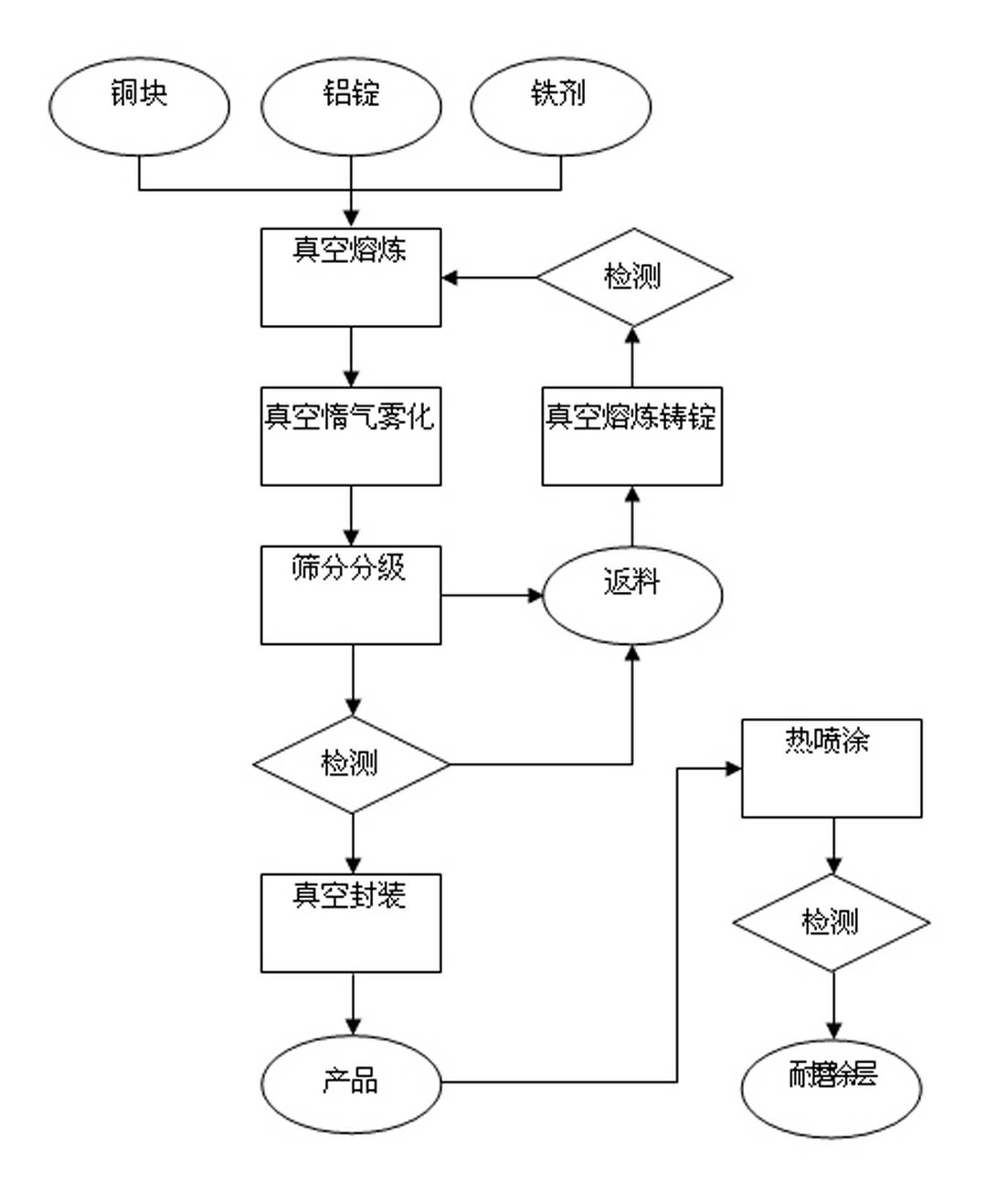

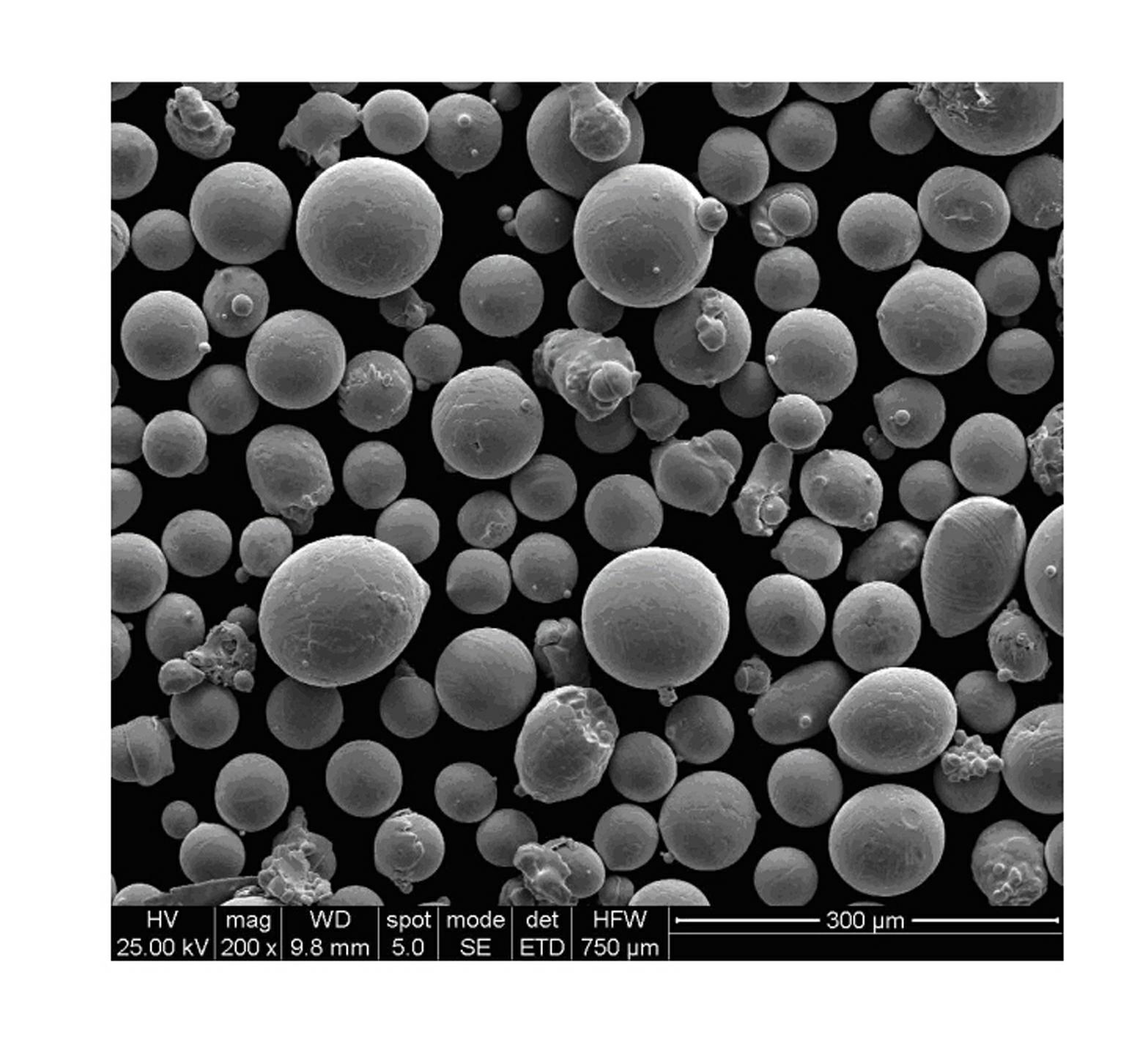

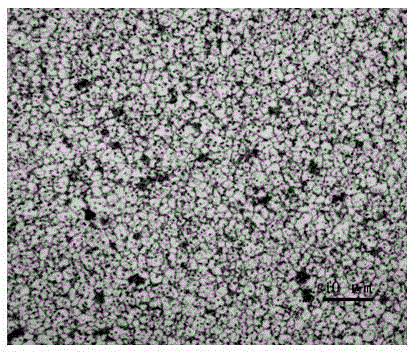

Low-oxygen-content and high-yield spherical aluminum bronze alloy powder for thermal spraying and preparation method thereof

The invention relates to a low-oxygen-content and high-yield spherical aluminum bronze alloy powder for thermal spraying and a preparation method thereof. A vacuum melting-inert gas atomization method is used for preparing the aluminum bronze alloy powder. The aluminum bronze alloy powder comprises the following components: 1-20wt% of aluminum, 0-5wt% of iron, less than or equal to 120ppm of oxygen and the balance of copper. The granularity is 25-124mu m, the main body is in the range of 25-45mu m, and the one-time powder yield in the range of 25-124mu m is greater than or equal to 75%. A soft support wear-resistant coating prepared by adopting the powder has the characteristics that the hardness HR15T is greater than or equal to 89, the bonding strength is greater than or equal to 35MPa, the oxide content is 0.8-1.5wt%, and the porosity is 8-11%. The invention solves the technical problems of poor powder sphericity, low one-time powder yield, unqualified oxide content and hardness in the coating and the like. The powder can be used as a raw material for preparing a soft wear-resistant coating material and a copper-aluminum / nickel-graphite sealing coating material. Compared with the traditional aluminum bronze alloy powder, the powder provided by the invention has the advantages that the thermal spraying process adaptability of the powder and the performance of the coating are better, and the oxide content is lower.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

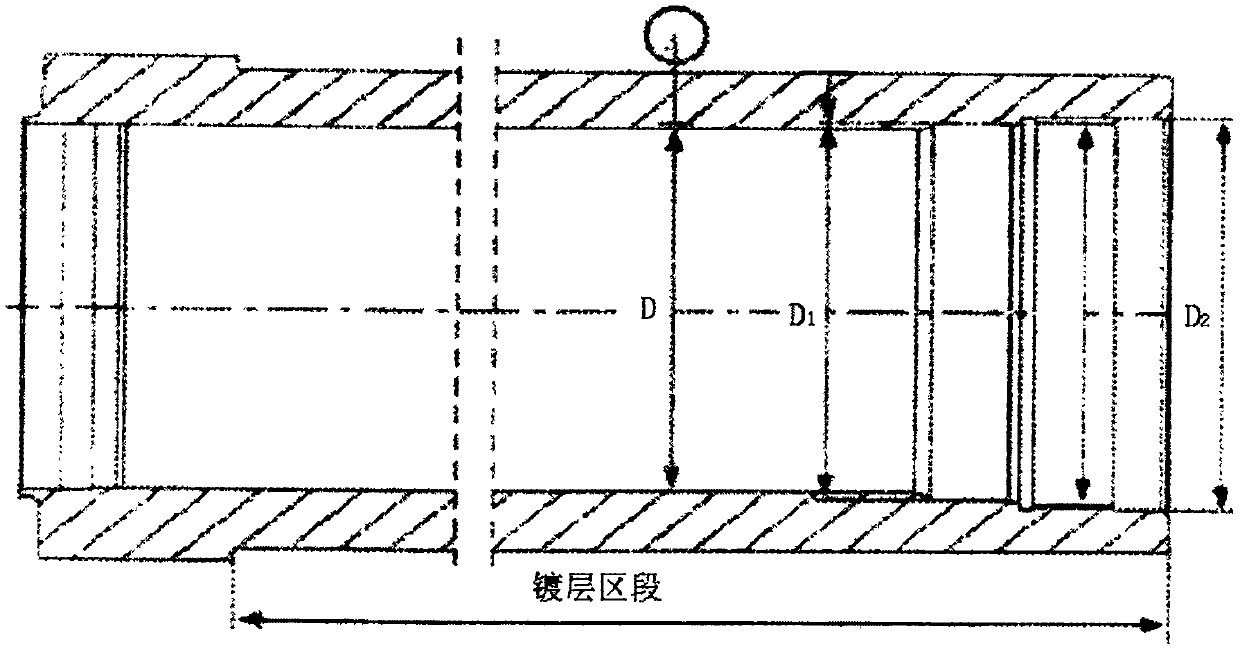

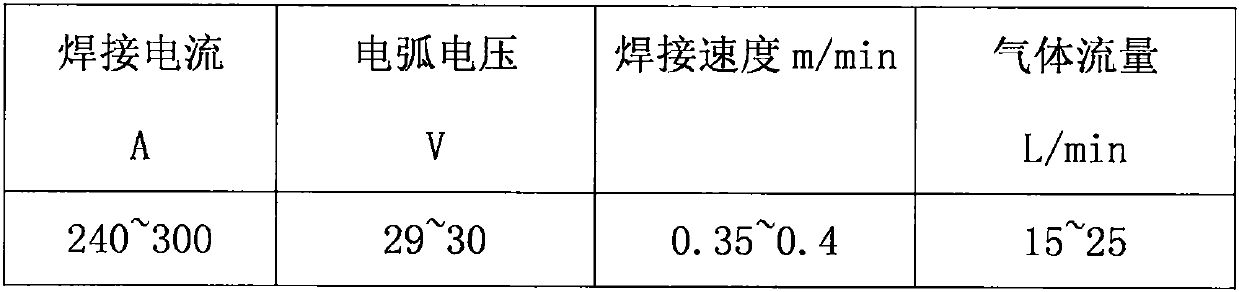

Technology of carrying out surfacing of aluminum bronze on inner surface of coal mine hydraulic bracket 27SiMn oil cylinder

InactiveCN111318785ARestore usabilityAchieve remanufacturingArc welding apparatusCoalMaterials science

The invention relates to the technical field of welding and discloses a technology of carrying out surfacing of aluminum bronze on the inner surface of a coal mine hydraulic bracket 27SiMn oil cylinder. The technology comprises the following steps: 1, evaluating the condition of the inner surface of the coal mine hydraulic bracket 27SiMn oil cylinder; 2, removing an accessory, rust and dirt; 3, boring the corrosion layer on the inner surface of the oil cylinder; and 4, adopting a HK 200 aluminium bronze welding wire with the diameter being 1-1.5 mm as the welding material, and adopting inert gas arc welding to weld the inner surface, except a thread, of the oil cylinder through a hot wire nonmelt electrode. With adoption of the technical scheme, the technology has the following benefits: the scrapped or to-be-scrapped hydraulic bracket 27SiMn oil cylinder is recycled, the original using performance of the oil cylinder is recovered through the technology, so that remanufacturing of theoil cylinder is reached; and the welding quality is stable, the technology completely replaces the electroplating technology to realize the remanufacturing effect, so that the production cost is greatly reduced, the production efficiency is improved and the service life of the oil cylinder is greatly prolonged.

Owner:TIANJIN YINGYUAN WELDING TECH +1

Powder for laser-cladding aluminum bronze alloy gradient coating layer and preparation method

ActiveCN108315733AImprove mechanical propertiesHigh environmental resistanceMetallic material coating processesManganeseMechanical equipment

The invention relates to a powder for a laser-cladding aluminum bronze alloy gradient coating layer and a preparation technology method. The alloy powder is prepared from nine elements, such as Al (aluminum), Cu (copper), Fe (iron), Ni (nickel), Mn (manganese), Si (silicon), Cr (cobalt), B (boron) and Mo (molybdenum),wherein the amount of Al element is 6 to 7%; the amount of Fe element is equal tothe amount of Ni element; the total amount of Fe element and Ni element is 1 to 12wt%; the total amount of Mn element, Si element, Cr element, B element and Mo element is 0.5 to 2wt%; the balance element is Cu. The novel aluminum bronze alloy gradient coating layer prepared by a laser cladding technique has the advantages that the hardness is high, the corrosion-resistant property, abrasion-resistant property and high temperature oxidizing-resistance property are excellent, and the like; the novel aluminum bronze alloy gradient coating layer can be widely applied to the repair and re-manufacturing of mechanical equipment in the fields of metallurgy, power, ocean transportation and the like, and the obvious economic benefits and social benefits are realized.

Owner:SHENYANG POLYTECHNIC UNIV

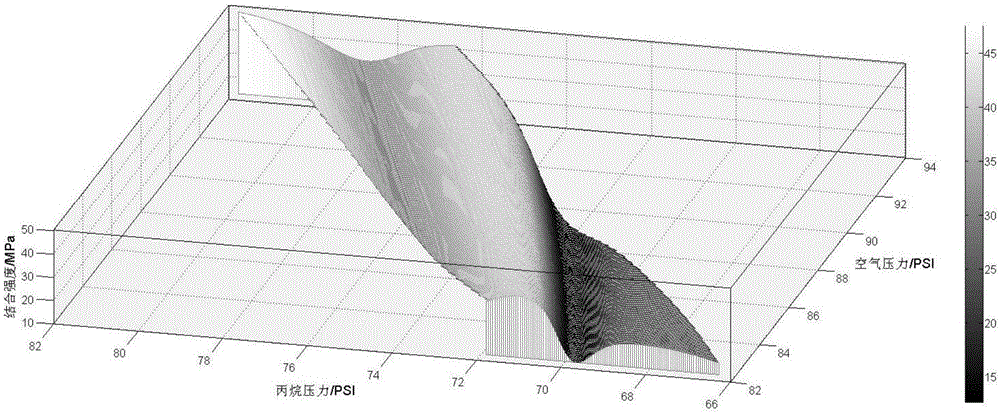

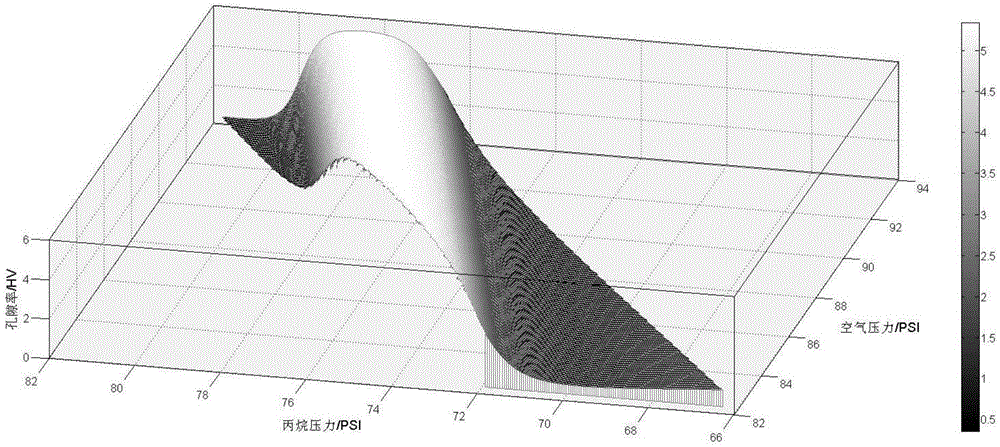

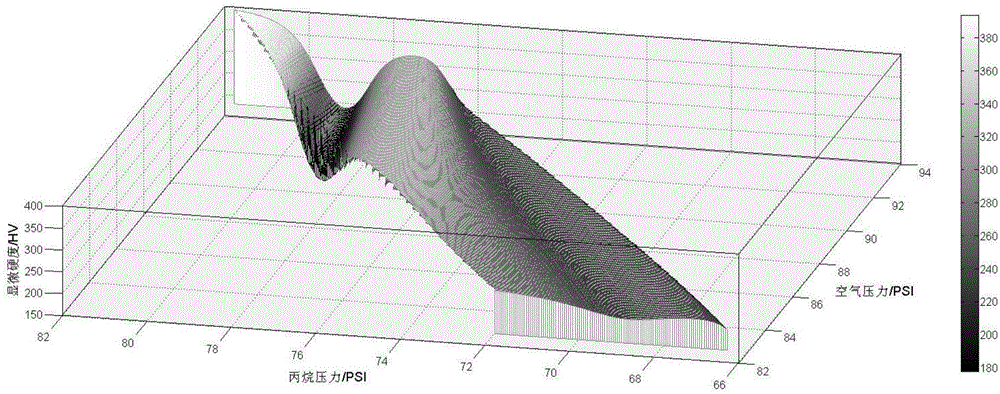

Establishment method for high aluminum bronze coating property forecasting model and optimization method for single property indicator of high aluminum bronze coating

ActiveCN105117599AImprove research efficiencySimplify the formulation processSpecial data processing applicationsTest sampleGenetics algorithms

The present invention discloses an establishment method for a high aluminum bronze coating property forecasting model and an optimization method for a single property indicator of a high aluminum bronze coating. The establishment method for the forecasting model comprises: establishing a training sample and a testing sample; constructing a BP neural network model; optimizing a weight and a threshold of the BP neural network by using the training sample and by using a genetic algorithm; and testing, by using the testing sample, the BP neural network model optimized by using the genetic algorithm, to obtain the high aluminum bronze coating property forecasting model. The optimization method is to perform extremum optimization on a single property indicator of a high aluminum bronze coating by using the forecasting model and the genetic algorithm. The high aluminum bronze coating property forecasting model established by the method provided by the present invention is high in forecasting accuracy, and implementing the high aluminum bronze coating property forecasting model greatly improves efficiency in researching a high aluminum bronze coating and making research and development of the high aluminum bronze coating become more directional and forward.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Aluminium Bronze Alloy, Method for the Production Thereof and Product Made from Aluminium Bronze

An aluminum bronze alloy containing 7.0-10.0% by weight Al; 3.0-6.0% by weight Fe; 3.0-5.0% by weight Zn; 3.0-5.0% by weight Ni; 0.5-1.5% by weight Sn; ≦0.2% by weight Si; ≦0.1% by weight Pb; and the remainder Cu in addition to unavoidable impurities. Also described is an aluminum bronze product having such an alloy composition, and a method for producing such a product from an aluminum bronze alloy.

Owner:OTTO FUCHS

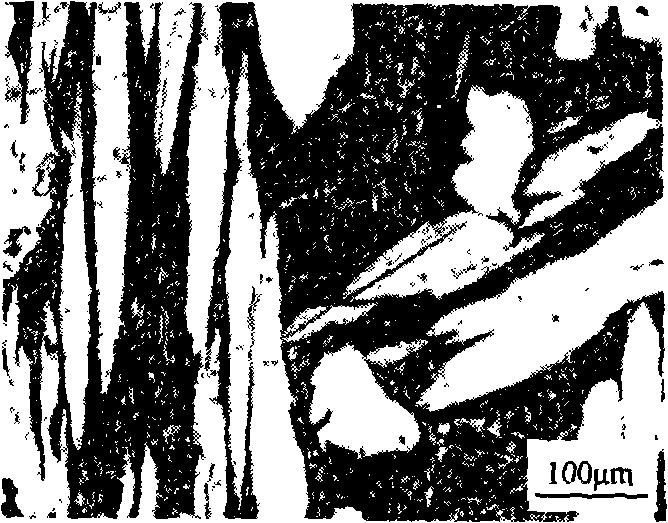

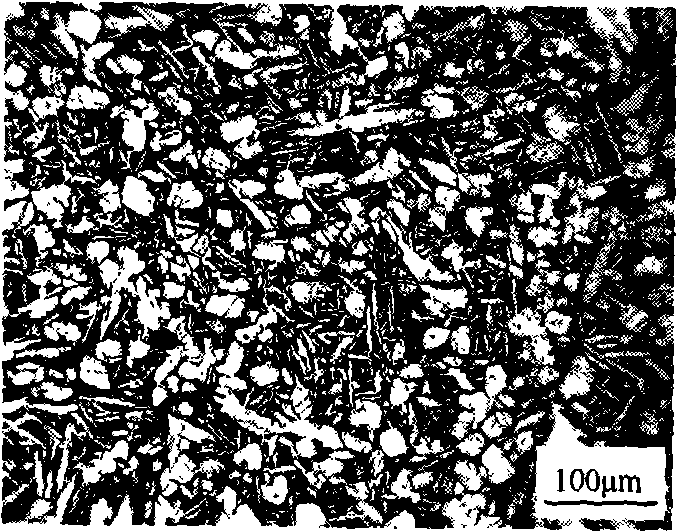

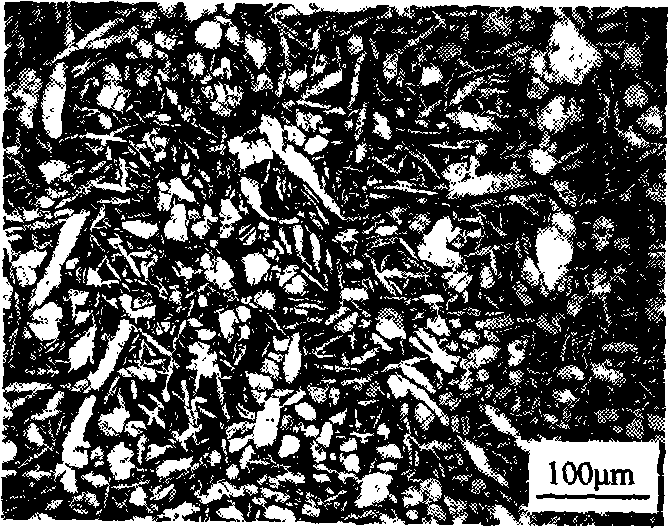

Grain refining method of aluminium bronze

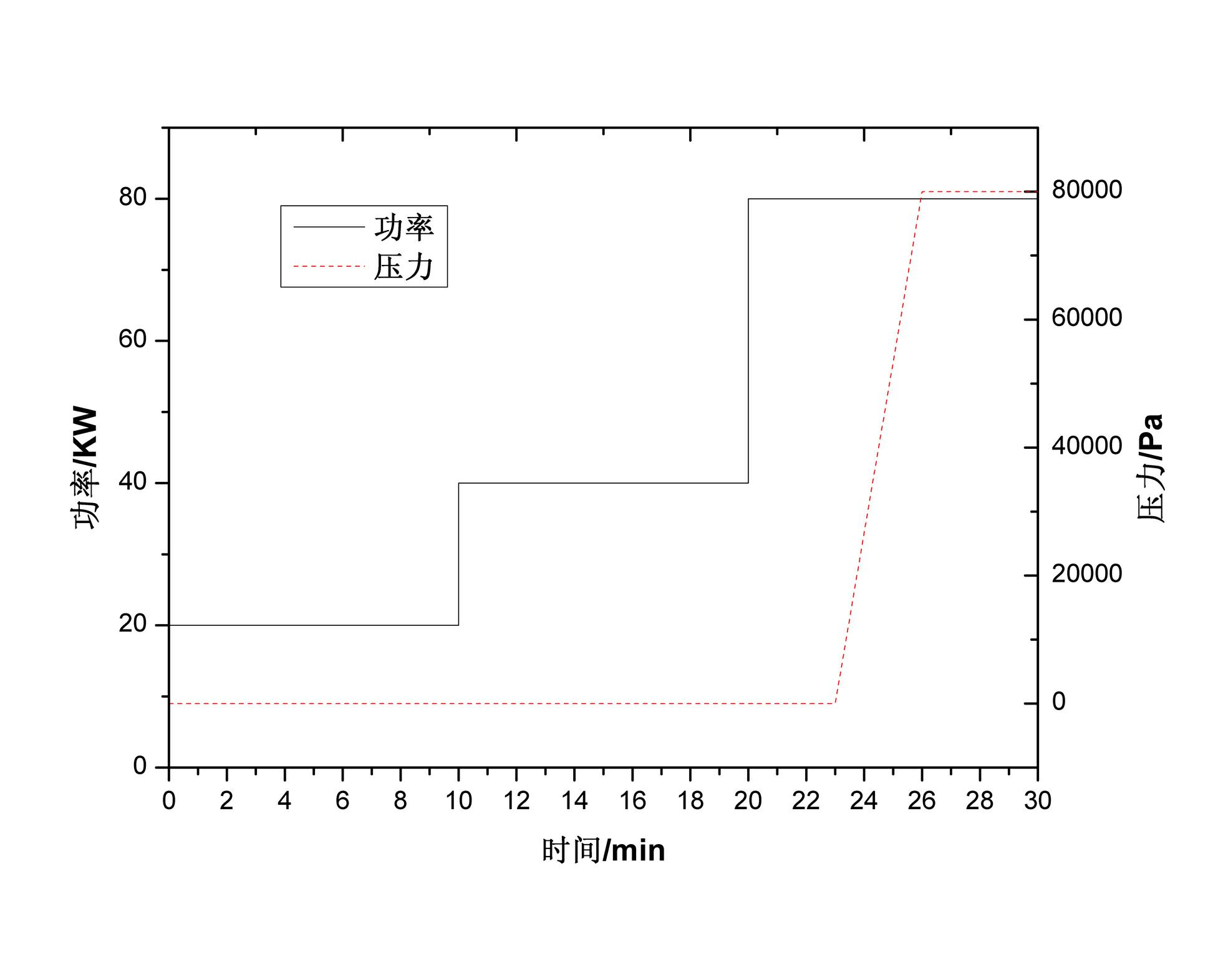

The invention discloses a method for thinning aluminium bronze crystal grains. The invention is characterized in that: the method comprises two parts of high pressure treatment and heat treatment, wherein, in the high pressure treatment, aluminium bronze is treated in a solid-state phase change region; the high pressure treatment comprises the following process parameters that: the pressure is between 1 and 6 GPa; the treatment temperature is between 700 and 900 DEG C and the heat preservation time is between 5 and 20 minutes; and the aluminium bronze is naturally cooled to the room temperature through power cutoff and pressure maintenance; in the heat treatment: the treatment temperature is between 600 and 750 DEG C; the heat preservation time is between 0.5 and 2 minutes; and the cooling speed is between 5 and 30 DEG C / min; and the aluminium bronze is cooled to the room temperature. The Al content in the aluminium bronze is between 10 and 15 weight percent. In the method, the aluminium bronze can acquire thinner and evener crystal grains by a combination of high pressure treatment and heat treatment, thereby achieving the perfect effect of crystal grain thinning.

Owner:YANSHAN UNIV

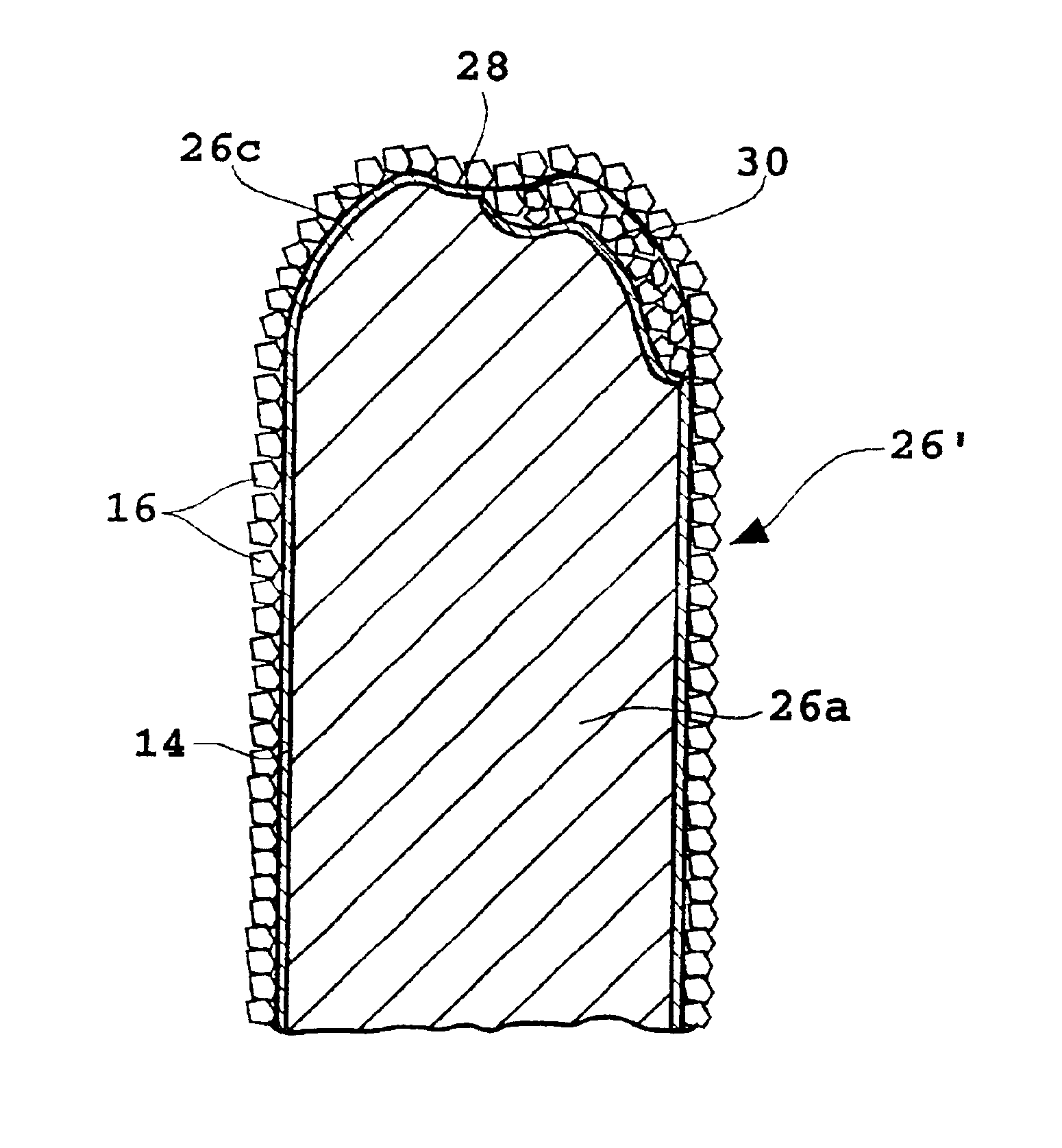

Metal bonded drilling and boring tool

InactiveUS6851418B2Stress concentrationImprove tool lifeLathesTransportation and packagingMetal bindingCopper alloy

A metal bonded drilling and boring tool which can prevent the separation of abrasive grains during drilling and boring to maintain a stable working performance for a long period of time without the need for tool exchange. The tool includes a rod-shaped body having a substantially semispherical front end portion and numerous abrasive grains bonded to an outer circumferential surface of the rod-shaped body at the front end portion and at a portion having a given length from the front end portion by a bond member formed primarily of copper alloy. The bond member contains a material selected from the group consisting of Ti, Al, and a mixture thereof. The copper alloy is selected from the group consisting of bronze containing 10 to 33 wt % of Sn, brass containing 5 to 20 wt % of Zn, and aluminum bronze containing 5 to 20 wt % of Al.

Owner:TENRYU SAW MFG

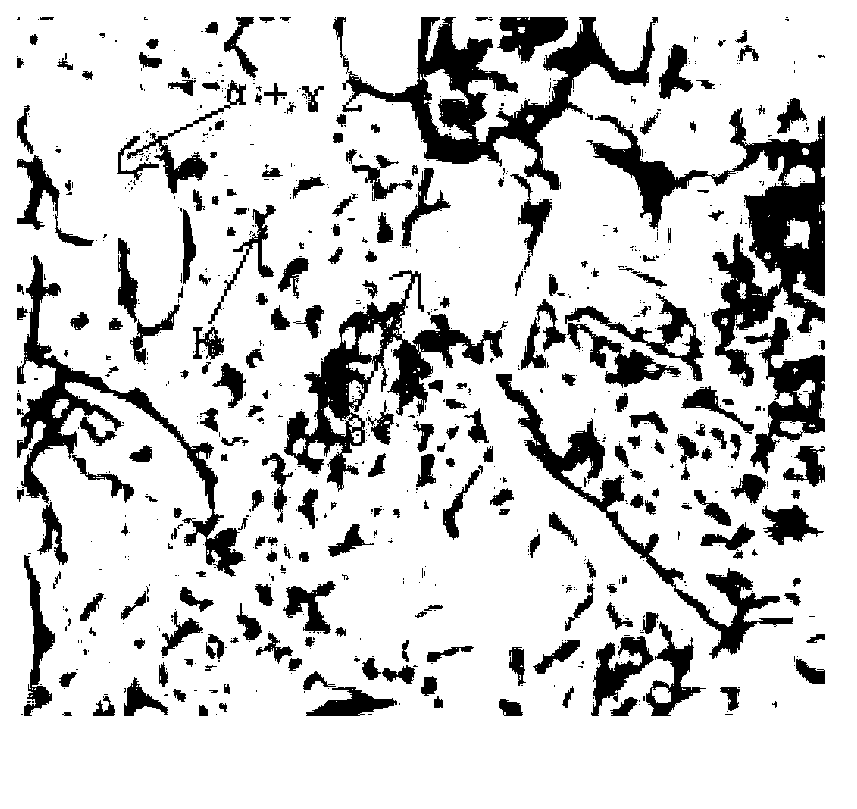

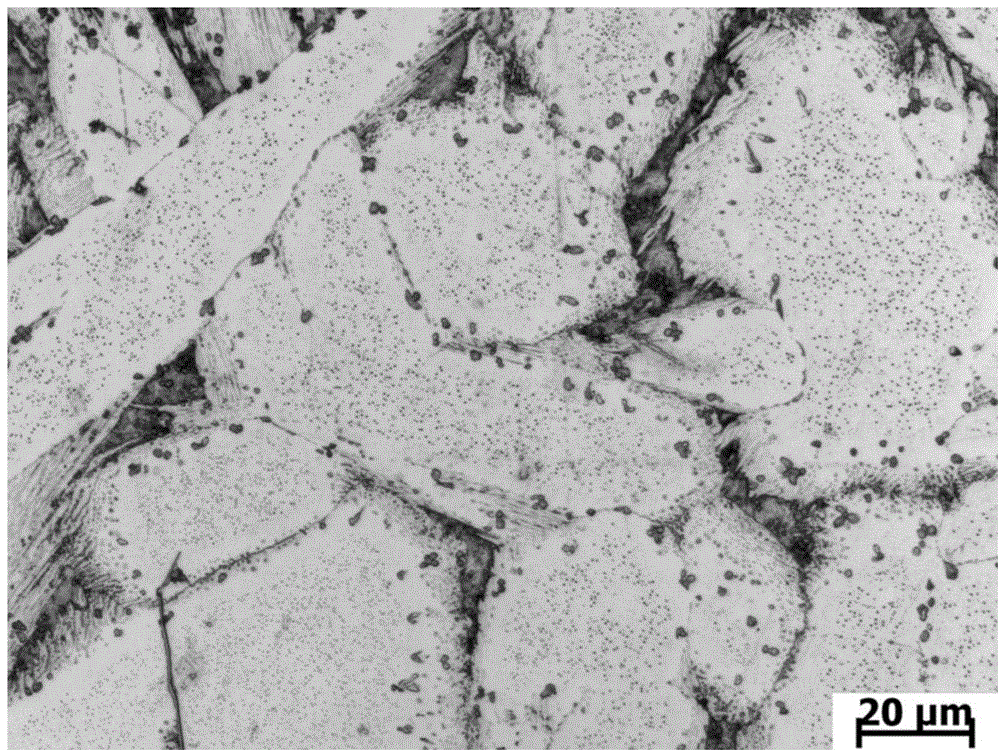

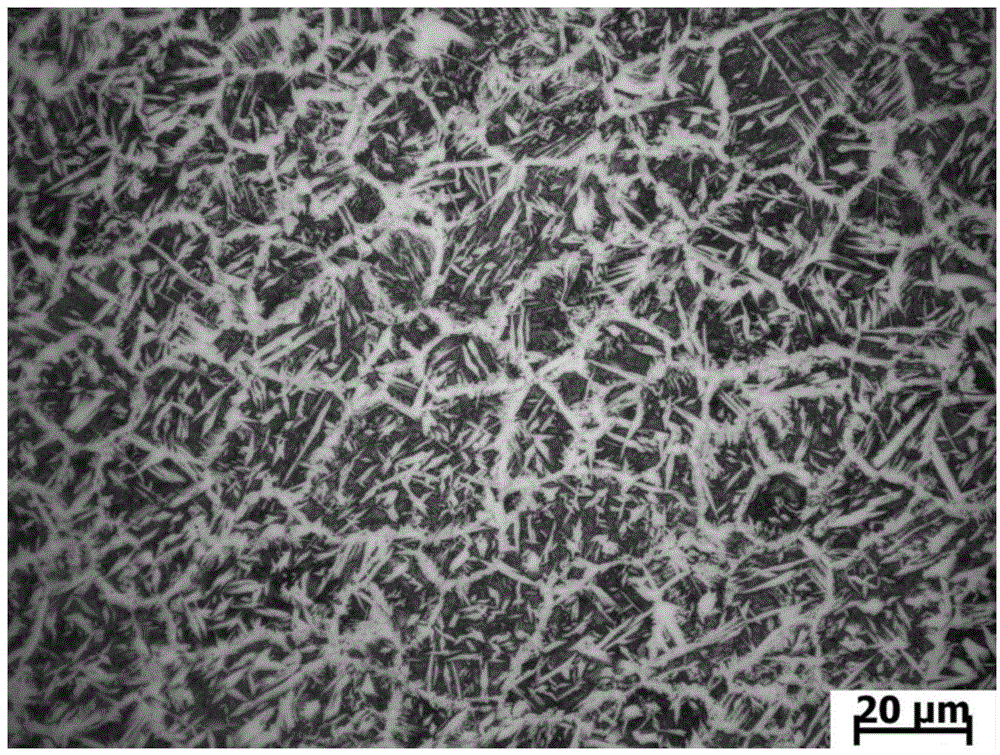

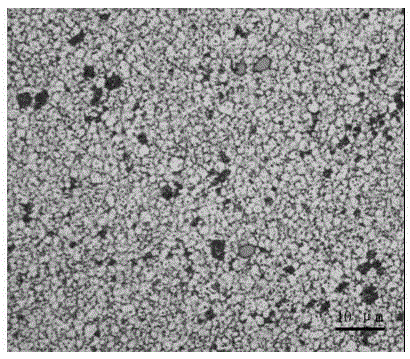

Metallographic erosion method of nickel-aluminum bronze crystal boundary

InactiveCN105352779AThe grain boundary is clear and completeNo heating requiredPreparing sample for investigationAlcoholGranularity

A metallographic erosion method of a nickel-aluminum bronze crystal boundary is provided. The method includes polishing the nickel-aluminum bronze by waterproof abrasive papers with granularity of 80, 280, 400, 600 and 800 in order, polishing the nickel-aluminum bronze by a lint and a 1 [mu]m diamond polishing slurry in order, adding nitric acid into hydrochloric acid, stirring the mixture uniformly, allowing the mixture to stand for 2 min to prepare a corrosive agent which has a preparation ratio according to every 30 ml hydrochloric acid in every 3-5 ml nitric acid, dipping the corrosive agent by an absorbent cotton clamped by a plastic tweezer, wiping the surface of the nickel-aluminum bronze for 5-15 s until the color of the surface of the nickel-aluminum bronze turns grey, washing the surface of the nickel-aluminum bronze by clear water, flushing the surface of the nickel-aluminum bronze by absolute ethyl alcohol, blow-drying the surface of the nickel-aluminum bronze by a electric hair drier, and putting the blow-dried nickel-aluminum bronze by the electric hair drier to a metallographic microscope to obtain a crystal boundary photograph of the nickel-aluminum bronze. The etching time is only 5-10 s, the crystal boundary not a K phase of the nickel-aluminum bronze can be preferentially etched, and the crystal boundary of the nickel-aluminum bronze is clear and intact.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

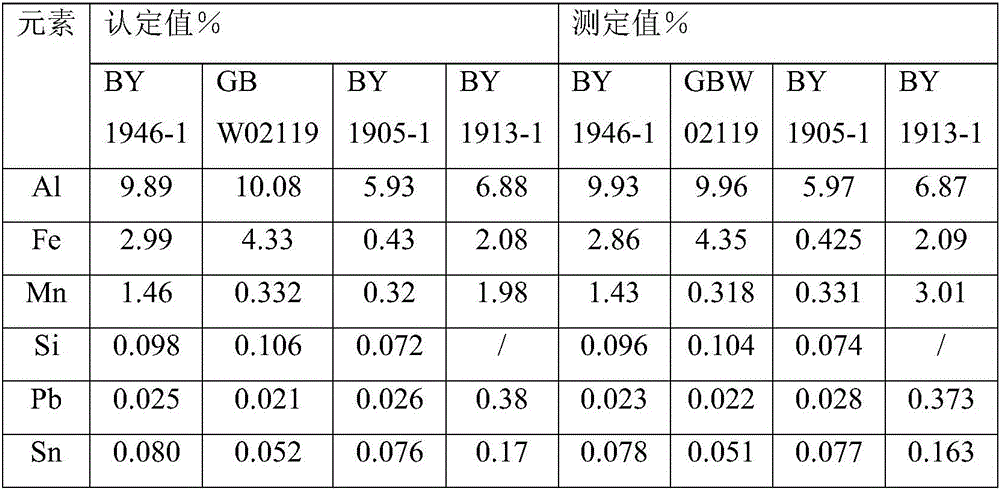

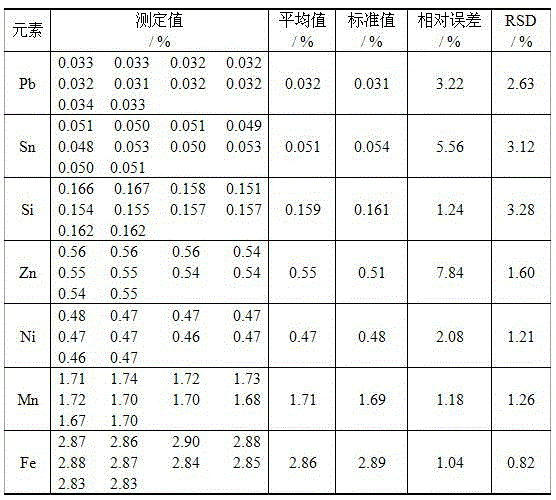

Method for measuring content of aluminum, iron, silicon, lead, tin and manganese in aluminum copper alloy simultaneously

InactiveCN106153605AEliminate distractionsImprove applicabilityAnalysis by thermal excitationManganeseInductively coupled plasma emission spectroscopy

The invention discloses a method for simultaneously determining the content of aluminum, iron, silicon, lead, tin and manganese in an aluminum-copper alloy. The steps are: making a sample of the aluminum-copper alloy to be tested and a blank sample of high-purity copper, dissolving the sample, cooling it to room temperature, and using Dilute with high-purity water to the mark, shake well and set aside, configure the standard calibration curve solution of each element, for the production of the standard curve, select the spectral lines of each element as the analysis line, introduce the standard calibration curve solution into the inductively coupled plasma emission spectrometer, and draw the calibration curve , introduce the sample to be tested and the blank sample into the inductively coupled plasma optical emission spectrometer, measure the signal intensity of the ion to be tested, and calculate the element content in the sample to be tested according to the calibration curve of each standard solution with known mass percentage. The invention has good application effect through multiple inspections of samples of aluminum bronze, aluminum brass and aluminum-copper alloy, adopts matrix matching to eliminate matrix interference, has the characteristics of wide linear range, high sensitivity, simple and convenient operation, and accurate and reliable analysis results.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

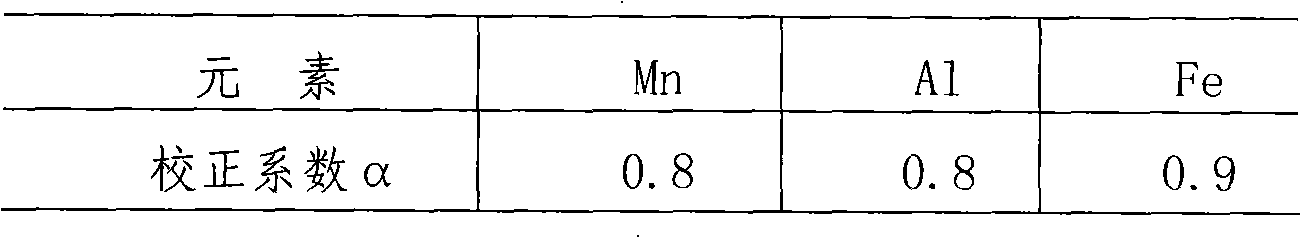

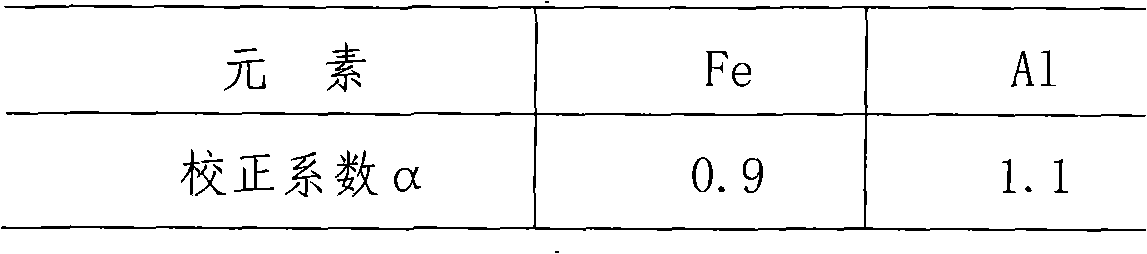

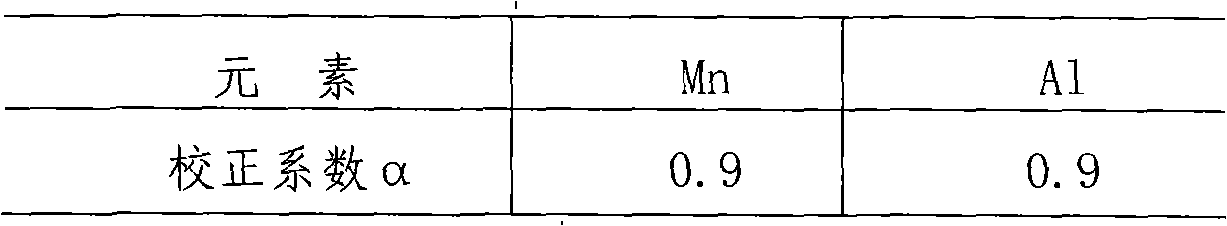

Aluminium bronze alloy composition rapid-measuring method

InactiveCN101644676AShort measurement timeImprove assay efficiencyAnalysis by material excitationSpectrometerAmount of substance

The invention belongs to the physical and chemical analysis testing technology and relates to an improvement of an aluminium bronze alloy composition rapid-measuring method; a PDA-5500II type vacuum direct-reading spectrometer is adopted to carry out measurement, the measuring steps are as follows: determining the working condition of instruments; determining standard substances; preparing samples; drawing standard curves; standardizing working curves; correcting and analyzing control samples; measuring the composition of samples to be measured. The invention has short measuring time and highmeasuring efficiency, and can carry out the measurement of various compositions at the same time.

Owner:HARBIN

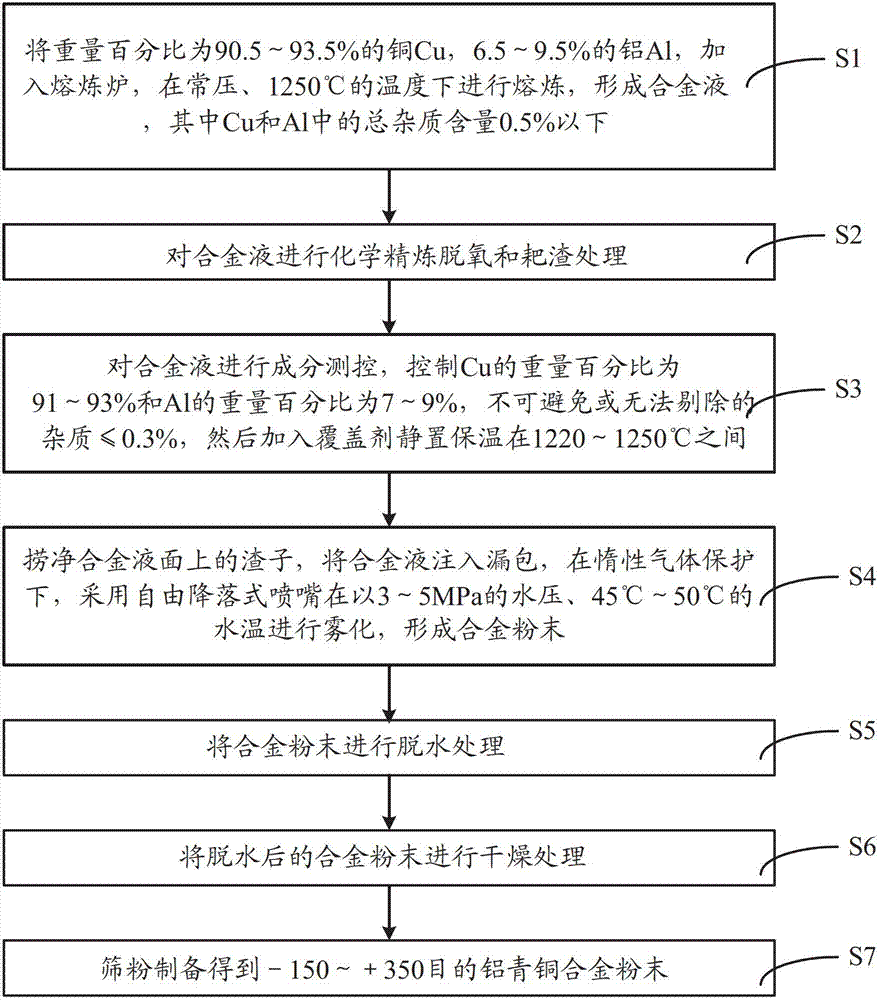

Method for preparing aluminum bronze powder by water atomization

An embodiment of the invention discloses a method for preparing aluminum bronze powder by water atomization. The method includes the steps: smelting 90.5-93.5% of Cu and 6.5-9.5% of Al to form alloy liquid under normal pressure at the temperature of 1250 DEG C; performing chemical refining deoxidation and slag raking; measuring and controlling components, adding covering agents into the alloy liquid and keeping the temperature at 1220-1250 DEG C in a standing manner; pouring the alloy liquid into a leakage ladle, atomizing the alloy liquid under the water pressure of 3-5MPa and at the water temperature of 45-50 DEG C by a free-fall nozzle under protection of inert gas to form alloy powder; dewatering and drying the alloy powder; and screening the alloy powder to obtain the aluminum bronze alloy powder with -150-+350 meshes. The aluminum bronze powder prepared by the method can serve as an anti-friction coating material in an engine sliding bearing, and environmental pollution caused by leaded anti-friction coating material is avoided.

Owner:PUJIANG HUIKAI POWDER TECH

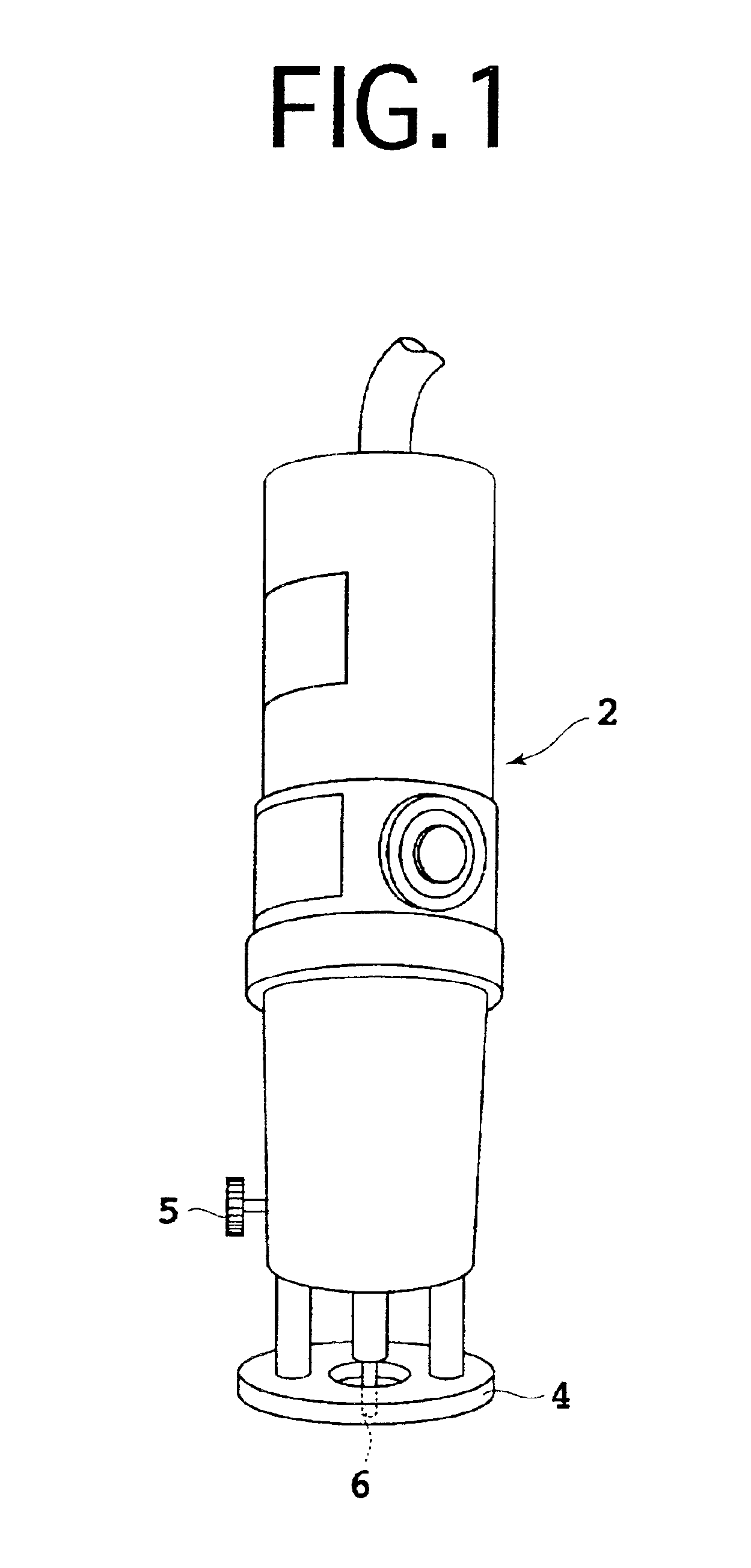

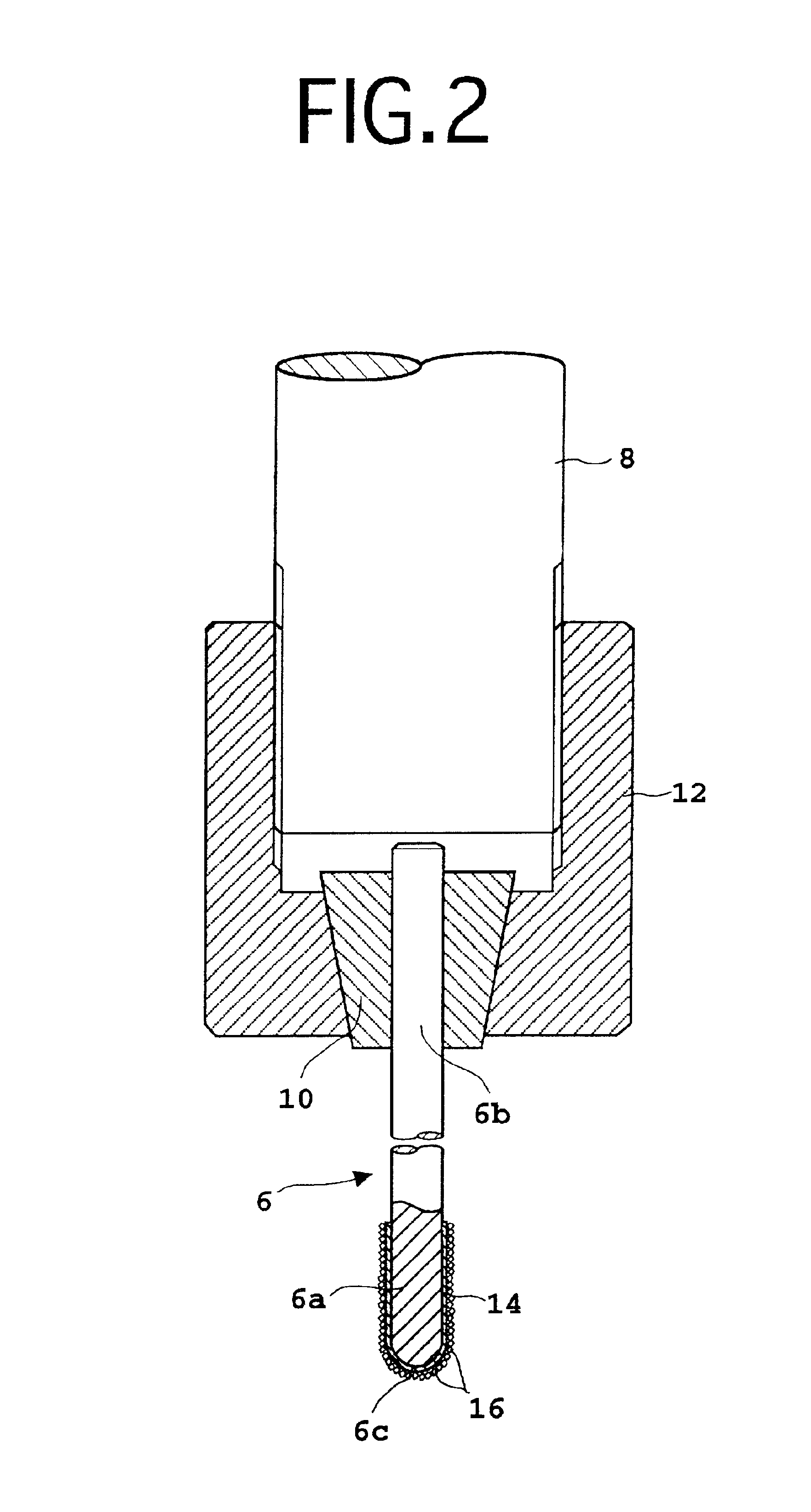

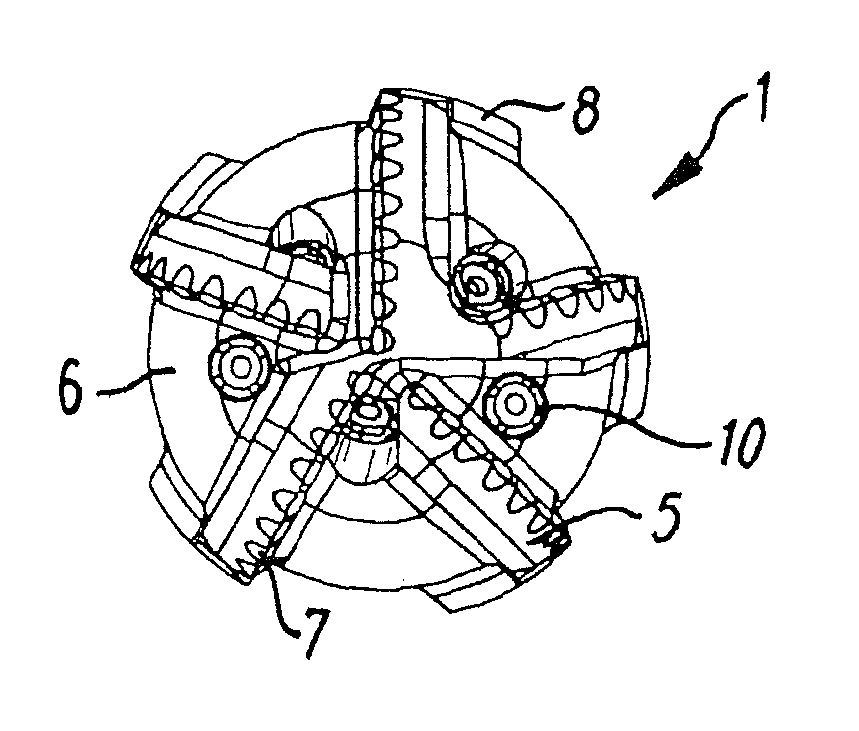

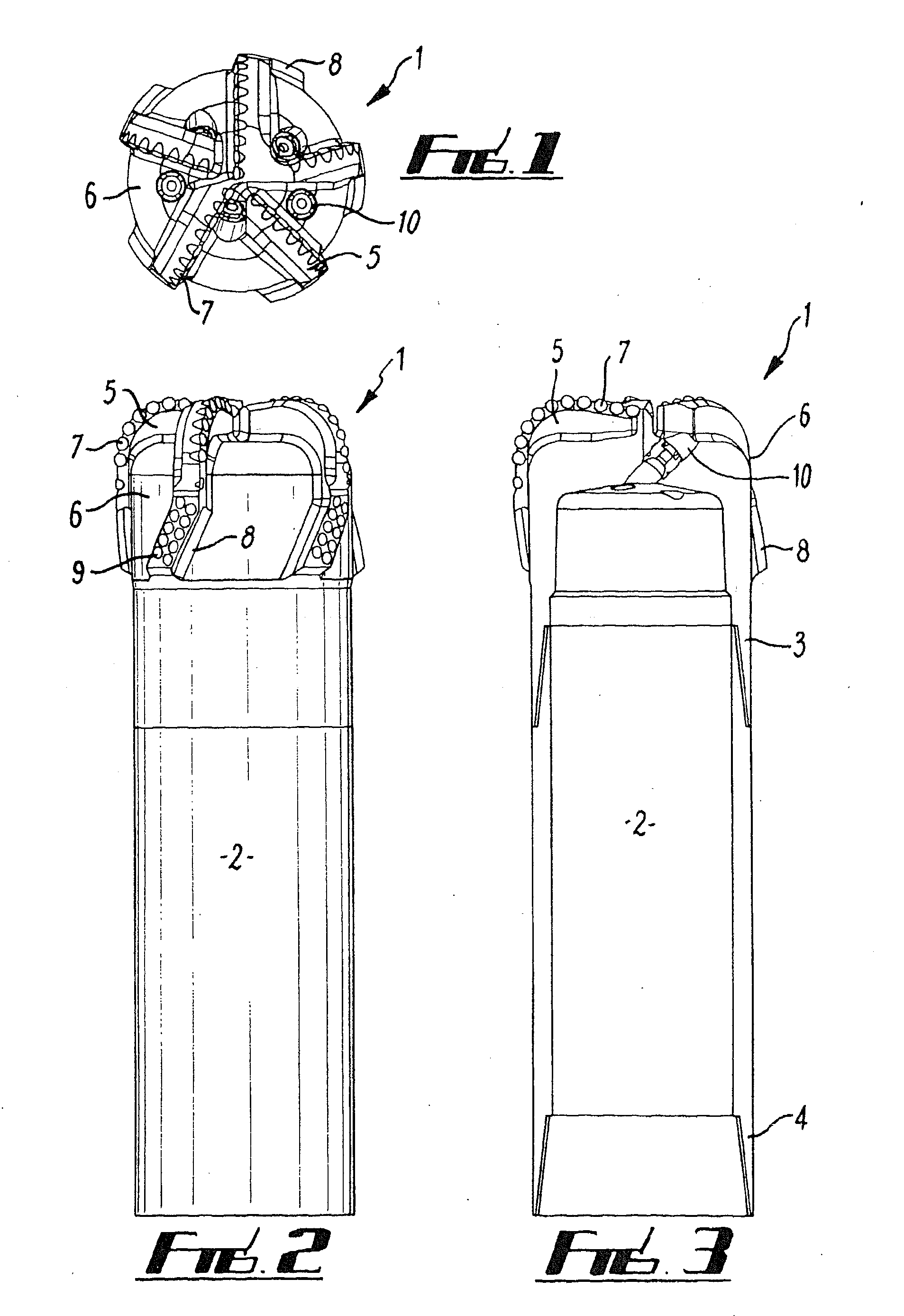

Drill bit

InactiveUS20130098692A1Time takenLow efficiencyPigmenting treatmentDrill bitsPolycrystalline diamondBoron nitride

The present invention provides a drill bit (1), and a method for its manufacture, that is suitable for use within a casing drilling process. The drill bit (1) comprises a monolithic body (5, 6, 8) made from bronze, e.g. aluminium bronze or nickel aluminium bronze, and a relatively hard material mounted thereon. The hard material may comprise polycrystalline diamond (PDC), tungsten carbide or cubic boron nitride. In one embodiment the monolithic body comprises a crown (6) and a plurality of cutting members (5). The hard material may be mounted directly on the crown or, alternatively, on the cutting members (5). The described drill bit (1) facilitates the drilling of hard rock formations while still being capable of being drilled through by a standard oilfield drill bit.

Owner:TESCO CORPORATION

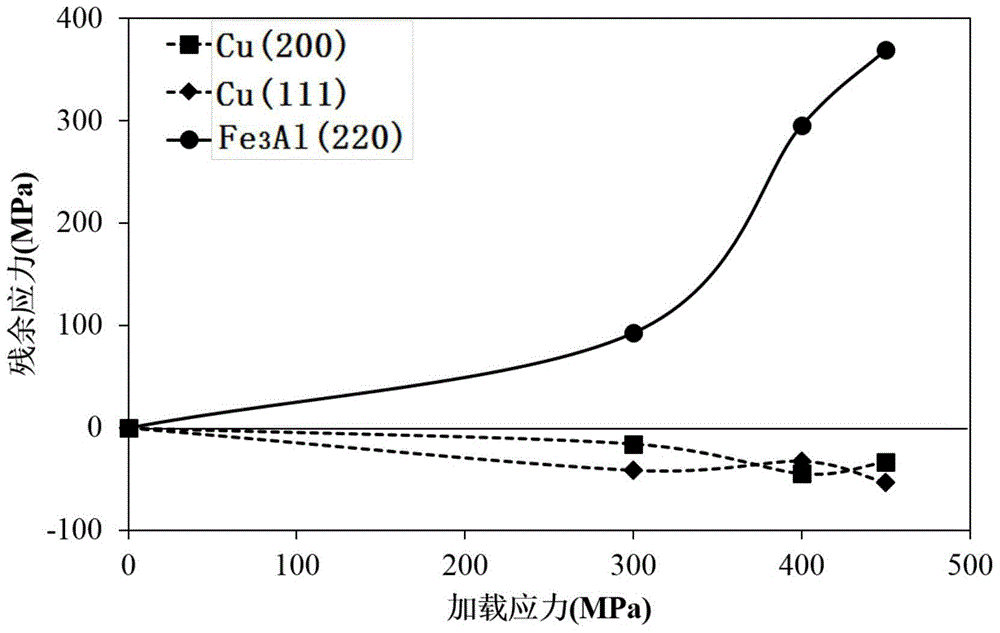

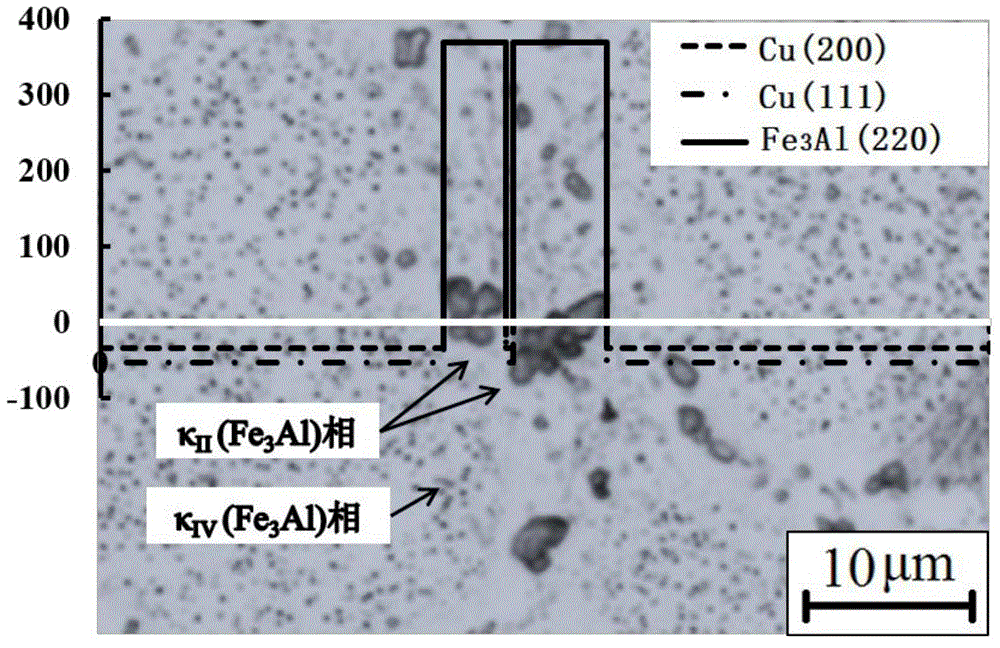

Method for measuring residual stress of nickel-aluminum bronze by utilizing neutron diffraction method

The invention discloses a method for measuring residual stress of nickel-aluminum bronze by utilizing a neutron diffraction method, which is used for measuring phase-to-phase stress between an alpha phase and a Fe3Al phase in nickel-aluminum bronze alloy caused by the deformation. The method comprises the following steps: step 1, preparing a nickel-aluminum bronze alloy tensile sample; step 2, selecting measuring parameters of neutron diffraction; step 3, in-situ measuring lattice distortion of a material; and step 4, calculating a second category of residual stresses. According to the method, the residual stress value of a copper basal body and the Fe3Al phase is obtained by utilizing the neutron diffraction method, a method for controlling the phase-to-phase stress of the nickel-aluminum bronze by utilizing the deformation is proposed, different residual stresses in different directions are produced between the alpha phase and the Fe3Al phase by loading and unloading different tensile stresses, and a variation trench and a numerical value of different residual stresses of the two phases under different loading situations can be obtained.

Owner:SHANGHAI JIAO TONG UNIV

Anticorrosive ship side plate with ceramic-based hot spray coating

ActiveCN102433526AImprove corrosion resistanceHigh volume contentMolten spray coatingSpray coatingCeramic

The invention discloses an anticorrosive ship side plate with a ceramic-based hot spray coating. The side plate comprises a gray cast iron matrix and the ceramic-based hot spray coating, wherein the ceramic-based hot spray coating is compounded on the outer surface of the gray cast iron matrix and sprayed by using supersonic and resists seawater corrosion. The ceramic-based hotspray coating is formed by coating a high aluminium bronze rare earth alloy on the SiC ceramic powder surface, and spraying the powder on the gray cast iron surface by using a hot spray method, wherein the SiC is distributed uniformly in the high aluminium bronze coating and the content of the SiC reaches 75%. The SiC ceramic in the ceramic-based hotspray coating is distributed uniformly, and the volume fraction of ceramic powder can reach 75 percent; and the ceramic-based hot spray coating and the gray cast iron matrix are in metallurgical bonding, so that the coating is not fragmented or does not fall; and the corrosion resistance of the side plate is over 5 times that of a gray cast iron side plate, the surface of which is coated with an anti-corrosive paint.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

High-manganese wear-resistant aluminum bronze alloy and preparation method thereof

The invention relates to a high-manganese wear-resistant aluminum bronze alloy. The high-manganese wear-resistant aluminum bronze alloy comprises the following components of 73.0%-75.0% of copper, 3.0%-4.0% of nickel, 0.5%-1.2% of chromium, 8.0%-10.0% of manganese, 3%-5% of silicon, 0.3%-1.0% of zirconium, 0.1%-0.3% of boron, 0.05%-0.25% of cerium and the balance aluminum and inevitable impurities, wherein the impurity content is less than or equal to 0.1%. The aluminum bronze alloy has excellent mechanical properties, good wear resistance and good machinability.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

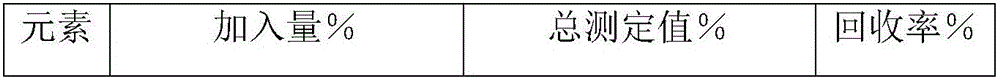

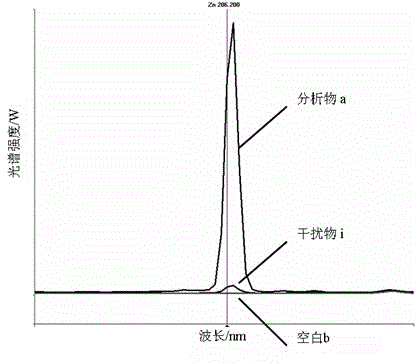

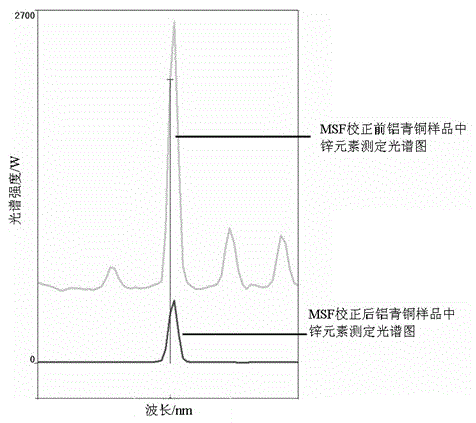

Method for simultaneously determining multi-element contents in aluminium bronze

ActiveCN104406957AEliminate errorsSimple methodAnalysis by thermal excitationElement analysisTrace element

The invention discloses a method for simultaneously determining multi-element contents in aluminium bronze. The method comprises the following determination steps of preparing a sample solution, preparing a working curve solution, determining an analyzing spectrum line of elements to be determined, determining the content of elements in the sample by an ICP (Inductively Coupled Plasma) method and correcting the spectrum disturbance by a multi-element spectral fitting method. According to the method disclosed by the invention, the enrichment or separated treatment for trace elements is avoided; after the sample is dissolve and treated at one time, the trace, the dose and the content of major elements can be simultaneously determined; the spectrum disturbance of a matrix to the elements to be determined is effectively corrected by a matrix matching and multi-element spectral fitting method; the analysis period is effectively shortened; the method has the advantages of quickness, simplicity, convenience, accuracy and reliability, and is suitable for quality control over the multi-element content in aluminium bronze products.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Zinc alloy casting and its making process

InactiveCN1932060AHigh tensile strengthReduce coefficient of frictionChemical compositionZinc alloys

The present invention is zinc alloy casting and its making process. The zinc alloy casting has the chemical composition comprising Al 20.0-32.0 wt%, Cu 1.6-3.0 wt%, Zn 62.0-78.0 wt%, Mg 0.006-0.1 wt% and other impurities less than 0.35 wt%. The making process of the zinc alloy casting includes the following steps: preheating smelter; adding the components into the smelter; smelting; casting; forming; and machining. The zinc alloy casting has reasonable composition, tensile strength not lower than 315N / mm2, specific elongation not lower than 3 %, and Brinell hardness not lower than 100 HB.

Owner:阳西县电梯配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com