Aluminium bronze alloy composition rapid-measuring method

A rapid measurement, aluminum bronze technology, applied in the direction of material excitation analysis, etc., can solve the problems of low efficiency, long analysis time, unable to complete the detection of the components to be measured at the same time, and achieve the effect of high measurement efficiency, improved efficiency, and short measurement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] To analyze the aluminum bronze QAL10-3-1.5 sample numbered H9-1, the test steps are as follows:

[0039] 1. Flush the excitation chamber with an argon flow rate of 8L / min for 10s,

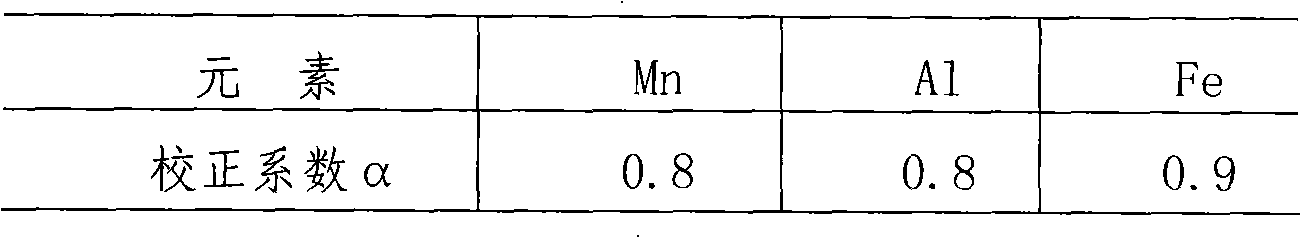

[0040] 2. From the standard sample QAl9-2, select samples 925 and 929 with the highest and lowest content of Al and Mn elements, and samples 920 and 924 with the highest and lowest content of Fe elements to excite and standardize the working curve respectively. See Table 1 for the value of the normalization coefficient α.

[0041] Table 1 Two-point standardized coefficient α value

[0042]

[0043] 3. Use the QAL10-3-1.5 sample with the number K-1 confirmed by chemical analysis as a specific control sample, stimulate twice, and take the average value as the analysis result to correct the standard analysis curve.

[0044] 4. Measure the QAL10-3-1.5 sample numbered H9-1, and the test results are shown in Table 2

[0045] Table 2 QAL10-3-1.5 analysis results (%)

[0046] the ele...

Embodiment 2

[0048] To analyze the QAL9-4 sample numbered H03D-19, the test steps are as follows:

[0049] 1. Flush the excitation chamber with an argon flow rate of 10L / min for 5s,

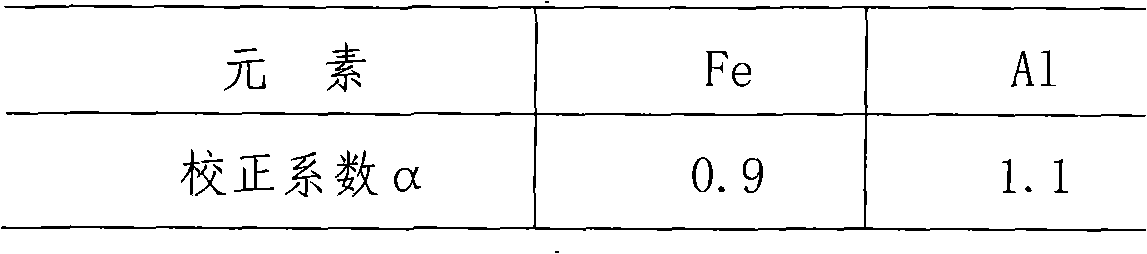

[0050] 2. From the standard sample QAl9-2, select the samples 925 and 929 with the highest and lowest Al element content, and the samples 920 and 924 with the highest and lowest Fe element content to excite and standardize the working curve respectively. See Table 3 for the value of the normalization coefficient α.

[0051] Table 3 Two-point standardized coefficient α value

[0052]

[0053] 3. Use the QAL9-4 sample numbered K-2 confirmed by chemical analysis as a specific control sample, stimulate twice, and take the average value as the analysis result to correct the standard analysis curve.

[0054] 4. Test the QAL9-4 sample with the number H03D-19, and the test results are shown in Table 4

[0055] Table 4 QAL9-4 analysis results (%)

[0056] the element

Embodiment 3

[0058] To analyze the QAL9-2 sample numbered BY926, the test steps are as follows:

[0059] 1. Flush the excitation chamber with an argon flow rate of 10L / min for 5s,

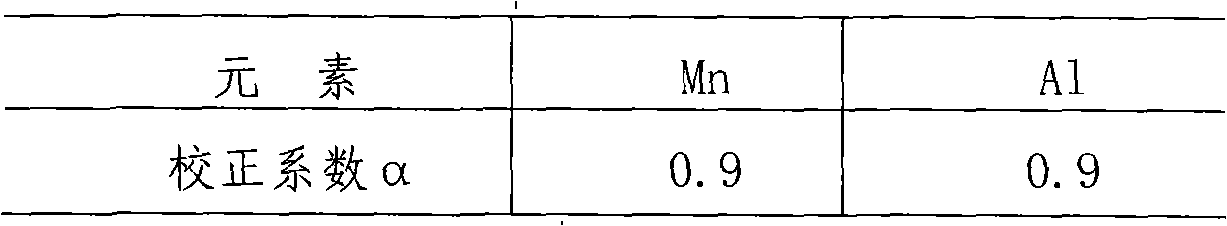

[0060] 2. Select the samples 925 and 929 with the highest and lowest content of Al and Mn elements from the standard sample QAl9-2 to excite and standardize the working curve respectively. See Table 5 for the value of the normalization coefficient α.

[0061] Table 5 Two-point standardized coefficient α value

[0062]

[0063] 3. Test the QAL9-2 sample number BY926, the test results are shown in Table 6

[0064] Table 6 QAL9-4 analysis results (%)

[0065] the element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com