Patents

Literature

201results about How to "Many steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

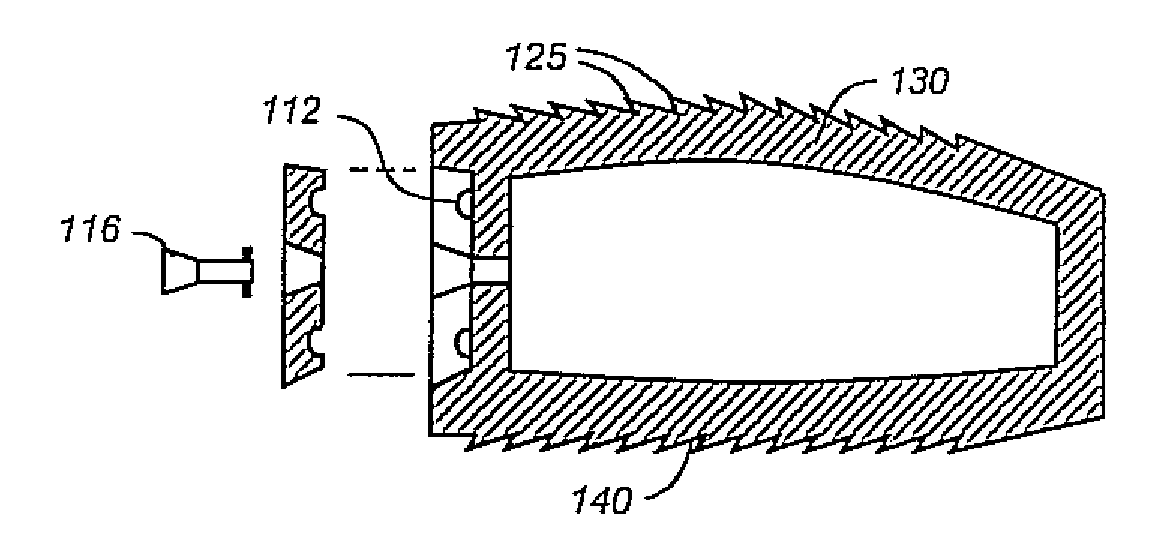

Expandable Self-Anchoring Interbody Cage for Orthopedic Applications

ActiveUS20130158669A1Maintain and create lordosisEasy to useBone implantSpinal implantsSpinal cageInterbody cage

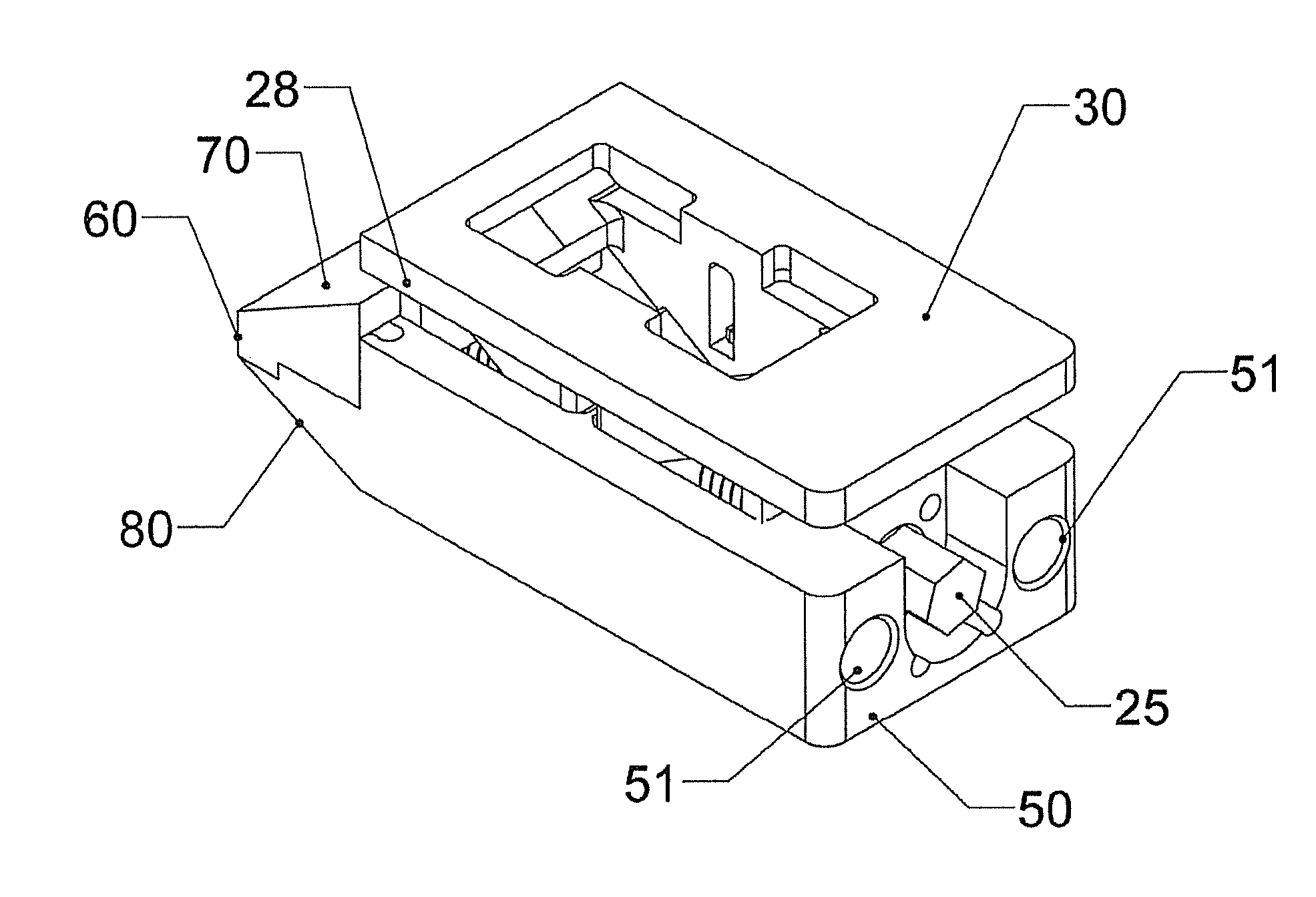

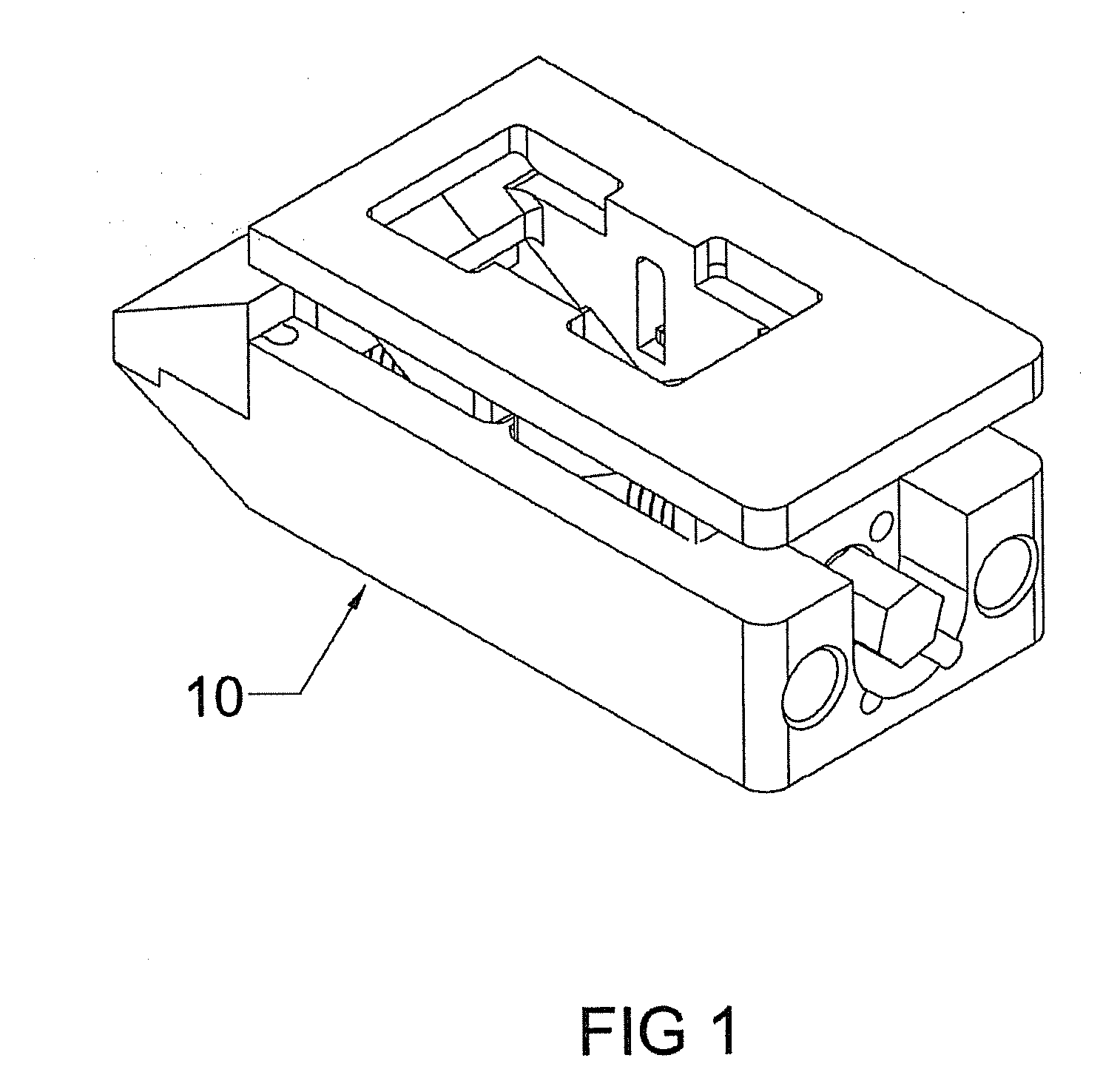

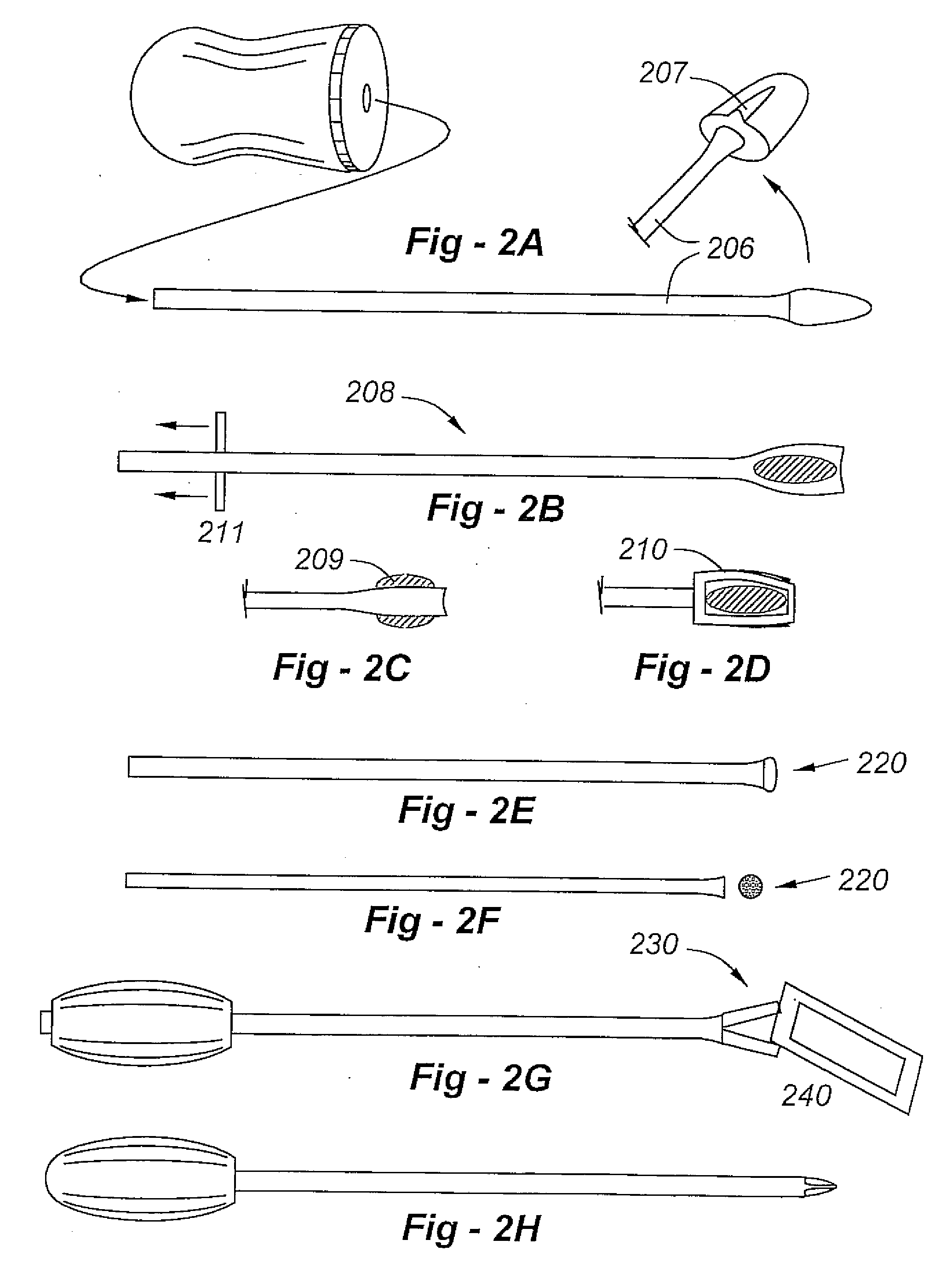

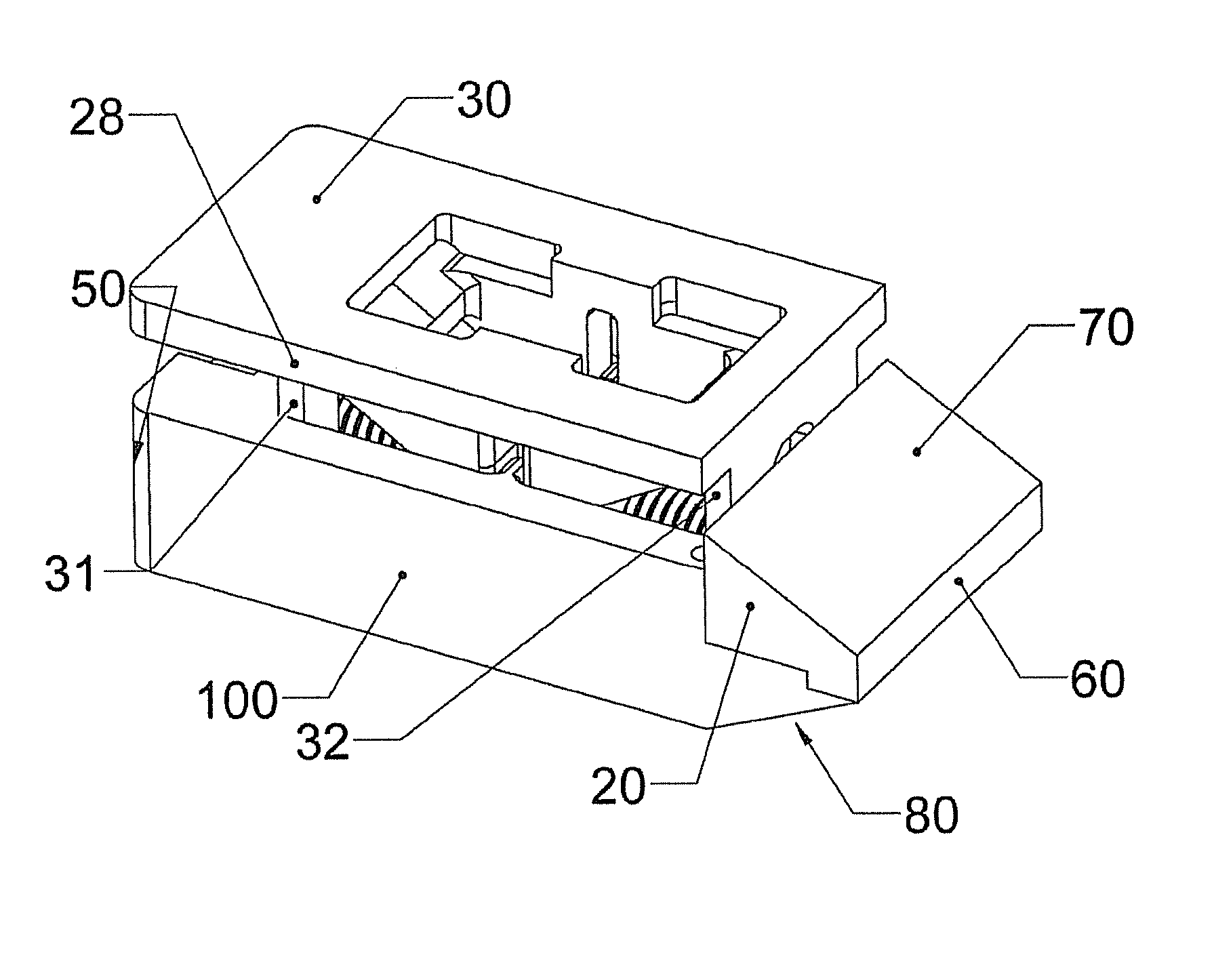

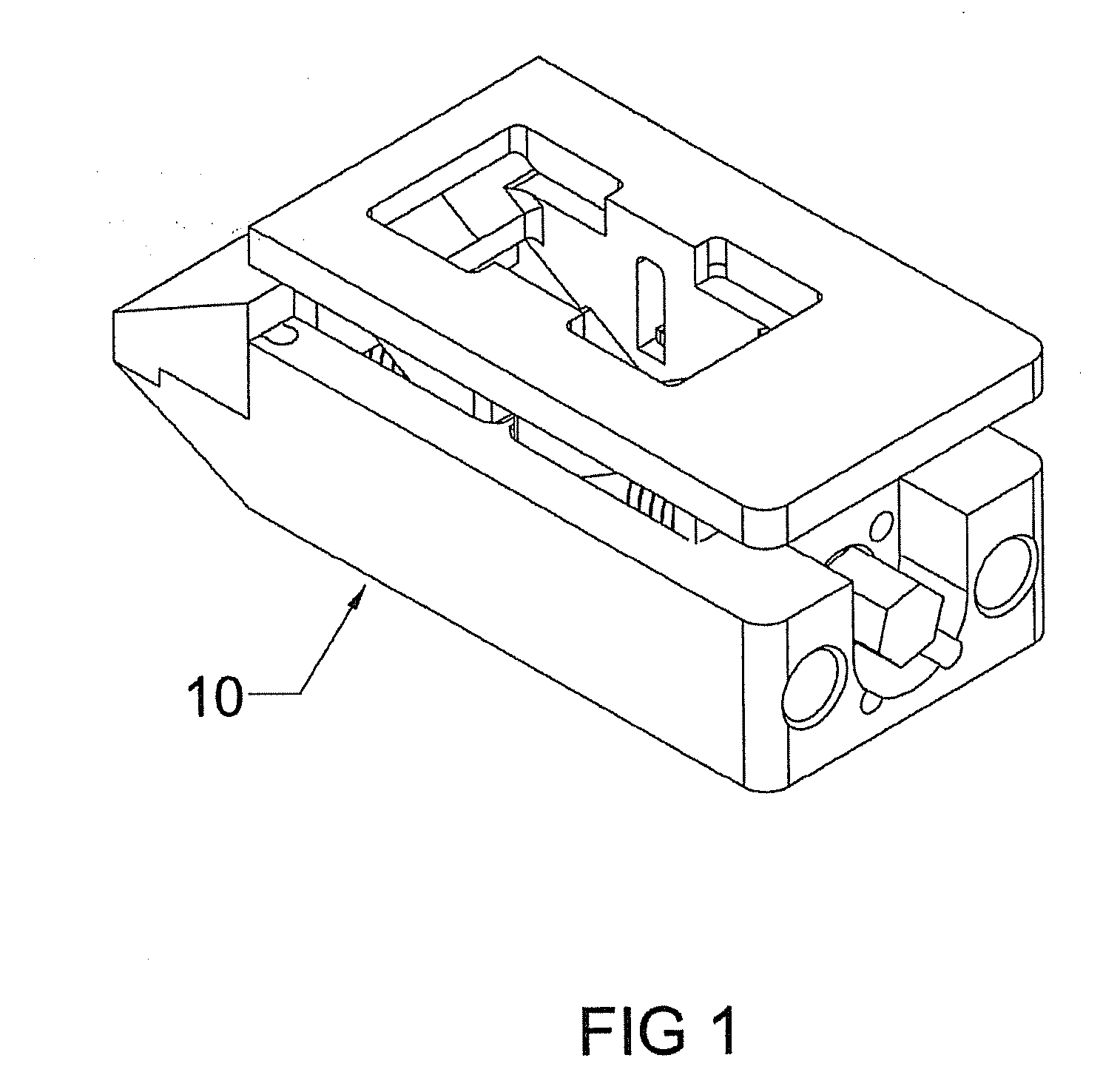

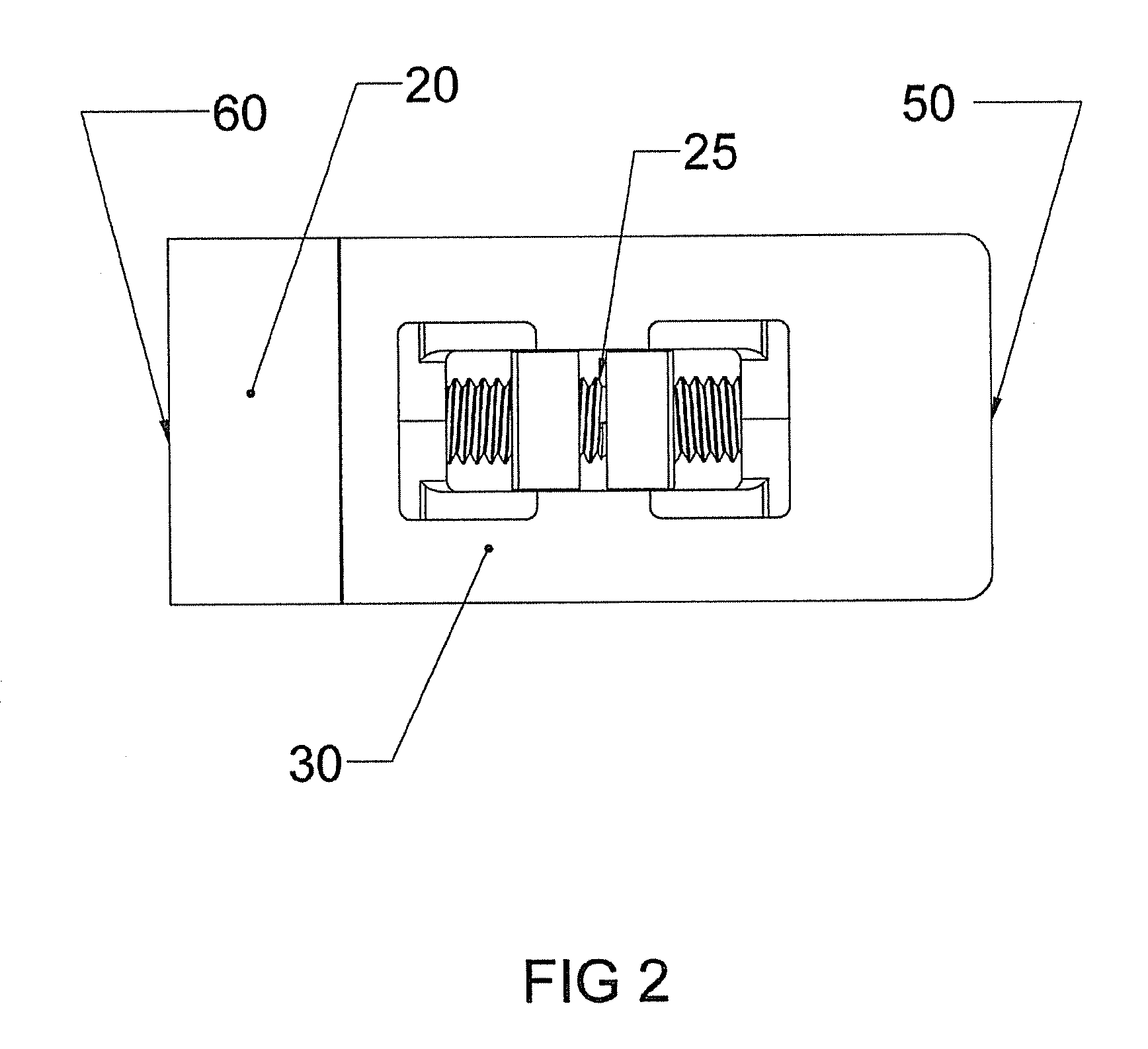

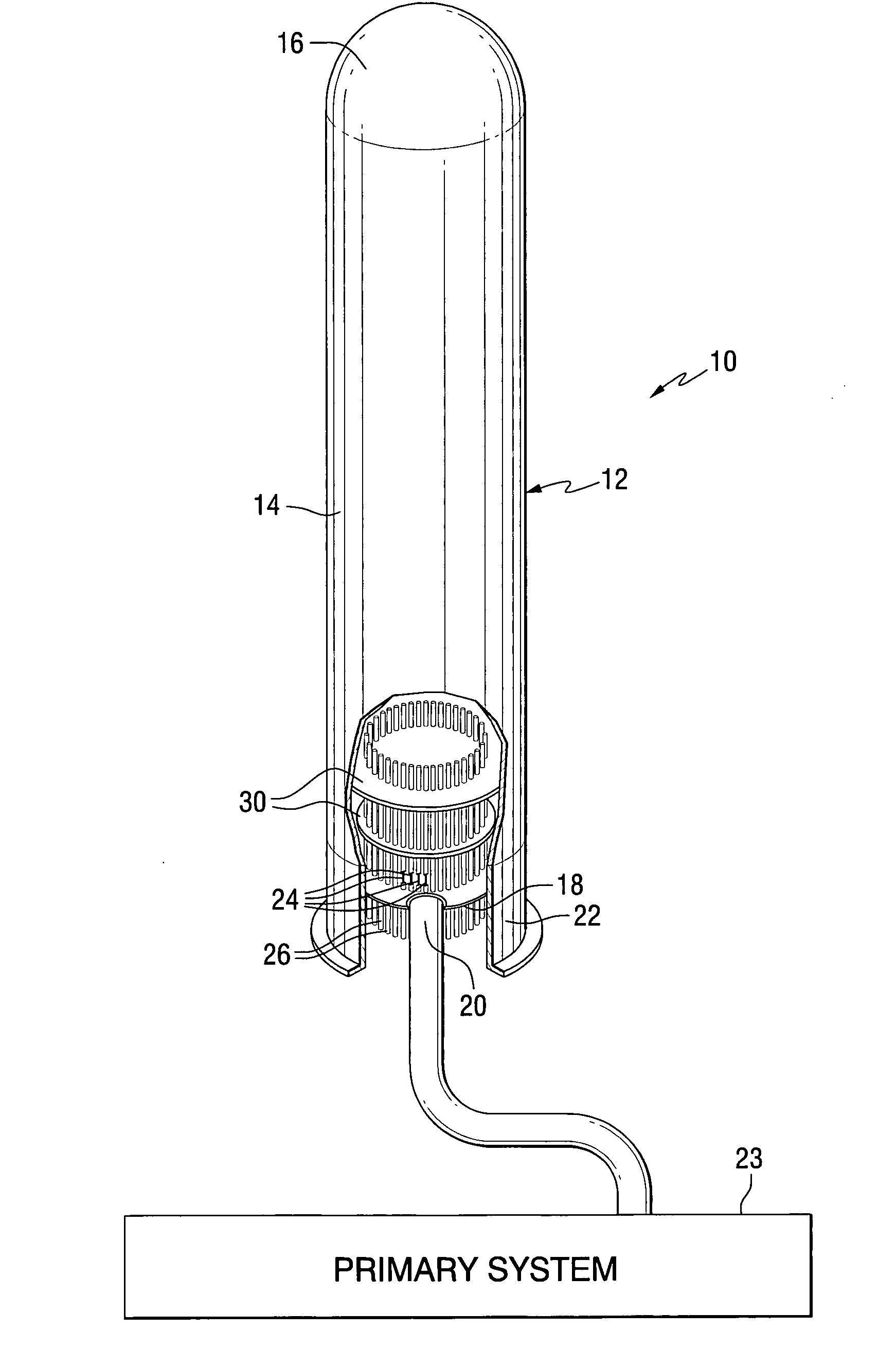

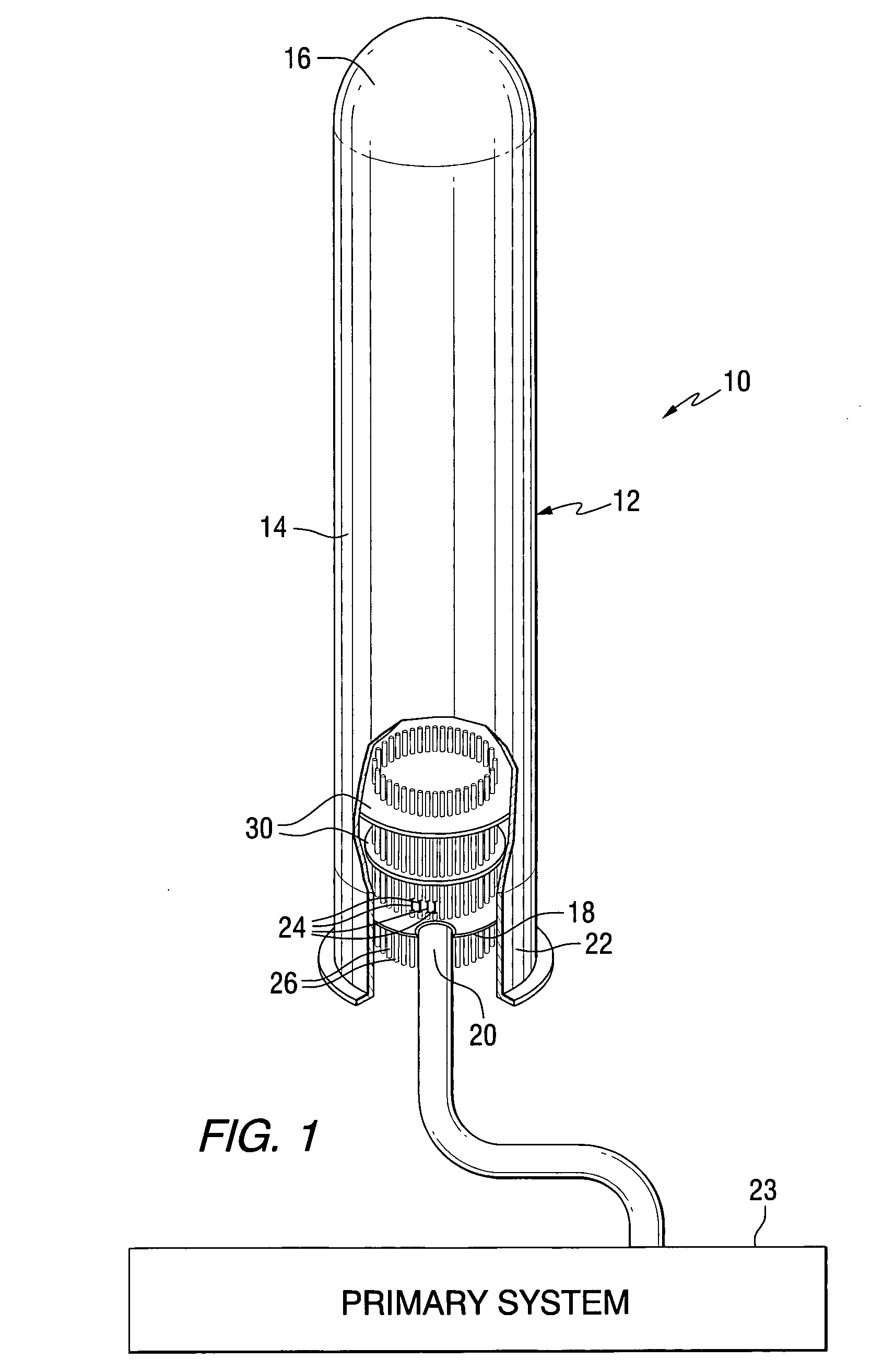

The present invention is directed to an expandable spinal fusion intervertebral implant that provides for maintaining and creating lordosis in the human spine that can be filled with biologics while in situ to encourage spinal fusion. A threaded rod that traverses an insertion / injection handle can be rotated to operate a screw within the interbody cage that displaces opposing vertical tapped sliding wedges, causing them to converge towards each other. Such contact causes the operation of a horizontal wedge that acts as a lift to expand the interbody cage to one of various dimensions in a preferred range. At its desired expansion, the spinal fusion implant of the present invention is sized to fit within the disc space between two vertebral bodies and fill all voids left while the vertical and horizontal wedges operate within, due to the biologics being contained within the interbody cage.

Owner:BLUE TIP BIOLOGICS

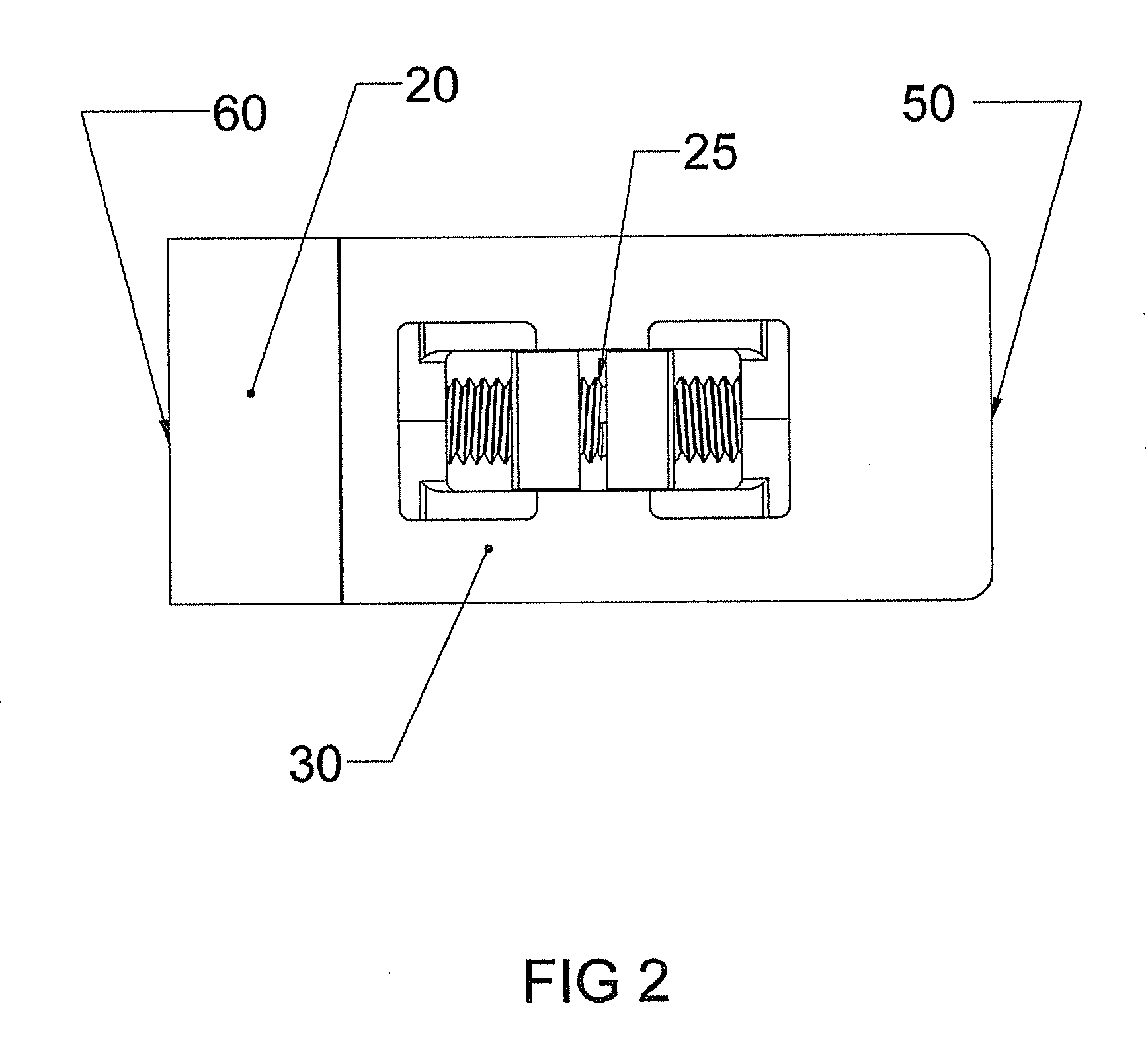

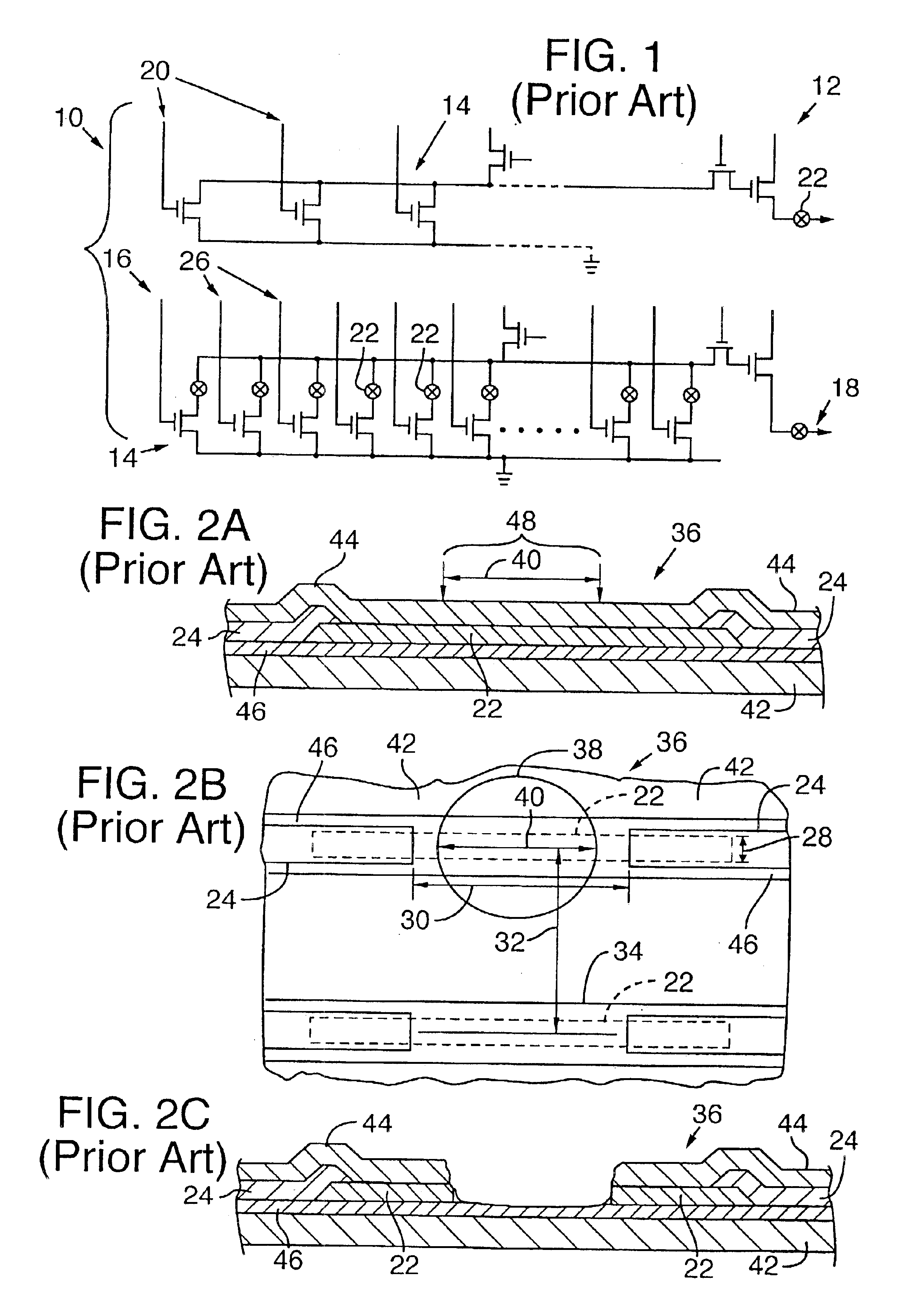

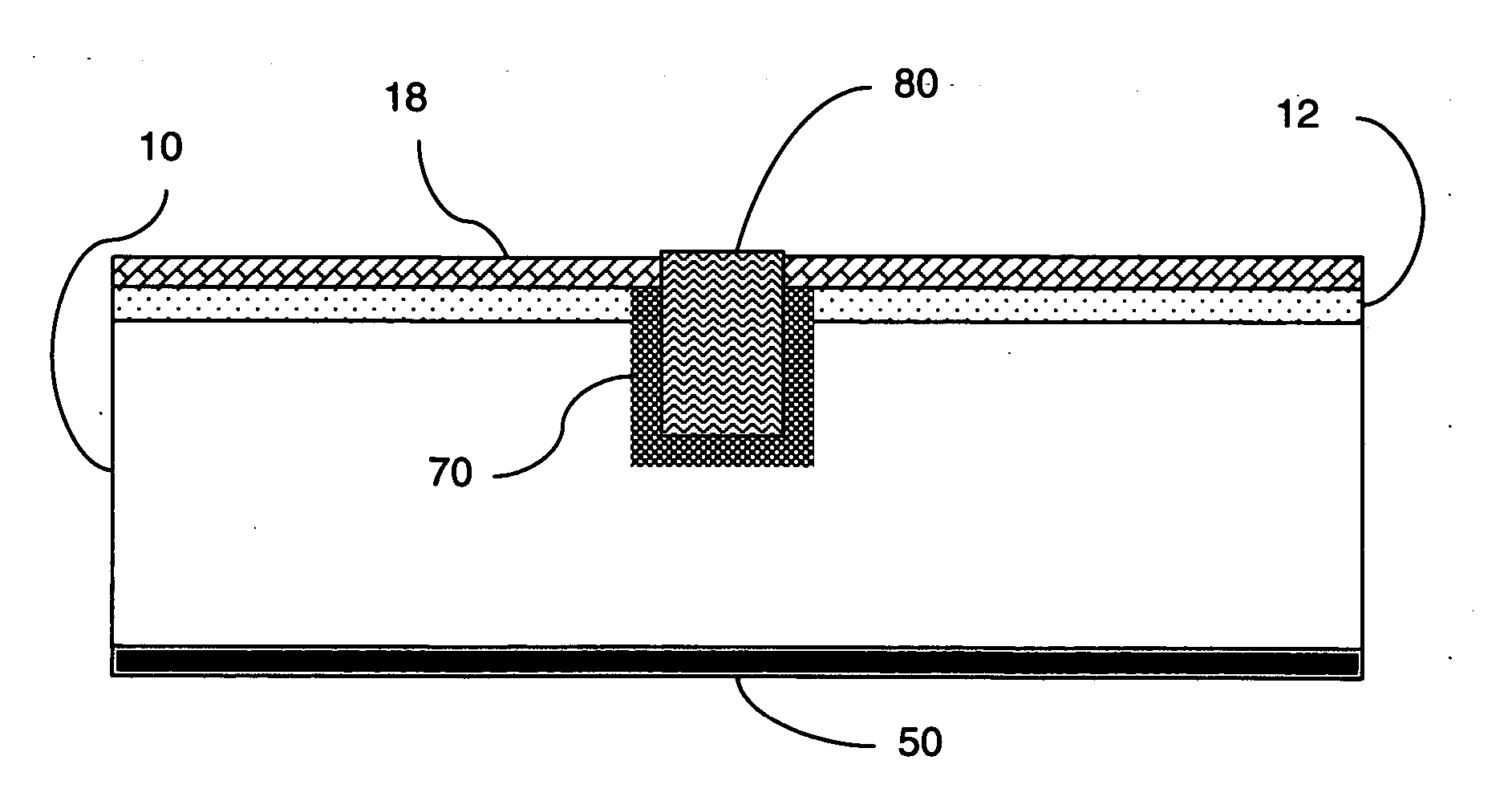

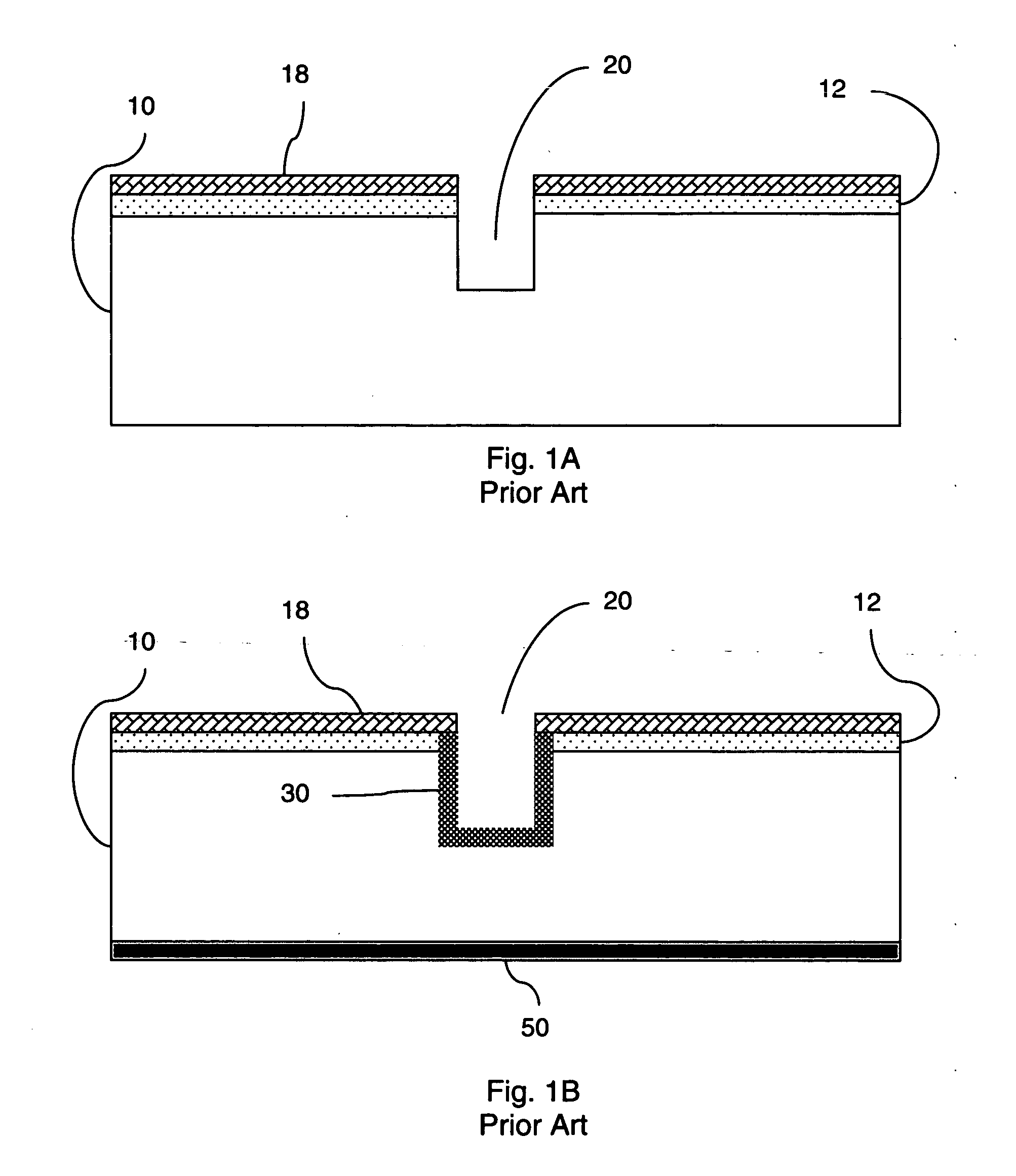

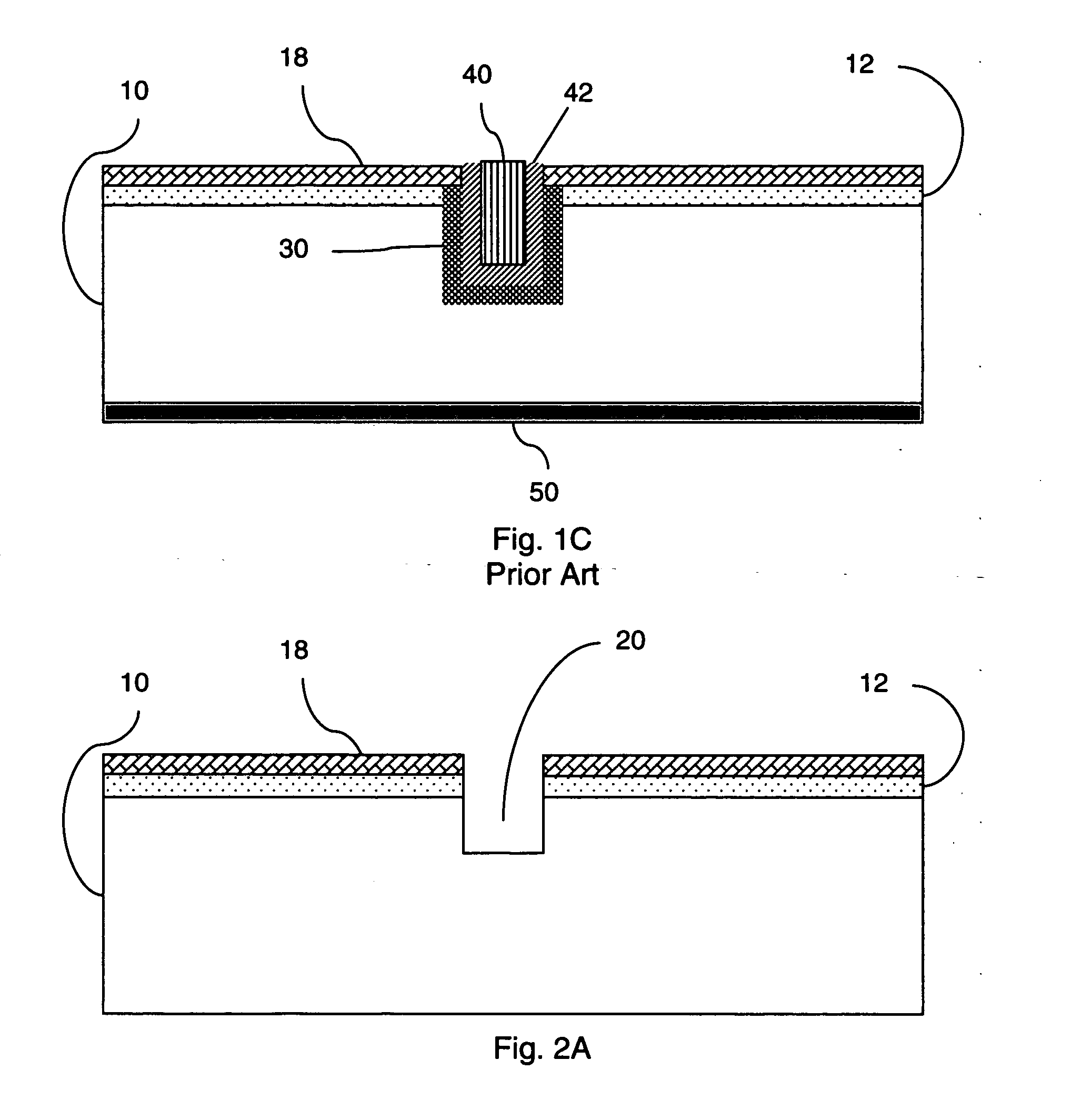

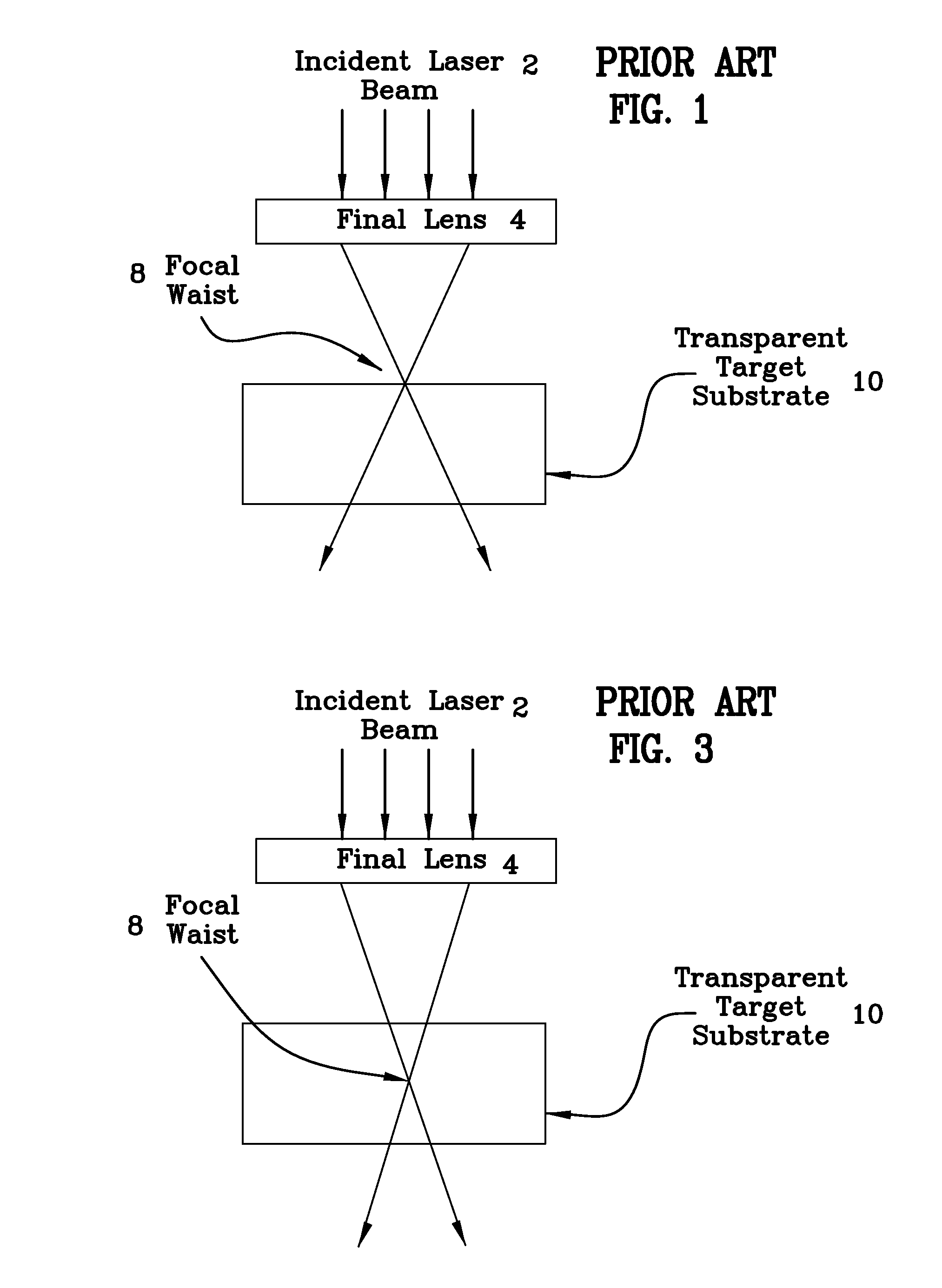

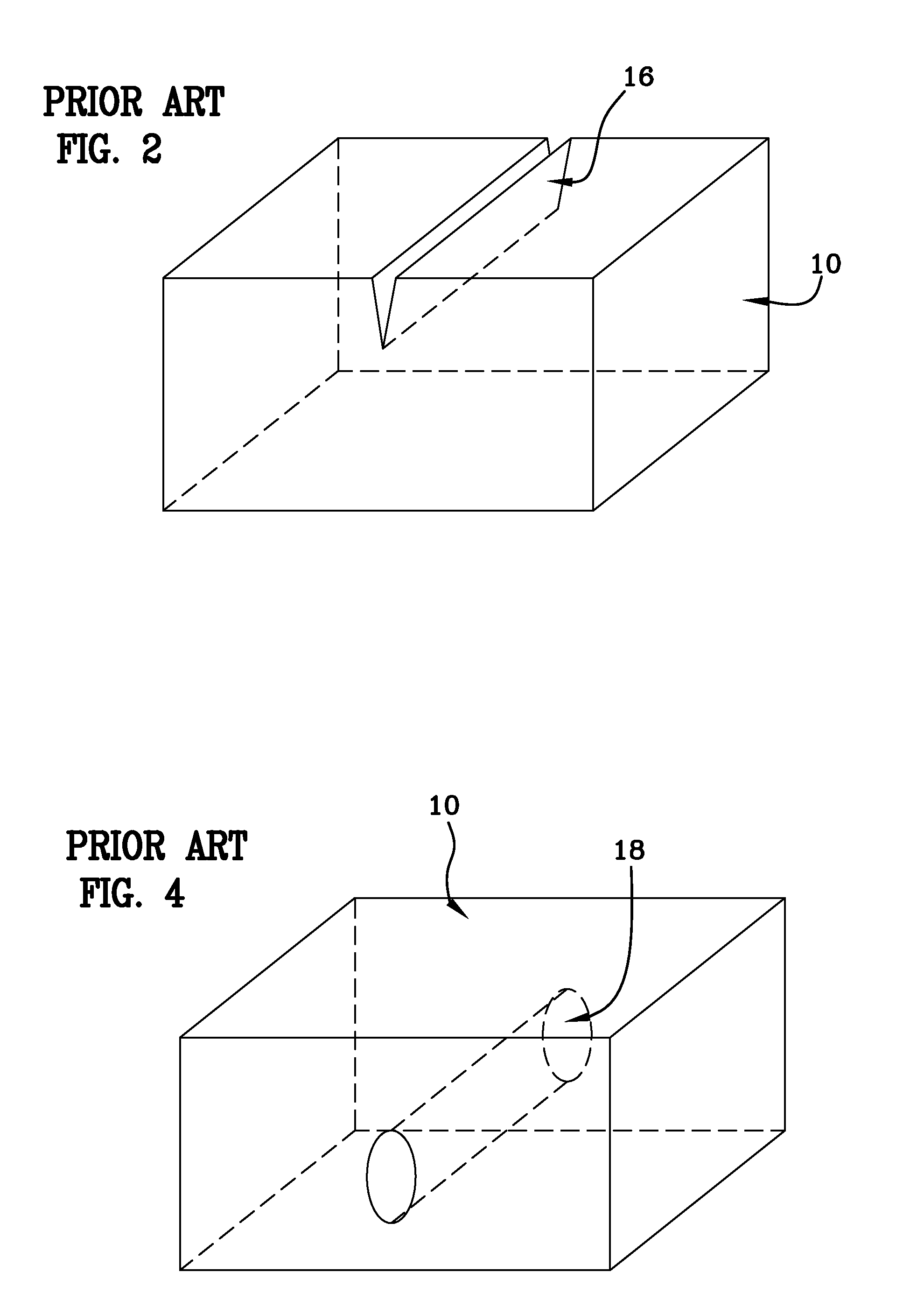

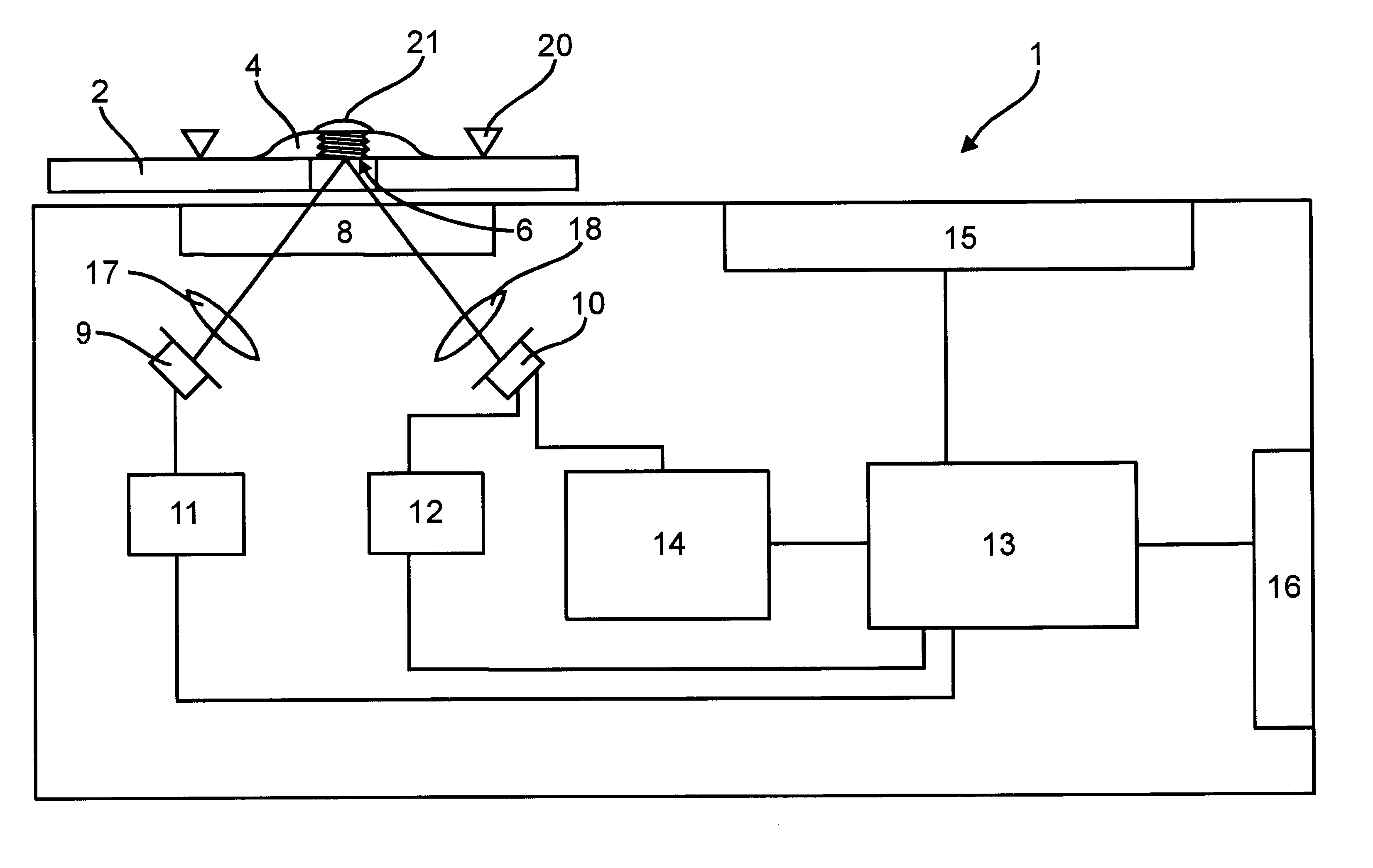

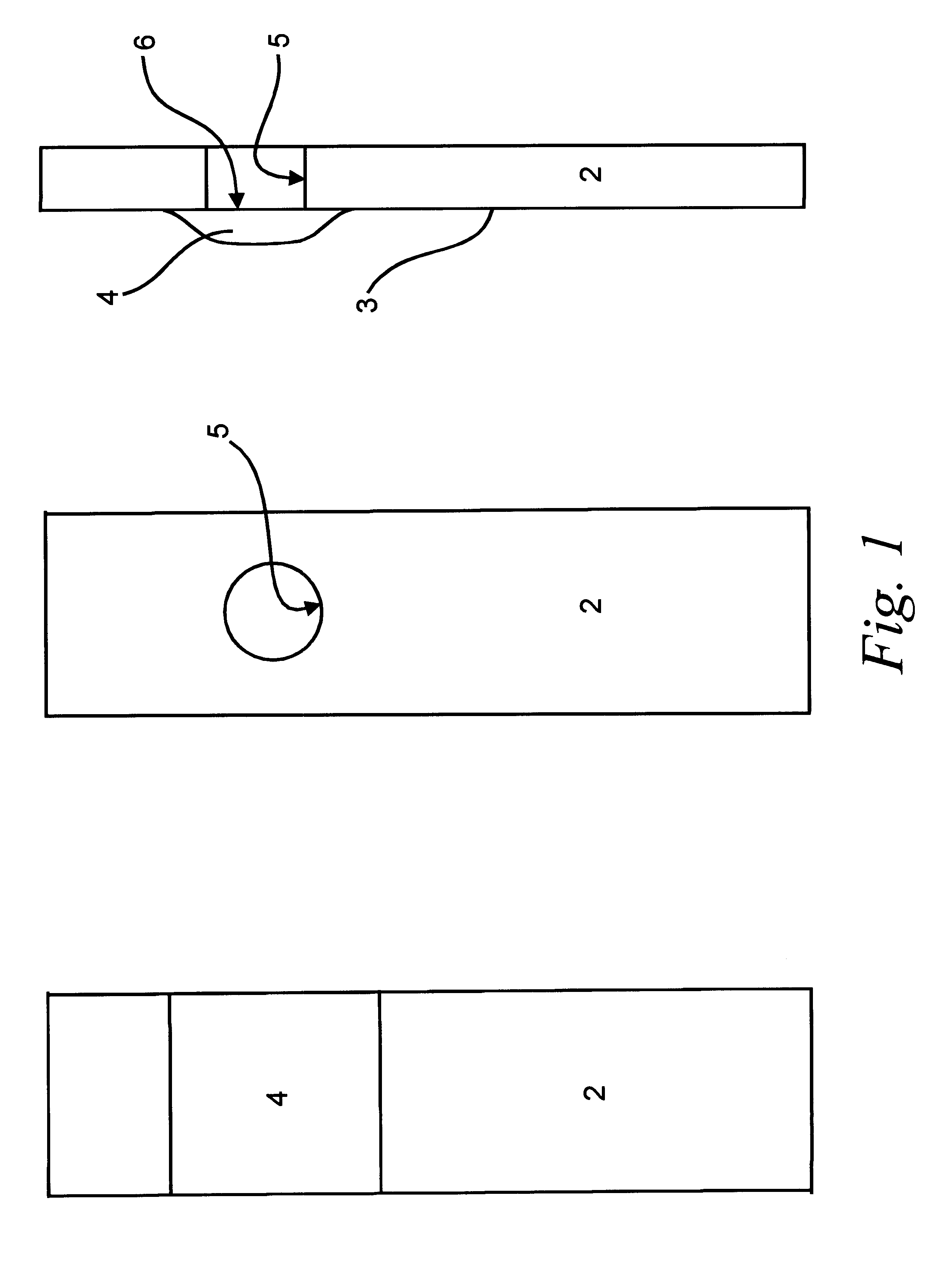

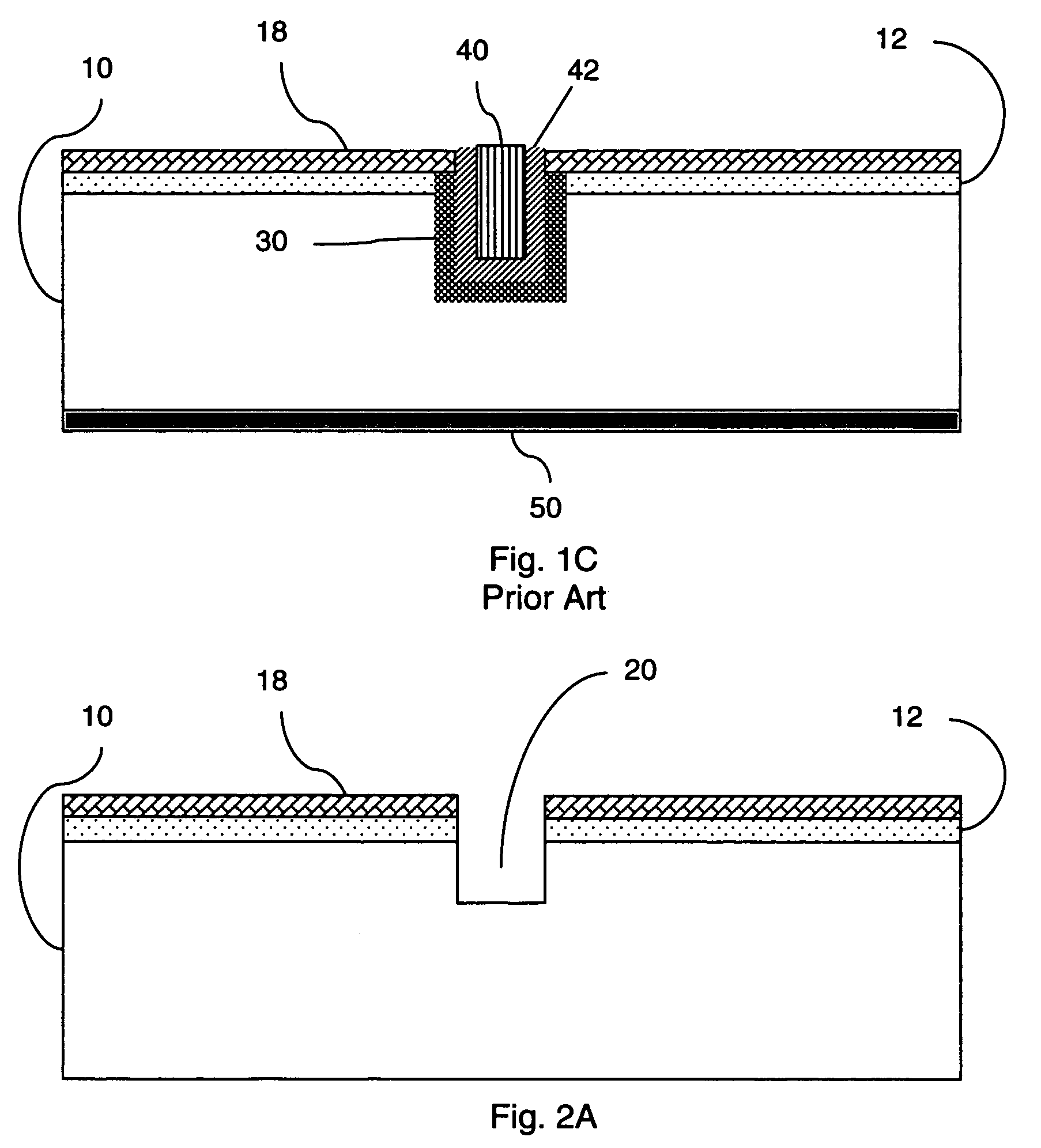

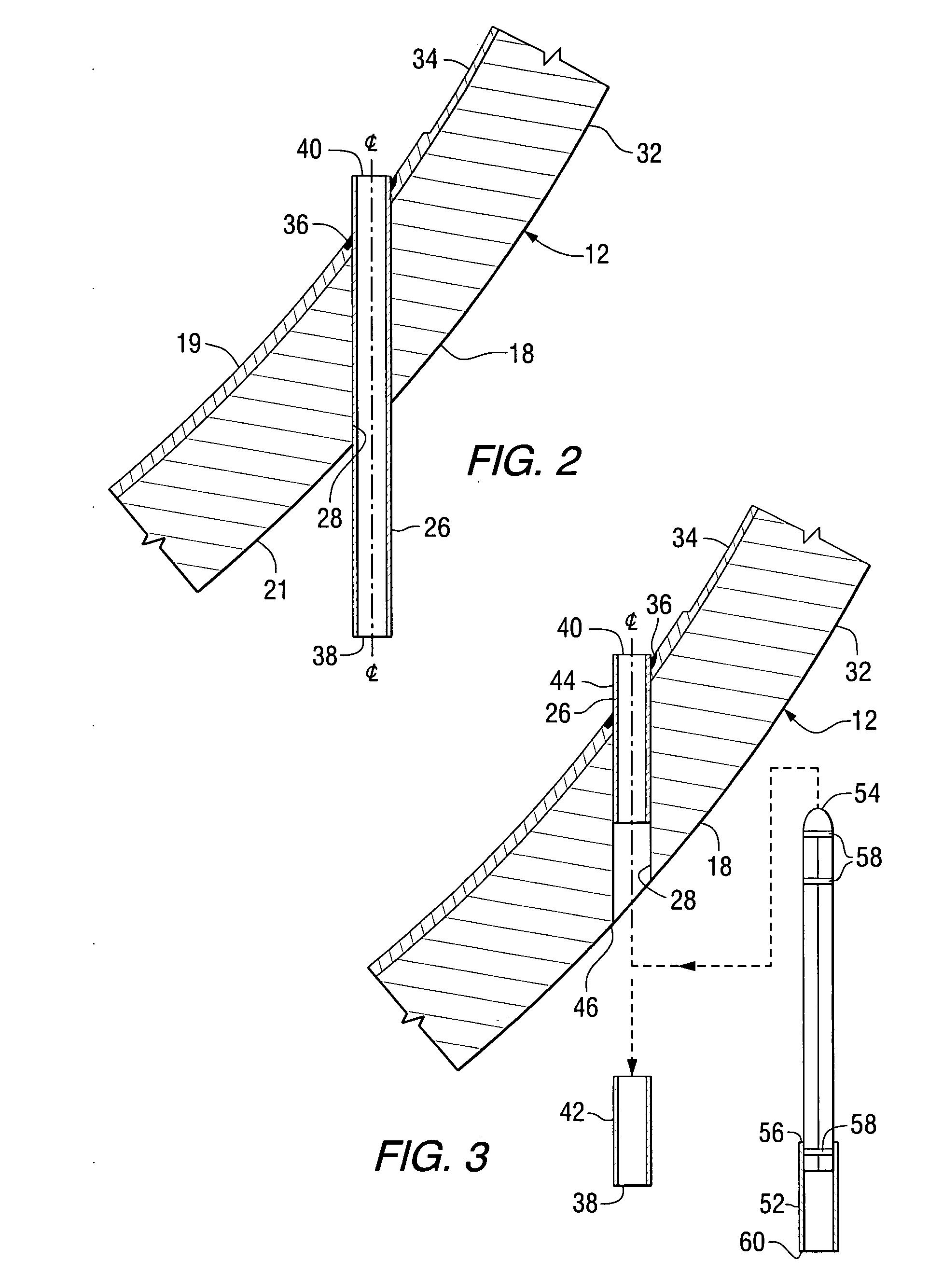

Passivation processing over a memory link

InactiveUS6887804B2Improve processing qualityAvoid and minimize substrate damage and undesirable damageSemiconductor/solid-state device detailsSolid-state devicesEtchingHarmonic

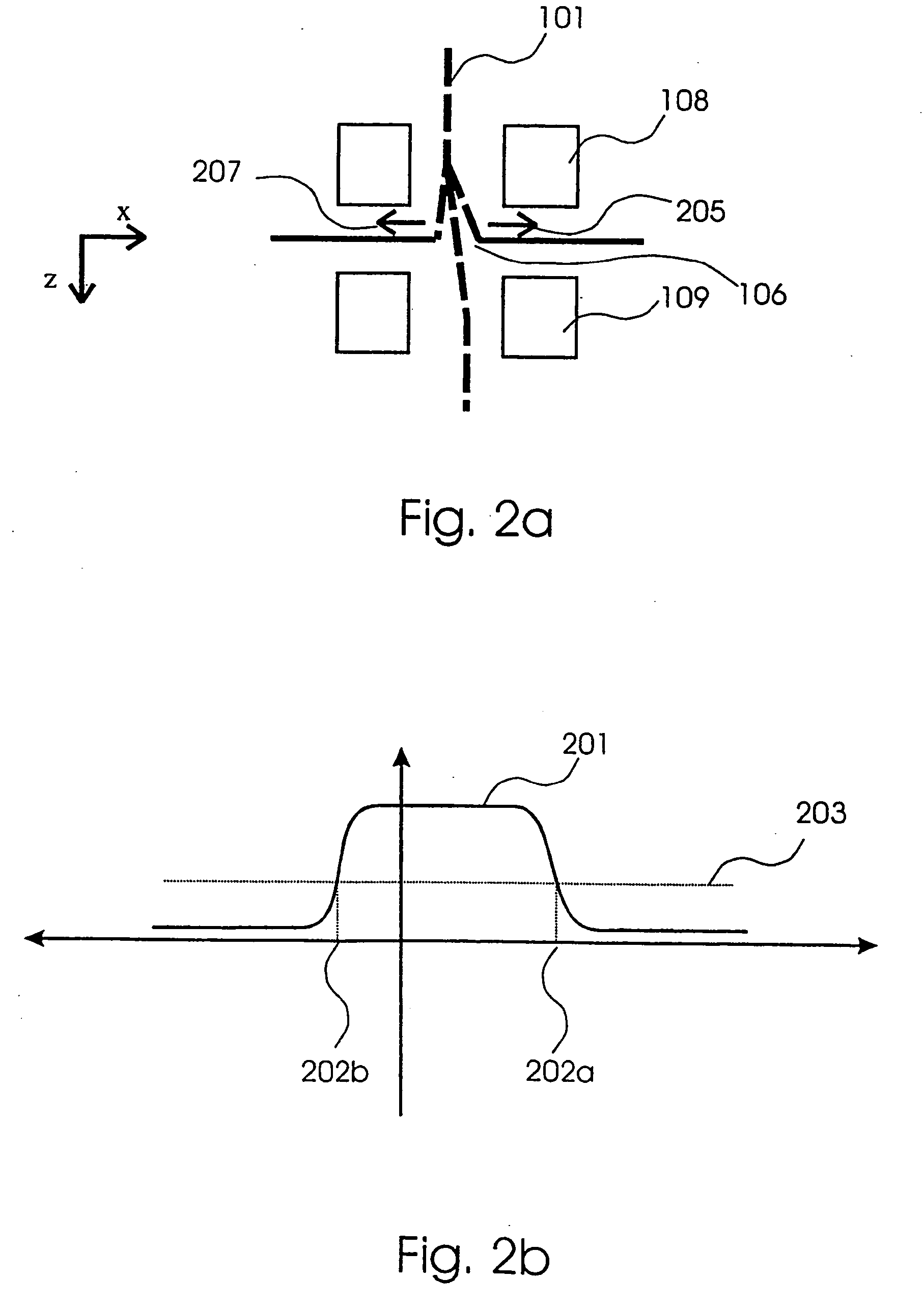

A set (50) of one or more laser pulses (52) is employed to remove passivation layer (44) over a conductive link (22). The link (22) can subsequently be removed by a different process such as chemical etching. The duration of the set (50) is preferably shorter than 1,000 ns; and the pulse width of each laser pulse (52) within the set (50) is preferably within a range of about 0.05 ps to 30 ns. The set (50) can be treated as a single “pulse” by conventional laser positioning systems (62) to perform on-the-fly material removal without stopping whenever the laser system (60) fires a set (50) of laser pulses (52) at each target area (51). Conventional wavelengths in the IR range or their harmonics in the green or UV range can be employed.

Owner:ELECTRO SCI IND INC

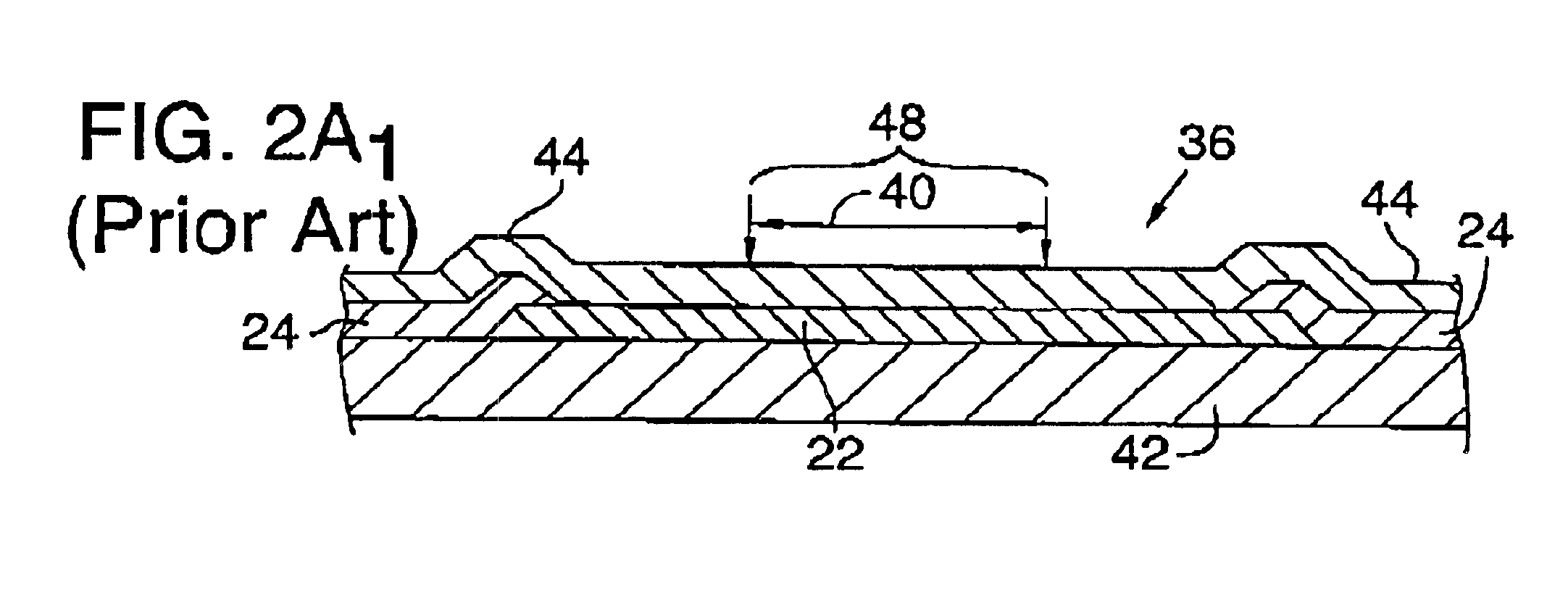

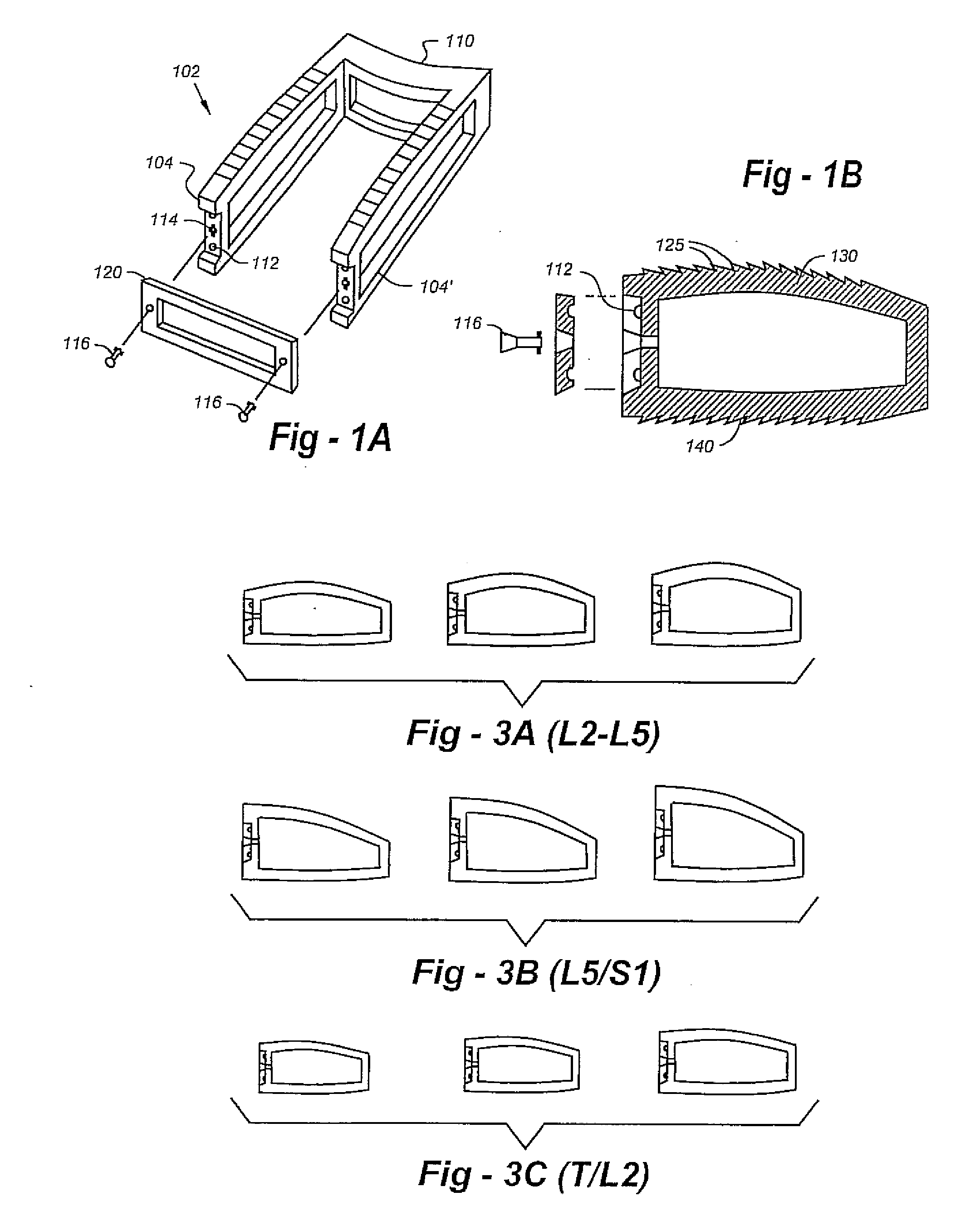

Intervertebral cage designs

InactiveUS20090030519A1Without excessive obscurationEasy and great accessDiagnosticsBone implantAutogenous graftCustom-fit

Cage systems that improve upon the prior art in various ways. In the preferred embodiments, devices are radiolucent, with markers, thereby allowing visualization of placement without excessive obscuration. Devices according to the invention eliminate multiple steps, instruments and trays, while being capable of a custom fit. The devices according to the invention permit easier and greater access to end plate surface area, and can be used with autografts, allografts, and biologics.

Owner:US SPINE INC

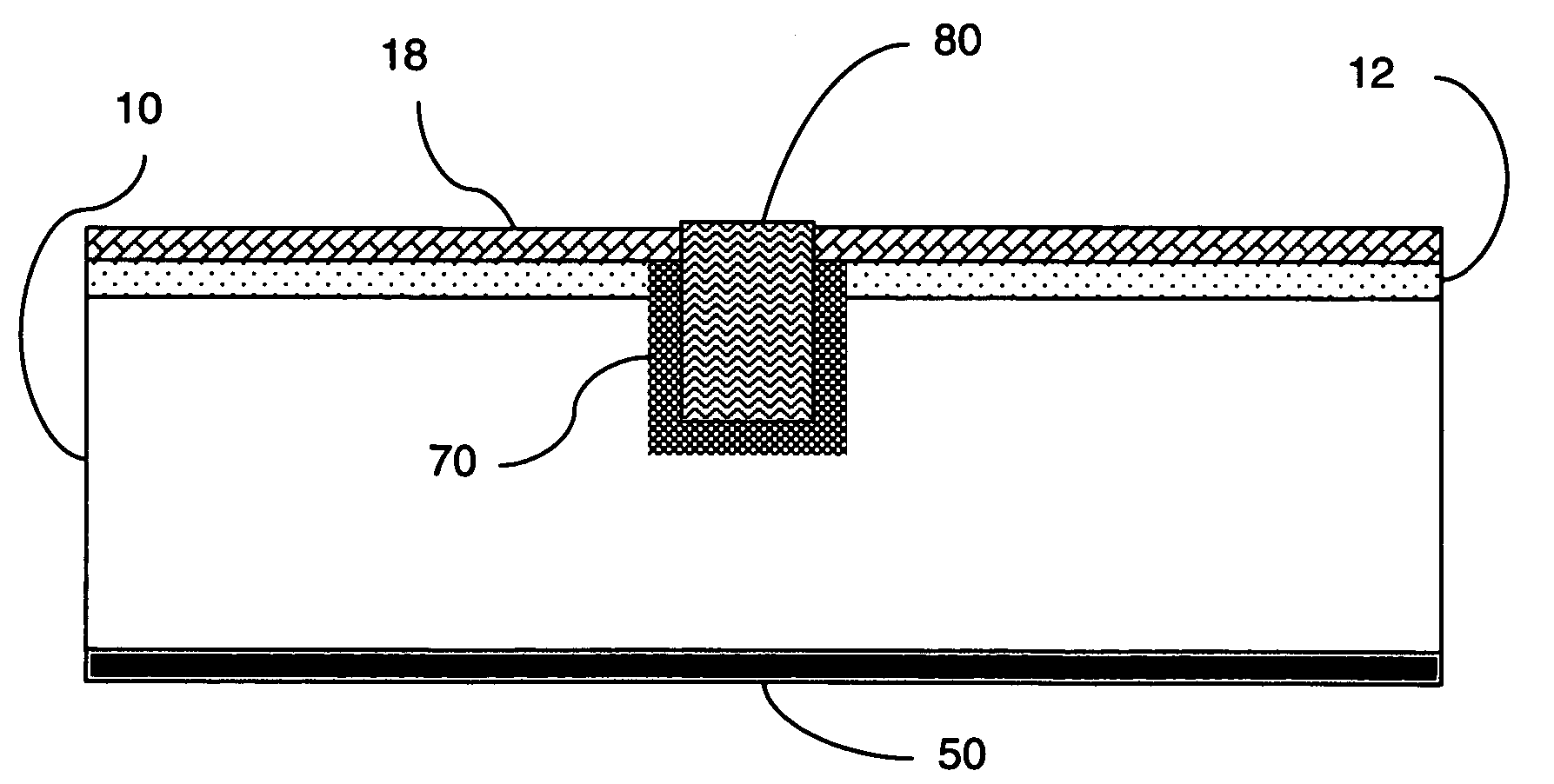

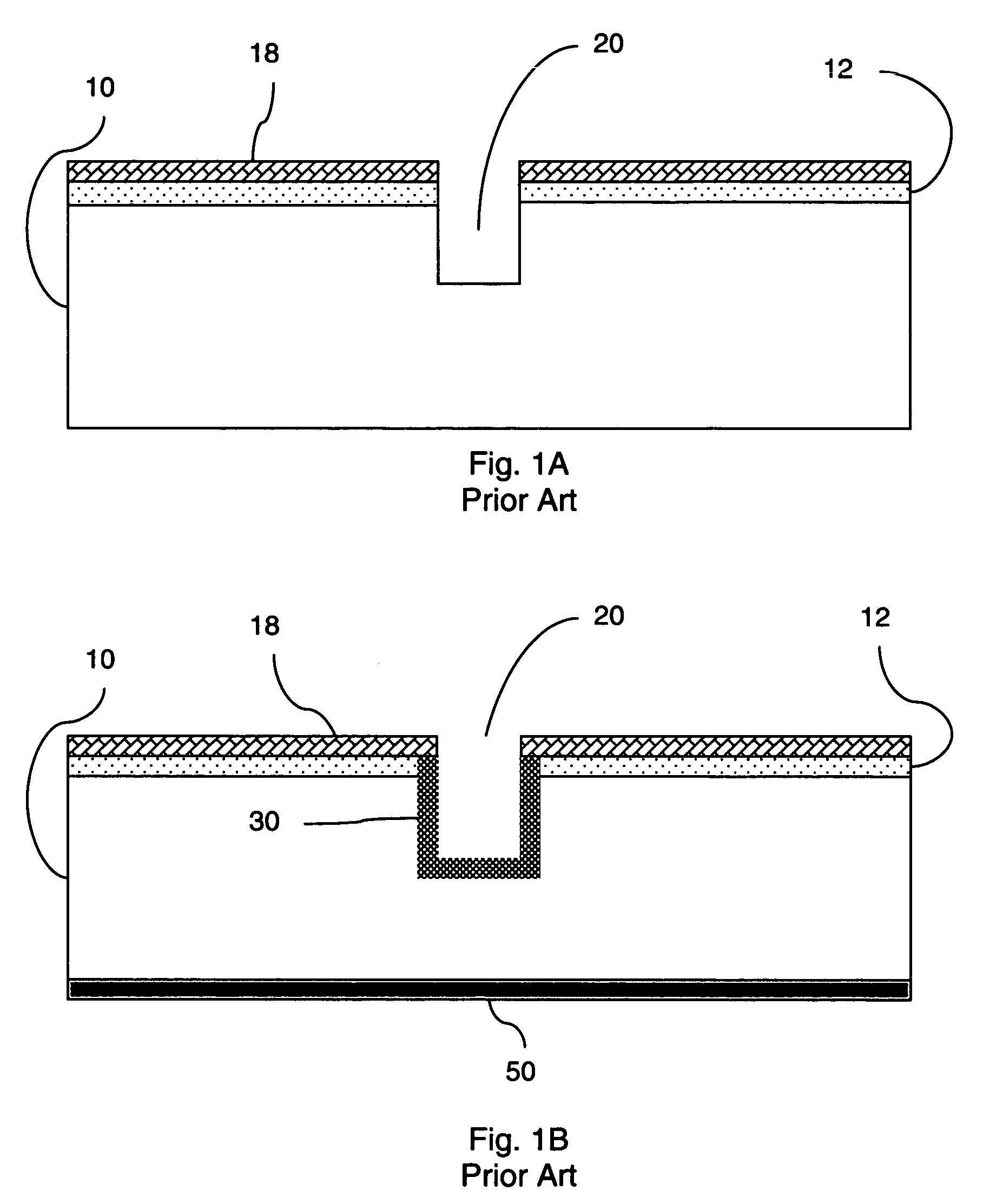

Buried-contact solar cells with self-doping contacts

InactiveUS20050172998A1Minimum of grid obscurationLess expensiveFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

A buried-contact solar cell, in-process buried-contact solar cell components and methods for making buried contact solar cells wherein a self-doping contact material is placed in a plurality of buried-contact surface grooves. By combining groove doping and metallization steps, the resulting solar cell is simpler and more economical to manufacture.

Owner:APPLIED MATERIALS INC

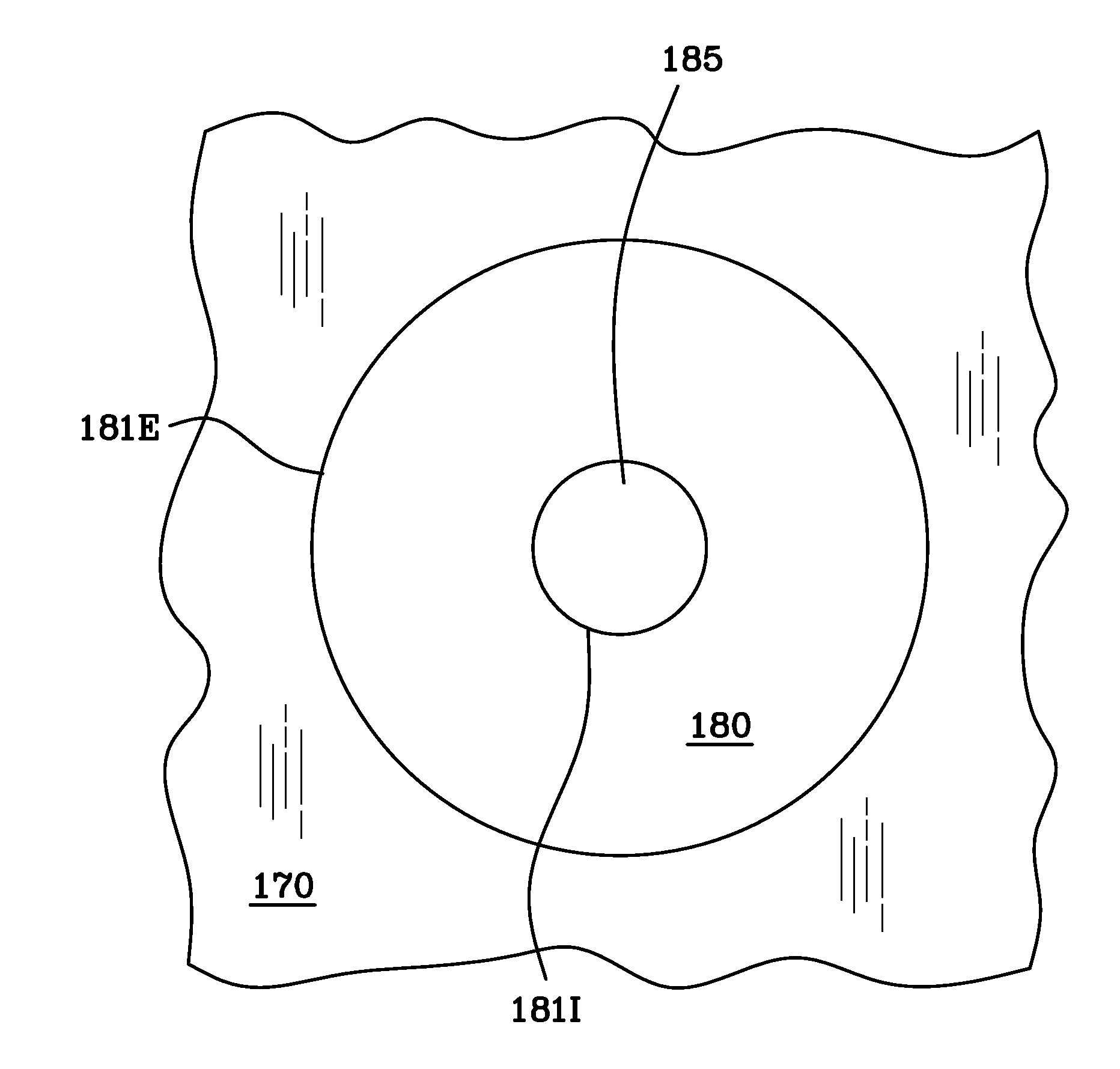

Method of fabricating a glass magnetic hard drive disk platter using filamentation by burst ultrafast laser pulses

ActiveUS20150118522A1Reduce manufacturing costExtreme precisionMagnetic materials for record carriersGlass furnace apparatusHard disc driveNon ablative

A non-ablative method and apparatus for making an economical glass hard disk (platter) for a computer hard disk drive (HDD) using a material machining technique involving filamentation by burst ultrafast laser pulses. Two related methods disclosed, differing only in whether the glass substrate the HDD platter is to be cut from has been coated with all the necessary material layers to function as a magnetic media in a computer's hard drive. Platter blanks are precisely cut using filamentation by burst ultrafast laser pulses such that the blank's edges need not be ground, the platter's geometric circularity need not be corrected and there is no need for further surface polishing. Thus the platters can be cut from raw glass or coated glass. As a result, this method reduces the product contamination, speeds up production, and realizes great reductions in the quantity of waste materials and lower production costs.

Owner:ROFIN SINAR TECH

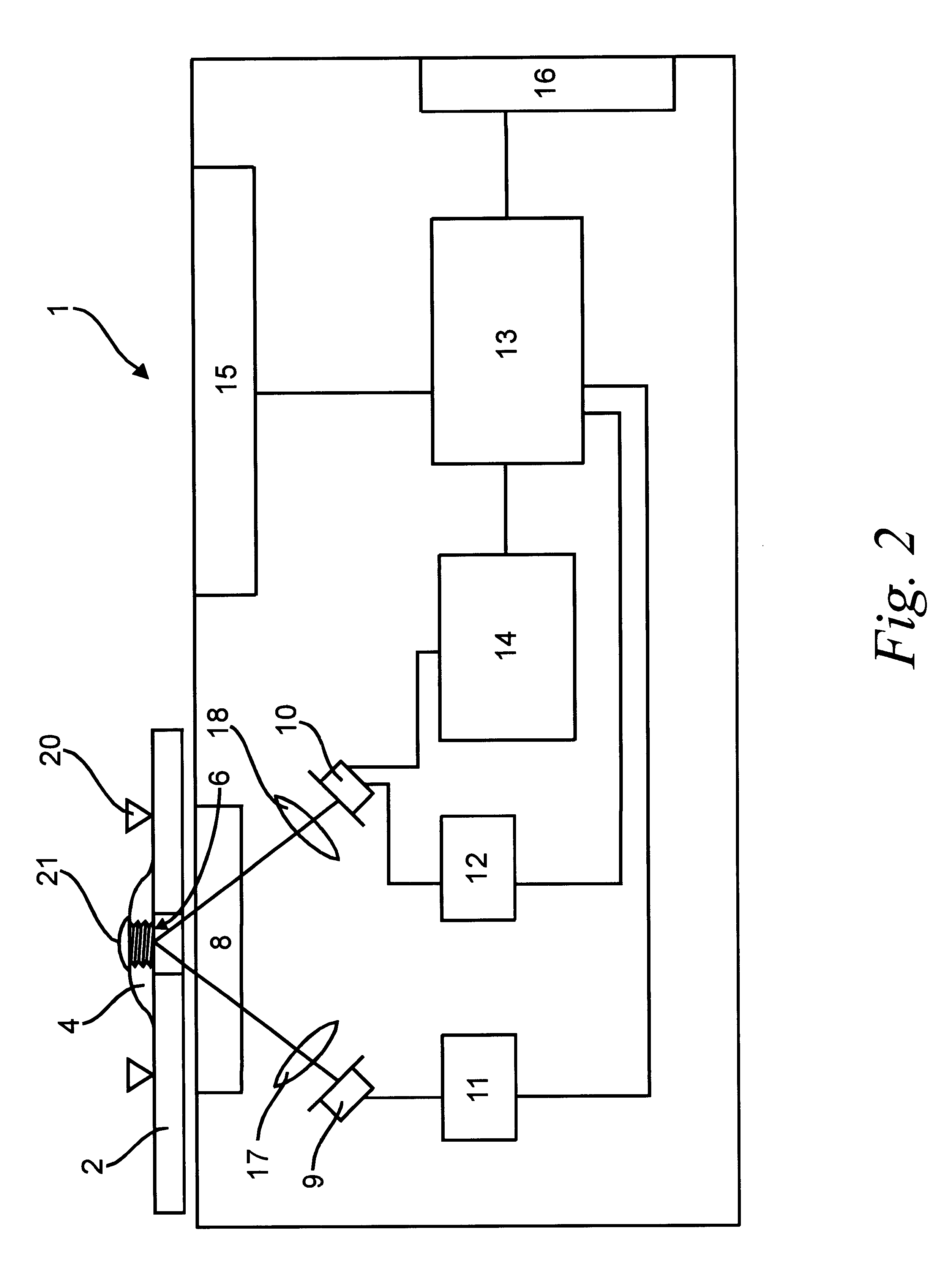

Method for determining the glucose content of a blood sample

InactiveUS6448067B1Easy to operateIncrease power consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsChemical compositionMeasurement testing

The invention relates to a method and apparatus for determining a chemical component from a sample, where the sample is measured on a test strip with the help of a color reaction. The method concerns finding the measurement time Tm for measuring the reflection of the test strip. The method comprises the following steps: a) Recording the R(t) function, b) Determining the T0 starting time at the detection of the wetting through of the sample, c) Generating the function R(t)+L(t), d) Monitoring and storing the ext[R(t)+L(t)] extreme value of the R(t)+L(t) function, and, at the same time, e) Generating the function R(t)+L(t)-ext[R(t)+L(t)] from the time of reaching an ext[R(t)+L(t)] extreme value, f) when the R(t)+L(t)-ext[R(t)+L(t)] function reaches a predetermined C(t) value, determining the Tm measuring time.

Owner:77 ELEKTRONIKA MUSZERIPARI

Buried-contact solar cells with self-doping contacts

InactiveUS7335555B2Less expensiveMinimum obscurationFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellSolar cell fabrication

Owner:APPLIED MATERIALS INC

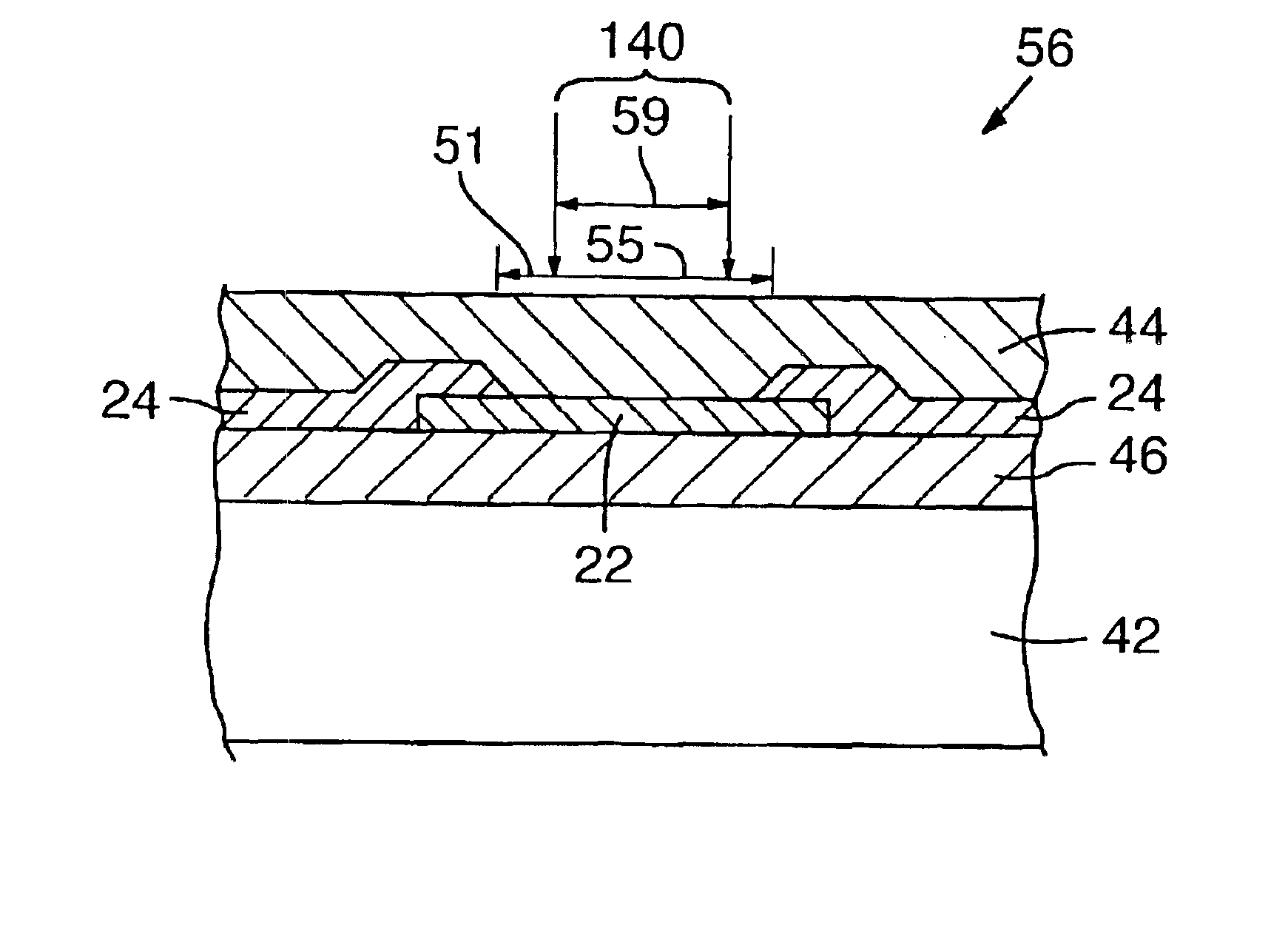

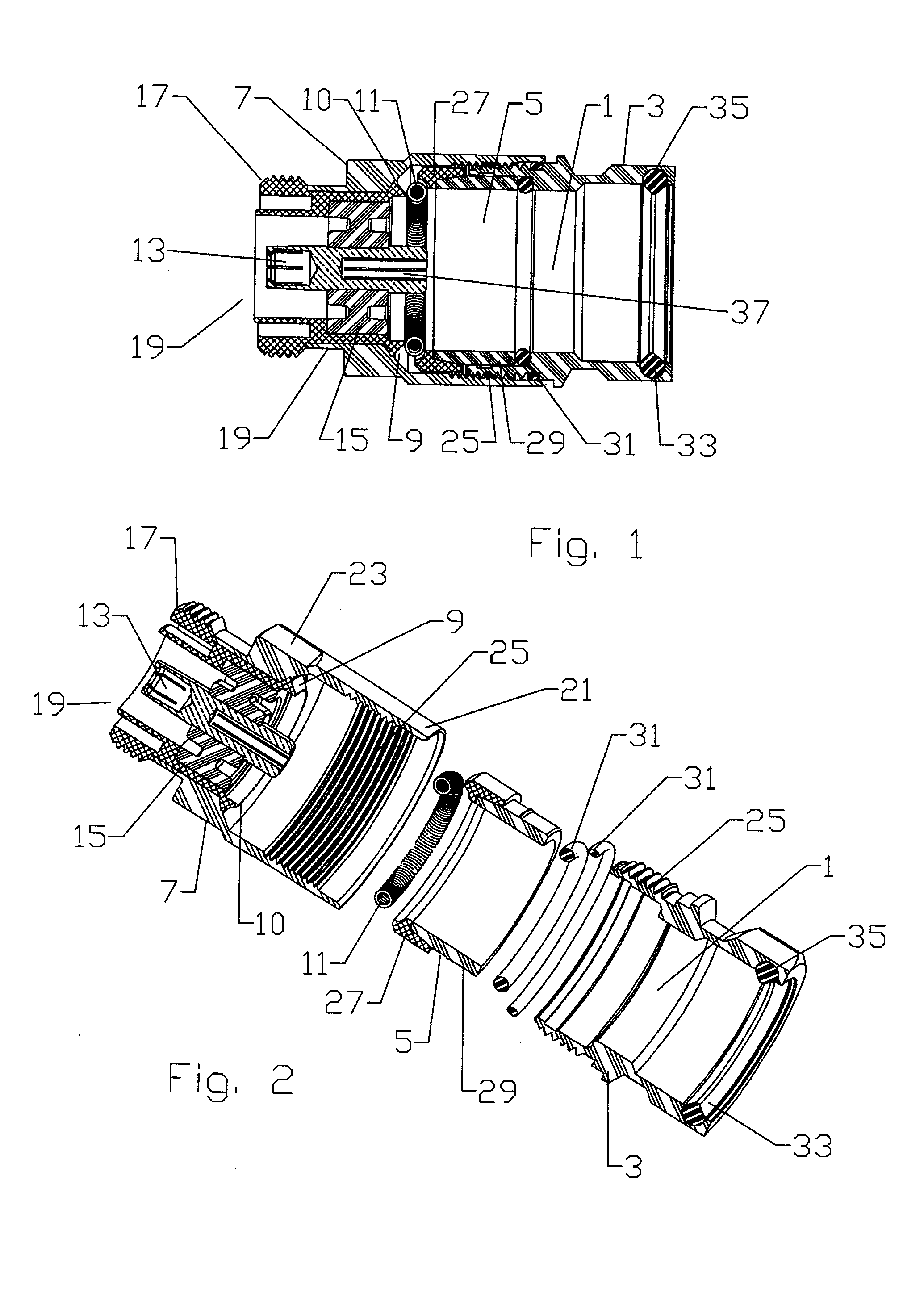

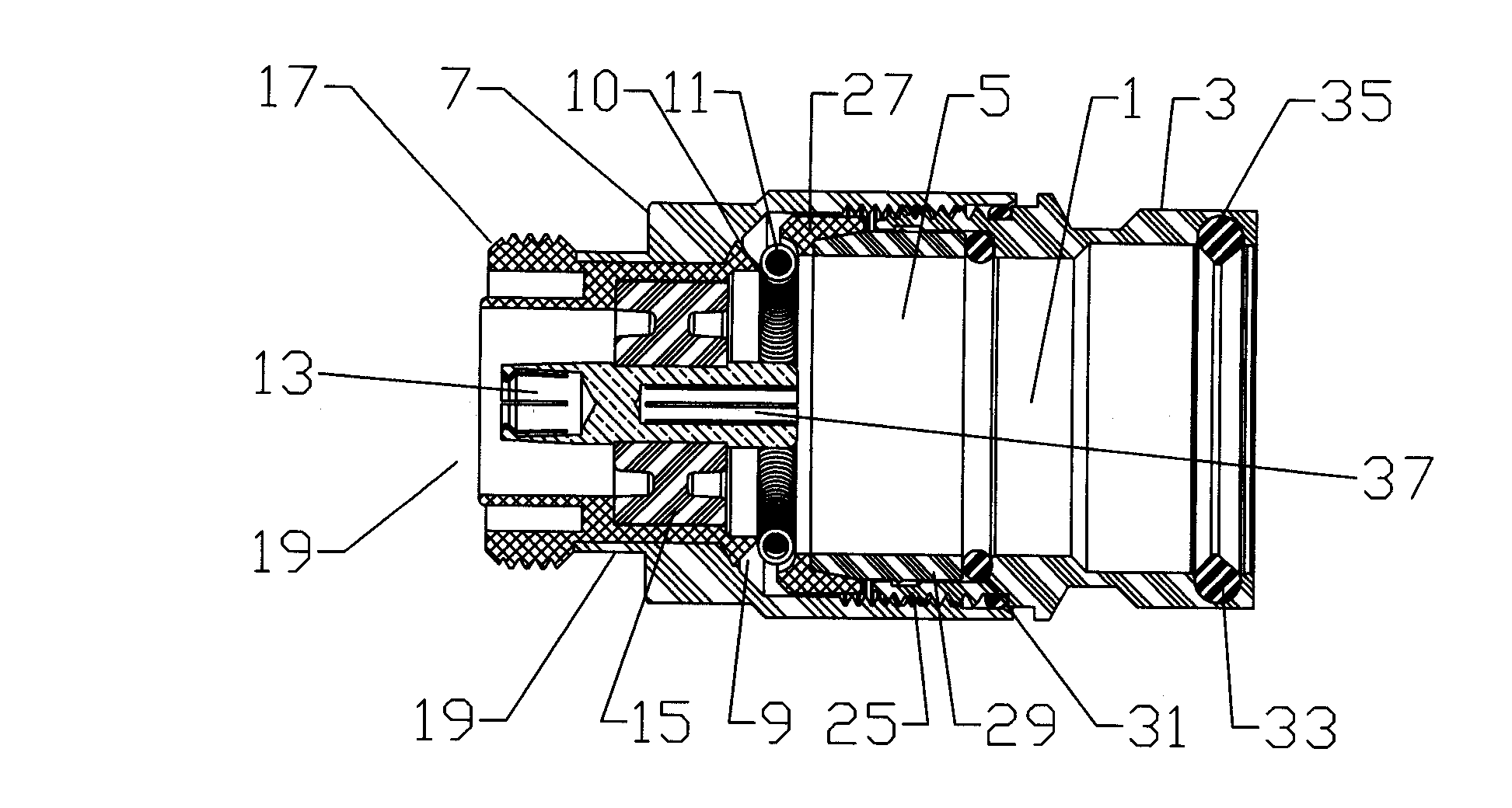

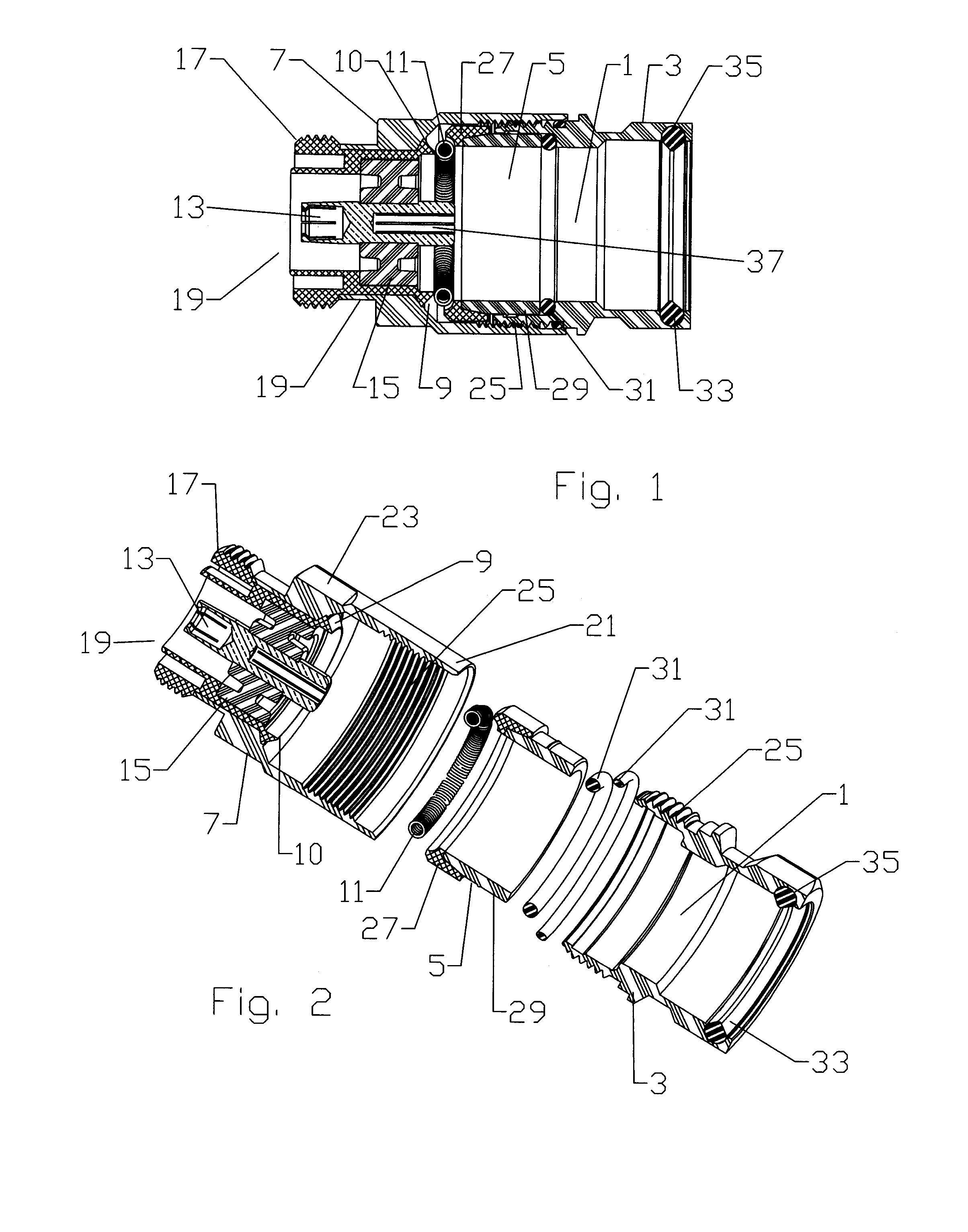

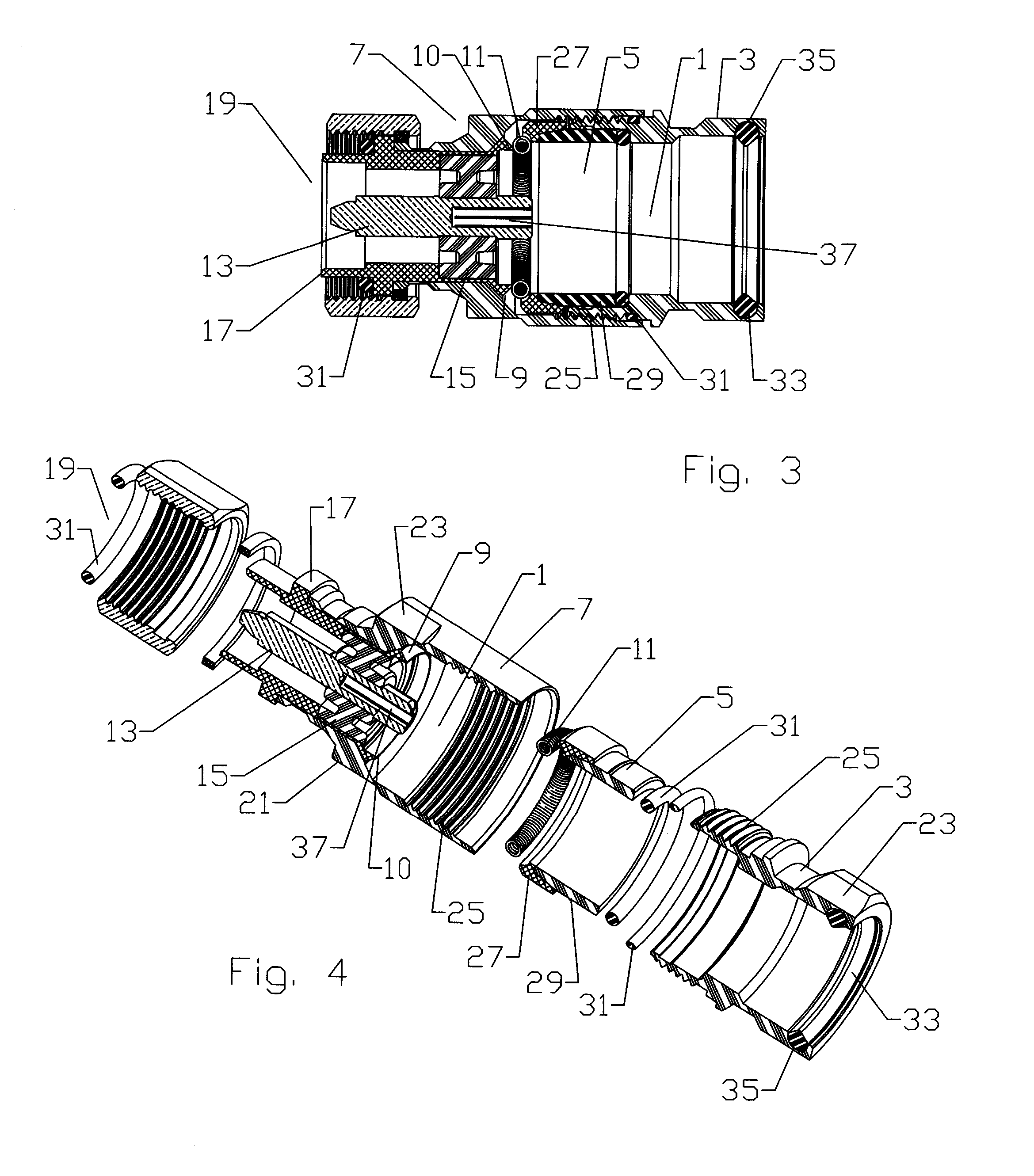

Multi-shot Connector Assembly and Method of Manufacture

InactiveUS20110003507A1Significant costSignificant materialTwo pole connectionsContact member cases/bases manufactureMultiple injectionCoaxial cable

A coaxial cable connector formed via multi-shot injection molding has a body formed by multiple injection molding layers of different injection moldable materials about a central inner contact to form an integral connector body. The connector body is provided with a coaxial dielectric spacer of dielectric polymer surrounding the inner contact; a coaxial inner body of injection molded metal composition surrounding an outer diameter of the dielectric spacer; and an outer body of polymer surrounding the inner body. Interlock features provide axial and / or rotational interlock between the layers of the connector.

Owner:ANDREW LLC

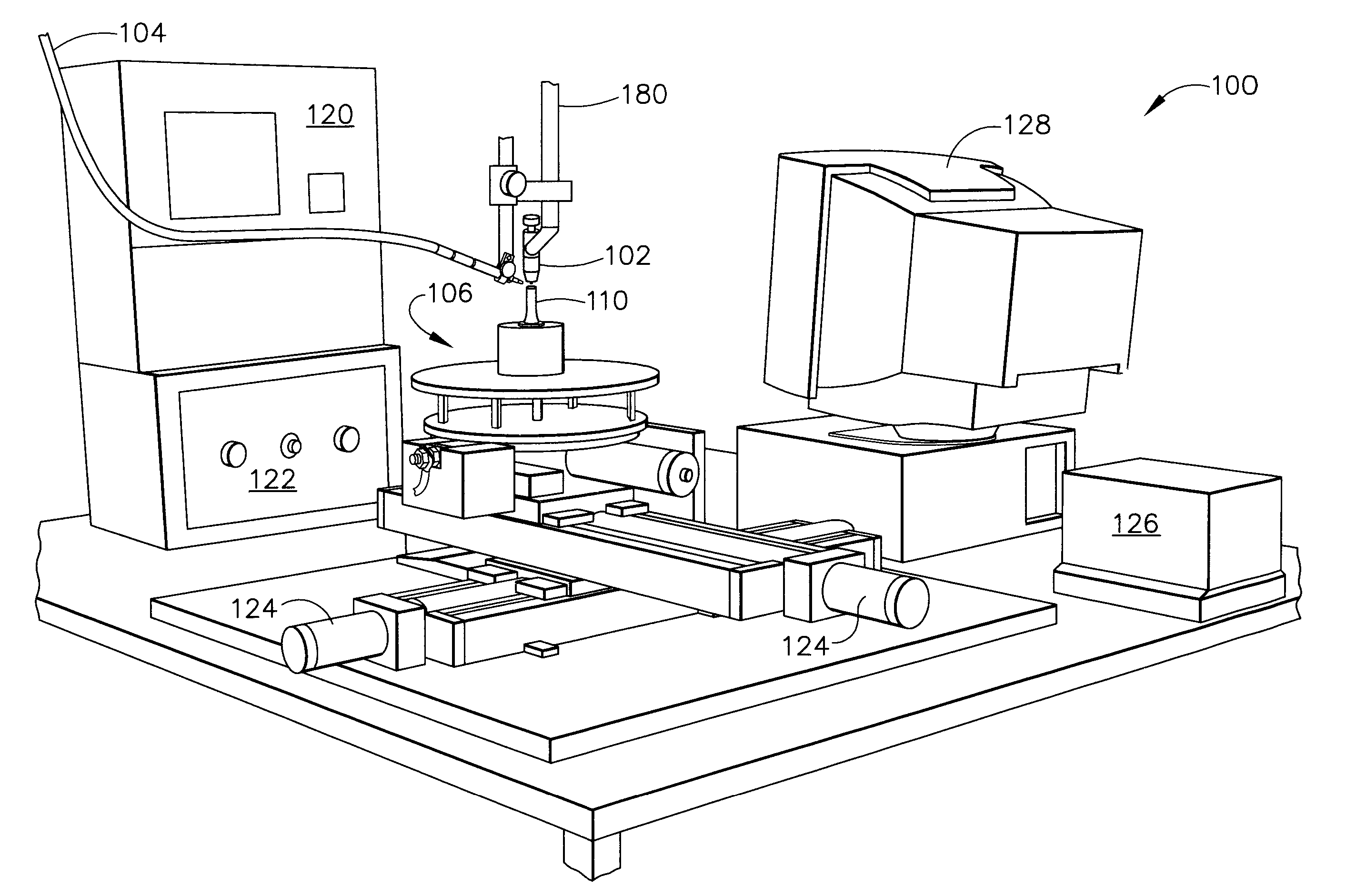

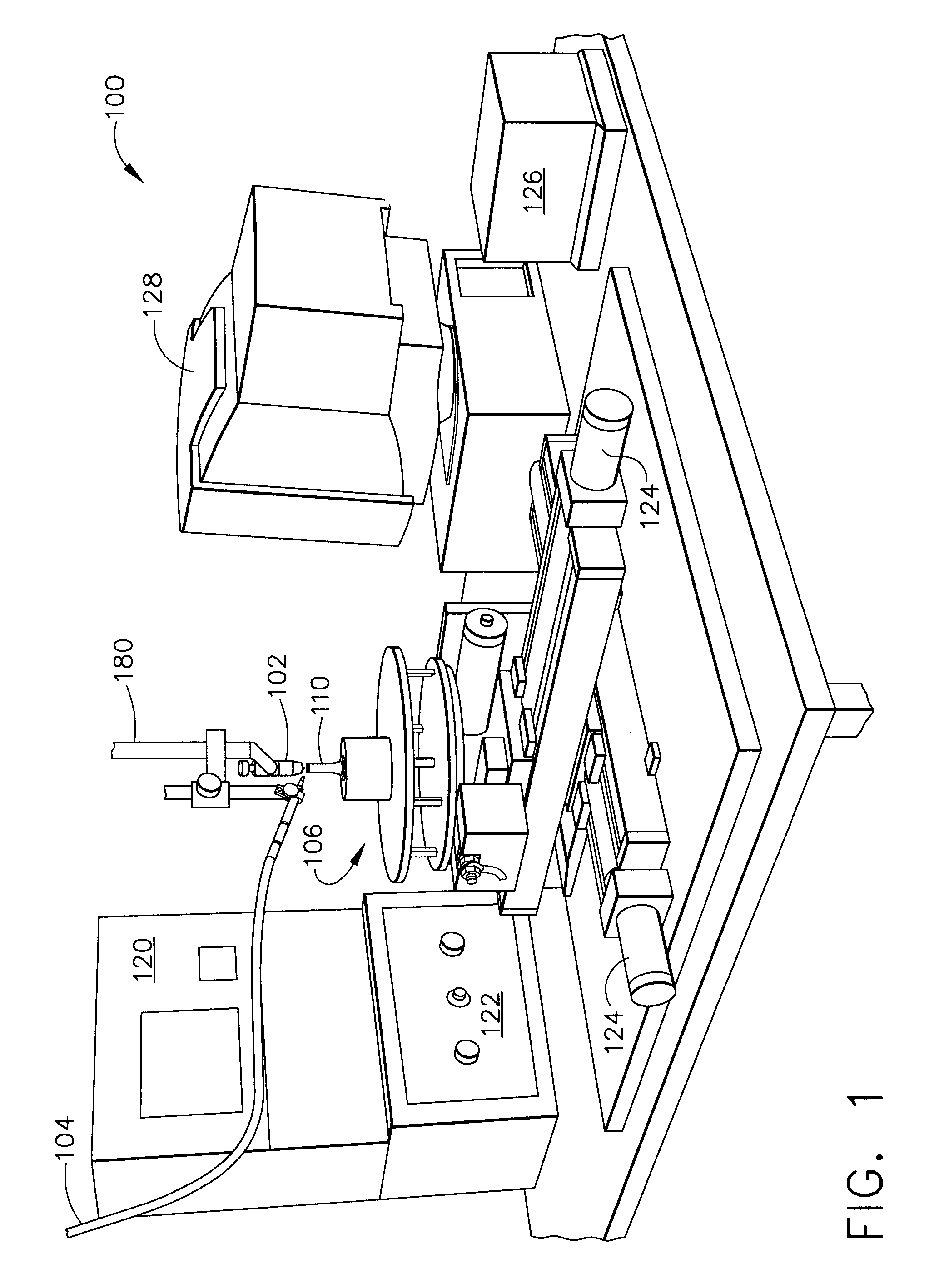

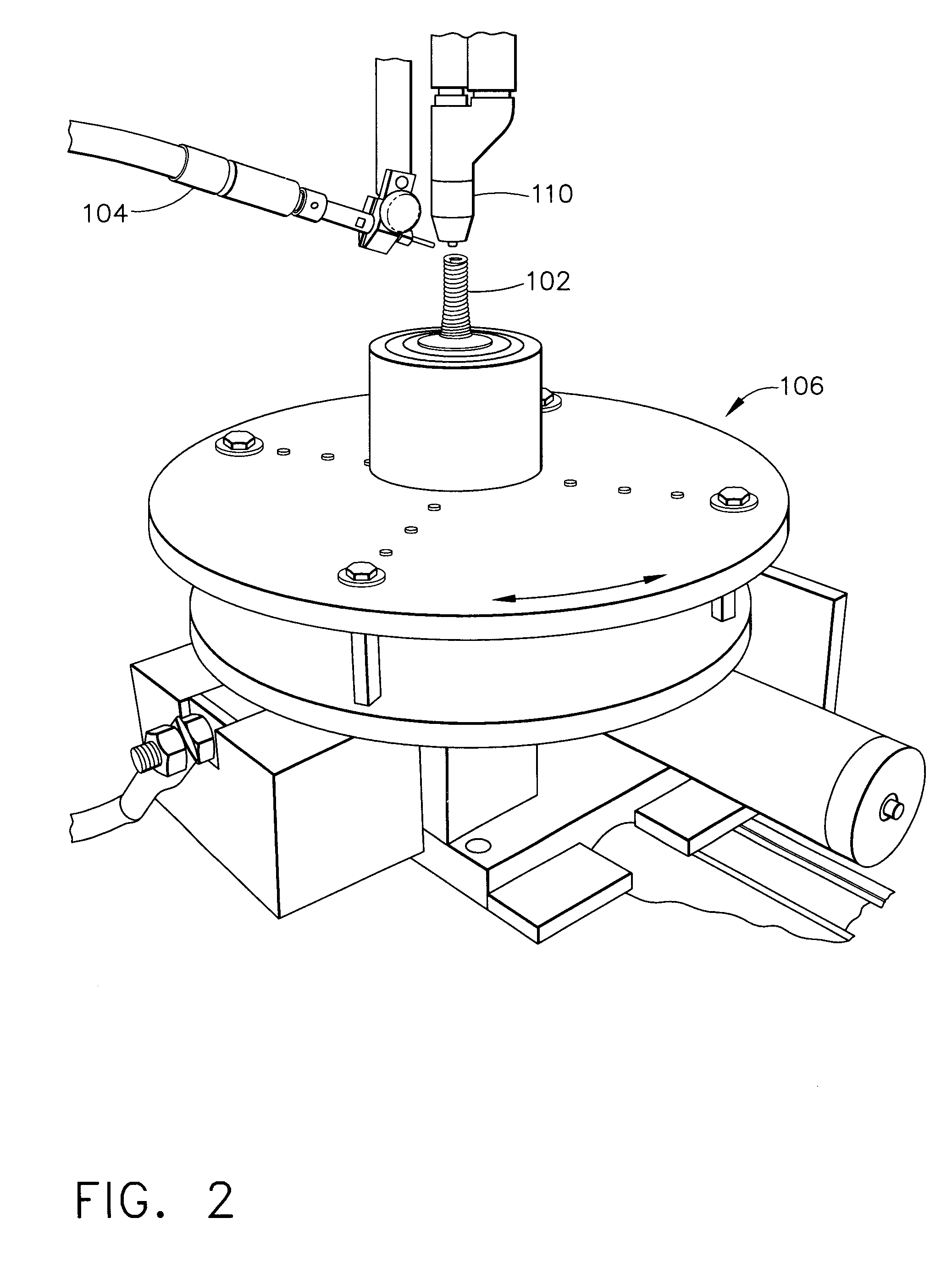

Ion fusion formation

InactiveUS6680456B2Increase the cross-sectional areaIncrease deposition rateLiquid surface applicatorsMolten spray coatingThree dimensional shapeArgon gas

An ion fusion formation (IFF) system uses a plasma welding torch to create ions that heat feedstock for application at a deposition point. A plasma welding torch may use argon gas or the like in order to provide extremely hot ions that impact or collide with the feedstock in order to melt it and enabling application of the melted feedstock to a deposition point on a workpiece. By positioning the workpiece, wire feeder, and / or welding torch, parts, devices, or components can be built in almost any three-dimensional shape. Parts can be manufactured in a "just-in-time fashion" with high precision and predictable performance.

Owner:NORSK TITANIUM

Preparation method of chelate coating with copper ions capable of controllably catalyzing release of nitrogen monoxide and polyphenol complex

ActiveCN104194460ALong-term antibacterialImprove antibacterial propertiesAntifouling/underwater paintsSurgeryBiocompatibility TestingPhenol

The invention discloses a preparation method of a chelate coating with copper ions capable of controllably catalyzing release nitrogen monoxide and a polyphenol complex. The preparation method comprises the following steps: soaking a target modified material or an instrument in a mixed aqueous solution consisting of soluble metal salt, soluble copper salt and a compound having an o-phenol structure; and depositing a layer of chelate coating with copper ions with a function of catalyzing nitrogen monoxide and the polyphenol complex on the surface. The chelate coating with the copper ions and the polyphenol complex, which is obtained by the preparation method disclosed by the invention, not only has excellent biocompatibility and bacterial resistance, but also has a function of inducing catalysis of endogenous nitrogen monoxide to release in a blood environment. In addition, the coating is nearly applicable to surface modification of materials of all textures, complex geometrical shapes and different topological structures.

Owner:GUANGZHOU NANCHUANG EVEREST MEDICAL TECH CO LTD

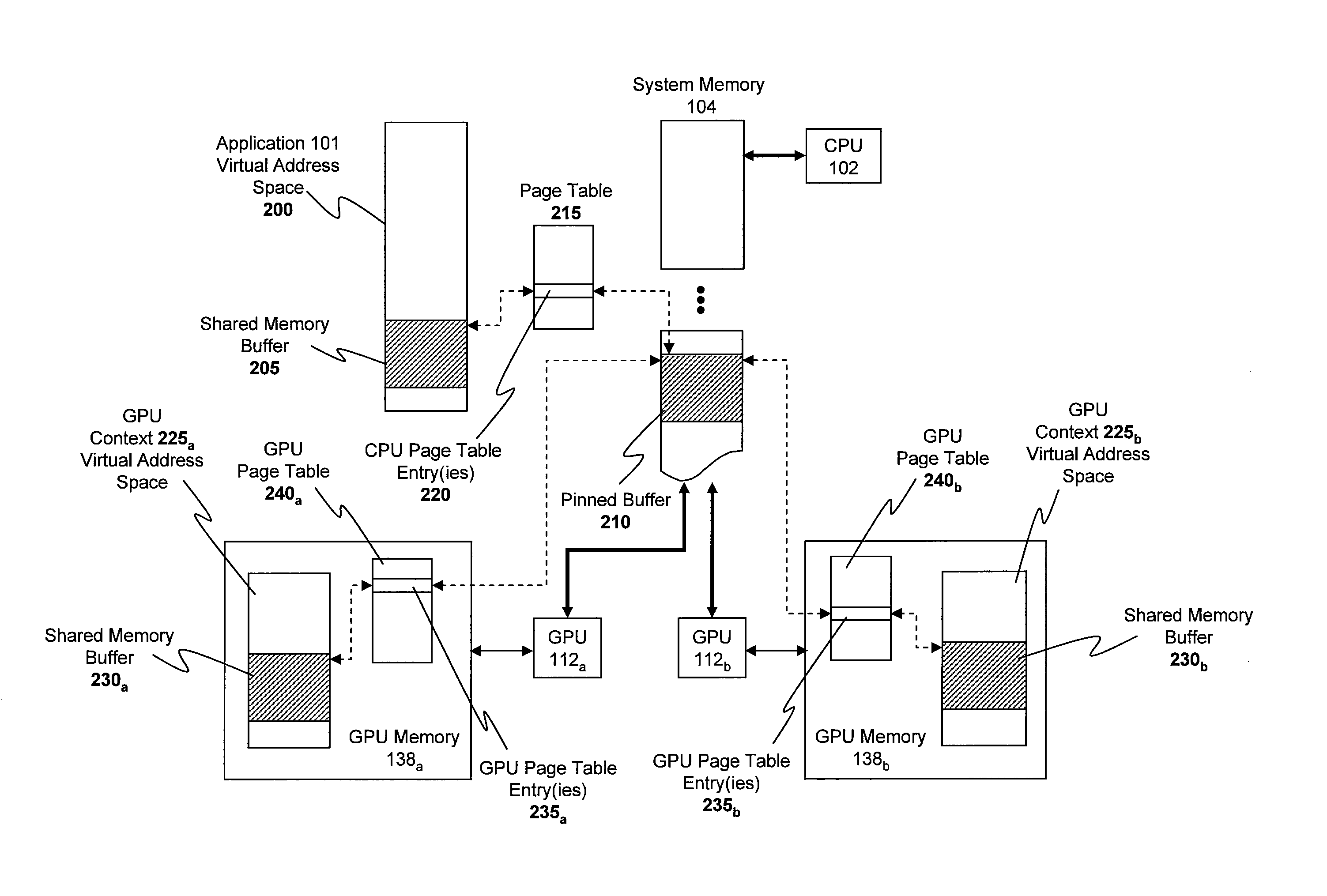

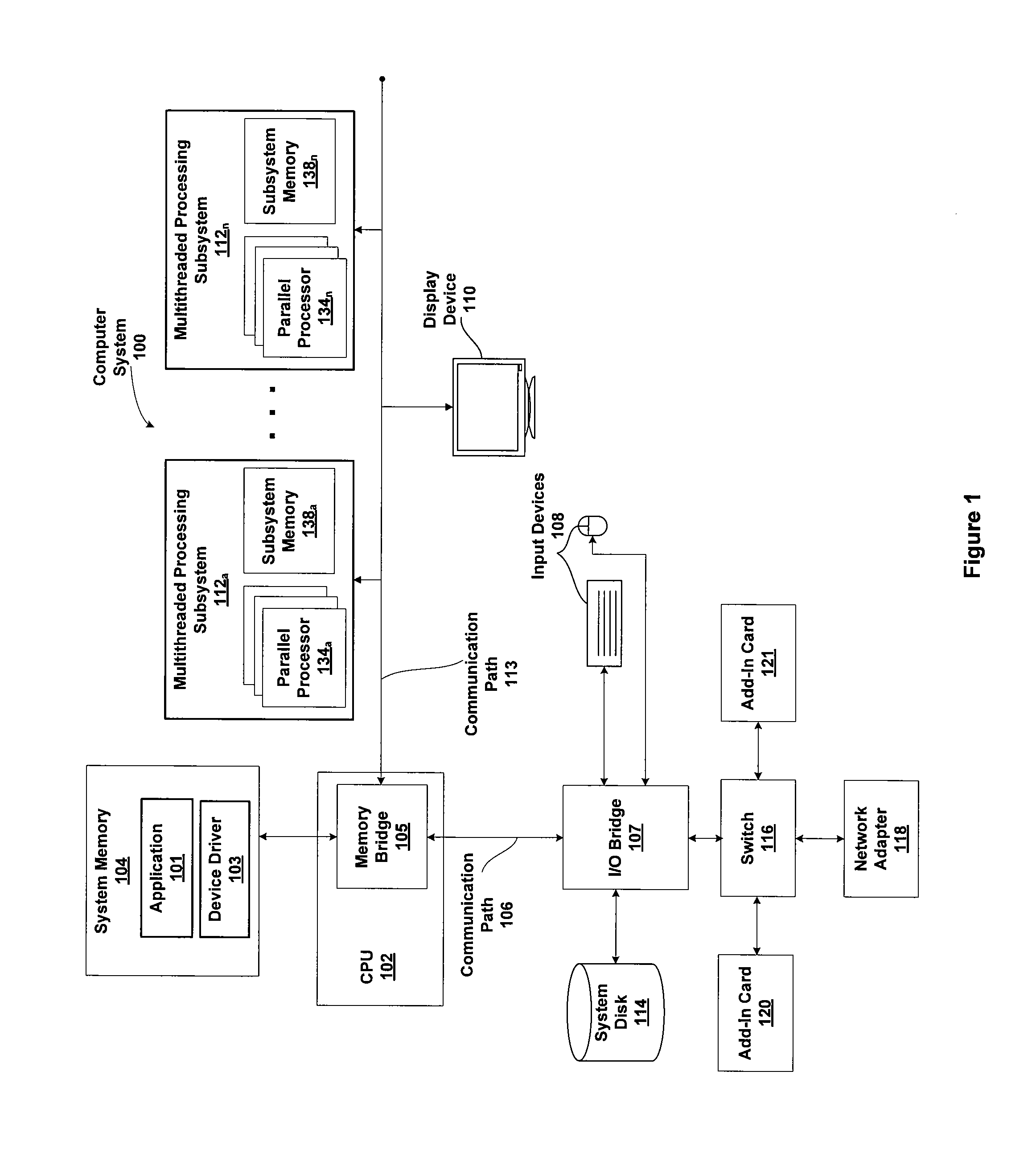

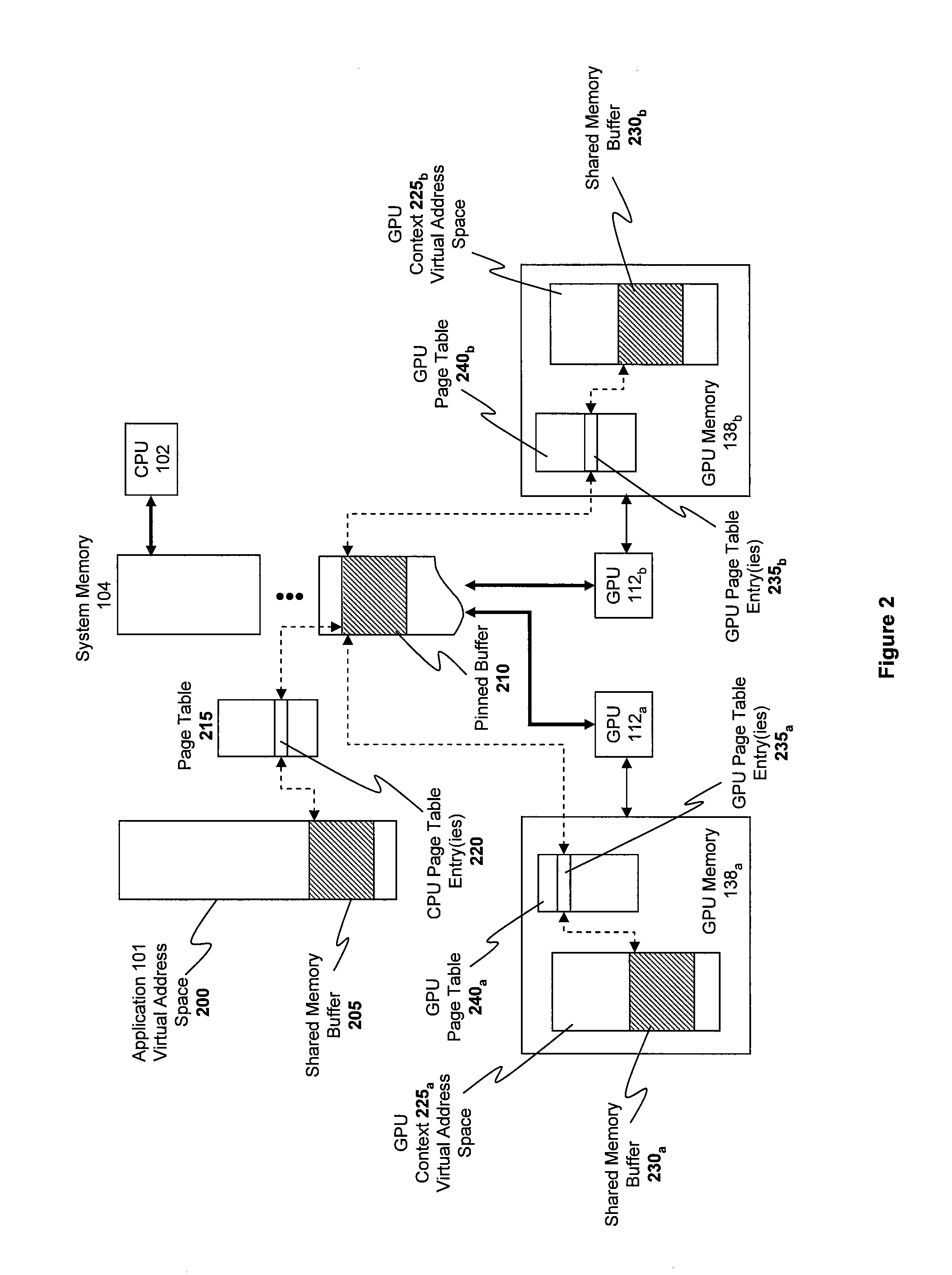

Method and system for providing shared memory access to graphics processing unit processes

ActiveUS9547535B1Exemption stepsImprove performanceInterprogram communicationCathode-ray tube indicatorsGraphicsDirect memory access

One or more embodiments of the invention set forth techniques to create a process in a graphical processing unit (GPU) that has access to memory buffers in the system memory of a computer system that are shared among a plurality of GPUs in the computer system. The GPU of the process is able to engage in Direct Memory Access (DMA) with any of the shared memory buffers thereby eliminating additional copying steps that have been needed to combine data output of the various GPUs without such shared access.

Owner:NVIDIA CORP

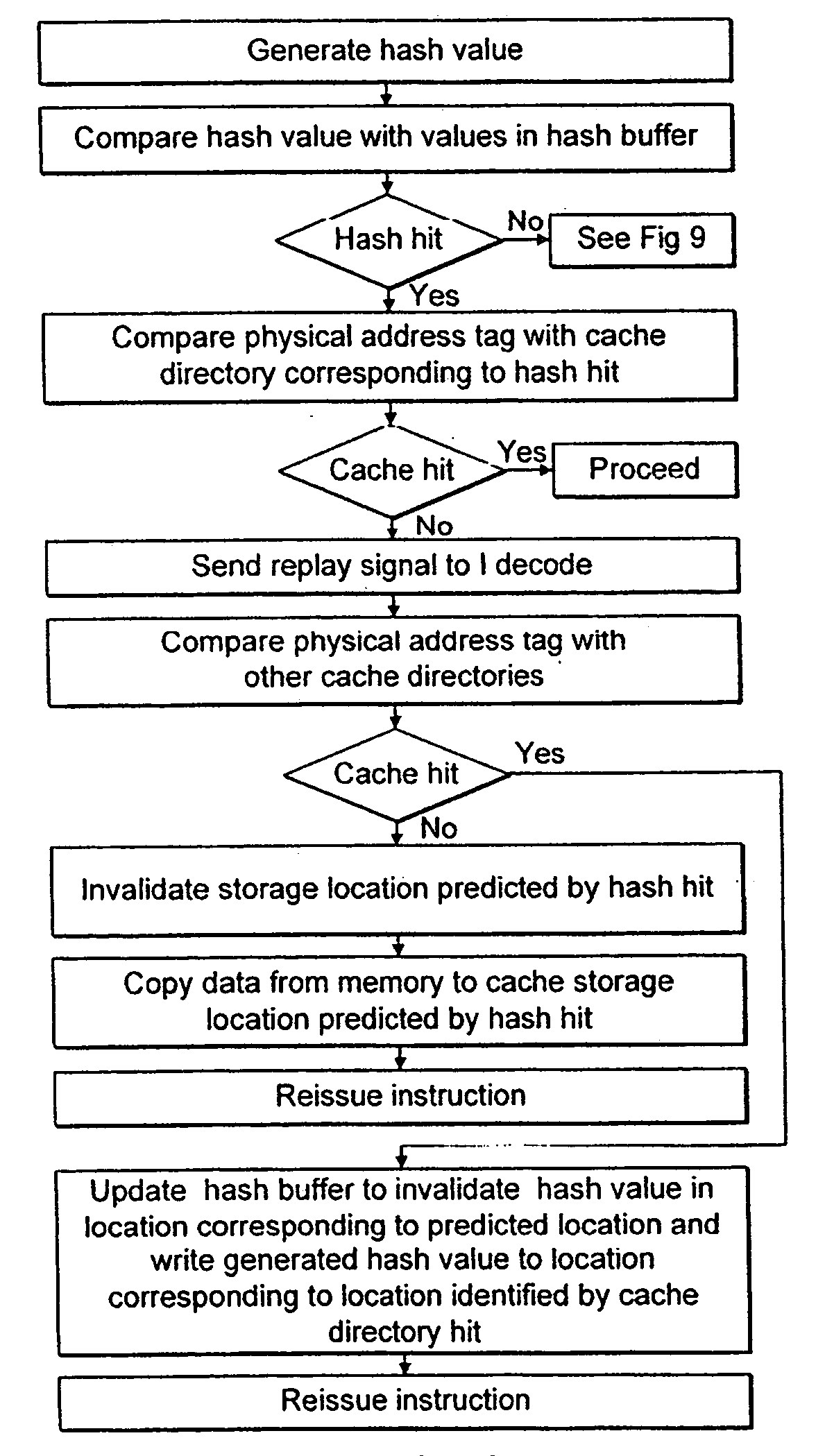

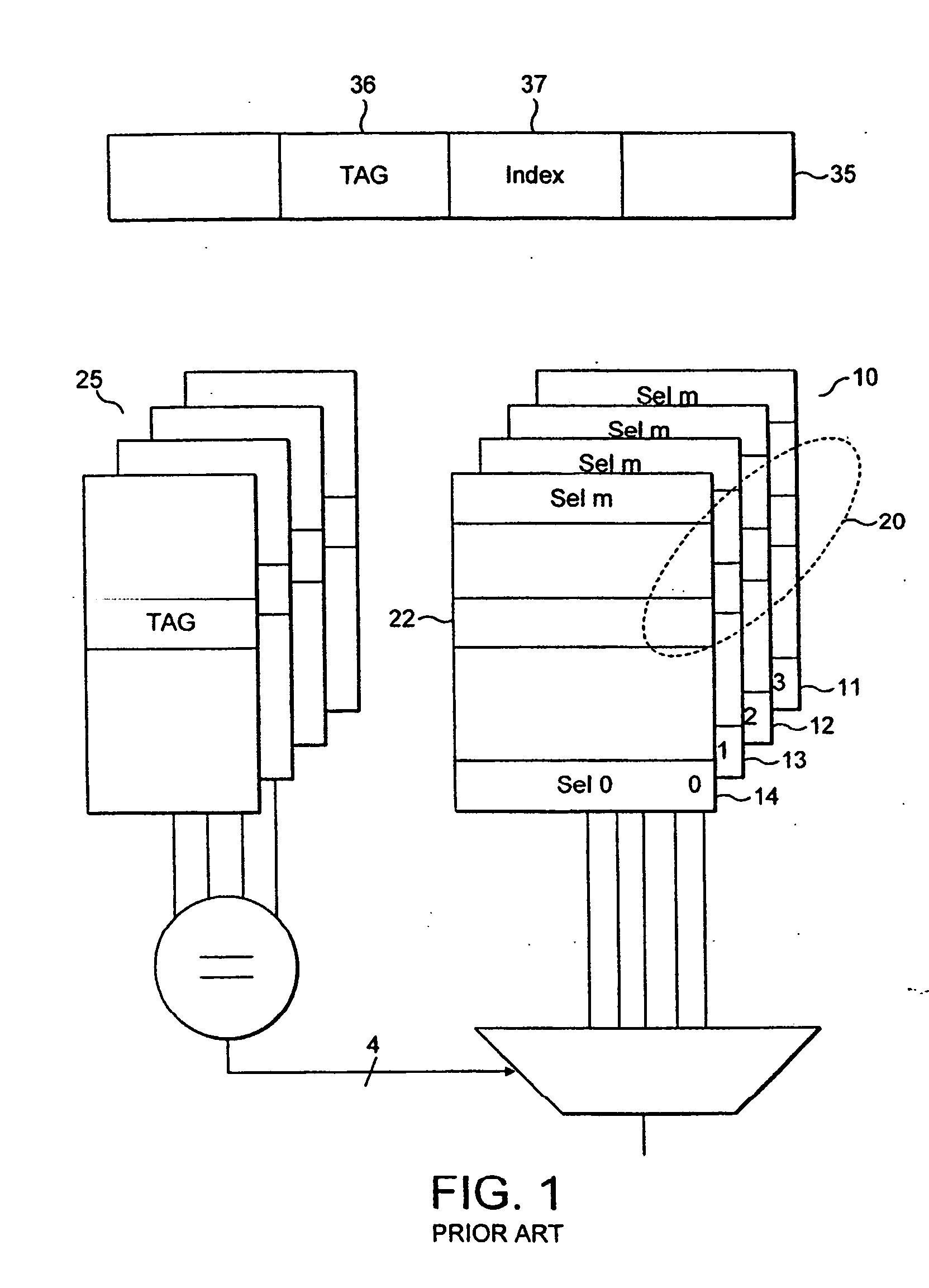

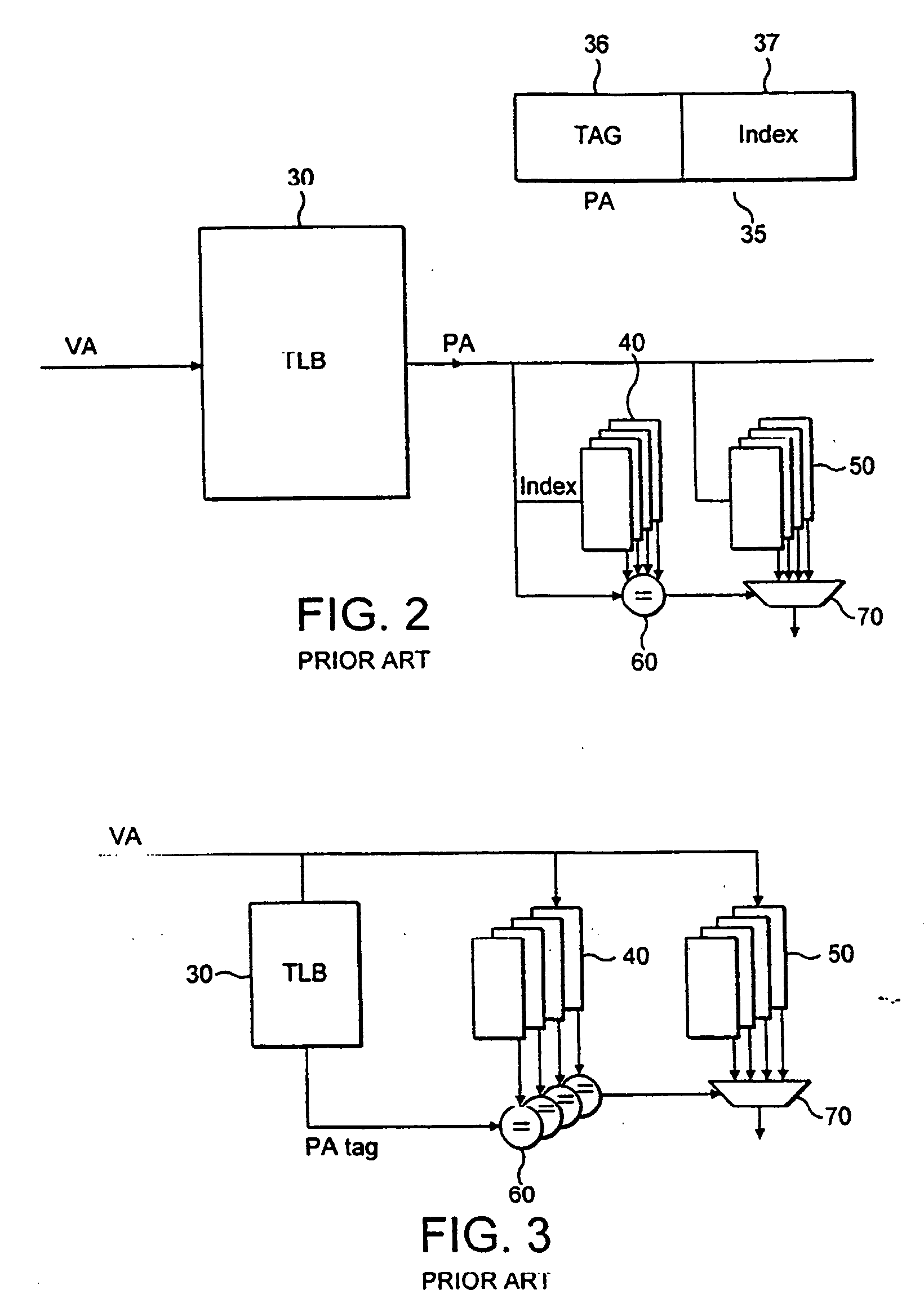

Time and power reduction in cache accesses

InactiveUS20070028051A1Reduce the number of stepsReduce widthMemory architecture accessing/allocationEnergy efficient ICTCache accessData buffer

Owner:ARM LTD +1

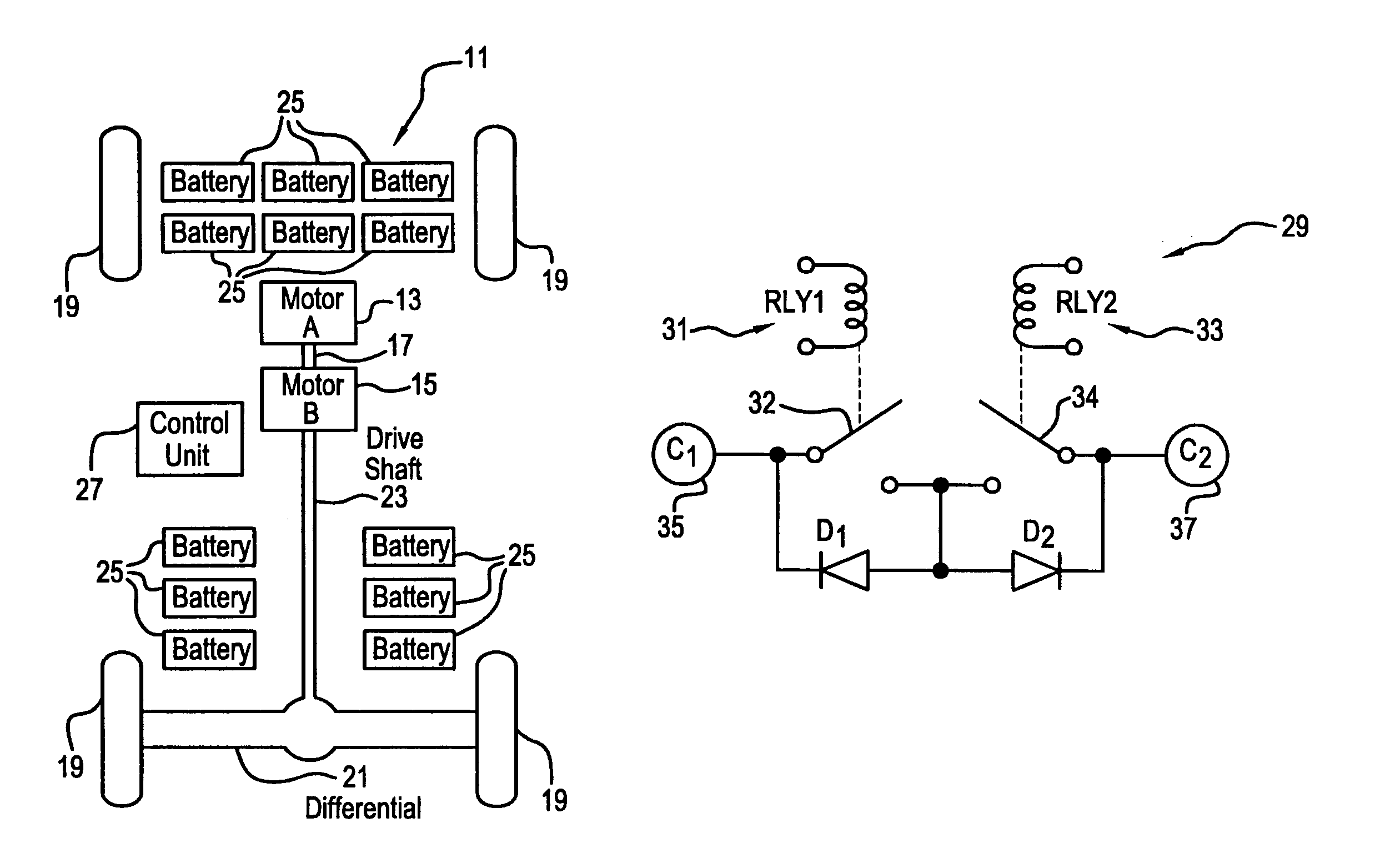

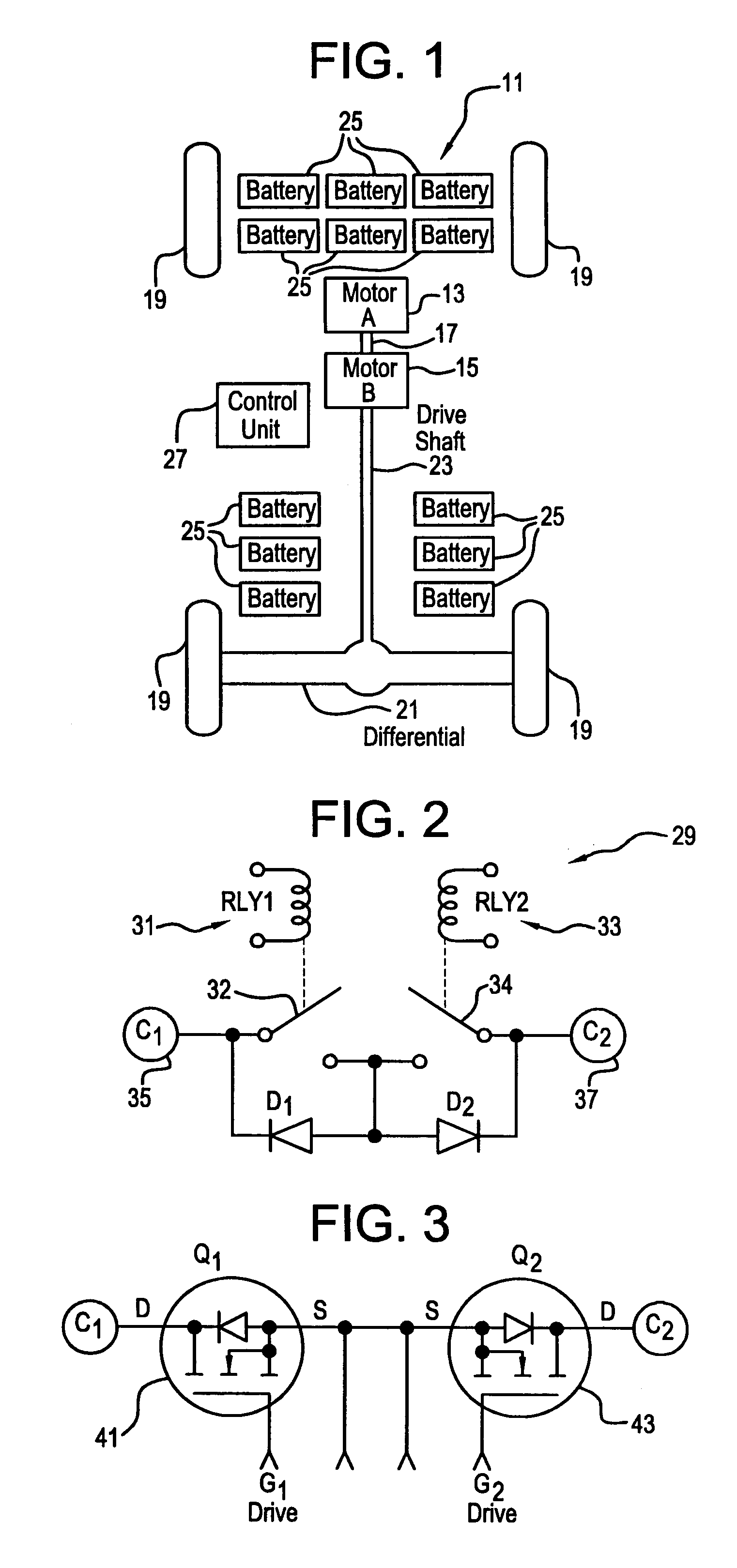

Electric vehicle motor and control system with high efficiency regeneration

InactiveUS7208894B1Increased low speed acceleration torqueAdvanced control systemAuxillary drivesBatteries circuit arrangementsLow speedControl system

The present invention is an electric vehicle power system that uses multiple permanent magnet motor / generators connected in series or parallel and multiple battery step switching. Motor, torque and speed are controlled by steps in series connection and then in parallel connection. Smooth acceleration, regeneration and current control are provided by delaying stepping from one battery step to the next until the next step is fully engaged. Transients are limited to the effect of one battery step by using rectifier shunt switching. Multiple motors provide acceleration torque at low speed in series connections and at cruising speeds in parallel connection. Regenerative deceleration is provided in the opposite manner. Battery depletion is averaged by flipping ends of a battery bank. Controls are provided with normal foot controls and a speed setter. A separate deceleration pedal or lever may be used.

Owner:EARLE JOHN L

Expandable self-anchoring interbody cage for orthopedic applications

The present invention is directed to an expandable spinal fusion intervertebral implant and a method for surgically implanting said implant that provides for maintaining and creating lordosis in the human spine that can be filled with biologics while in situ to encourage spinal fusion. A threaded rod that traverses an insertion / injection handle can be rotated to operate a screw within the interbody cage that displaces opposing vertical tapped sliding wedges, causing them to converge towards each other. Such contact causes the operation of a horizontal wedge that acts as a lift to expand the interbody cage to one of various dimensions in a preferred range. In its expanded height, the overall length of the interbody cage is maintained. At its desired expansion, the spinal fusion implant of the present invention is sized to fit within the disc space between two vertebral bodies and fill all voids left while the vertical and horizontal wedges operate within, due to the biologics being contained within the interbody cage.

Owner:BLUE TIP BIOLOGICS

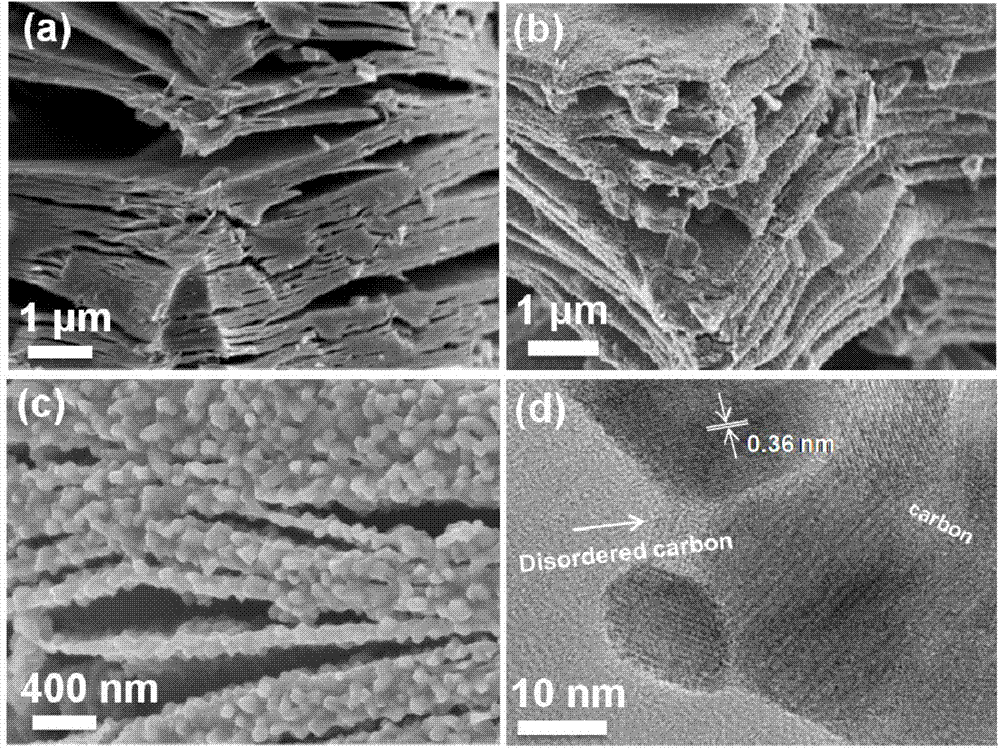

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

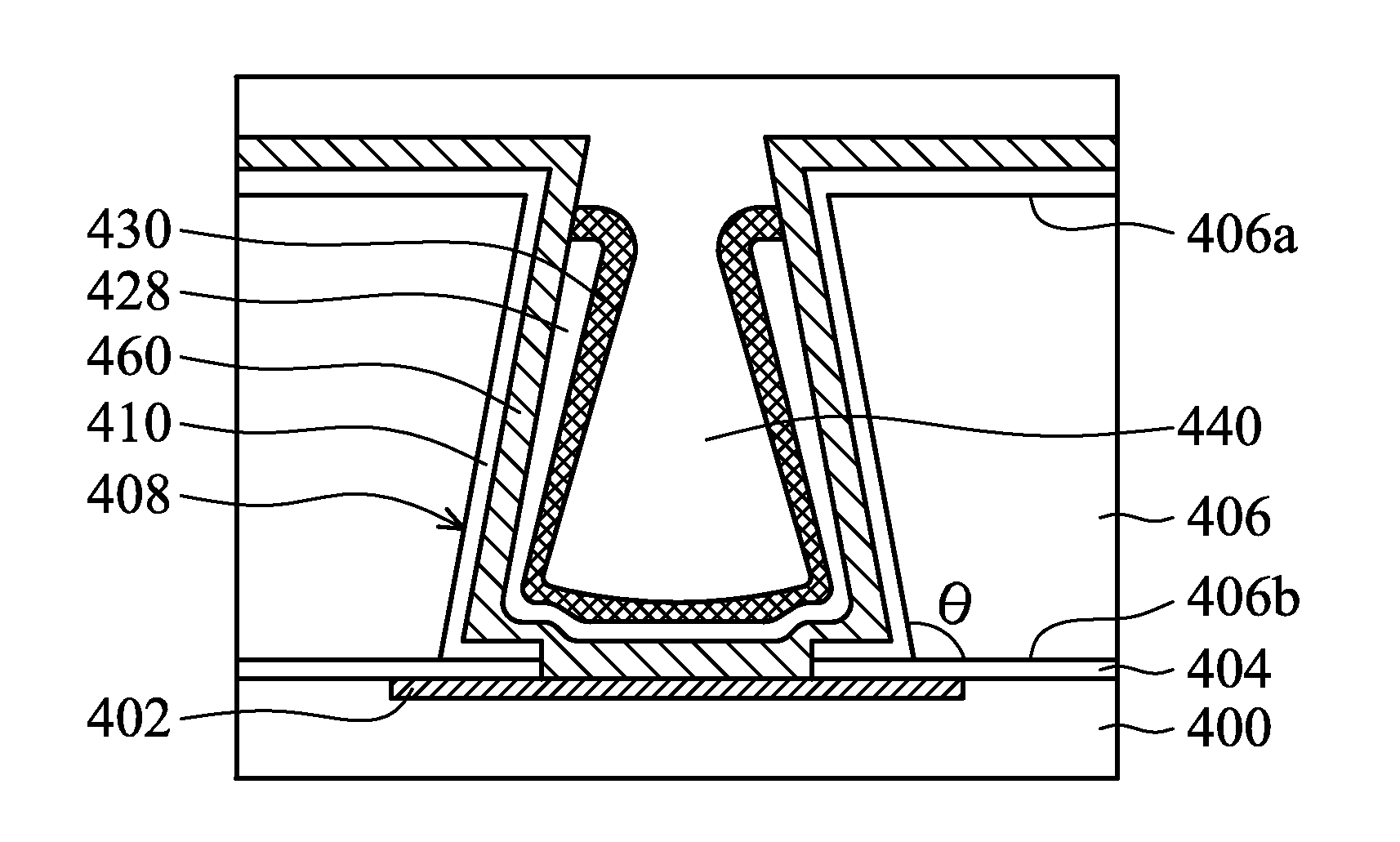

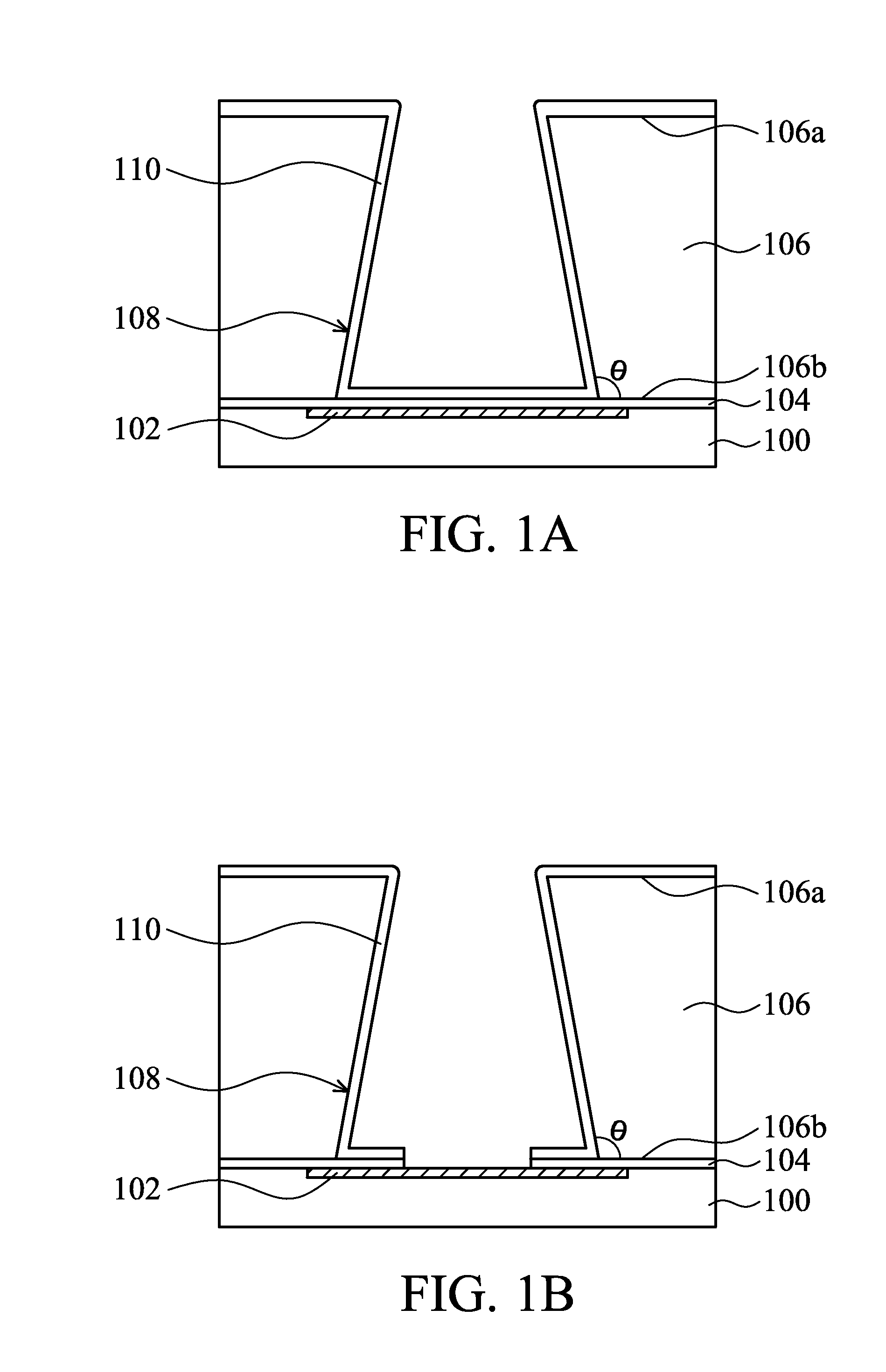

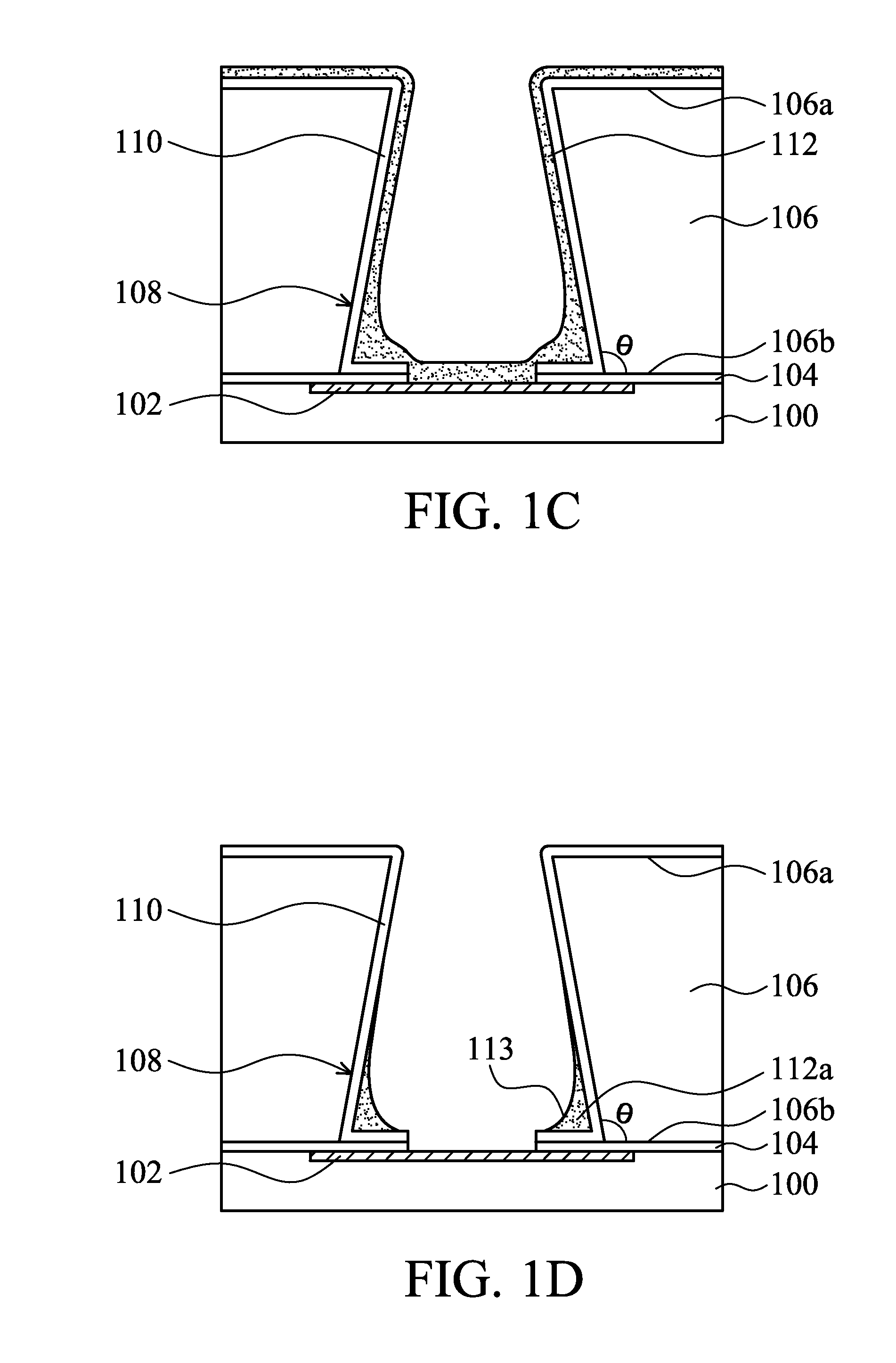

Chip package and method for forming the same

ActiveUS20110193241A1Reduce thicknessImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPhysics

According to an embodiment of the invention, a chip package is provided, which includes: a substrate having an upper surface and a lower surface; a hole extending from the upper surface toward the lower surface; an insulating layer located overlying a sidewall of the hole; and a material layer located overlying the sidewall of the hole, wherein the material layer is separated from the upper surface of the substrate by a distance and a thickness of the material layer decreases along a direction toward the lower surface.

Owner:XINTEC INC

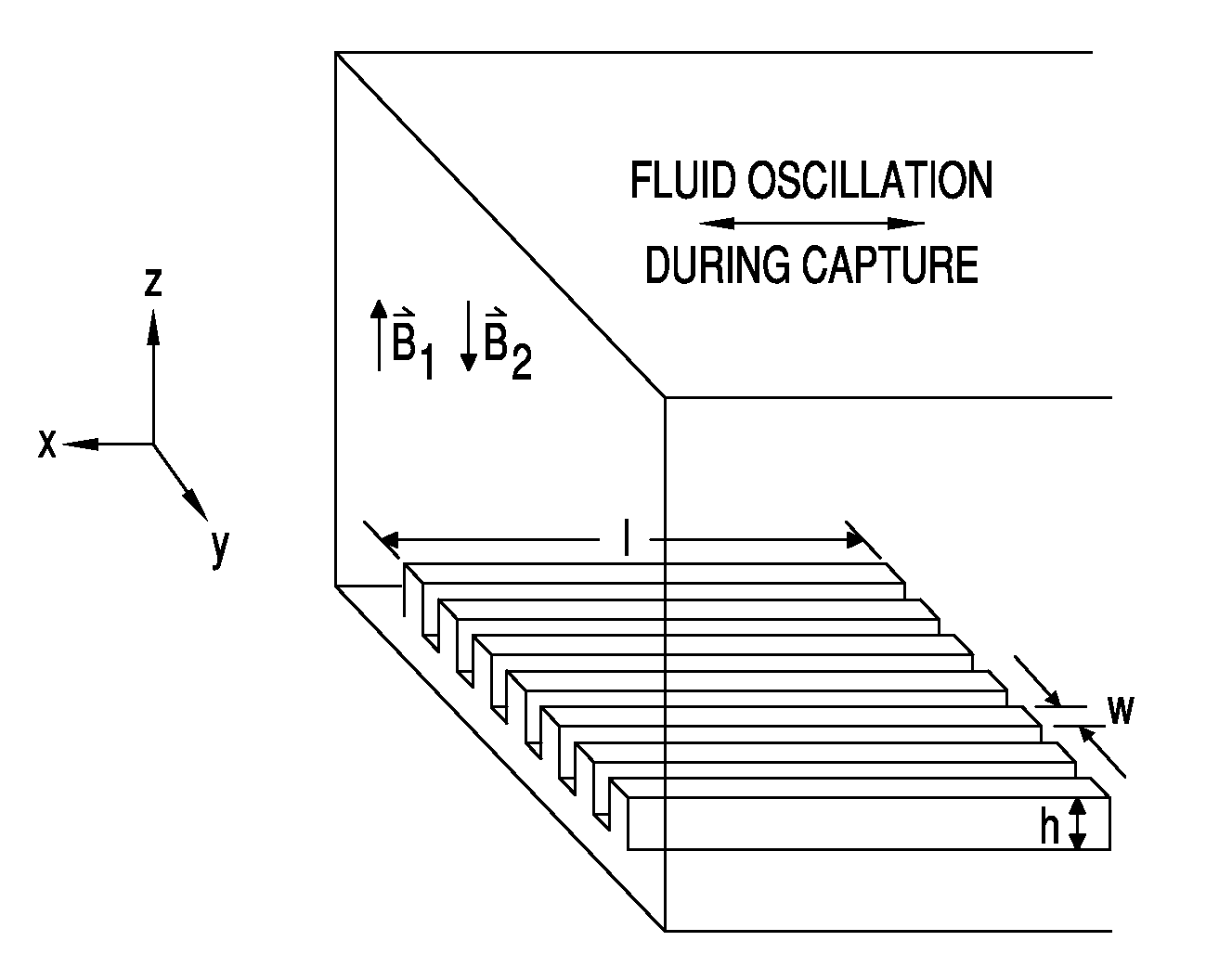

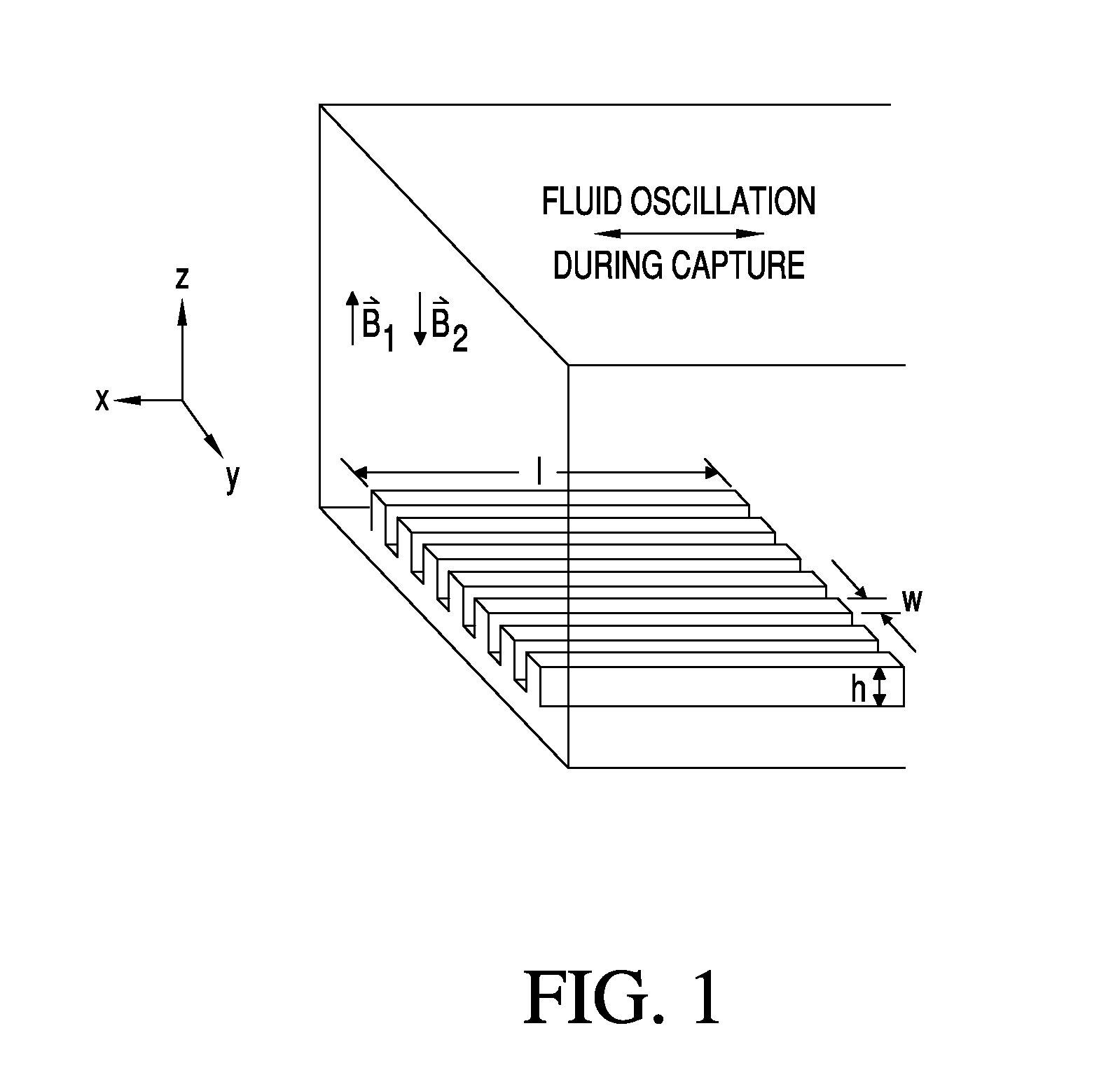

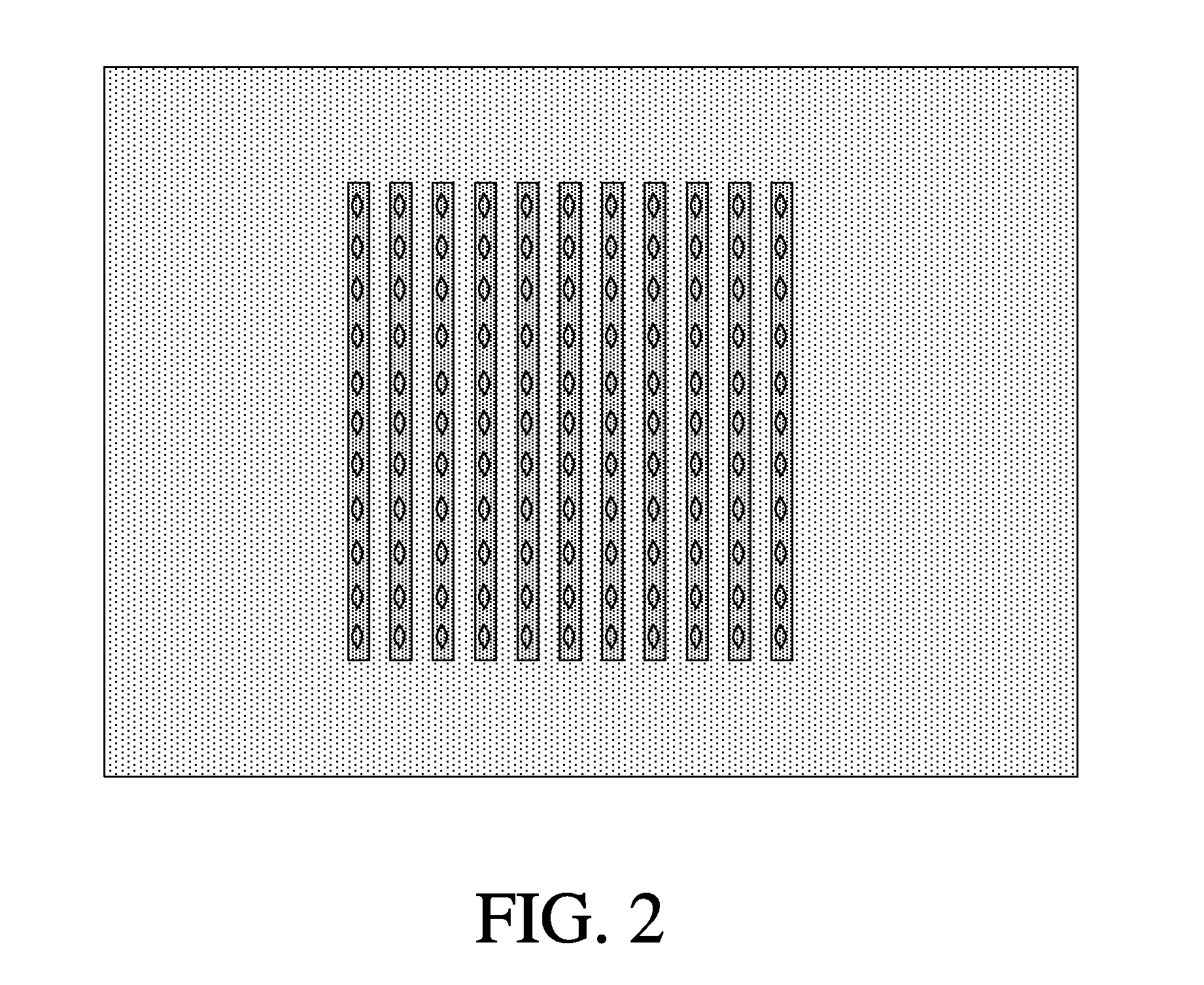

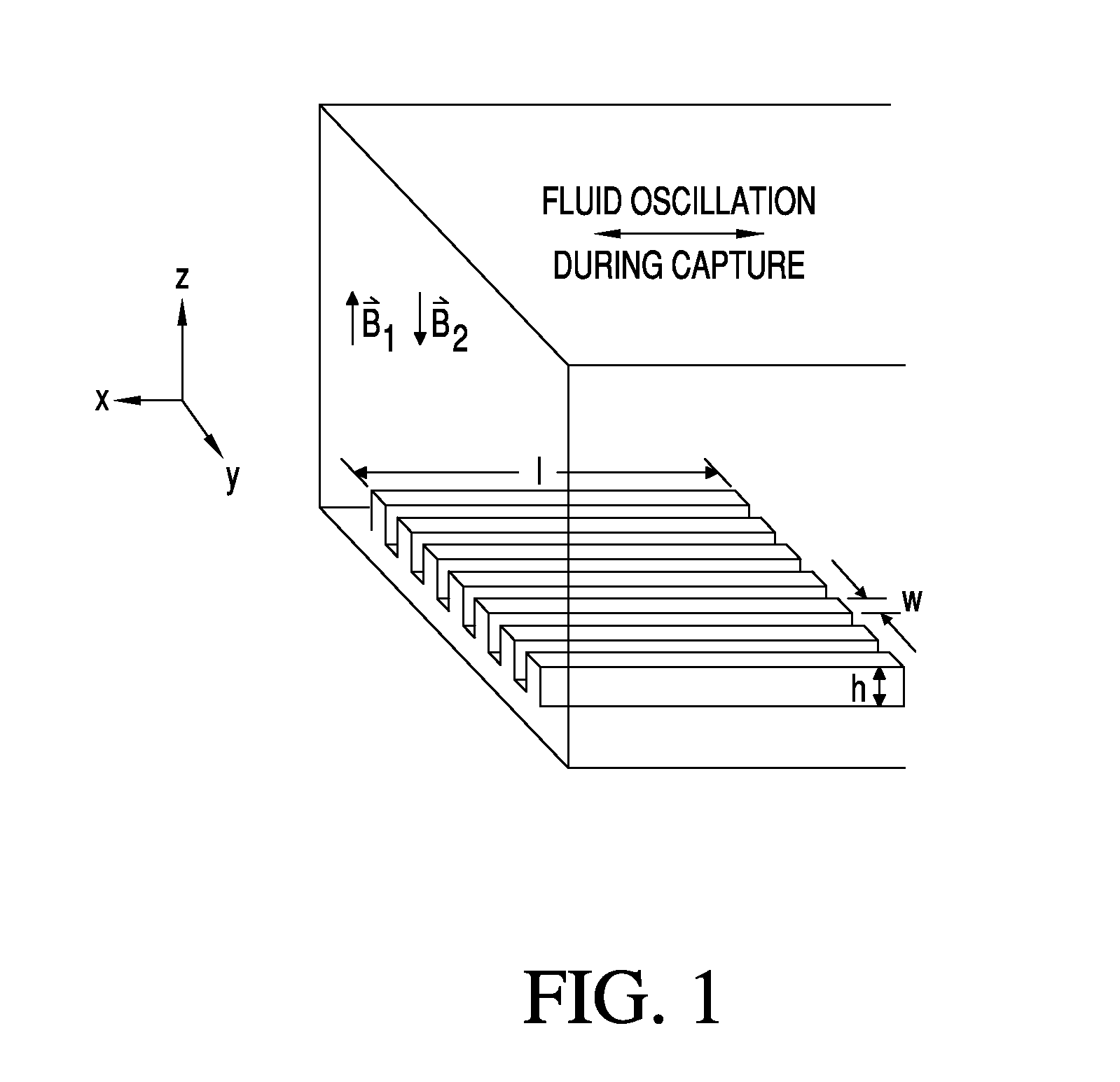

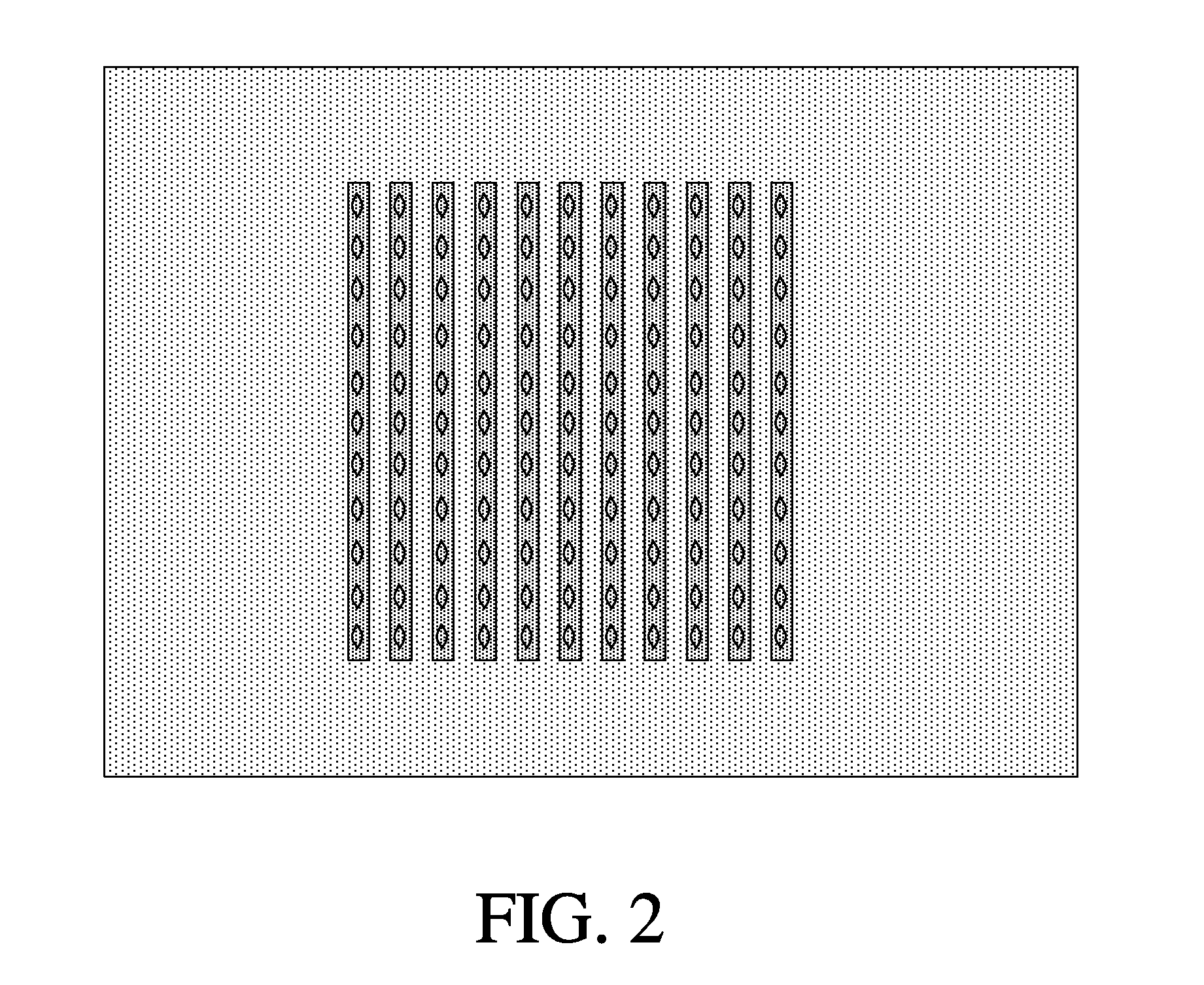

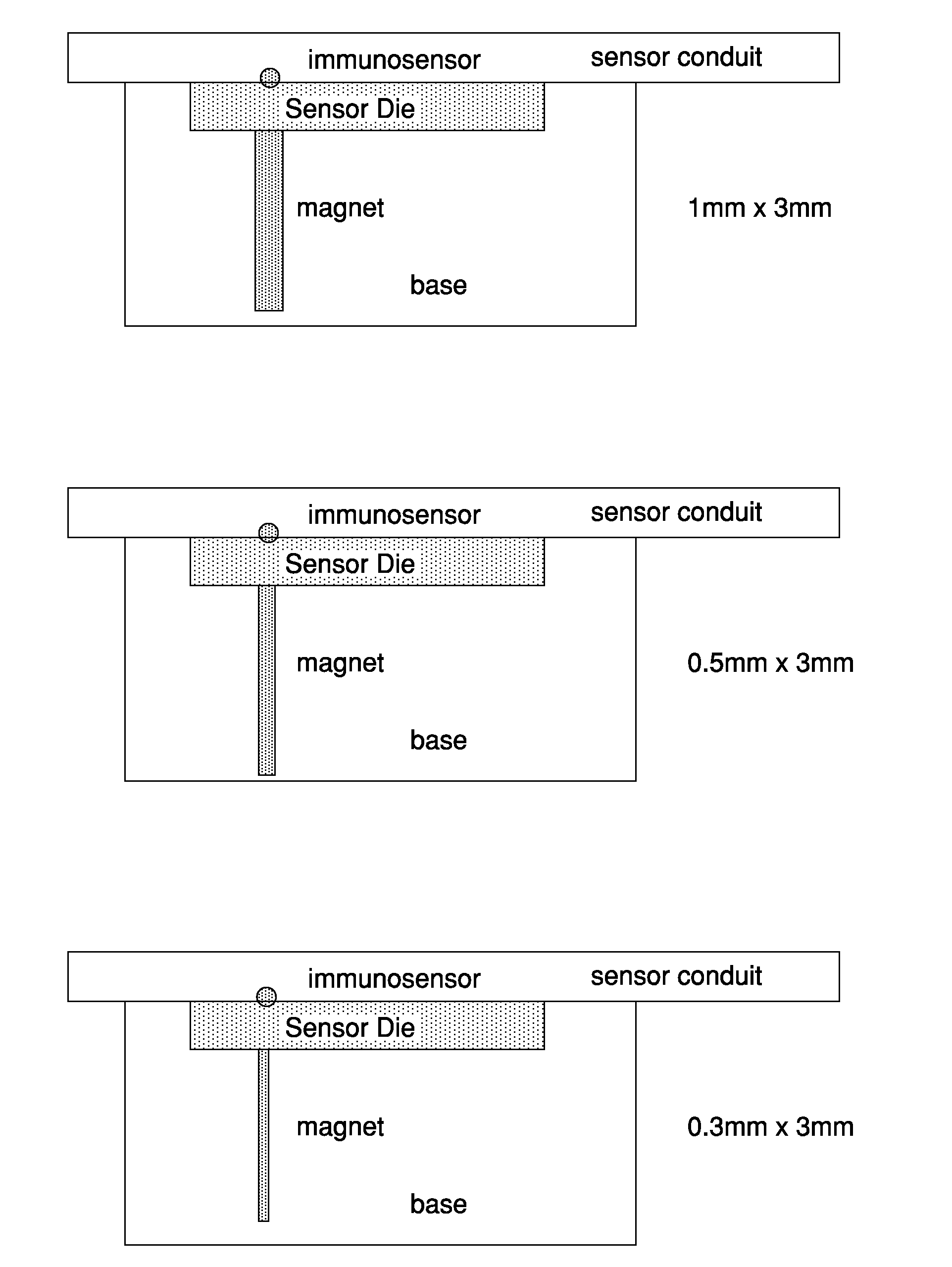

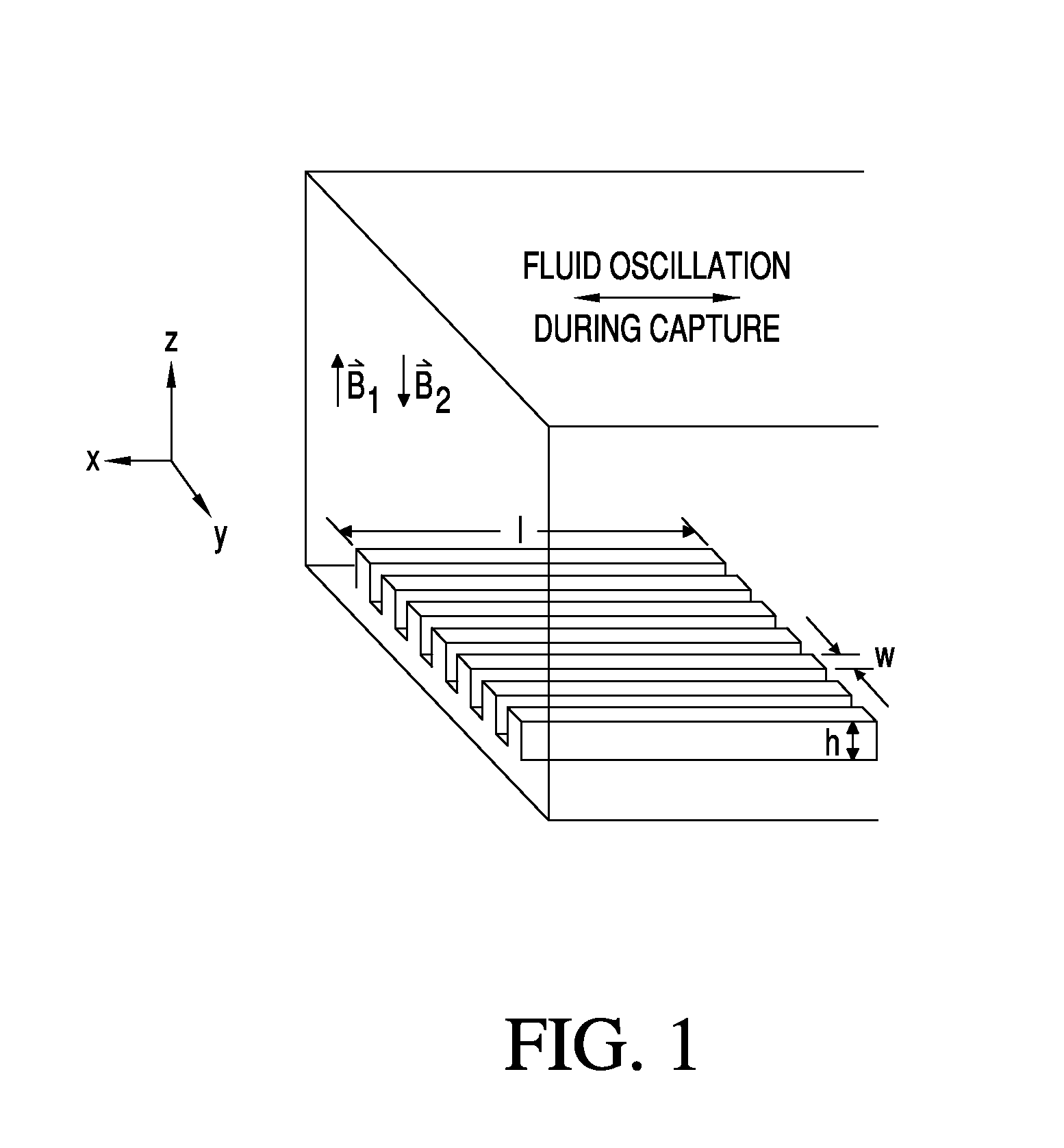

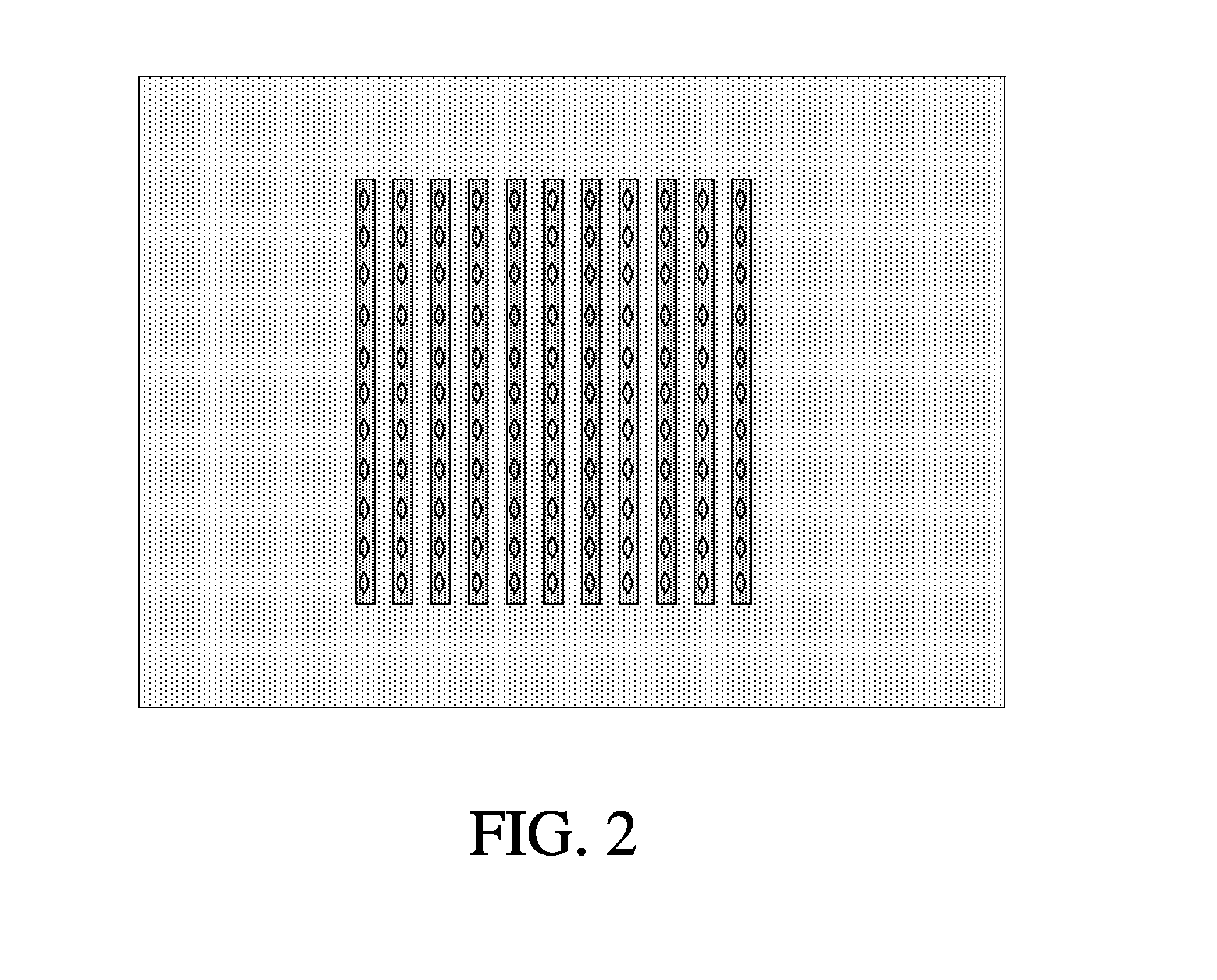

Magnetic immunosensor and method of use

ActiveUS20120034633A1Improving low-end sensitivityElimination of user induced errorBioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careAnalyte

Owner:ABBOTT POINT CARE

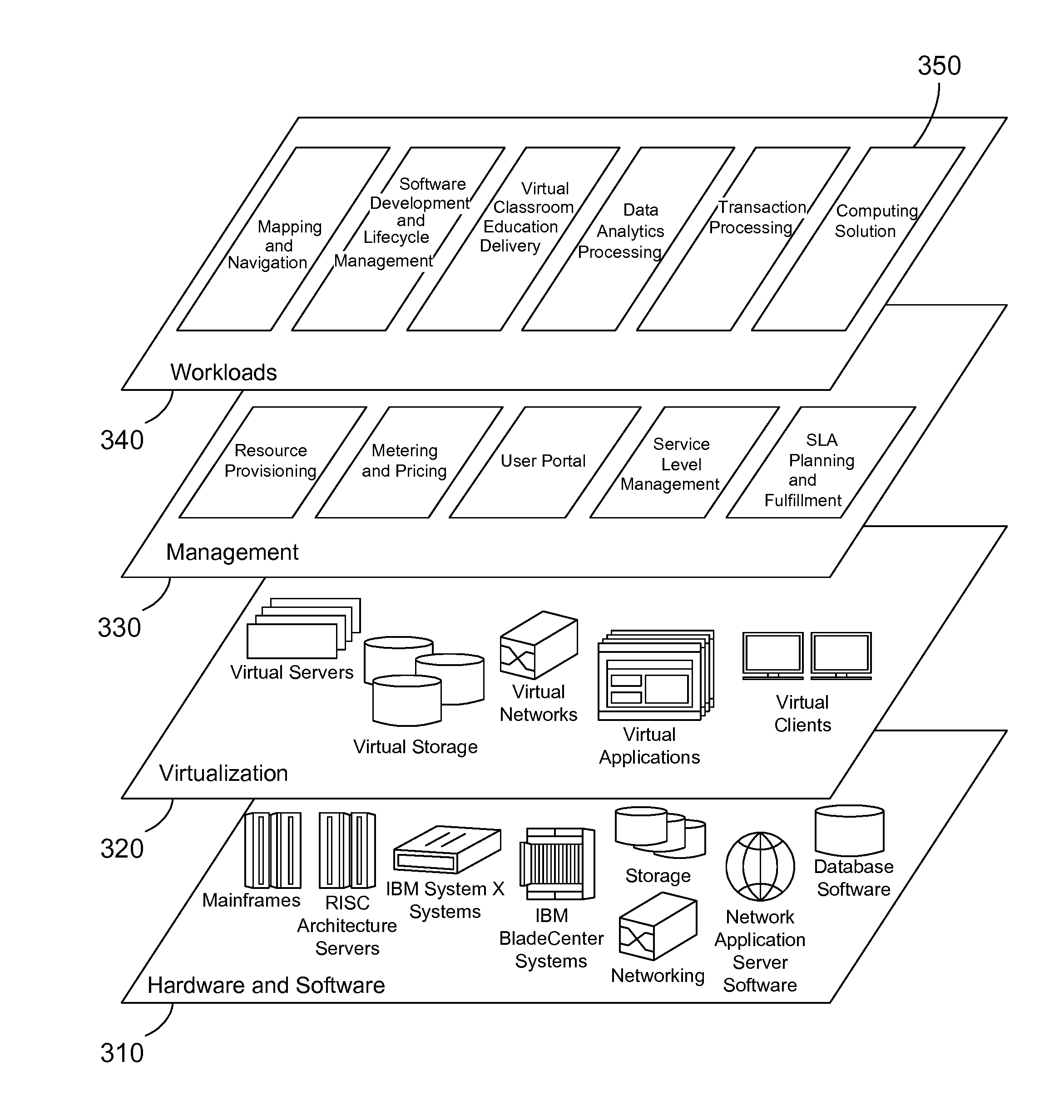

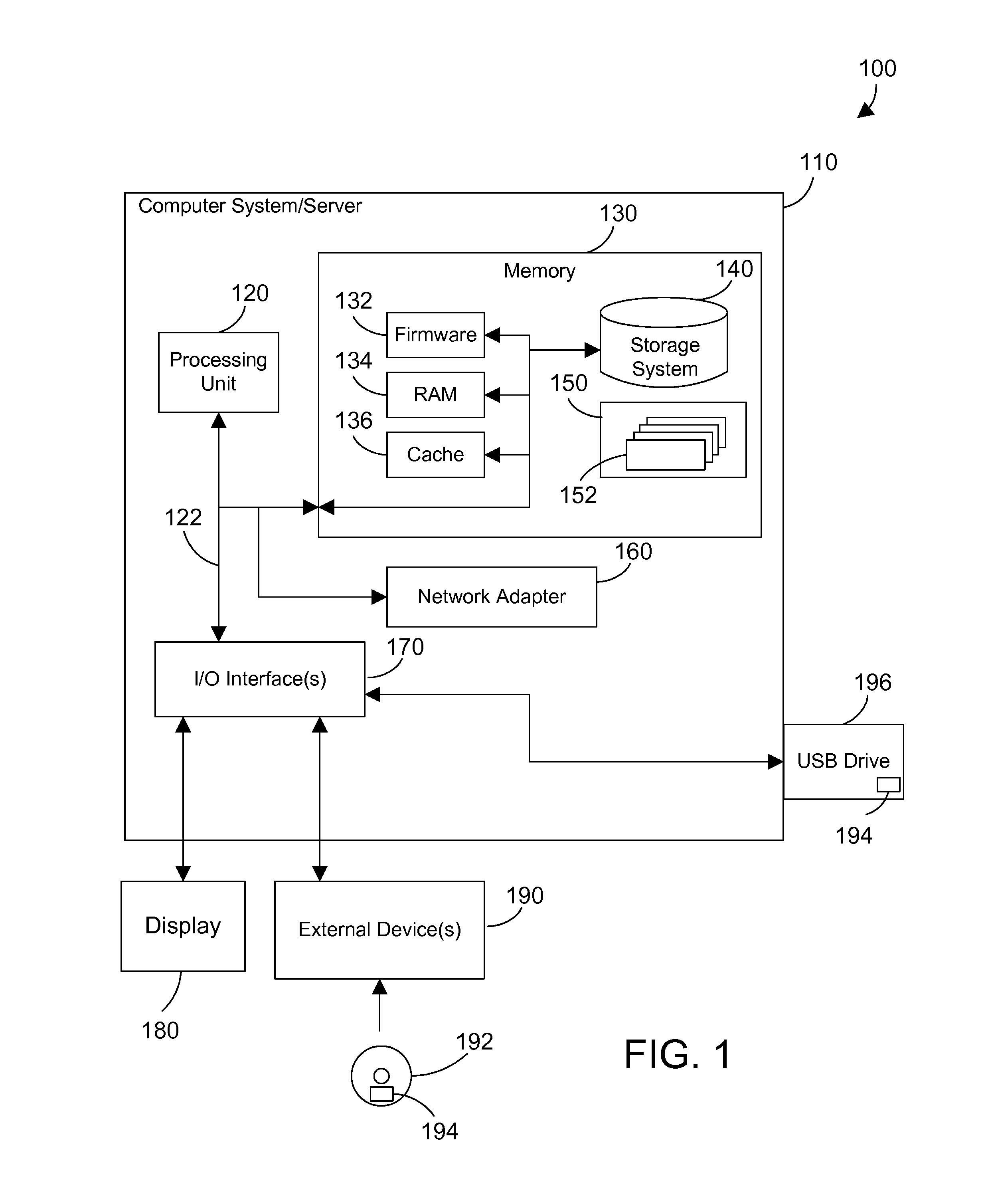

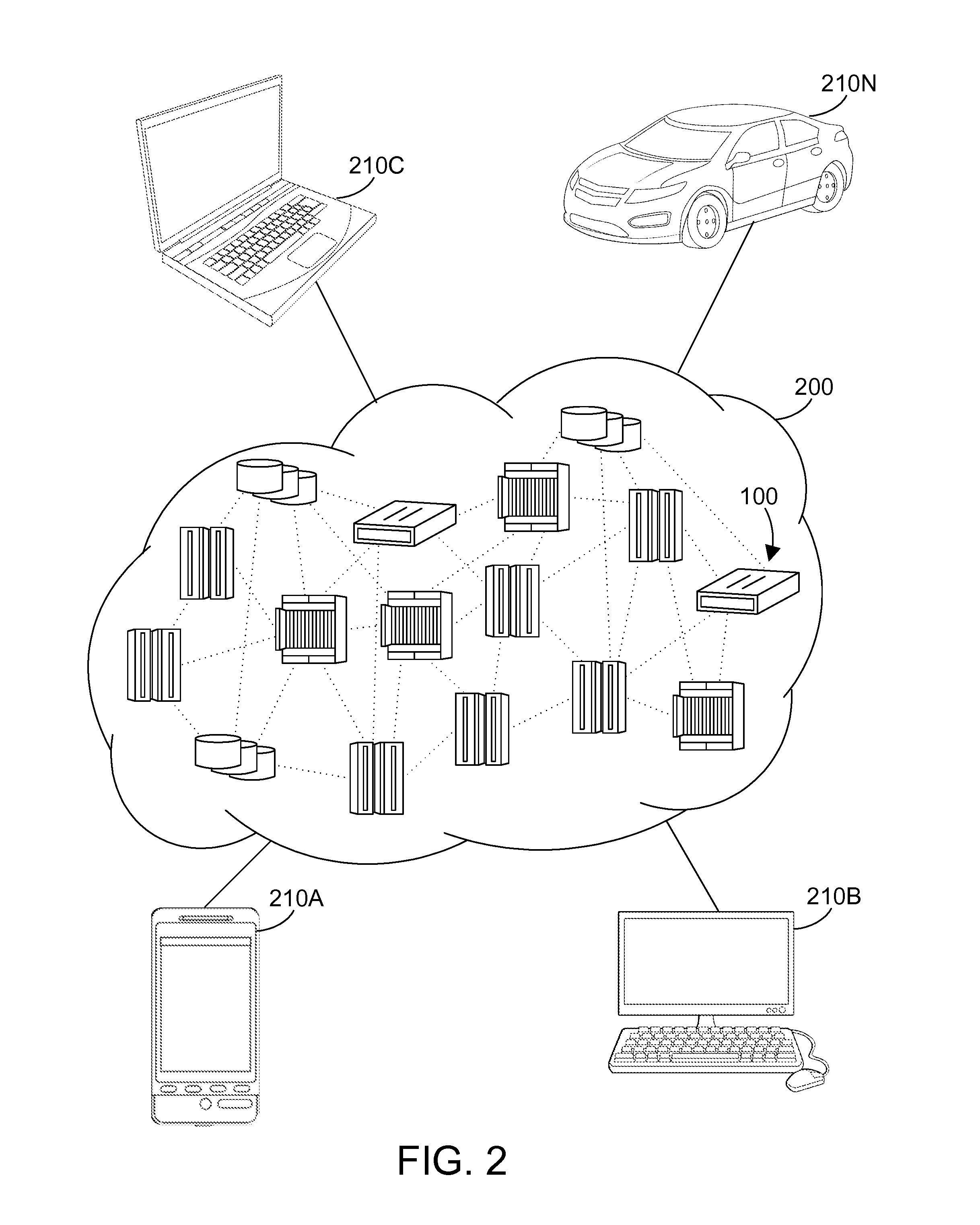

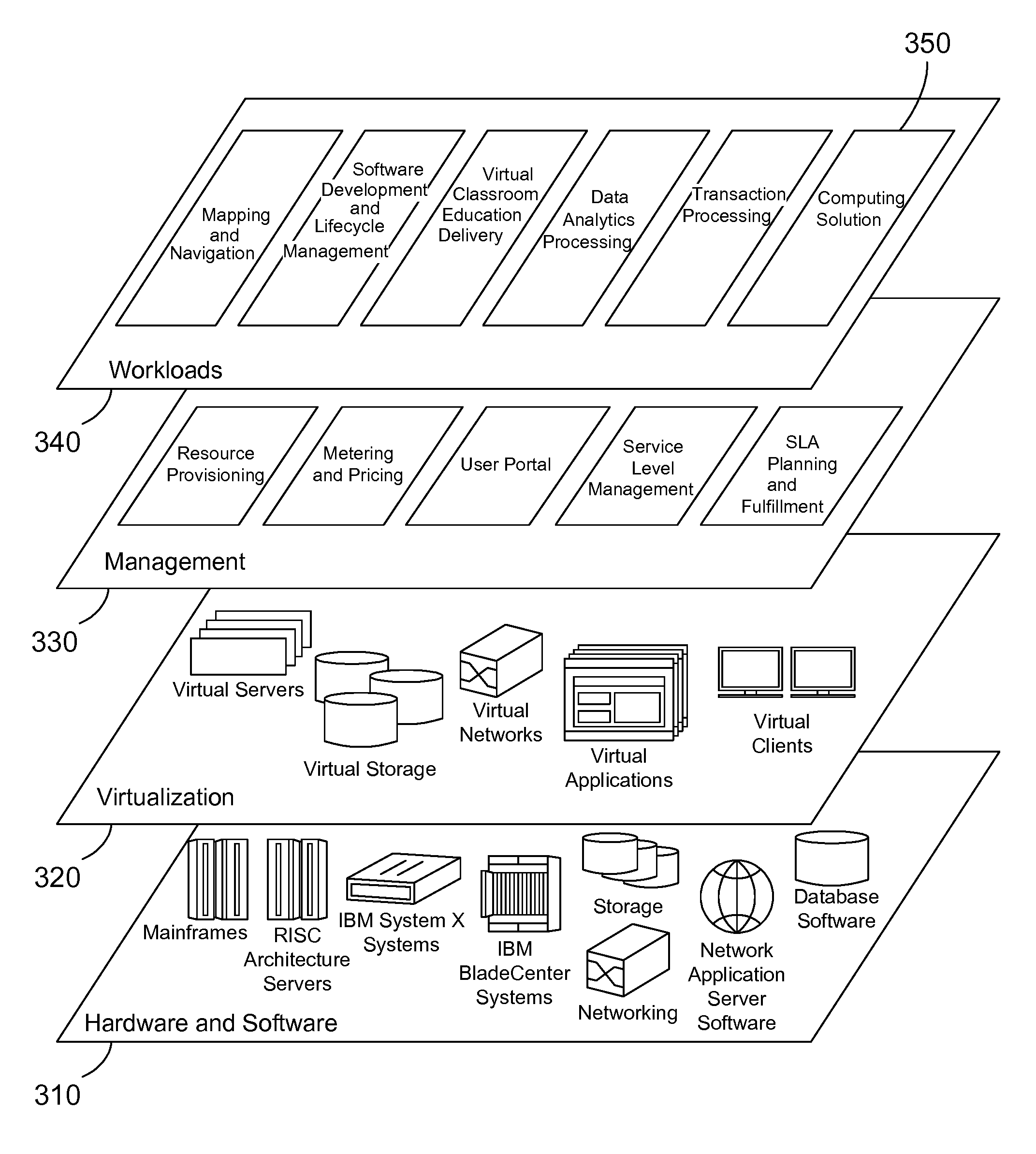

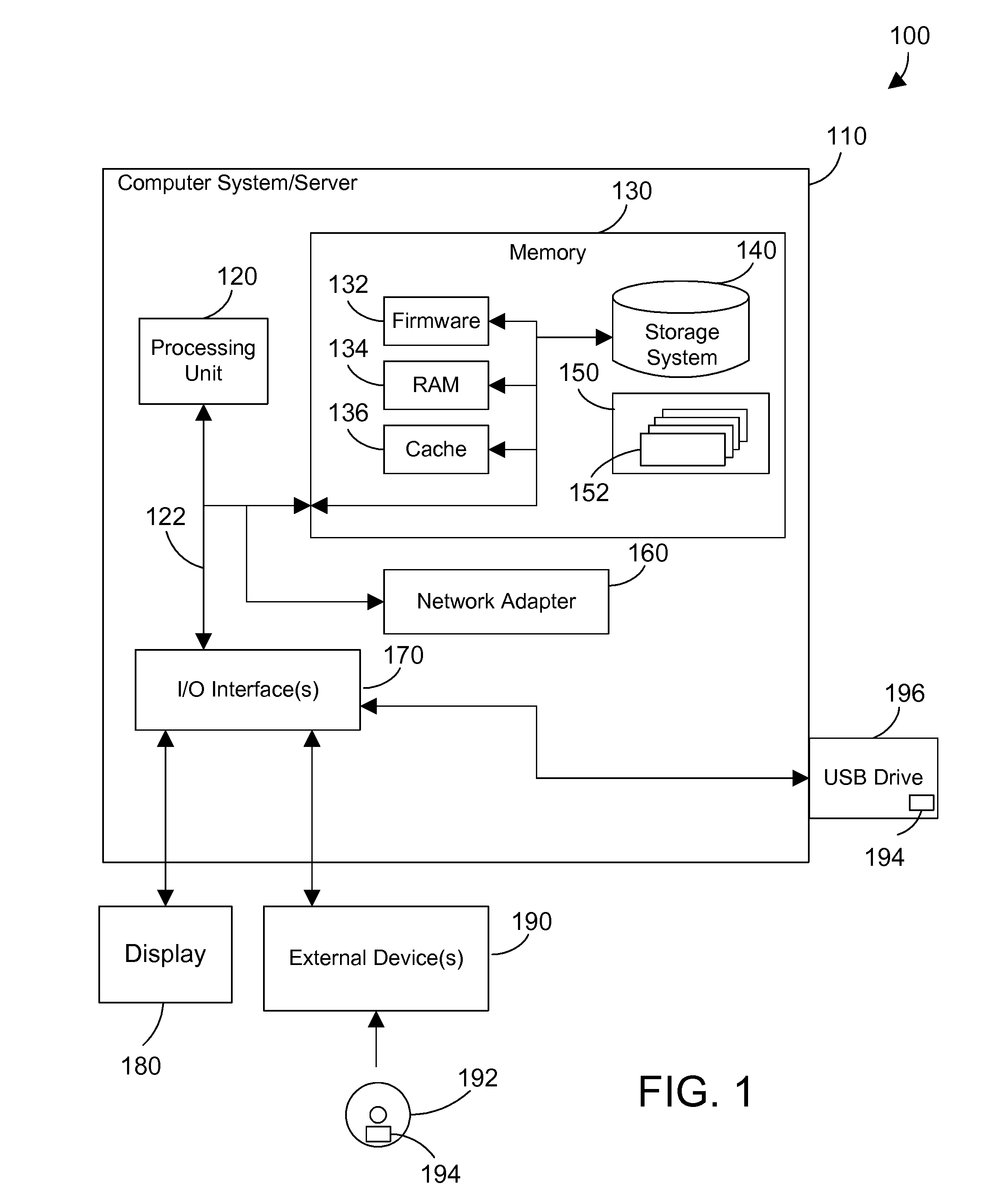

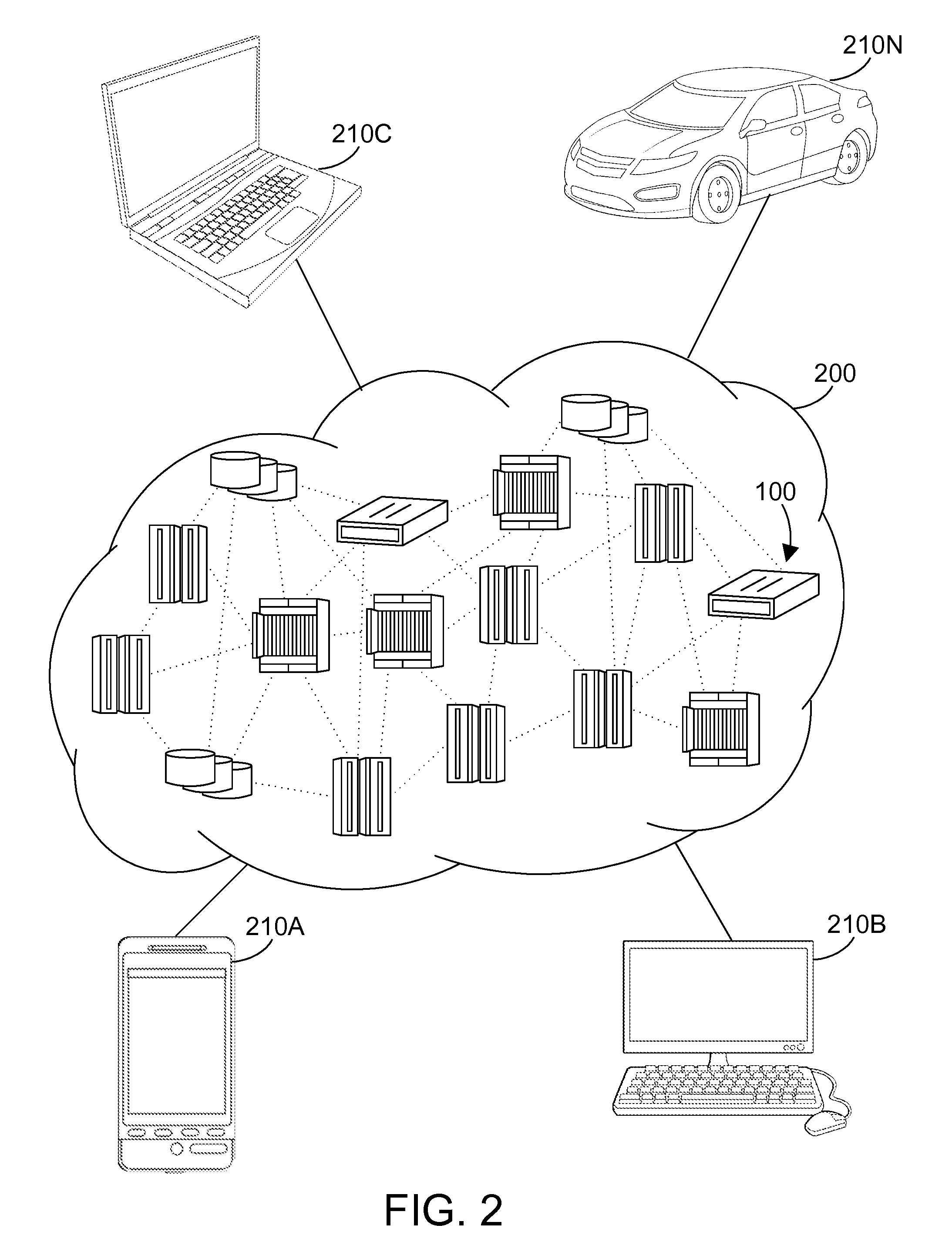

Pluggable cloud enablement boot device and method

ActiveUS20150106611A1Rapid deploymentMany stepsDigital computer detailsTransmissionCustomer requirementsAuto-configuration

A pluggable cloud enablement boot device (PCEBD) is a bootable device that includes all information needed to automatically provision hardware and software to create a computing solution that meets customer requirements. This allows for quickly deploying a computing solution in a manner that eliminates many manual steps that are typically performed today. The PCEBD uses firmware to verify a given platform has sufficient resources to deploy the PCEBD. The computing solution, once provisioned and running, can be modified, and these modifications may be reflected in the definition of the PCEBD. In addition, a computing solution may include multiple resources provisioned from multiple PCEBDs, which can be packaged into a PCEBD that will include other PCEBDs. The result is a way to deploy computing solutions that is much more efficient than the manual methods used in the prior art.

Owner:IBM CORP

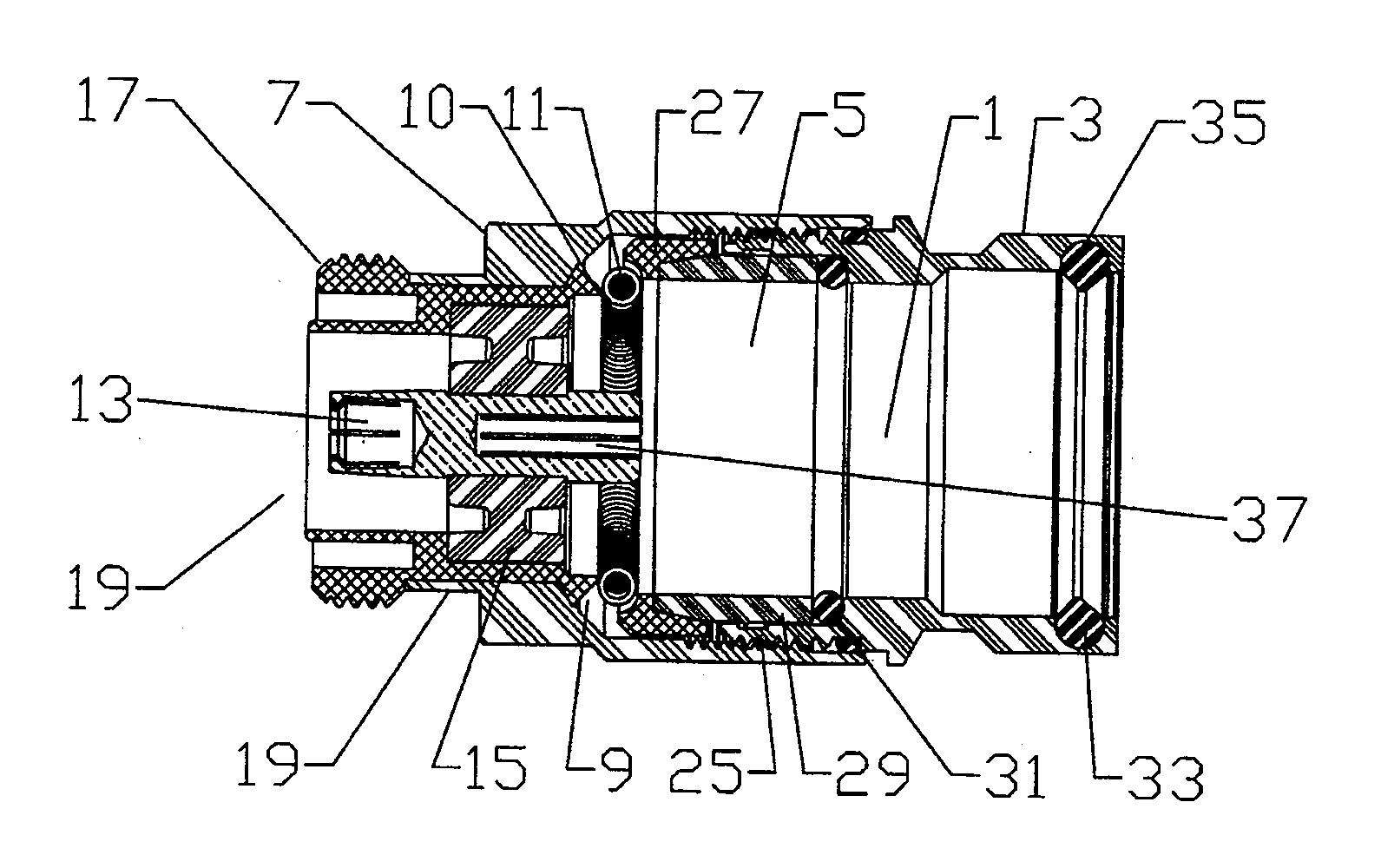

Multi-shot Coaxial Connector and Method of Manufacture

InactiveUS20100041271A1Significant costSignificant materialElectrically conductive connectionsTwo pole connectionsMultiple injectionCoaxial cable

A coaxial cable connector formed via multi-shot injection molding has a body formed by multiple injection molding layers of different injection moldable materials about a central inner contact to form an integral connector body. The connector body is provided with a coaxial dielectric spacer of dielectric polymer surrounding the inner contact; a coaxial inner body of injection molded metal composition surrounding an outer diameter of the dielectric spacer; and an outer body of polymer surrounding the inner body. Interlock features provide axial and / or rotational interlock between the layers of the connector.

Owner:ANDREW LLC

Magnetic immunosensor and method of use

ActiveUS9233370B2Improving low-end sensitivityElimination of user induced errorBioreactor/fermenter combinationsBiological substance pretreatmentsPoint of careAnalyte

Owner:ABBOTT POINT CARE

Immunoassay method and device with magnetically susceptible bead capture

ActiveUS20120031773A1Improving low-end sensitivityElimination of user induced errorImmobilised enzymesBioreactor/fermenter combinationsPoint of careAnalyte

Owner:ABBOTT POINT CARE

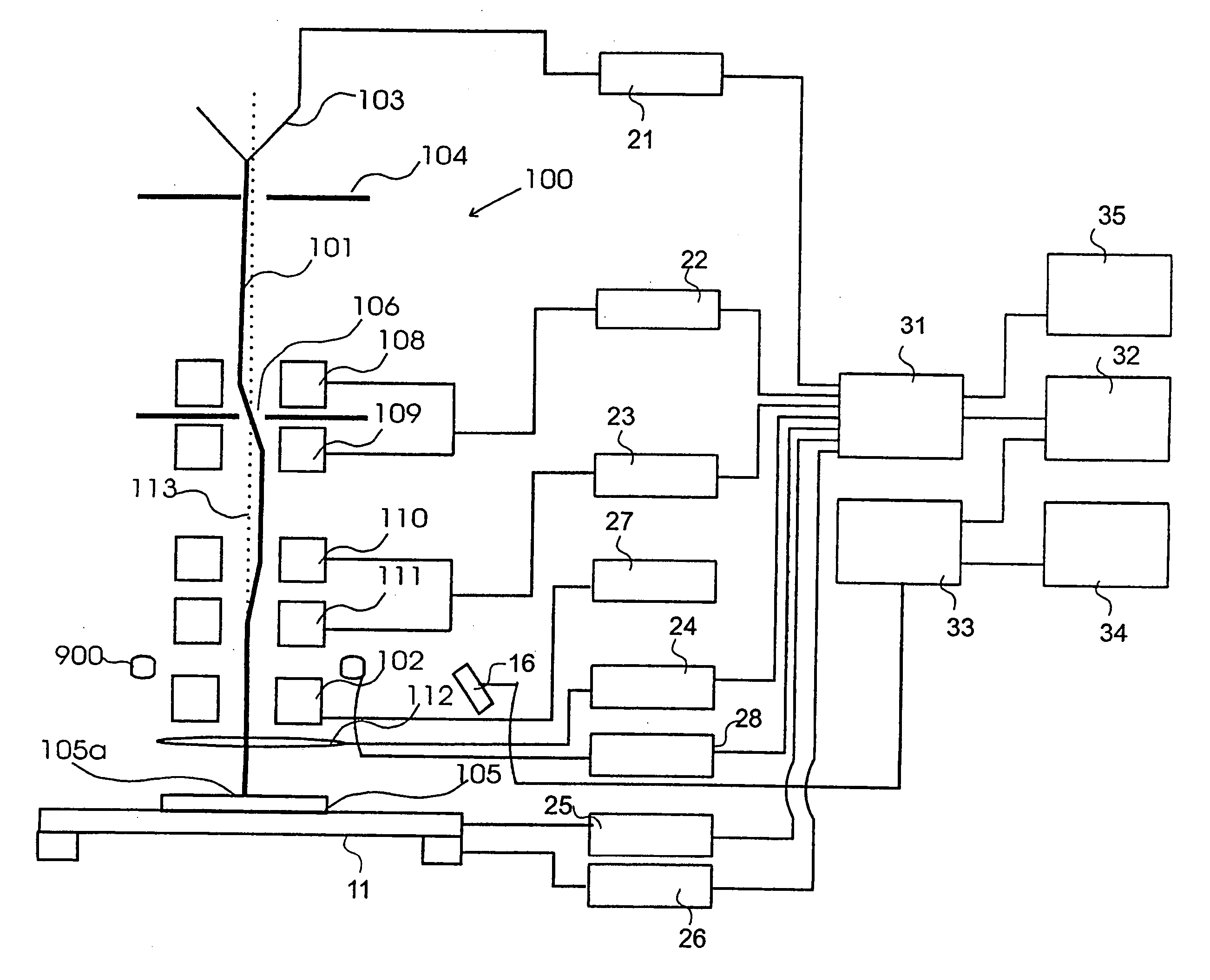

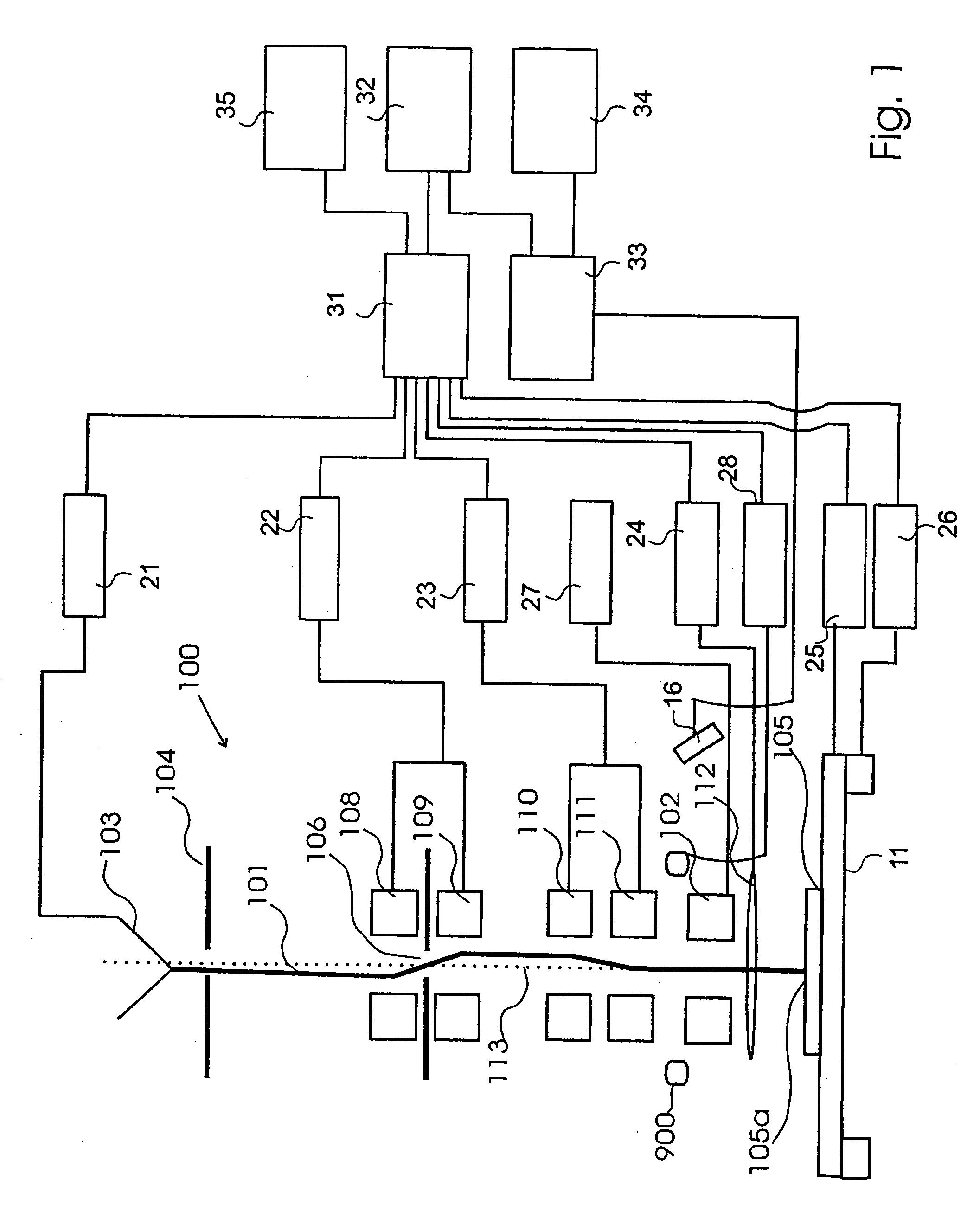

Method and device for aligning a charged particle beam column

InactiveUS20050012050A1Shorten the timeMany stepsThermometer detailsMaterial analysis using wave/particle radiationOptical axisLight beam

The invention provides a method for automatically aligning a beam of charged particles with an aperture. Thereby, the beam is defelcted to two edges of the aperture. From the signals required to obtain an extinction, a correction deflection field is calculated. Furter, a method for automatically aligning a beam of charged particles with an optical axis is provided. Thereby a defocusing is introduced and a signal calculated based on an introduced image shift is applied to a deflection unit. Further, a method for correction of the astigmatism is provided. Thereby the sharpness is evaluated for a sequence of frames measured whilst varying the signals to a stigmator.

Owner:APPL MATERIALS ISRAEL LTD

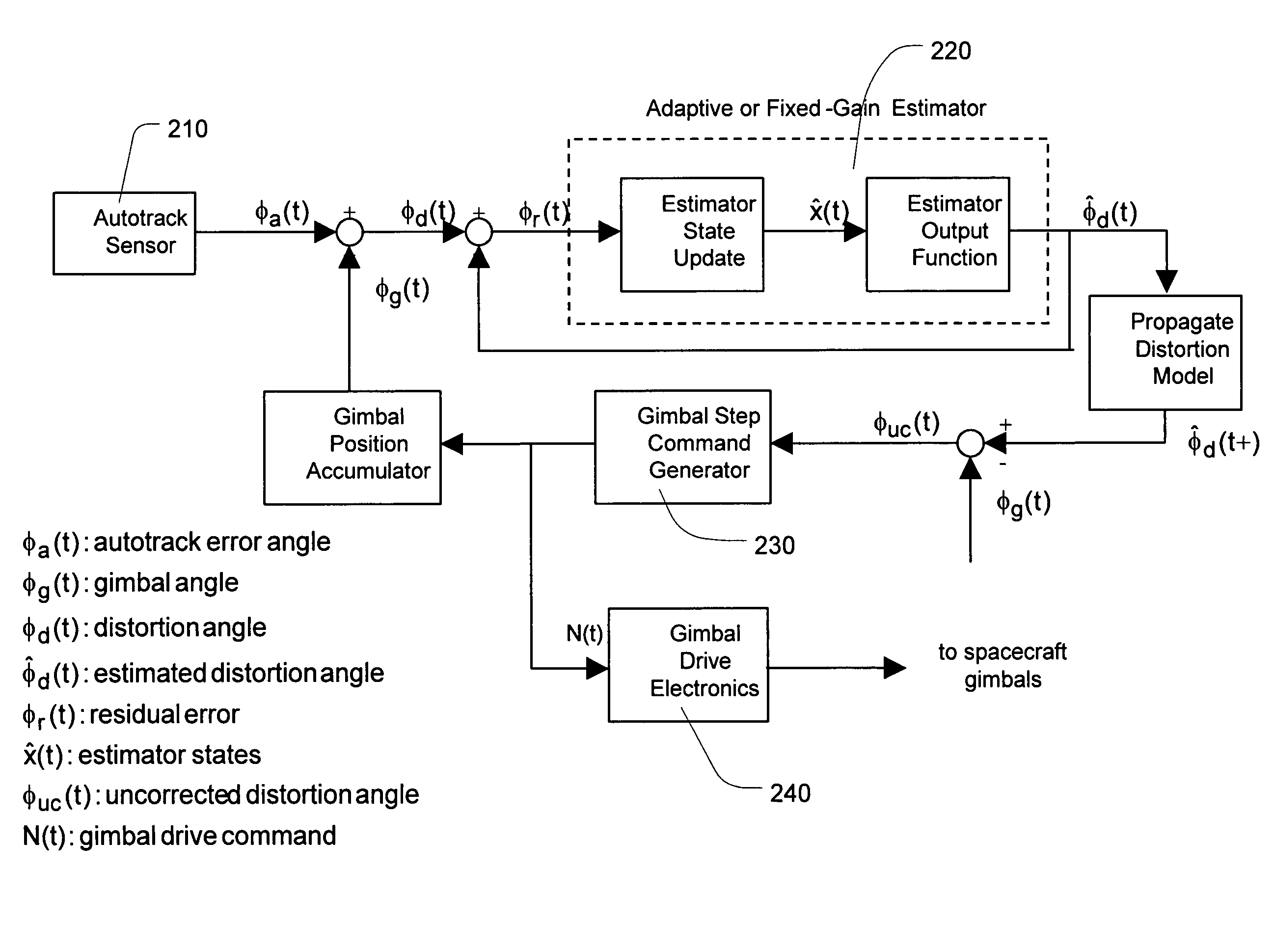

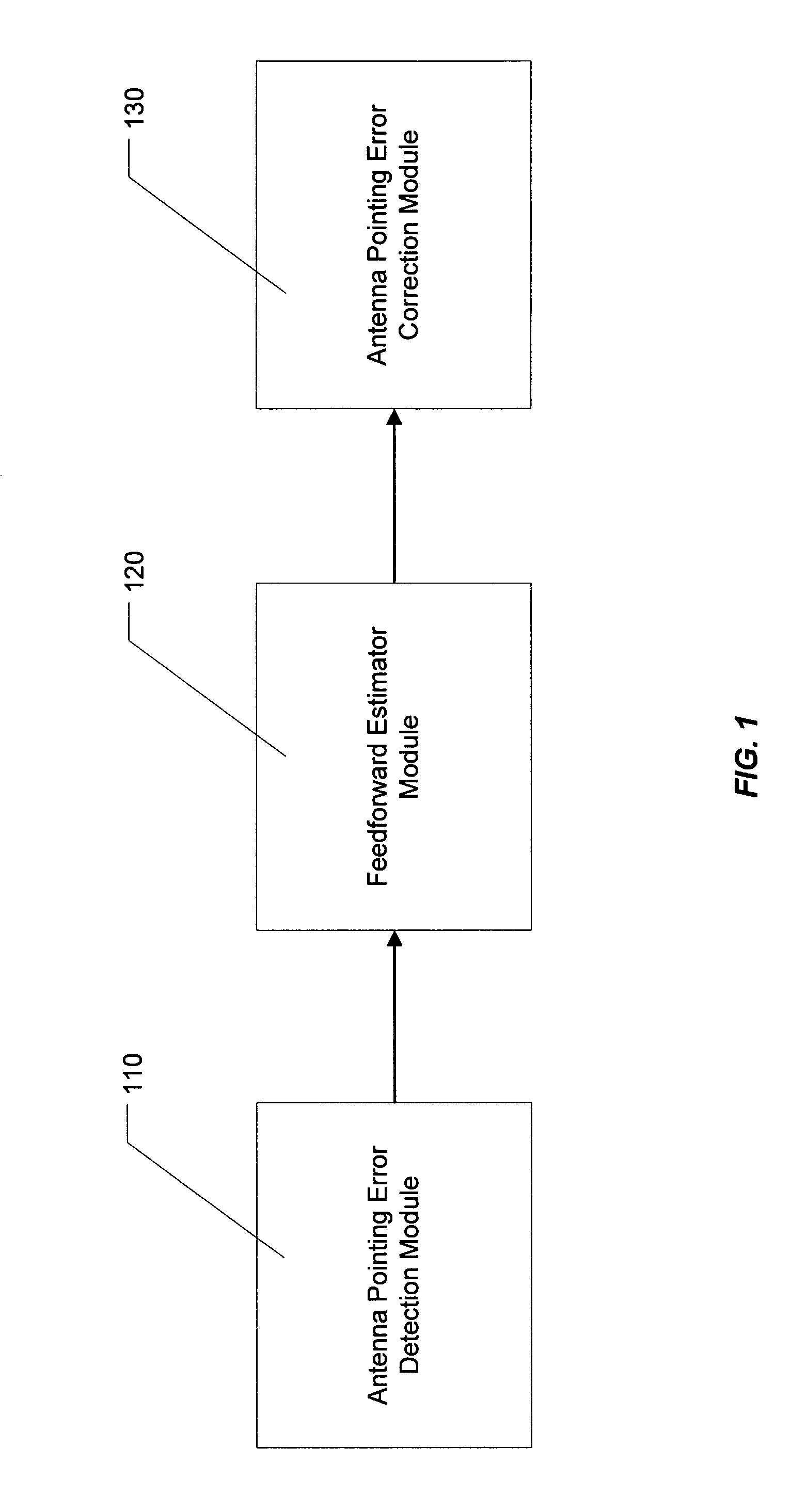

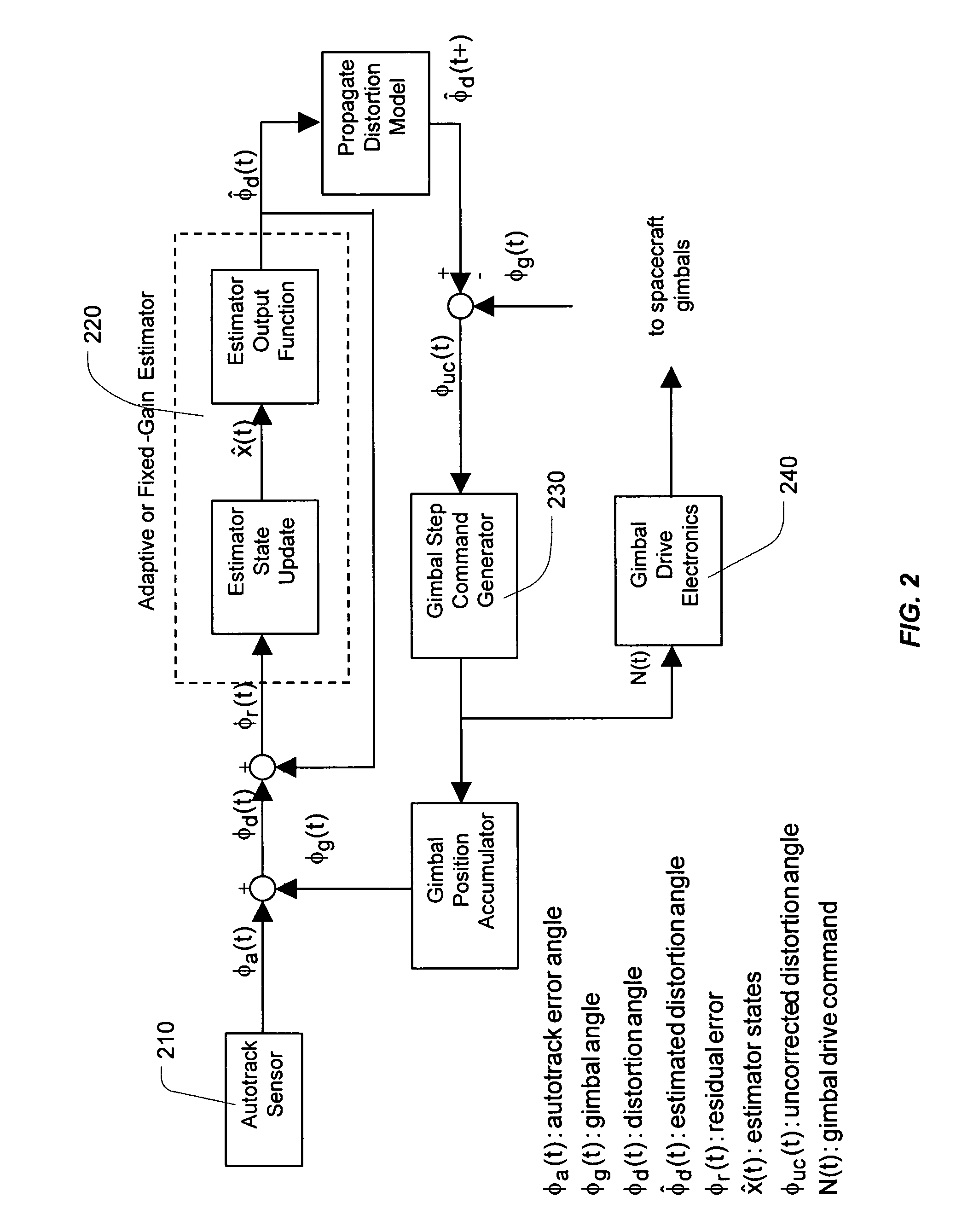

Antenna autotrack control system for precision spot beam pointing control

ActiveUS7663542B1Improve performancePreventing excessive gimbal steppingAntenna detailsControl systemLearning models

The present invention provides a system and a method for improving spacecraft antenna pointing accuracy utilizing feedforward estimation. The present invention takes advantage of the fact that spacecraft antenna pointing error has periodic behavior with a period of 24 hours. Thus, unlike the prior art feedback systems which blindly correct antenna pointing error continuously reacting only to presently sensed error, the present invention takes an intelligent approach and learns the periodic behavior of spacecraft antenna pointing error. Then, an estimate of antenna pointing error at a particular time going forward is predicted based on the learned model of the periodic behavior of the antenna pointing error. The predicted estimate is then used to correct or cancel out the antenna pointing error at a particular time in the future. The result is more accurate correction of spacecraft antenna pointing error by more than a factor of two.

Owner:LOCKHEED MARTIN CORP

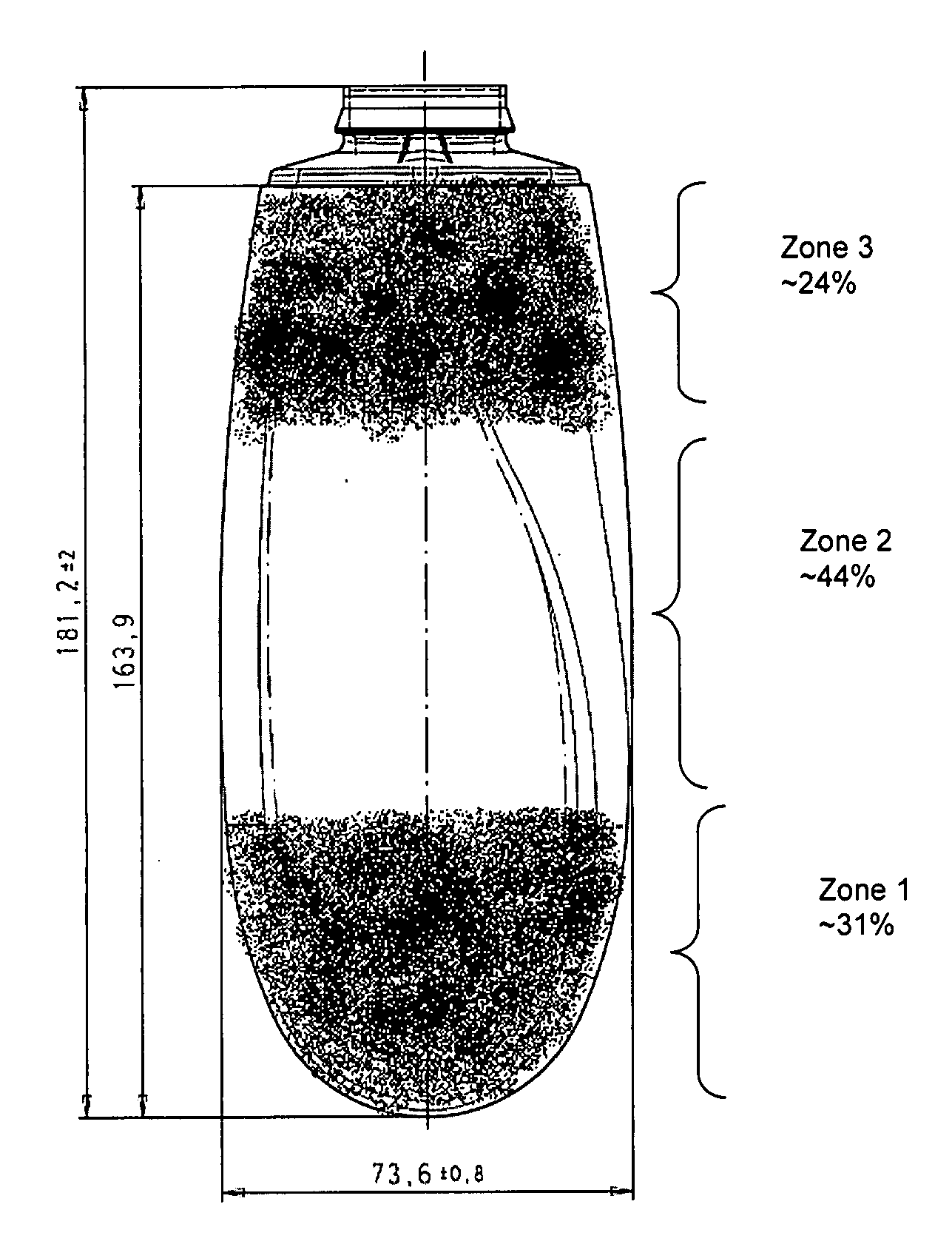

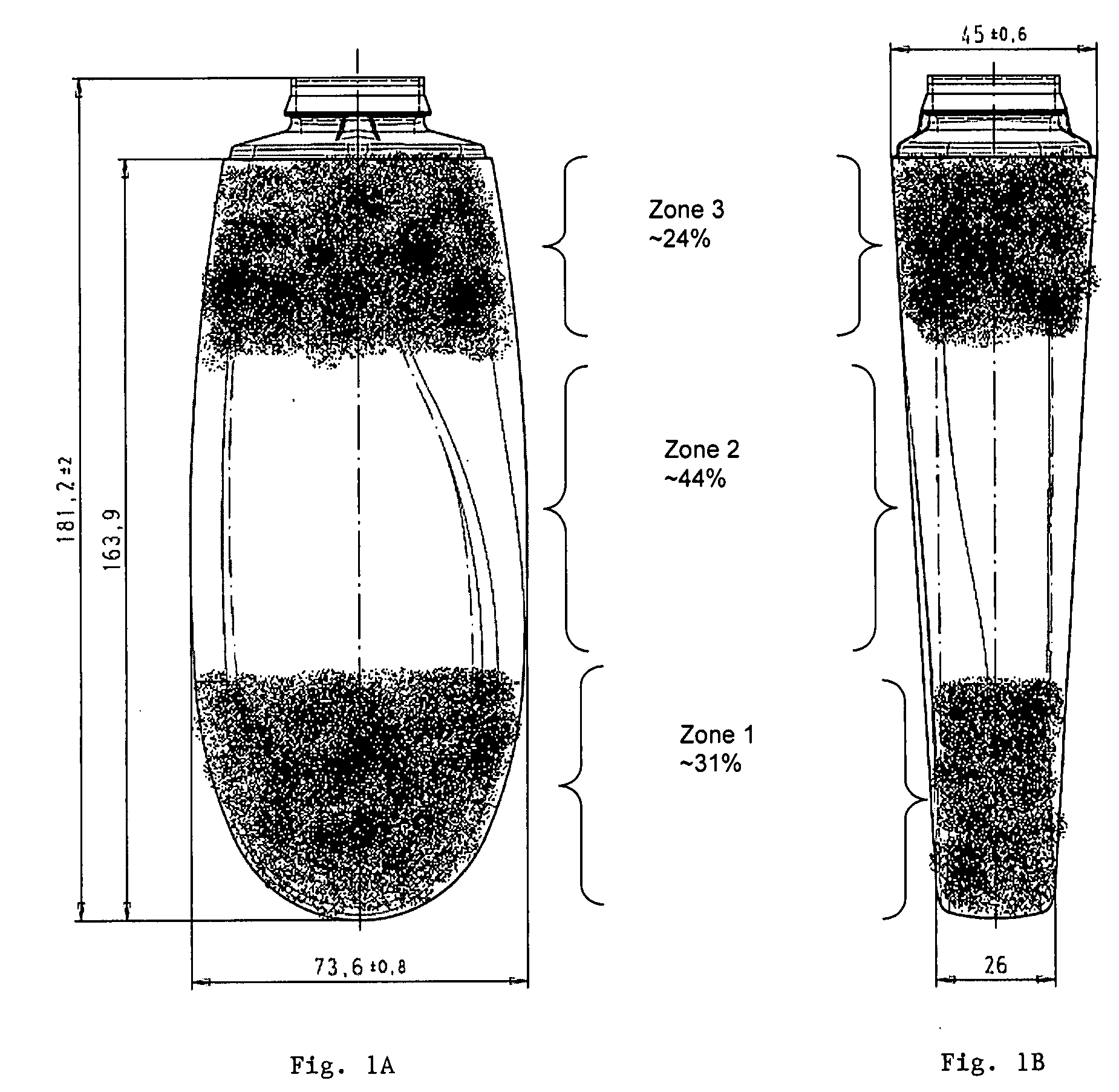

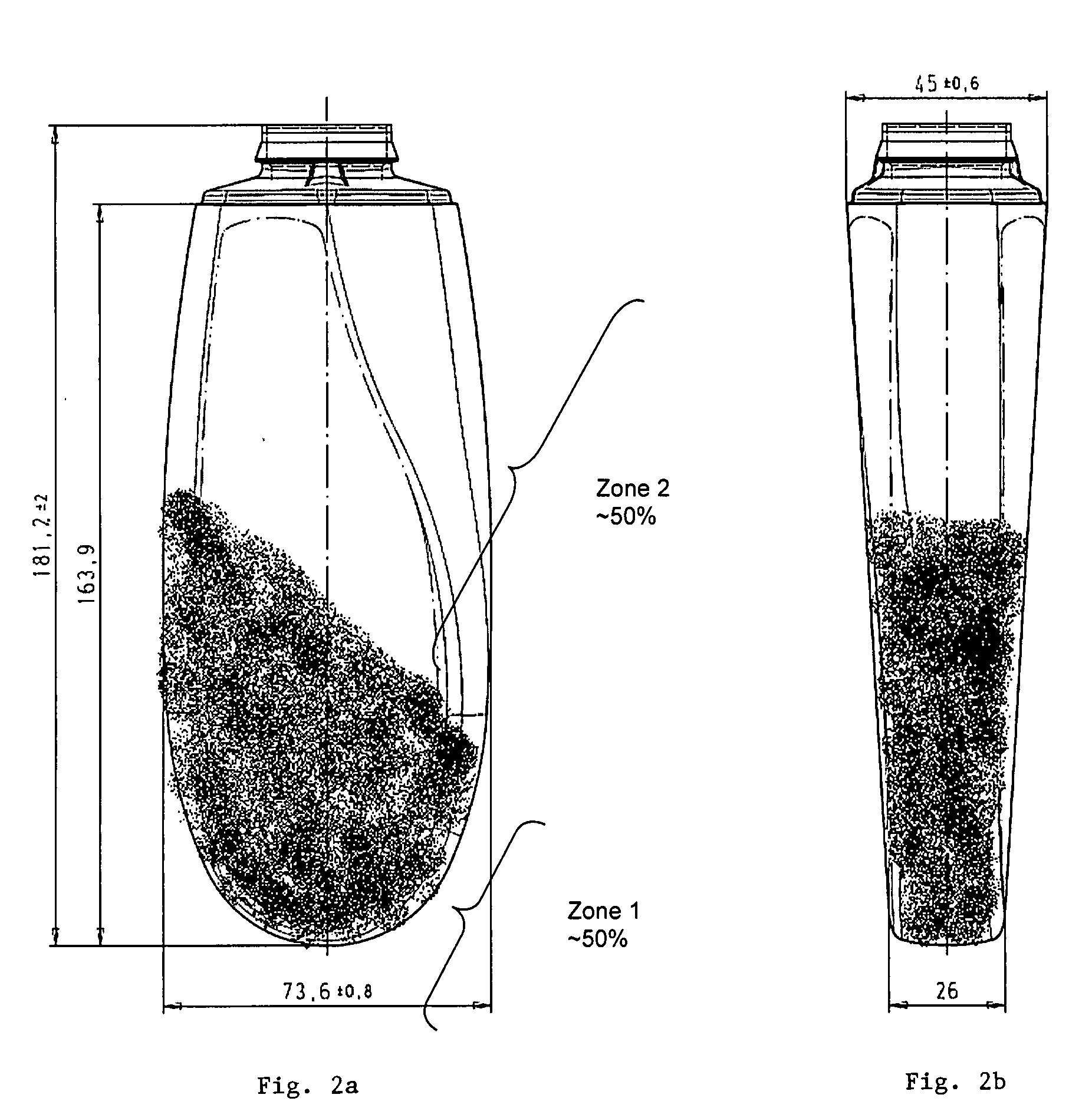

Personal care article for sequentially dispensing compositions with variable concentrations of partitioned benefit or suspended benefit agents

The present invention relates to a personal care article for providing at least two liquid personal care compositions. The personal care article comprises a single chamber package and a liquid personal care product. The package comprises a dispensing orifice, a first zone proximate to the dispensing orifice and a second zone distal to the dispensing orifice. The liquid personal care product comprises a first personal care composition substantially disposed within the first zone and the second personal care composition substantially disposed within the second zone. The first composition comprises a comprising a first concentration of a partitioned benefit agent or a suspended benefit agent. The second composition comprises a benefit phase comprising a second concentration of the partitioned benefit agent or the suspended benefit agent. The first concentration is different from said second concentration.

Owner:THE PROCTER & GAMBLE COMPANY

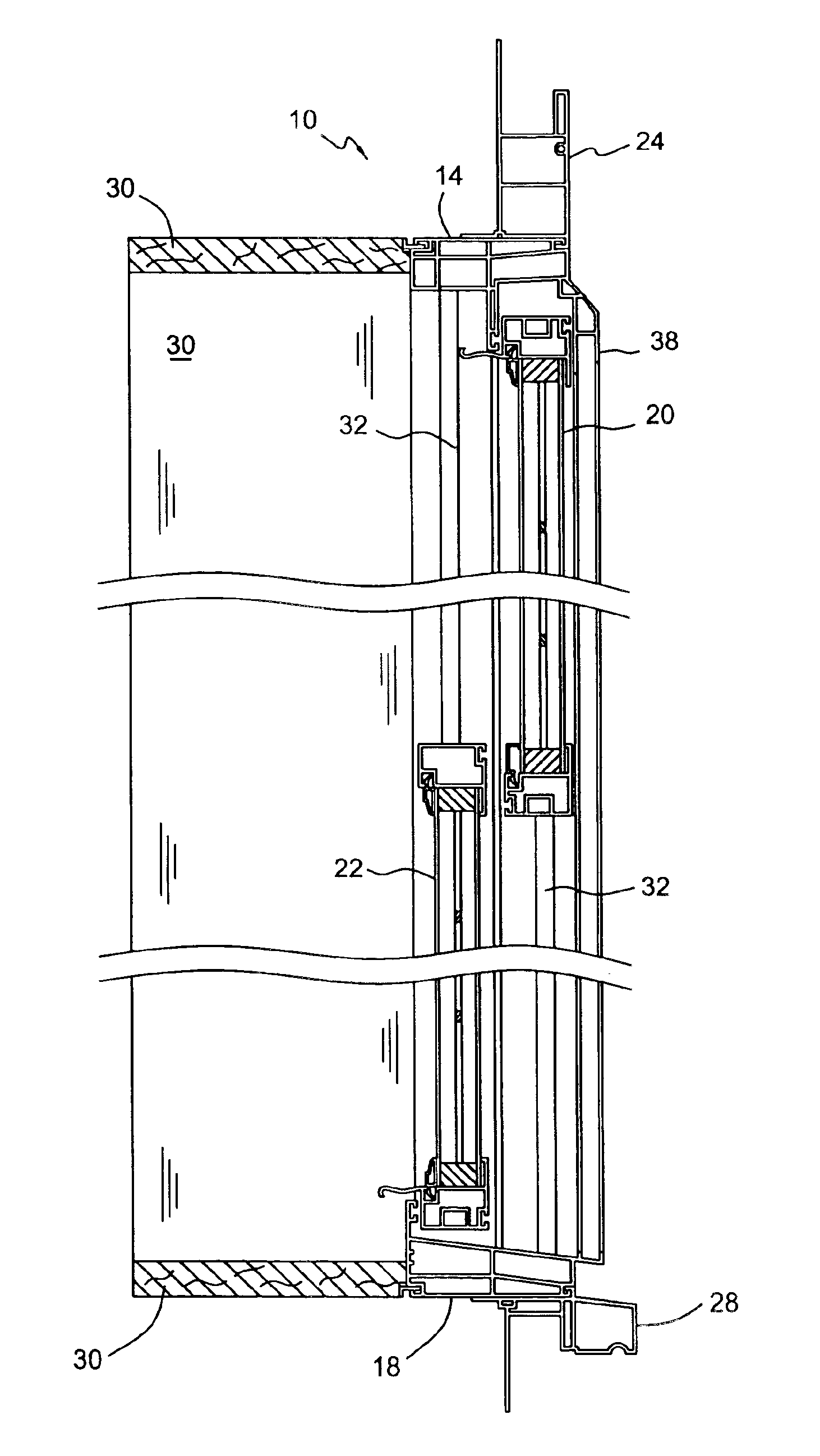

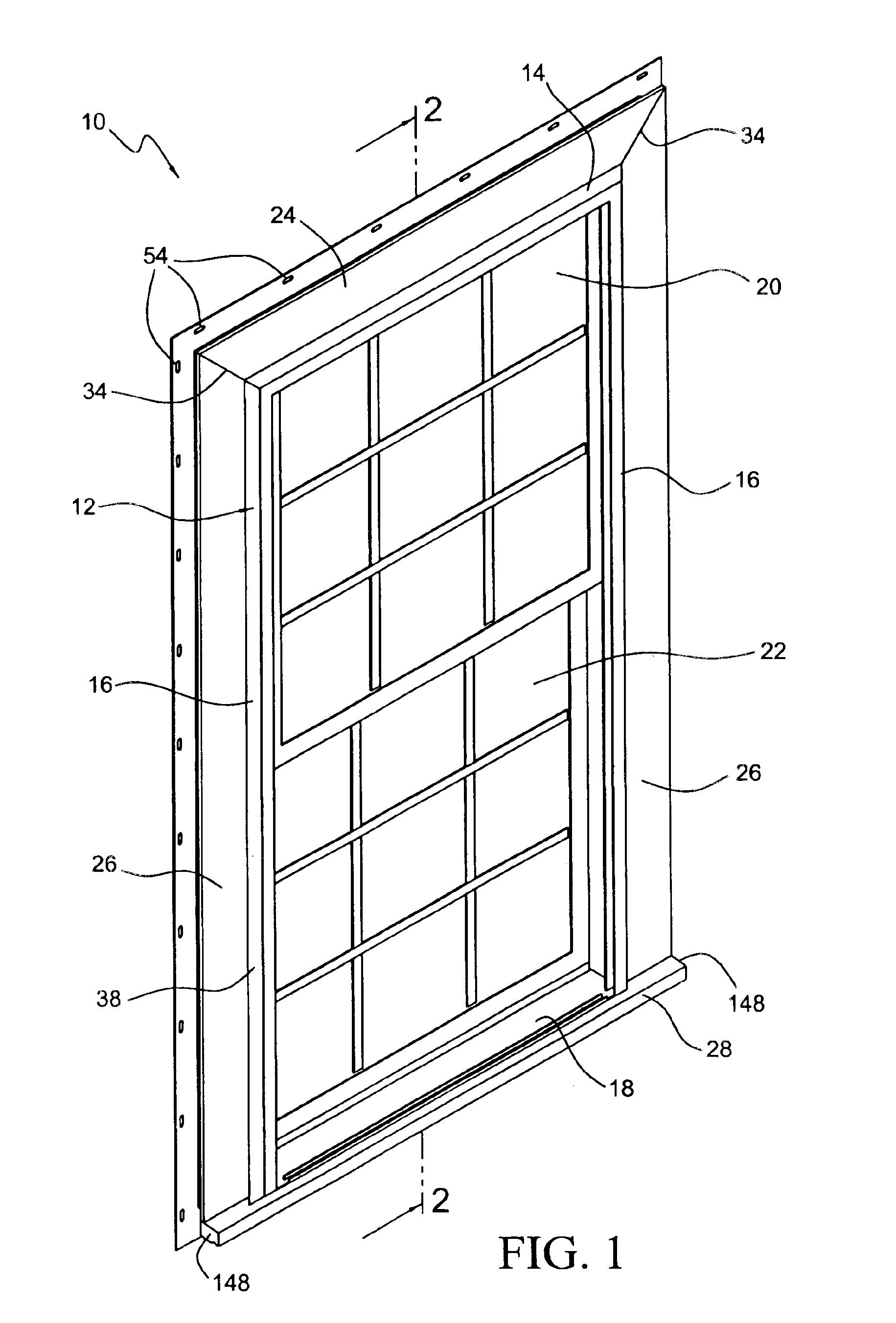

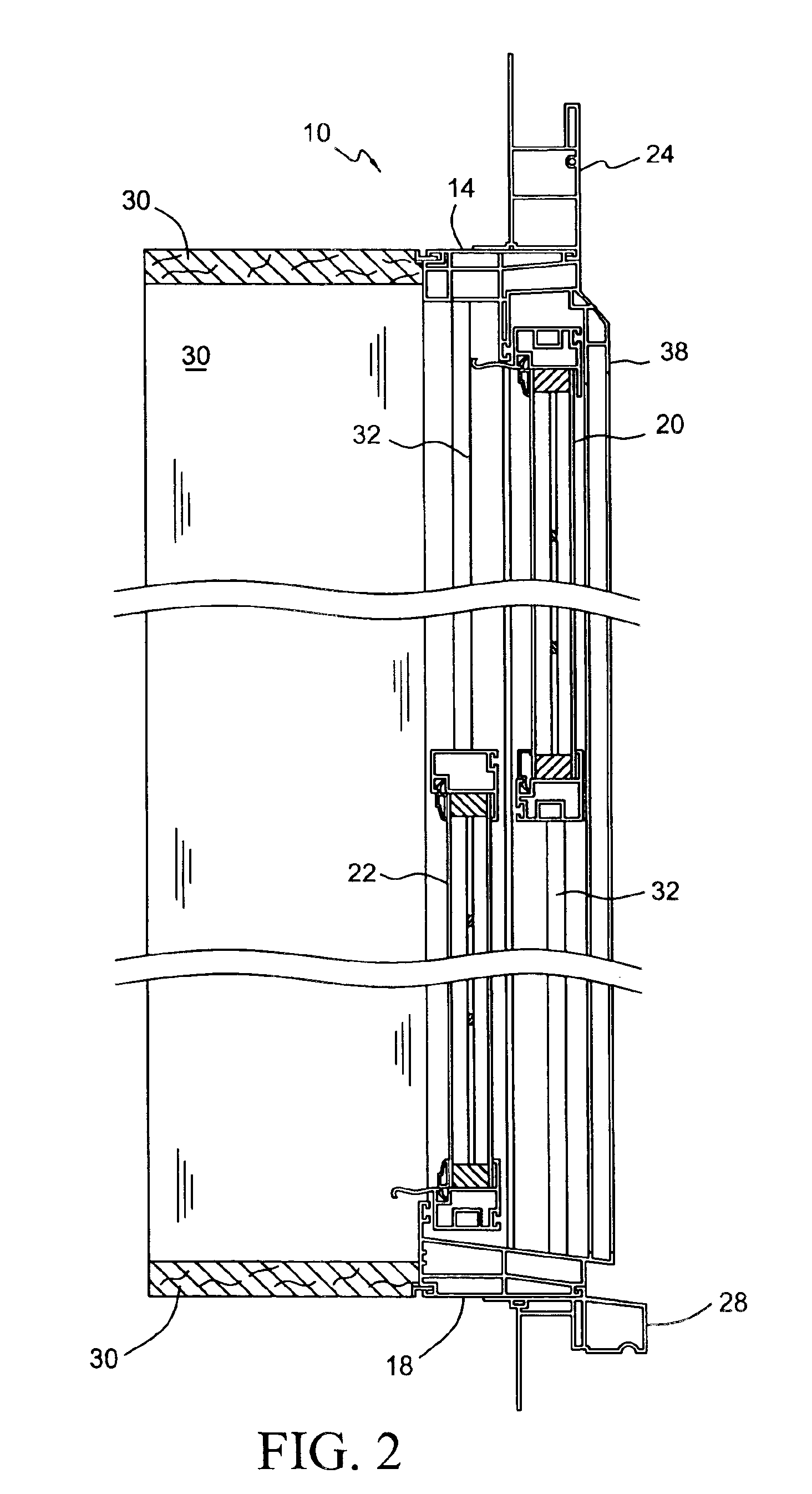

Window construction with integrated sill and casing and method of making same

InactiveUS6922958B2Easy to installTime-consumeFrame fasteningWindow/door framesArchitectural engineeringBuilding construction

Owner:MERRIMACK VALLEY WOOD PRODS

Pluggable cloud enablement boot device and method

ActiveUS20150106521A1Rapid deploymentMany stepsDigital computer detailsProgram controlCustomer requirementsAuto-configuration

A pluggable cloud enablement boot device (PCEBD) is a bootable device that includes all information needed to automatically provision hardware and software to create a computing solution that meets customer requirements. This allows for quickly deploying a computing solution in a manner that eliminates many manual steps that are typically performed today. The PCEBD uses firmware to verify a given platform has sufficient resources to deploy the PCEBD. The computing solution, once provisioned and running, can be modified, and these modifications may be reflected in the definition of the PCEBD. In addition, a computing solution may include multiple resources provisioned from multiple PCEBDs, which can be packaged into a PCEBD that will include other PCEBDs. The result is a way to deploy computing solutions that is much more efficient than the manual methods used in the prior art.

Owner:IBM CORP

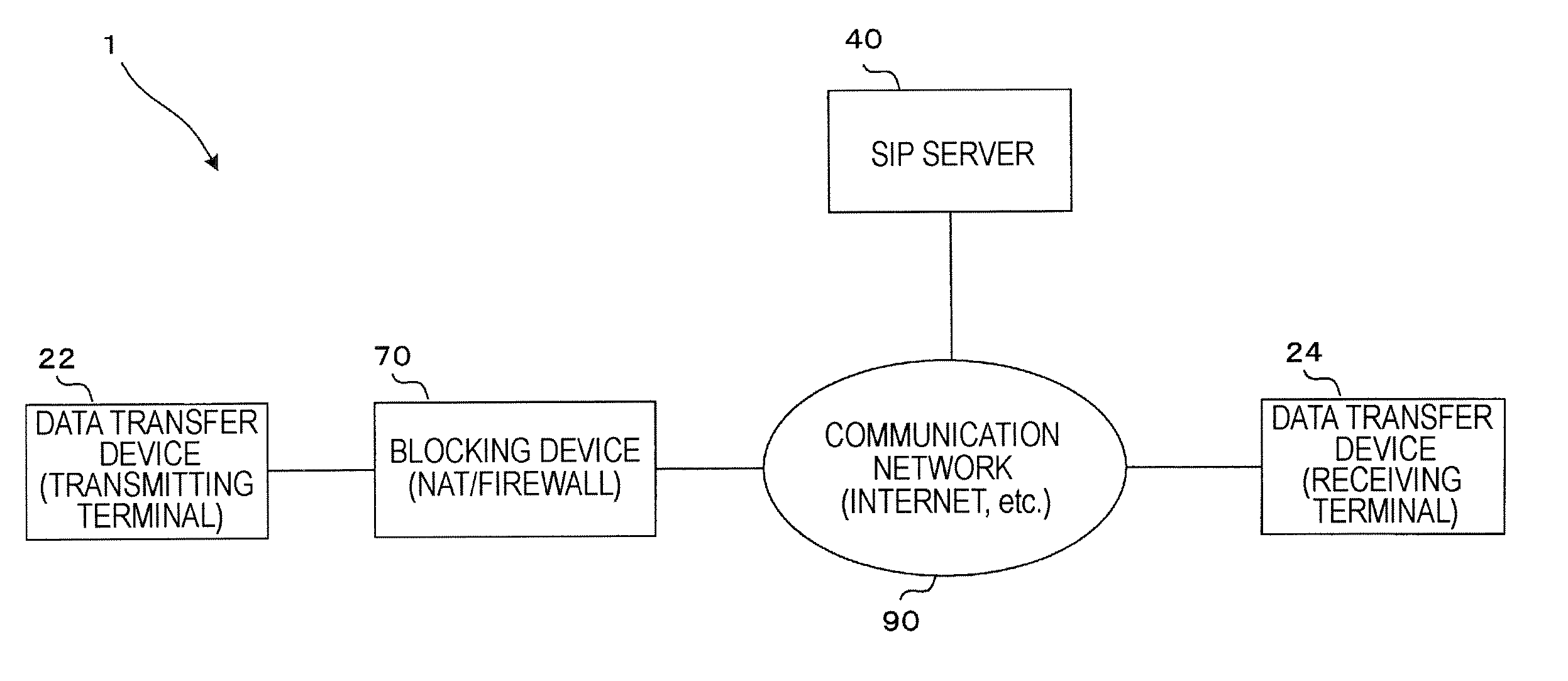

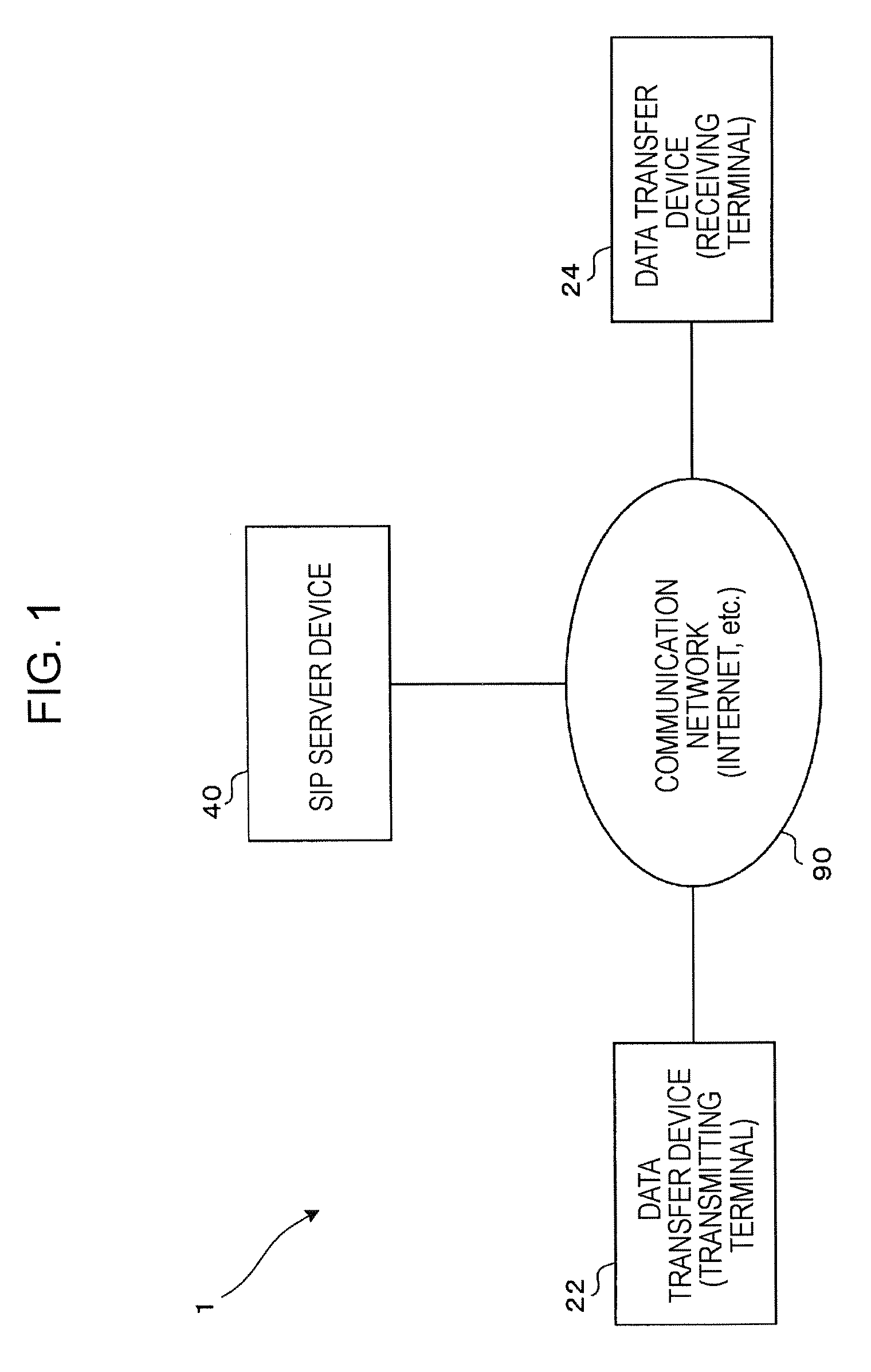

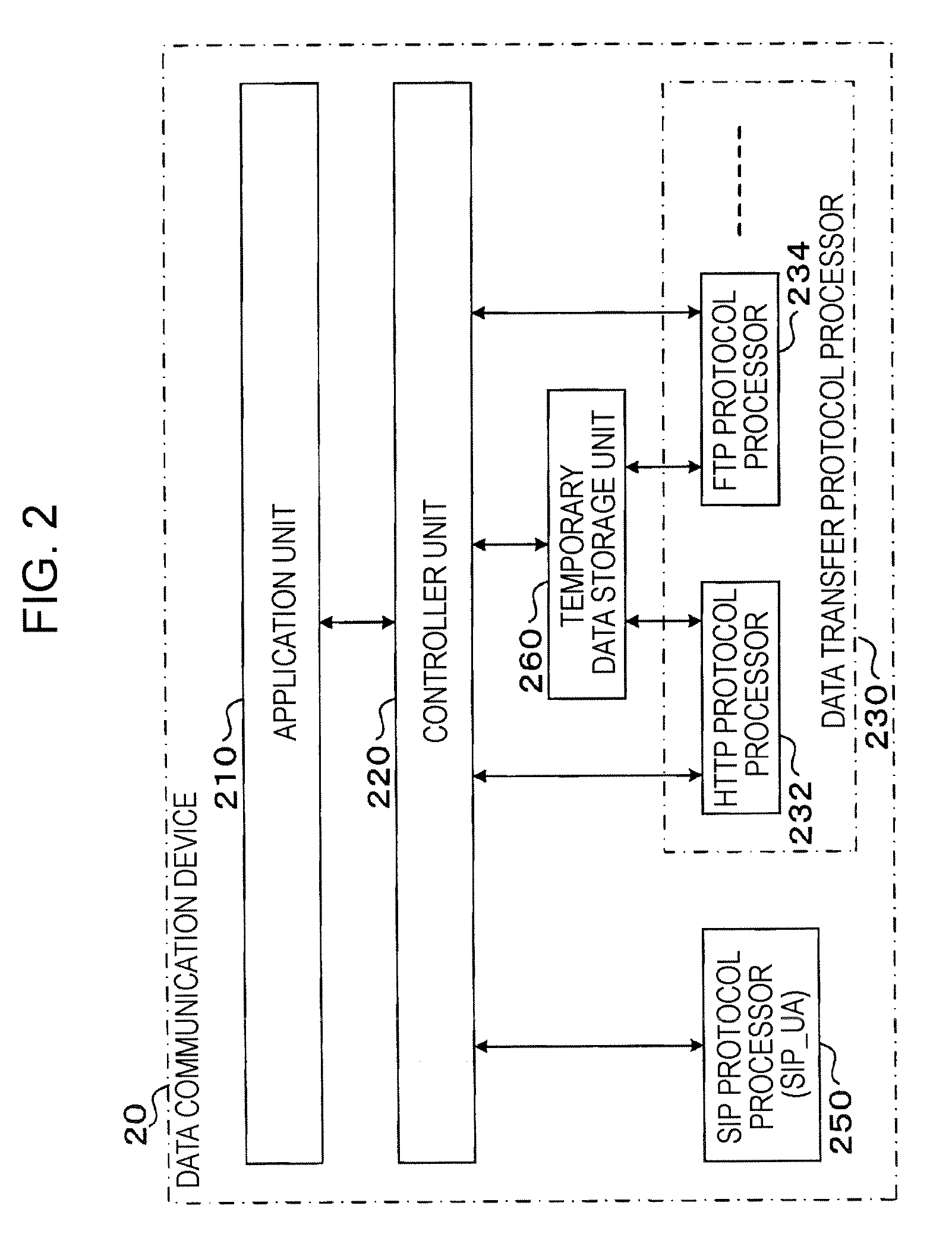

Communication method, communication system, communication device, and program

InactiveUS20060268839A1Reliable data communicationFew stepsError preventionFrequency-division multiplex detailsCommunications systemCommunication device

Owner:SONY CORP

Method for separating and recovering vanadium and chromium from vanadium-chromium slag

ActiveCN104152704AImplement step-by-step extractionHigh yieldProcess efficiency improvementSlagMaterials science

The invention discloses a method for separating and recovering vanadium and chromium from vanadium-chromium slag. The method comprises the following steps: (1) carrying out first roasting on the vanadium-chromium slag and first sodium-containing materials and carrying out solid-liquid separation after leaching the product obtained after first roasting in water, thus obtaining first solid phases and a first liquid phase; (2) carrying out solid-liquid separation after carrying out vanadium precipitation on the first liquid phase, thus obtaining second solid phases and a second liquid phase; (3) carrying out secondary roasting on the first solid phases and second sodium-containing materials and carrying out solid-liquid separation after leaching the product obtained after secondary roasting in water, thus obtaining third solid phases and a third liquid phase; (4) carrying out solid-liquid separation after contacting the second liquid phase with the third liquid phase and carrying out precipitation, thus obtaining fourth solid phases and a fourth liquid phase; (5) calcining the second solid phases and the fourth solid phases and extracting vanadium; and (6) reducing the fourth liquid phase and precipitating chromium. By the method, vanadium and chromium can be simply separated and recovered from the vanadium-chromium slag at high yield.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method of forming a weld pad

InactiveUS20050199591A1Fast installationQuick installationArc welding apparatusWelding/soldering/cutting articlesBiomedical engineeringPressure vessel

Owner:WESTINGHOSE ELECTRIC CORP

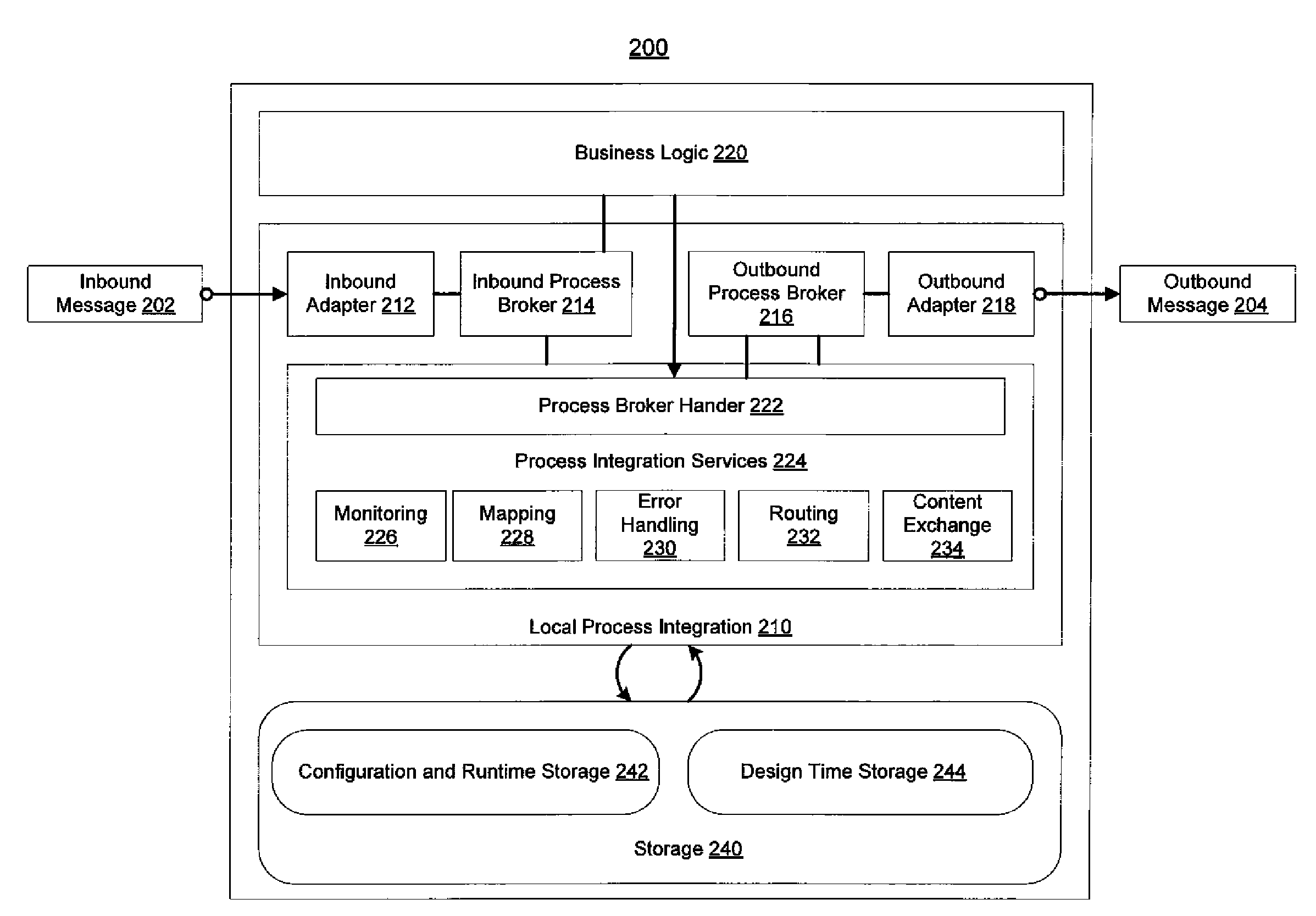

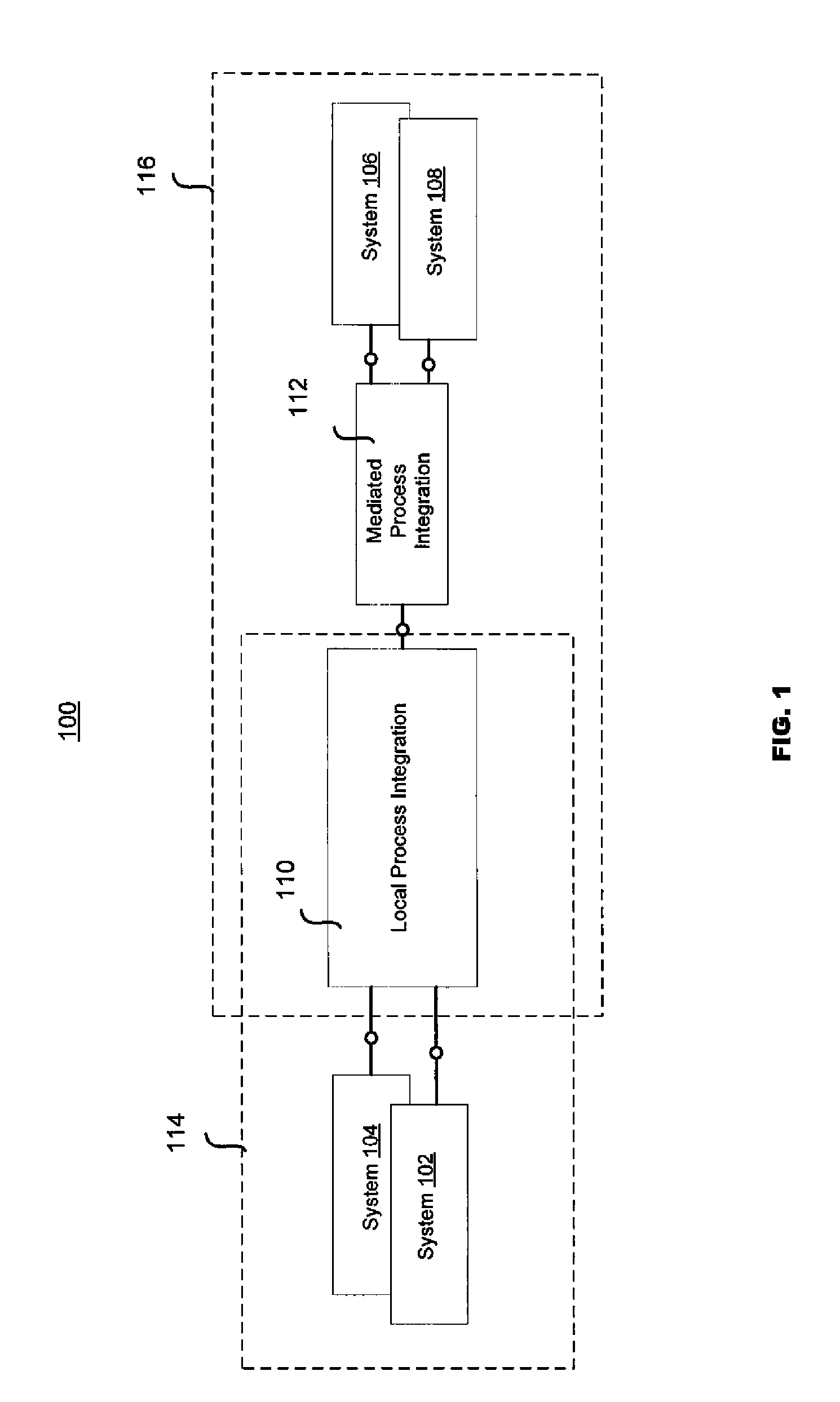

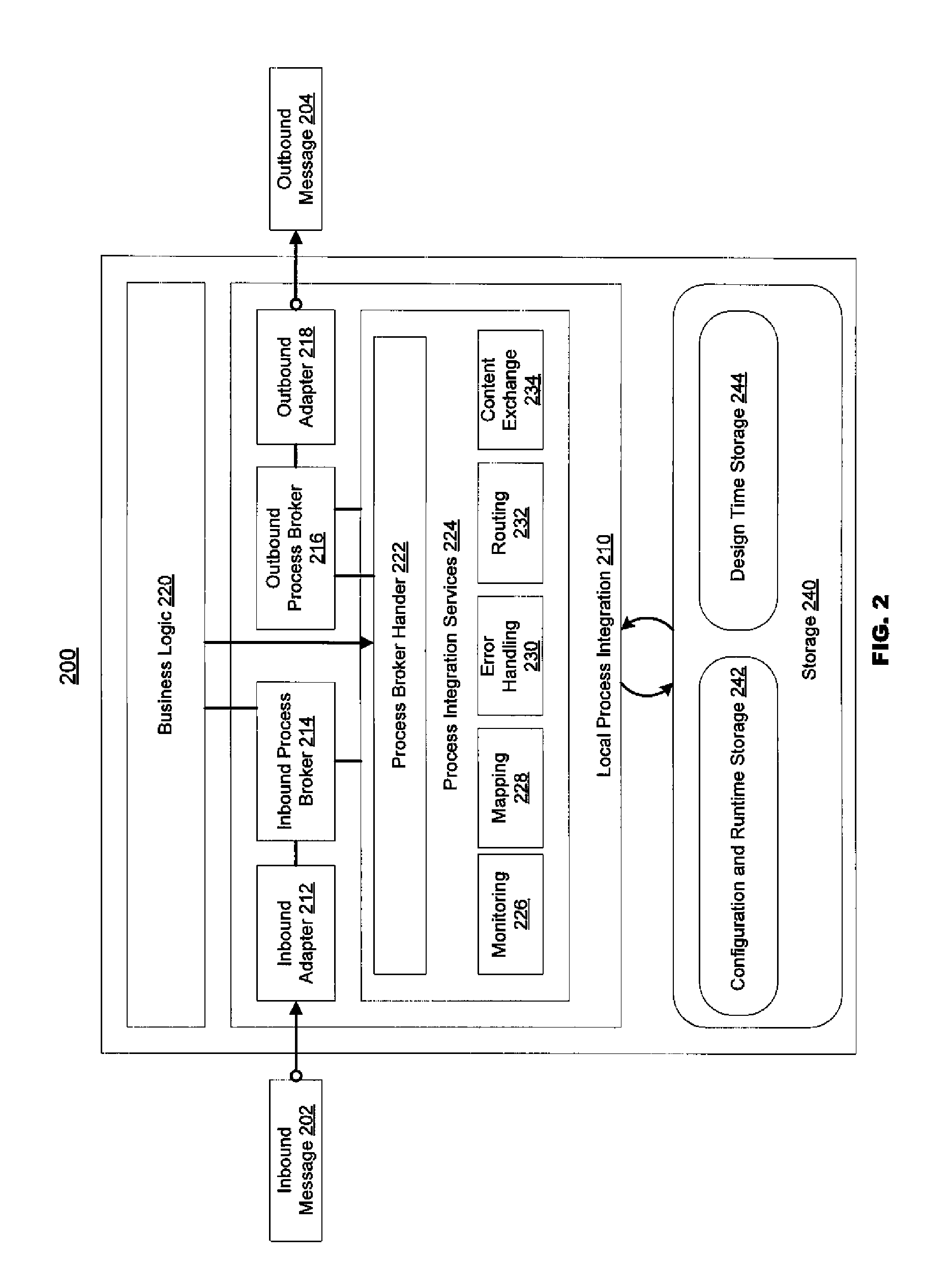

System and method for a process broker and backend adapter based process integration

ActiveUS20120137307A1Many stepsAvoid additional format transformation stepMultiprogramming arrangementsOffice automationProcess integrationApplication software

A computer-implemented method for process integration may comprise providing a business logic layer that hosts business object(s), providing process broker(s), providing adapter(s) and providing a process broker handler. Each process broker may perform process integration tasks by dynamically determining whether, when and / or how routines of the business logic layer need to be integrated with routines of a second application. Each adapter may be part of a first application and implement methods to perform communication protocol specific logic. Each adapter may also be interoperable with at least one of the process brokers and one of the business objects to transform a message exchanged between the process broker and the second application from an internal format to an external format or vice versa. The process broker handler may be operable to instantiate the process broker and to instantiate an adapter stored in association with the instantiated process broker.

Owner:SAP AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com